I am interested in pricing for etching different width and length silicon nitride waveguides, for Raman measurements. Widths would be ~0.8-1.6 um and lengths from 0.5 to 11 cm. Quantity would be 2-5 for each for optimization testing. assuming a 1.5 cm interval for the horizontal, and 100 nm for the width. Which results in 8 lengths by 5 widths for ~40 combinations, and ~5-10 waveguides per combination, with the assumption that many waveguides should fit on each wafer.

Wafers for Raman Measurements

What Wafers are Used for Raman Measurements?

How we help scientists.

Researcher:

Reference #271542 for specs and pricing.

Get Your Quote FAST! Or, Buy Online and start Researching Today!

Does Gold Coated Silicon Help with Enhancing Raman Signal?

Yes, gold-coated silicon can help enhance the Raman signal. This is due to a phenomenon called surface-enhanced Raman spectroscopy (SERS). SERS is a powerful analytical technique that enhances Raman scattering signals by several orders of magnitude.

Gold-coated silicon substrates are a type of SERS-active substrate where a thin layer of gold is deposited onto a silicon surface. The gold layer creates localized surface plasmon resonances (LSPRs) when it interacts with light. These LSPRs amplify the electric field in the vicinity of the gold surface, which in turn enhances the Raman scattering of molecules adsorbed onto the gold-coated surface.

The SERS enhancement provided by gold-coated silicon can be used to detect low concentrations of analytes or improve the sensitivity and resolution of Raman spectroscopy measurements. However, the degree of enhancement depends on factors such as the thickness and quality of the gold layer, the size and shape of the gold nanostructures, and the properties of the target molecules.

(100) Oriented Silicon Wafers for Raman Measurements

A PhD researcher requested help with the following:

I am looking for silicon wafers with the orientation (001) for Raman measurements. Do you have such kind of orientations .If yes would like to send the price Please?

I would like to order the test grade. So it is a polished wafer

oriented Si(100), would you kindly like to confirm? If yes I would like to

order 24 wafers. How to proceed?

Reference #156462 for specs and pricing.

Raman Maps

An assistant professor in a chemical and biomolecular engineering department asked the following:

I am interested in monolayer graphene, and I have some questions about it.

I am interested in grain boundaries in graphene monolayers, so I am looking for a high quality monolayer with grain size ~10micrometers (or larger) and otherwise very clean specimens. Do your monolayers possibly satisfy these requirements?

We grow graphene on Cu ourselves, but we are having trouble finding high quality lots of Cu foil recently (other groups have the same complaints). So, I would like to know what kind of analysis/characterization do you have for your graphene monolayer. Do you have large area Raman maps? Do you have high res SEM? Do you have TEM (I found some TEM for the bilayer on your UW site).

I would also be very interested in item 20 of your excel list, "Suspended Monolayer Graphene on TEM Grids (Quantifoil Gold)". What are the specs for the quantifoil grid (e.g., the size of the holes)? Is this a transfer from Cu foil? How do you do the transfer? Do you have TEM of a transferred grid? Any other spec/characterization?

And finally, for whatever characterization/analysis you provide, would this be a "representative" one, i.e., one from a random sample from the lot, or do you provide spec/characterization for each particular specimen you sell?

Question and Answers:

Q: I am interested in grain boundaries in graphene monolayers, so I am looking for a high quality monolayer with grain size ~10micrometers (or larger) and otherwise very clean specimens. Do your monolayers possibly satisfy these requirements?

A: The grain size is above 2microns but we do not know exactly how much bigger they are. We have now adapted our Titan TEM in our to be able to zoom out and measure more accurately our grain size. We have imaged grain boundaries in our graphene and they are composed of heptagons and pentagons.

Q: We grow graphene on Cu ourselves, but we are having trouble finding high quality lots of Cu foil recently (other groups have the same complaints). So, I would like to know what kind of analysis/characterization do you have for your graphene monolayer. Do you have large area Raman maps? Do you have high res SEM? Do you have TEM (I found some TEM for the bilayer on your UW site).

A: We have HRTEM images (see an example in the attached datasheet). We do Raman in two different areas and 5 points per area per graphene batch.

Q: I would also be very interested in item 20 of your excel list, "Suspended Monolayer Graphene on TEM Grids (Quantifoil Gold)". What are the specs for the quantifoil grid (e.g., the size of the holes)? Is this a transfer from Cu foil? How do you do the transfer? Do you have TEM of a transferred grid? Any other spec/characterization?

A: The lacey carbon layer has 2micron holes. We transfer graphene synthesized on Cu onto the Quantifoil grids using wet chemical etching methods. See TEM image on datasheet. We have more images if you would like.

Q: And finally, for whatever characterization/analysis you provide, would this be a "representative" one, i.e., one from a random sample from the lot, or do you provide spec/characterization for each particular specimen you sell?

As I mentioned before we do characterization per batch but not per graphene sample.

Reference #156972 for specs and quantity.

Raman Analysis of Cells

A PhD candidate requested the following quote:

I need to know if item 1707 could be used for Raman analysis of cells. I need Silicon wafers with single side polished. I need to know polished´s quality.

Reference # 187281 for specs and pricing.

Thin Quartz for Raman Measurements at High Temperatures

A Assistant Professor requested the following quote:

I am interested in buying thin quartz, about 50 microns or less, do you have something like this?

I am going to use it as a substrate, on top of it I am going to translate graphene, then I need to performed Raman measurements at high temperatures, about 800 °C or 900 °C. Which one do you recommend?

3 units of 1"x1"x25 microns preferentially

Reference #223649 for specs and pricing.

Silicon Nitride Waveguides for Raman Measurements

A Spectroscopy Scientist requested the following quote:

I am interested in pricing for etching different width and length silicon nitride waveguides, for Raman measurements. Widths would be ~0.8-1.6 um and lengths from 0.5 to 11 cm. Quantity would be 2-5 for each for optimization testing. assuming a 1.5 cm interval for the horizontal, and 100 nm for the width. Which results in 8 lengths by 5 widths for ~40 combinations, and ~5-10 waveguides per combination, with the assumption that many waveguides should fit on each wafer.

Diameter: 4inch

Orientation: <100>

Type: P

Resistivity: 0.08 -0.01 Ohm-cm

Thickness: 500+/-10um

Surface: SSP

2 SEMI Flats

SiN Thickness: 1um

Reference # 271542 for specs and pricing.

What Is Raman Measurements?

Raman spectroscopy is a spectroscopic technique used to study the vibrational, rotational, and other low-frequency modes of a sample by analyzing the shift in energy of scattered photons. In order to perform Raman measurements, the sample must be placed on a substrate, which serves as the base material for the measurement.

There are several types of substrates that can be used for Raman measurements, including:

- Glass: is a transparent, non-porous, and chemically stable material that is commonly used as a substrate for Raman measurements. It is particularly useful for samples that are sensitive to moisture or other environmental factors, as it provides a hermetic seal and protects the sample from the ambient environment

- Quartz: is a highly transparent and chemically stable material that is often used as a substrate for Raman measurements. It is resistant to thermal and mechanical stress, making it suitable for use in high-temperature or high-pressure environments.

- Silicon: is a semiconductor material that is widely used as a substrate in microelectronic devices. It is also commonly used as a substrate for Raman measurements due to its high transparency and chemical stability.

- Sapphire: is a single crystal of aluminum oxide (Al2O3) that is highly transparent and chemically stable. It is often used as a substrate for Raman measurements due to its excellent properties, such as high strength, high hardness, and high thermal conductivity.

The choice of substrate depends on the specific requirements of the measurement, such as the nature of the sample, the wavelength of the incident light, and the environmental conditions. The substrate should be transparent to the incident light, chemically stable, and not interfere with the measurement in any way.

What Wafers Are Used For Raman Measurements?

The use of Raman measurements is an important part of the semiconductor industry. This type of research and development is non-destructive, and offers a method to accurately determine the relationship between silicon and various facets.

Understanding the Relationship Between Silicon and the Various Facets

Understanding the relationship between silicon and the various facets used for Raman Measurements is important for materials scientists. It can help us to understand the role of physical processes and perturbations in semiconduct ors.

ors.

Raman spectroscopy is a versatile technique that is capable of detecting, imaging, and interpreting subtle perturbations in a semiconductor. In addition to its ability to detect and visualize the properties of individual atoms and bonds, it is also able to extract information about the crystal structure. It is an excellent tool for nondestructive assessment of irradiated SiC materials.

A standard Raman instrument is composed of three major components. These are the illumination system, the spectrometer, and the sample. The illumination system is usually composed of one or more lasers. However, this varies depending on the type of instrument.

In Raman spectroscopy, the polarizability of a bond is an important factor. The polarizability is a measure of the separation of electric charge between the atoms of the molecule. The polarizability is related to the deformability of a bond in an electric field.

Raman spectroscopy is an effective method for determining the position of the Fermi level in a material. This information is obtained through the Fano resonance induced broadening of the Fano-Raman spectrum. The asymmetric broadening of the Raman spectra is a hallmark of the Fano resonance.

The Fano resonance is caused by electronic continuum vibrations interacting with discrete phonons. It is observed in doped Si wafers. The resonance can be confirmed by antiresonance in Raman spectra.

Raman spectroscopy can be applied to determine the Fermi-energy for doped and un-doped Si. It is associated with the strength of the Fano coupling. This can be done by performing temperature dependent Raman spectromicroscopy.

This type of spectroscopy is helpful in assessing the effects of microstructural changes and property changes induced by irradiation. It can be combined with XPS analysis to evaluate the concentration of substituents. It is also a useful tool for detecting As-based minor phases.

In this study, Raman spectromicroscopy was performed on a commercially available p-type and n-type Si wafer. This was done with a Horiba Jobin-Yvon Raman (LABRAM HR) spectrometer. The spectral resolution of the LABRAM HR is 0.5 cm-1.

Metasurfaces Enable Efficient Optical Absorption

Using metasurfaces, efficient optical absorption is achieved for Raman measurements. This is important for solar energy conversion, photo-induced water splitting, and photon detection. It also provides a good way to enhance the signal.

Metasurfaces have emerged as a promising new platform for optoelectronic applications. They offer many advantages, including high performance, low fabrication cost, and a large area. These properties make them suitable for a wide range of applications, from explosive detection to food safety monitoring. The following demonstrations show how a new type of metasurface can boost light absorption.

In this study, we use the combination of a hybrid metasurface and surface-enhanced Raman scattering (SERS) to generate a strong local electric field that enhances light absorption by an atomic thin graphene layer. These combined features are capable of significantly enhancing the original Raman signal. The results of this study demonstrate the potential of this novel metasurface for sensing, detecting, and measuring.

This new type of metasurface is constructed using standard thin film deposition methods. It provides a larger area for effective coupling between incident light and plasmon resonance. The resulting enhancement factors are 17 times larger than silver island nanoparticles on glass. The resulting near-total optical absorption is predicted for this simplified SIOM metasurface.

Metasurfaces are also useful for creating spatially varying material compositions and structures. They can produce a variety of physical, chemical, and electrical properties. They are able to achieve strong interactions with incident waves, which can greatly improve the performance of devices.

In addition to creating the desired material compositions, metasurfaces can provide degrees of freedom in designing the shape of the wavefronts. This can be accomplished through a variety of techniques, such as nanoprinting. The advantage of these techniques is that they allow the metamaterials to be designed with a subwavelength thickness. This provides minimal propagation phase, which reduces undesirable losses.

Special designed metasurfaces can be developed to shrink bulky optical components to a planar device structure. This type of technology can enhance the capacity of nanophotonic networks. It could also be used for sensing and communication applications.

These novel dielectric metasurface approaches are well suited for sensitive surface-enhanced sensors. They can be tuned by changing the external voltage. The resulting transmission can be tunable by as much as 50%.

Non-Invasive and Non-Destructive Method to R&D in Semiconductor Processing

Non-destructive methods are vital to semiconductor processing. They offer many advantages, including cost-effectiveness, accuracy, and speed. Aside from defect detection, they also facilitate the testing of speciality materials. ZEISS is leading the charge in this arena. They offer a variety of tools for process and characterization, mask metrology, and repair solutions.

The FemtoMetrix Harmonic F Metrology System is an example of an innovative and non-destructive optical characterization technique that is used in the semiconductor industry. It uses silicon wafer property and an optical second harmonic generation to detect defects. The FemtoMetrix enables semiconductor manufacturers to find defects that would otherwise be impossible to measure.

Scanning acoustic microscopy is another technology that allows non-destructive inspection of components. In fact, it's the non-destructive technique that most people are aware of. It can be used to examine the smallest of components, such as microchips.

Using air-coupled ultrasound, non-destructive inspection of previously untestable materials is possible. It's also useful for additive manufacturing, which is increasing in popularity. In addition, it offers a low and highly penetrating frequency, making it suitable for use in dense materials.

SAM equipment has evolved a lot since its inception. It now incorporates technologies that are able to inspect a wide variety of components, including flexible substrates and IGZO (Oxide TFT). In addition to its ability to detect subsurface flaws, it also measures moisture and dis-bonds, which are two of the most common types of defect found in ICs.

iRay offers a large 16-inch detector and 85-micron pixel resolution. It's also augmenting the capabilities of detectors with amorphous silicon and flexible substrates. In addition, it provides a tabletop measurement platform. Unlike other UT systems, it can inspect the tiniest of chips.

The semiconductor industry has been dealing with a long list of issues, including a lack of non-destructive test methods for measuring a variety of defects. With the advent of advanced technologies like AI, data analytics, and autonomous vehicles, robust, non-destructive inspection methods are needed to support the utilization of these emerging technologies. ZEISS is a leader in these areas, and they're extending their reach into the semiconductor industry with the opening of their Process Control Solutions (PCS) business unit.

Single Molecule Level Analysis

Single molecule level Raman measurements are based on two main approaches. The first approach relies on the principle of ensemble averaging to calculate the optical properties of individual molecules. This method allows for a systematic approach to calculating Raman spectra for many different molecules. The second approach relies on the principles of spatial chemical mapping. The results from these mappings support the theory of single molecule detection.

The underlying concept of single molecule detection is that single molecules should occupy hot spots on the substrate. To achieve this, a bias voltage is applied between the tip and the substrate. This is done in order to tune the conduction states of the single-molecule junction.

An interesting property of single molecule SERS is that it is accompanied by fluctuations of the Raman signal. In fact, spectral fluctuations were once considered as experimental evidence for the existence of single molecule events. However, this does not guarantee that a particular molecule will act in a particular way.

The fluctuations are due to the movement of the molecule with respect to the intense plasmon field. The appearance of the Raman signal depends on the geometry of the hot spot. As a result, single molecule SERS spectra are sensitive to orientations and the distribution of local fields. This means that single molecule SERS has the potential to provide information about reaction pathways.

The main advantage of single molecule SERS is that it provides high throughput. The method can be used to study chemical reactions and to examine intermediates in complex systems. It can also help to guide the design of highly efficient catalysts. Currently, the technology is still in its infancy. In the future, a greater variety of single molecule tools will be available.

Several important contributions have been made by these methods. For example, single molecule detection can be used to study DNA-protein interactions. It can also be used to compare subpopulations of heterogeneous systems, such as those in equilibrium. This ability to examine reaction pathways is especially useful in systems that are difficult to synchronize. Moreover, the technique offers a new window for studying eukaryotic cells.

Does the Gold (Au) coated on Silicon (Si) help with enhancing Raman signal?

In this article, we will discuss the optical properties of porous silicon. We will also discuss the structure of disordered material and how it helps in enhancing the Raman signal. In addition, we will discuss the optimum spot size for Raman analysis.

Structures with Disordered Structure Enhance Raman Signal

Gold coated Silicon structures with disordered structure can improve Raman signal sensitivity and amplify its intensity. AuNRs exhibit high porosity and large interparticle spacing. They are useful materials for SERS applications. Their properties enable them to produce reproducible SERS signals.

The EFs of substrates can be measured by measuring the Raman signal of the same molecule. These enhancement factors are due to electromagnetic enhancement caused by the geometry of the structure and not to chemical enhancement. Moreover, the regular nanostructure guarantees uniform enhancement factor distribution on the surface and high reproducibility of the Raman signal.

In a recent study, researchers have fabricated a high-density silicon cone array containing gold nanoparticles. They found that these nanowires could enhance the SERS signal to 60-fold compared to a flat substrate. In addition, they found that the signal enhancement was well-homogeneous with an average standard deviation of 3.9%. The researchers also found that these gold-coated silicon structures were less susceptible to oxidation in air and had a smaller EF than silver-coated silicon surfaces.

Au/SiNWs are characterized by scanning electron microscopy (SEM) and energy-dispersive X-ray analysis (EDX). SEM images show that Au/SiNWs have disordered and randomly oriented NWs. SEM images also show that Au/SiNWs exhibit a tapered structure.

The gold nanorod supraparticles are designed to be suitable for sensing applications. Their porosity, interparticle distance, and optical properties can be tuned. The size of water droplets in the emulsion also has an impact on the assembly structure. The optimal surface structure should provide a wide range of molecular adsorption sites to enhance the Raman signal.

The performance of surface-enhanced Raman spectroscopy is heavily dependent on the porosity of supraparticles. Moreover, the interparticle distances and the surface accessibility of the surfaces influence their performance. The SERS-EM method, developed by Duyne et al., extends this two-dimensional correlative imaging approach, to a 3D environment.

The CV SERS signal was clearly affected by the interparticle distance (DIP) between the supraparticles (Figure S11, Supporting Information). A lower interparticle distance increased the Raman signal intensity. This is consistent with plasmonic coupling.

Optimal spot-size of Analysis for Optimum Raman Signal

The optimum spot-size of analysis for optimum Ramans signal can be determined by considering the delay time between Raman lines. We have measured a range of delay times in the past, and found that the optimal time lies between 75 and 225 ps. We then recorded additional spectra at different delay times, and integrated each spectrum for 10 s. This allowed us to compare signal to background ratios for each measurement.

The Raman spectra are useful in chemistry to identify molecules and study chemical bonding. In addition to identifying molecules, Raman spectra can also be used to study the addition of a substrate to an enzyme. The wavenumber of the Raman spectra provides a fingerprint for identifying molecules.

The resolution of Raman spectra varies greatly. Higher resolution provides higher analytical information, but this comes with a tradeoff in signal-to-noise ratio. Raman measurements are usually conducted at a 4 cm-1 resolution, as this provides the optimal balance between analytical information and noise. In addition, modern Raman instruments allow for complete control of exposure time and number of exposures. The longer the exposure time, the better the spectrum is, even for weak Raman scatterers.

Optimal spot-size of analysis for optimal Raman signal for biological samples was measured using two space-relevant samples: diopside (pyroxene) and olivine (crystalline silicon). The two samples have distinct Raman lines, including 665 cm-1 and 1.009 cm-1. By comparing the two, we determined that the RMS for these two samples was 150 um.

Raman spectroscopy depends on the polarizability of a bond and the ability of electrons to displace themselves. When a molecule has a large concentration of loosely held electrons, a high-amplitude Raman signal is produced. Because of these characteristics, Raman spectra can detect the polarity of the molecule's framework.

Raman spectroscopy has a wide range of applications. It is particularly suitable for revealing information about bio-samples. However, Raman scattering in bio-samples usually has a low signal level because of the inelastic scattering of photons. In such cases, high numerical aperture objectives are required and a long working distance is preferred in clinical diagnostics. In addition, a parabolic reflector is commonly used to boost the Raman signal.

Modern Raman systems have sophisticated algorithms that optimize instrument parameters. Here, we discuss the importance of optimum spot-size and delay parameters for Raman spectroscopy. We also discuss the key aspects of dispersive Raman systems such as sample focus, background handling, cosmic ray rejection, photobleaching, and alignment and calibration.

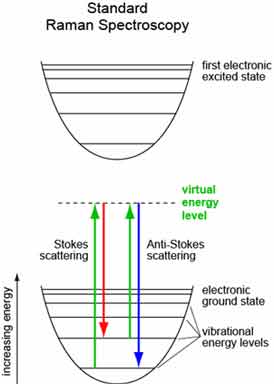

What Types of Raman Scattering are Available?

There are two types of Raman scattering: elastic scattering and inelastic scattering.

Elastic scattering, also known as Rayleigh scattering, occurs when the energy of the scattered photon is equal to the energy of the incident photon. This type of scattering is observed when the frequency of the incident light is not changed by the scattering process. Elastic scattering is relatively weak and is typically not used for analytical purposes.

In contrast, inelastic scattering, also known as Raman scattering, occurs when the energy of the scattered photon is different from the energy of the incident photon. This type of scattering is observed when the frequency of the incident light is shifted by the scattering process. Inelastic scattering is much stronger than elastic scattering and is used in a variety of analytical techniques, including Raman spectroscopy and Surface-enhanced Raman spectroscopy (SERS).

In Raman scattering, the energy difference between the incident photon and the scattered photon is equal to the energy of a vibrational mode in the molecule. The frequency and intensity of the scattered light can be used to identify the vibrational modes and provide information about the molecular structure and chemical environment of the molecule.