Understanding Glass Wafer Technology

Unlike crystalline materials such as silicon, glass wafers are amorphous—meaning their atoms are arranged without a repeating lattice. This gives them unique isotropic properties, allowing engineers to use them as transparent, chemically stable, and thermally tolerant substrates across many photonic and microelectronic systems. The lack of grain boundaries minimizes internal stress and birefringence, which is especially valuable in optical and sensor applications.

Learn How Glass Wafers Elevate Your Research

Discover how borosilicate, fused-silica, and aluminosilicate wafers can enhance transparency, stability, and integration in your experiments. UniversityWafer experts can guide you from concept to prototype.

Get Your Quote Glass Wafer FAST! Or, Buy Online and Start Researching Today!

How Glass Wafers Are Manufactured

The production of high-quality glass wafers begins with a melt of silica and modifying oxides such as boron, aluminum, or sodium compounds. The molten material is cast, floated, or drawn into sheets, which are then precision-sliced into wafers. These blanks undergo sequential lapping, double-sided polishing, cleaning, and inspection to achieve optical-level surface quality and tight thickness uniformity.

- Float or Fusion Draw: Produces extremely smooth, flat sheets with minimal contamination.

- Mechanical Lapping: Controls wafer thickness before polishing.

- Chemical-Mechanical Polishing (CMP): Removes residual subsurface damage and provides atomic-level smoothness.

- Annealing: Relieves internal stress and improves dimensional stability, especially important for large-diameter wafers.

Optical and Thermal Behavior

Glass wafers are selected for their optical clarity and wide transmission range. Fused silica and quartz transmit from the deep ultraviolet through the near-infrared, while borosilicate and aluminosilicate transmit primarily in the visible range. The refractive index (≈ 1.46–1.52) varies slightly by composition, and dispersion can be engineered through dopant control.

- Optical Transmission: Defines performance in spectroscopy and photolithography systems.

- Thermal Conductivity: Glass dissipates heat more slowly than silicon (~1 W/m·K vs. 150 W/m·K), so thermal design is critical when integrating heaters or LEDs on glass substrates.

- Coefficient of Thermal Expansion (CTE): Matching the CTE between glass and bonded materials prevents delamination or cracking during temperature cycling.

Electrical and Surface Characteristics

Pure glass is an excellent insulator, with resistivities exceeding 1012 Ω·cm, making it ideal for isolation layers and dielectric carriers. When electrical functionality is required, conductive coatings such as ITO or thin metal films are deposited using sputtering or evaporation. Surface roughness and contamination are measured to verify bonding readiness and optical quality.

- RMS Surface Roughness: Polished glass can achieve < 1 nm RMS, suitable for wafer bonding.

- Hydrophilic vs. Hydrophobic Surfaces: Controlled by plasma or chemical treatment depending on the bonding process.

- Ion Content: Alkali ions (Na⁺, K⁺) affect anodic bonding and dielectric breakdown; UniversityWafer can supply alkali-free glass for contamination-sensitive processes.

Testing and Measurement

Characterization is essential for quality control and integration into semiconductor environments. UniversityWafer offers access to wafers verified by industry-standard testing methods:

- Interferometric Flatness: Measures total thickness variation (TTV), bow, and warp for bonding readiness.

- Optical Transmission Spectra: Confirms wavelength-dependent transparency and absorption bands.

- Stress-Birefringence Analysis: Ensures optical isotropy and low internal stress in fused silica.

- Surface Cleanliness: Verified by particle inspection and contact-angle measurements.

Why Glass Wafers Matter in Modern Fabrication

As semiconductor and optoelectronic devices become thinner, more transparent, and thermally demanding, glass offers a reliable alternative to traditional substrates. Its insulating nature allows close coupling of optical and electronic components without shorting, while its transparency enables new generations of photonic sensors, lab-on-chip devices, and microdisplays. Researchers increasingly rely on UniversityWafer glass wafers to prototype and scale these emerging technologies.

Design Insight for Researchers

- When bonding to silicon, choose borosilicate with compatible CTE and Na⁺ content.

- For optical and UV applications, use fused silica or high-purity quartz for superior transparency.

- In microfluidics, specify double-side-polished wafers to ensure channel uniformity and imaging clarity.

- For display or photovoltaic testing, select aluminosilicate wafers with AR or ITO coatings for light efficiency.

Support & Collaboration

UniversityWafer assists research teams in defining the correct wafer geometry, coating stack, and bonding approach for each experiment. Clients can request metrology reports, transmission data, and surface roughness profiles to ensure process compatibility. Whether you are developing a MEMS pressure sensor, a transparent touch panel, or a new type of lab-on-chip, our team can deliver wafers that meet your design and cleanliness standards.

Premium Glass Wafers for Advanced Research & Production

At UniversityWafer, we offer a comprehensive portfolio of high-performance glass wafers engineered for MEMS, microfluidics, photovoltaic, optical and display applications. Our inventory spans borosilicate (e.g., Borofloat® 33, Pyrex® 7740), fused silica/quartz, aluminosilicate (D263®, EagleXG®) and soda-lime glass. Available in diameters from 50 mm to 300 mm (and custom sizes), these substrates are compatible with micromachining, high-precision polishing, coating and advanced bonding protocols.

Material Families & Performance Characteristics

Selecting the appropriate glass wafer begins with understanding how material composition impacts thermal expansion, optical transmission, chemical durability and bonding viability.

- Borosilicate Glass: CTE ≈ 3.2–3.8 × 10-6/K, excellent thermal stability and chemical resistance. Sodium-bearing glass enables anodic bonding to silicon—a common requirement for MEMS sealing. UniversityWafer’s borosilicate wafers are optimized for flatness and low bubble content. :contentReference[oaicite:1]{index=1}

- Fused Silica / Quartz: CTE ≤ 0.5 × 10-6/K, ultra-low impurity levels, broad UV–IR transparency, and high resistance to thermal shock. Ideal for laser optics, UV lithography and high-temperature processing. :contentReference[oaicite:2]{index=2}

- Aluminosilicate (e.g., D263®): Designed for strength, scratch-resistance and low alkali content—well suited for display covers, thin-glass optics and glass-on-silicon assemblies. UniversityWafer stocks wafers with excellent polish and tight thickness control. :contentReference[oaicite:3]{index=3}

- Soda-Lime Glass: Economical and accessible, suitable for optical windows, test fixtures and non-critical packages. While it has higher CTE and alkali content, it remains a cost-effective choice when performance demands are moderate. :contentReference[oaicite:4]{index=4}

Specifications & Custom Options

Our glass wafer offering supports a broad range of process requirements. Key parameters and options include:

- Diameters: 50, 100, 150, 200, 300 mm. Custom shapes and sizes available.

- Thickness: From ~200 µm up to 1.1 mm standard; ultra-thin (<300 µm) and custom thicknesses available on request.

- Surface finish: Single-side polish (SSP), double-side polish (DSP), optical-grade polish with Ra < 1 nm in advanced applications.

- Flatness / TTV: Tight TTV and low bow/warp for wafer bonding and lithography; specification defined per job.

- Edge & shape: Ground/chamfered edges standard; custom shapes, flats or alignment notches possible.

- Coatings & films: ITO/IZO transparents, AR/HR coatings, seed layers (Cr/Au), mask films (SiO₂, Si₃N₄) available in house or via partner services.

- Micromachining: Laser drilling/cutting, ultrasonic micro-drilling, sandblasting, HF-etching for channels and cavities, through-glass vias (TGV) preparation.

Processing & Integration Features

Glass wafers often require specialized operations beyond standard silicon processes. UniversityWafer supports these with the following capabilities:

- Laser & CNC Micromachining: Manufacture of holes, slots, cavities, micro-channels suitable for microfluidic and MEMS packaging.

- Wet & Dry Etching: HF or HF-based chemistries for borosilicate; fluorine-based ICP/RIE for quartz/fused silica to achieve high-aspect-ratio features.

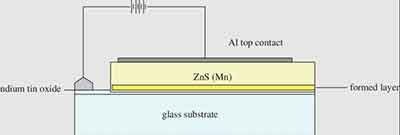

- Thin-film Deposition: Transparent conductive coatings (e.g., ITO 5-60 Ω/□), AR coatings, hydrophobic/hydrophilic treatments for biosensing applications.

Bonding & Assembly Options

Proper bonding and assembly are critical for glass wafer stacks, and UniversityWafer supports the full spectrum from glass-on-silicon to glass-on-glass integration:

- Anodic Bonding (Silicon–Borosilicate): Requires Na⁺-bearing glass and clean silicon surface; typical process: 300-450 °C, 200-1000 V under vacuum or inert ambient; ideal for MEMS caps and hermetic packages.

- Fusion Bonding: Direct glass-glass bonds using elevated temperature and pressure; suitable for optics, vacuum devices and hermetic windows.

- Adhesive/Intermediate Layers: For low-temperature or flexible assemblies: BCB, epoxies, photo-curable adhesives, solder/metal frames for stacking glass, silicon, and other substrates.

Target Applications

The glass wafers supplied by UniversityWafer are engineered for numerous advanced applications across research and production:

- MEMS packaging and optical capping for silicon devices.

- Microfluidic substrates—channels, reservoirs and covers for lab-on-a-chip systems.

- Optical substrates and viewports: AR/HR coatings, fused silica windows, spectroscopy cells.

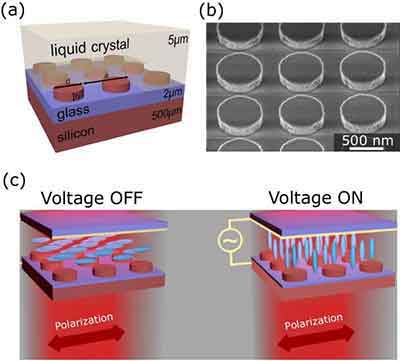

- Display and thin-film devices: ITO electrodes, electroluminescent layers, touch panels.

- Photovoltaic research: solar cover glass, high-transmission wafers for modules and cells.

Why UniversityWafer?

• Single-wafer and small volume orders for research and prototyping; • Customized services: polish finish, custom thickness, film/coating application, micromachined features; • Tight specification control: surface roughness, flatness, thickness tolerance, edge quality; • Experienced support team to guide material selection, bonding strategy and integration; • Fast quote turnaround and global shipping from our U.S. facilities.

Related: Fused Silica/Quartz · Oxide Wafers · Silicon Wafers