What happened to Pyrex 7740 Substrates?

Short version: Corning stopped making wafer-friendly PYREX  7740 flat/rolled sheet years ago, so the industry switched to drop-in borosilicate equivalents (mainly SCHOTT BOROFLOAT® 33 / 8330, and thin-polished MEMpax®). Today, “Pyrex 7740 wafers” you see are usually legacy stock or relabeled BOROFLOAT®. Some distributors also note a newer Corning PYREX SG3.3 thin-sheet line, but classic 7740 rolled sheet remains discontinued

7740 flat/rolled sheet years ago, so the industry switched to drop-in borosilicate equivalents (mainly SCHOTT BOROFLOAT® 33 / 8330, and thin-polished MEMpax®). Today, “Pyrex 7740 wafers” you see are usually legacy stock or relabeled BOROFLOAT®. Some distributors also note a newer Corning PYREX SG3.3 thin-sheet line, but classic 7740 rolled sheet remains discontinued

Silicon Thin Film on Pyrex 7740 Wafers

A quantum sensors research scientist requested a quote for the following:

Question:

We are interested in Pyrex wafers (4" thickness 0.5/1 mm) that have a thin layer of Si on top of them. We would need these to be DSP. Is this a service you can provide?

Answer:

(Yes. What is the desired thickness of Si layer? How about quantity?)

Question:

Alternatively, we could purchase The Pyrex wafers, and the a Si thin wafer and bond them in-house (we have an anodic bonder). Would you be able to sell these stacked to each other (not bonded).

Answer:

(Yes. I suggest that you can purchase them seperately and then get them bonded in-house after receiving them, not that complicated as stacked wafers.)

Reference #303927 for specs and pricing.

Get Your Quote FAST! Or, Buy Online and start researching today!

What is Pyrex 7740?

Pyrex 7740, also known as Corning 7740, is a type of borosilicate glass renowned for its low thermal expansion, making it highly resistant to thermal shock. This specific glass composition includes silica and boron trioxide, which contribute to its unique properties. It is widely used in various industries, including semiconductor manufacturing, due to its robust characteristics.

Properties of Pyrex 7740

- Low Thermal Expansion: It has a very low coefficient of thermal expansion,

meaning it doesn't expand or contract significantly with temperature changes. This property makes it ideal for high-temperature applications.

meaning it doesn't expand or contract significantly with temperature changes. This property makes it ideal for high-temperature applications.

- High Thermal Shock Resistance: It can withstand rapid temperature changes without cracking.

- Chemical Durability: It is resistant to chemical corrosion, making it suitable for use in harsh environments.

- Optical Clarity: It is highly transparent, which is beneficial for certain optical applications.

- Electrical Insulation: It has good electrical insulating properties.

Uses in Semiconductors

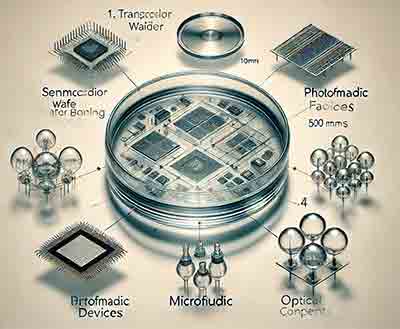

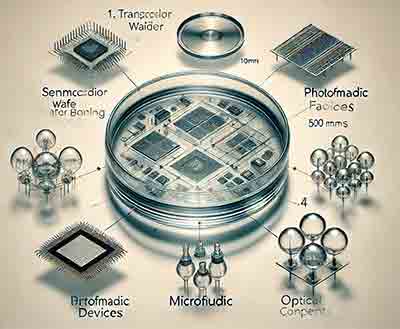

In the semiconductor industry, Pyrex 7740 is used for various applications, including:

-

Photomask Substrates: Pyrex 7740 serves as a substrate material for photomasks used in photolithography, a process for patterning parts of a thin film or the bulk of a substrate.

-

Wafer Bonding: It is used in wafer bonding processes where semiconductor wafers are bonded together. Its thermal and chemical properties help maintain integrity during high-temperature processing.

-

Microfluidic Devices: Due to its chemical resistance and transparency, Pyrex 7740 is used to fabricate microfluidic devices which are essential in labs-on-a-chip technology.

-

Packaging and Encapsulation: It is used for packaging and encapsulating sensitive semiconductor devices, providing protection from environmental factors while maintaining electrical insulation.

-

Substrates for Thin Films: Pyrex 7740 serves as a substrate for depositing thin films used in various semiconductor devices. Its stability and flatness are critical for ensuring the quality of the thin films.

Overall, Pyrex 7740’s unique combination of thermal stability, chemical resistance, and optical clarity makes it a valuable material in the semiconductor manufacturing process.

7740 flat/rolled sheet years ago, so the industry switched to drop-in borosilicate equivalents (mainly

7740 flat/rolled sheet years ago, so the industry switched to drop-in borosilicate equivalents (mainly meaning it doesn't expand or contract significantly with temperature changes. This property makes it ideal for high-temperature applications.

meaning it doesn't expand or contract significantly with temperature changes. This property makes it ideal for high-temperature applications.