I'm interested in fabricating black-silicon nanowires via dry-etch (RIE with SF6/O2/Ar). The fabrication protocol I'm hoping to follow says that they used "unpolished" <100> n-type silicon substrates, and that the unpolished finish is crucial to reproducibility of the generated black-silicon features between wafers. Would the As-cut silicon wafers work for this purpose, or could you advise me on which wafers may be best suited to this? Please also provide pricing.

What are Silicon Nanowires?

What Silicon Wafer Spec is Used in Silicon Nanowires?

SiNWs nanowires have used P-type (100) silicon wafers with 300 nm heat-resistant oxides having low-gated Ti/Au (10/200 nm) gate electrode. A silicon nanowire array was employed as the substrate for covalently bonding different fluoroionophores to detect heavy metal ions since it allows for higher carrier mobility, hence higher sensitivity for the analytes that are adsorbents at their surfaces.

Purchase the wafers online here.

Get Your Quote FAST!

Key Terms of Silicon Nanowires Research

- silicon nanowires

- nanowire arrays

- nanowire matrix

- nanowire structures

- sinws nanowires

- semiconductor nanowire

- nanowire solar

- nanowires possess

- nanowire type

- fabricated nanowires

- ratio nanowires

- nanolithography techniques

- silicon wafers

- nanoelectronic memory

- silicon materials

Silicon Nanowire Arrays

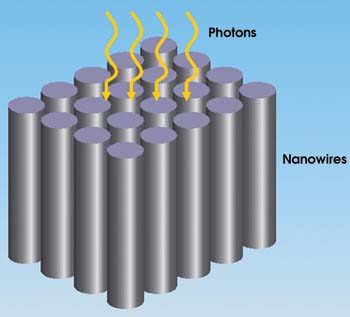

A silicon nanowire array is a collection of super-thin silicon wires, all organized neatly in a specific pattern or structure. Imagine a bed of nails, but instead of nails, you have these tiny wires, each much thinner than a human hair. They're all standing close together in an orderly fashion.

![]()

What substrates are used to fabricate silicon nanowire arrays?

Si Item #763

50.8mm P/B <100> 1-10 ohm-cm 275um SSP Prime

How to Fabricate Black-Silicon Nanowires?

A PhD candidate requested the following quote:

Reference # 276538 for specs and pricing.

Functionalizing Silicon Nanowires for Sensor Applications

Silicon nanowires are a type of semiconductor nanomaterial that is typically formed by catalyzed growth or  etching of solid from the liquid or vapor phase. These nanomaterials exhibit remarkable properties that aren't present in bulk 3-dimensional silicon materials such as high Young Modulus and tensile strength. They are also used for applications such as lithium ion batteries and thermoelectrics.

etching of solid from the liquid or vapor phase. These nanomaterials exhibit remarkable properties that aren't present in bulk 3-dimensional silicon materials such as high Young Modulus and tensile strength. They are also used for applications such as lithium ion batteries and thermoelectrics.

Due to their unique characteristics such as biocompatibility, tunable optical and electrical properties, and high surface-to-volume ratio, nanowires are ideal for sensor devices. They can be made into field-effect transistor (FET) based sensors, which are sensitive to gases, ions, DNA, proteins and many other chemicals. In addition, they can be arranged in a crossed architecture to form resonators, which have the capability of producing extremely high oscillating frequencies.

Nevertheless, in order to utilize SiNWs as sensing elements in real applications, the physical/chemical properties must be modified to enhance their sensitivity and selectivity. This can be done by functionalizing the oxidized silicon surfaces on which the SiNWs reside. Several techniques have been developed to deposit organic layers or doping agents onto the silicon surfaces. Among them, silanization is the most popular technique.

To demonstrate the potential of functionalized silicon nanowires in sensor applications, Yang et al. designed a humidity sensor utilizing Te-modified H-terminated SiNWs. The authors reported that the resonant frequency of the device was strongly dependent on humidity. In fact, the resonance frequency shifted by 35 MHz at higher relative humidity.

Video: Silicon Nanowires Detect Explosions

How to Design Silicon for Use in Optical Sensors

When considering optical sensors, one important consideration is the type of silicon used in the sensor. ![]() Silicon is widely used for optical sensors, such as those used for spectroscopy. Typically, a sensor is made of a thin film of silicon or another material, such as an organic semiconductor. For example, the optical response of a 10 nm thick biolayer is characterized by a slope of 100 nm/RIU.

Silicon is widely used for optical sensors, such as those used for spectroscopy. Typically, a sensor is made of a thin film of silicon or another material, such as an organic semiconductor. For example, the optical response of a 10 nm thick biolayer is characterized by a slope of 100 nm/RIU.

Silicon Nanowire SiNW

The symbol for Silicon Nanowores is (SINW) The emergence of this new material as an alternative to bulk silicon has brought numerous advantages. In addition to its high-quality amplification, it has excellent optical properties. However, despite its advantages, it is not without its drawbacks. Unlike bulk silicon, which is susceptible to corrosion and oxidation, SiNWs are resistant to ultraviolet rays and have a small optical band gap.

The light-harvesting efficiency of SiNWs has two aspects, namely light-concentration efficiency (LCE) and light-absorption efficiency (LAE). Essentially, LHE measures how efficiently a nanowire absorbs or collects light. Obviously, this is very important in any device. The size of a SiNW is a determining factor for its LHE.

The process used to produce SiNWs involves two microlithography steps. The first is the bottom-up method, which involves growing SiNWs from a silicon wafer, followed by a metal-catalyzed reaction. The second method, which is known as the top-down method, begins with a bulk silicon wafer and trims it to the required size and shape. These differences can lead to different band gaps.

A bottom-up approach is a more efficient technique for the fabrication of SiNWs. The bottom-up approach ![]() requires a more sophisticated lithography technique, while the top-down approach requires a less expensive method. Top-down synthesis requires more lithography tools, which is not always feasible. Bottom-up synthesis of SiNWs is the most promising option, as it allows for control over size and direction of growth.

requires a more sophisticated lithography technique, while the top-down approach requires a less expensive method. Top-down synthesis requires more lithography tools, which is not always feasible. Bottom-up synthesis of SiNWs is the most promising option, as it allows for control over size and direction of growth.

Another technique is the SiNW-FET sensor, which can detect DNA directly and without labelling. The SiNW surface is first modified by APTES, followed by the carboxyl group of the target DNA. The amine and carboxyl groups then bind to the target DNA and induce a change in the SiNW surface's electrical properties. The detection limit was 0.1 fM for the DNA target. The negative charge of the target DNA induces the increase in resistance, while only one base of the mismatched DNA reduced the sensitivity.

A fully compatible CMOS optical sensor is designed around this principle, based on a ring resonator mechanism. The sensor is comprised of SiNW arrays arranged in a ring structure. The modes and effective index of this structure were analyzed using a commercial simulator eigenmode solver, a propagator, and a 3D finite difference time domain model.

PSi sensors

Optical sensors fabricated from silicon are a very interesting field of research. A new generation of CMOS sensors based on silicon uses a ring resonator mechanism. They are built from SiNW arrays arranged on a SiO2 substrate. The PSi sensors have been fabricated using a combination of gold film deposition, colloidal lithography, and etching solutions, resulting in different-sized pores. The MACE process creates a sophisticated interference pattern, and the resulting sensor can be used to detect changes in refractive index in real time.

The basic principle of PSi sensors is the Fabry-Perot effect. The Fabry-Perot effect predicts the position of the fringe maxima and minima using the reflectance spectrum. Its refractive index, L, and wavelength are calculated using the Fabry-Perot relationship. Silicon is used in optical sensors due to its high refractive index and wide range of wavelength. Silicon is a good material for this application because it is cheap and can be used to build optical sensors with high sensitivity.

CMOS and SOI technologies are both silicon-based. CMOS has superior oxidation-resistant properties. Single-crystal silicon carbide (SiC), on the other hand, is transparent and acts as a Fabry-Perot etalon. This technology eliminates the need for an external interferometer, thus making it possible to create optical sensors in a single device. This is the preferred method for optical sensors.

Porous silicon has tremendous potential in optical sensors. Porous silicon can be tuned for its refractive index and can detect biological and chemical vapor. Silicon can be fabricated into multilayer structures that have tunable spectral characteristics, including distributed Bragg reflectors and rugate filters. Different fabrication parameters are used to tune the spectral characteristics of the sensors. This leads to improved sensitivity. There are various approaches to fabricating PSI sensors in the laboratory.

Si is used in the fabrication of optical sensors for biosensing and data communication links. Silicon photonics is emerging as a key player in CMOS-integrated optical devices. Silicon has enormous potential for mass-production. Silicon is used for high-speed interactions with light, and the CMOS process enables low-power fabrication. Silicon-based optical sensors are used in biosensing, gas sensing, environmental sensing, and the automotive industry.

How to Fabricate Silicon Optical Sensors?

The fabrication of silicon used in optical sensors involves a number of different technologies. During the deposition process, two successive layers of glass particles are deposited on the Si substrate. This process requires a solvent such as SiCl4. Then, the silicon layer is densified by heating it to 900o C for 5 minutes. A subsequent deposition is performed to reduce scattering losses. Several modifications have been made to this fabrication technique to make it more stable and to improve the response.

The next step in the fabrication process involves a glass soldering process. This process enables precise control over temperature to minimize optical alignment perturbation and avoid thermal damage. Optical components are then mounted on the silicon chip. High-finesse and low-finesse silicon FPI sensors are fabricated to demonstrate their temperature capability and measurement resolution. However, further research is required to optimize the fabrication process. A high-finesse silicon FPI sensor is an excellent candidate for an optical sensor.

The fabrication process flow involves the formation of n+ diffusion and p+ ion implantation areas on the silicon wafer. After that, a new surface oxide is formed. The next step involves patterning a via for photodiode contacts and depositing metal contacts. Then, the fabricated device is tested by measuring reflectance spectra. The polished silicon wafer was used as a reference in these measurements.

Another technique that can be used for making high-performance optical sensors is to combine micromachined silicon with a fiber optic sensor. The combination of silicon and fiber optic sensors provides a noise-free reading and does not require any electrical power at the measurement point. With this technique, designers can design many different types of optical sensors. One such technique is the use of a polysilicon resonant microbeam structure with a built-in Fabry-Perot interferometer.

The most recent advances in photodiode technology make it possible to fabricate silicon as a semiconductor. Photodiodes use this technology to detect UV light in dark-field environments. They can also be used in photodiodes. By combining these two techniques, a high-quality hemispherical imager can be fabricated in a compact camera that has a 160-degree field of view and 80 fill factor.

How to Design Silicon Nanowires (SiNWs)

The present study investigates the design of SiNWs for use in optical sensors. By using discrete dipole approximation simulations, we obtained quantitative relationships with SiNW. These relationships were verified by deriving comprehensive equations. Besides, four extra equations were derived to estimate the optimal size of SiNWs for light-harvesting applications. These equations have implications for future photonic devices.

A highly sensitive SiNW is required for a successful sensor. The researchers designed an ultrasensitive SiNW-FET sensor to simultaneously detect Cu2+ and Pb2+. The researchers used probe oligopeptides, which comprise Cys-Asp-Arg-Val-Tyr-Ile-Pro-Phe-Leu. This compound was able to generate an extremely strong Raman signal.

The optimized SiNW-FET sensor displayed a detection limit of 0.1 fM for the target DNA. The sensor showed a 40% change after hybridization with a full-complementary DNA, a 20% change when one base of the target DNA was mismatched, and a 5% change for a second base-mismatched DNA. These results prove that the design of SiNWs-FETs is feasible for optical sensors.

The RW of SiNWs depends on its diameter and length. They increase in RW linearly with the diameter, and according to leaky mode theory, RW is reflective at the cut-off wavelength. The equations for the cut-off wavelength and the RW of SiNWs can be calculated. These equations are based on the theoretical model of light-harvesting in optical sensors.

The ideality factor of SiNWs is 1.8, which is obtained from forward bias measurements. The high ideality factor can be attributed to the presence of trapped charges in the silicon oxide surrounding the nanowires, which have recombination sites near the SiNW/oxide interface. Furthermore, the measurement of the RIU of individual SiNWs reveals that they can resist current densities up to 106 A/cm2.

The SEM micrograph of a typical device shows 500 SiNW p-i-n junctions connected in parallel between two large silicon pads. These junctions are approximately 372 nm apart and spaced regularly. The thickness of these junctions is 120 nm. These measurements demonstrate that the resulting structure is a high-performing SiNW sensor. However, the cost of fabrication is a major challenge.