Monitor Quartz Crystal for Thin Film Deposition Control

Monitor Quartz Crystal for Thin Film Deposition Control

A postdoc requested a quote for the following.

Question:

Do you have monitor quartz crystal for thin film deposition control?

Answer:

Yes, we have Monitor quartz crystals . Below is the quotation for Gold and Alloy .

| Freq | Contour | Diameter | type |

| 6M | 3 diopter Plano-Convex | 13.97mm | Alloy |

| 6M | 3 diopter Plano-Convex | 13.97mm | Gold |

Get Your Quote FAST! Buy Online and Start Your Research Today!

How to Choose the Right Monitor Quartz Crystal

UniversityWafer, Inc. and our partners research into quartz crystal characteristics results in ongoing improvements to offer

the highest reliability in your process. We recommend gold crystals for most applications. They have low contact resistance, high chemical stability. The gold electrodes crystals are best suited for low stress material coating

monitoring, Such as gold, silver, copper film thickness control. Silver crystals will provide superior performance in processes with high heat loads, such as sputtering. They may also improve the deposition of oxides.

Alloy crystals are recommended for optical coating with dielectric materials and for semiconductor

processes with high-stress materials, Such as SiO, SiO2, MgF2, TiO2 and so on.

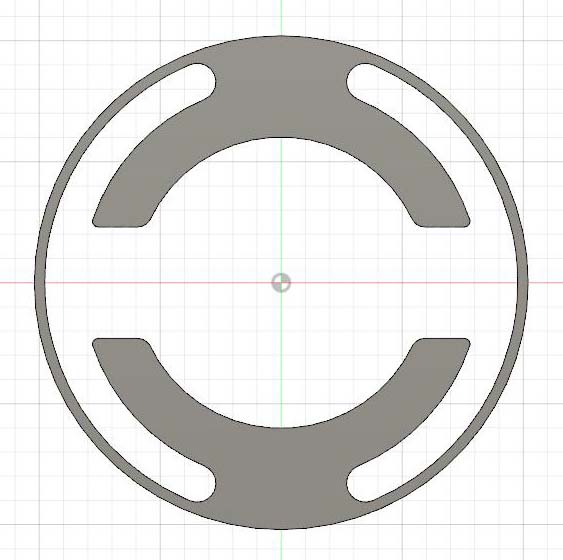

Carousel Packaging

Carousel Packaging

We have Convient Packages for our Monitor Quartz Crystals

- Black flat-pack carousel dispenser with vacuum plastic bags-holds 10 crystals which are extracted by vacuum pencil or dispensed directly into the holder.

- White flat-pack carousel dispenser with vacuum plastic bags-holds 10 crystals which are extracted by vacuum pencil or dispensed directly into the holder.

- Compact box with vacuum plastic bags and crystals in dust-free paper bags-holds 5 crystals which are extracted by vacuum pencil or plastic tweezers.

Advantages of Monitor Quartz Crystal

Plano-convex configuration suppresses unwanted modes for greater accuracy. AT-cut crystal orientation enhances stability over a wide range of operating temperatures. Improving of adhesion underlayer from electrode-to-crystal assures the crystals’ reliability and long-life.

Gold or silver electrode coating for maximum electrode life. 100% testing of each crystal’s frequency and activity (Series resistance). Compatibility with all our sensor heads and most other manufactures instruments. Clean room processing to avoid particulate contamination.

Quartz Monitor Crystals Manufacturing Process

Our quartz monitor crystals are 100% manufactured in house from raw material to final product.

We control every distinct production step in the manufacture of our Quartz Monitor Crystals, from the supply of the high Q raw Quartz to the super precise Wire Saws used to cut the primary wafers. Add to this a strictly controlled lapping and contouring process and you have the foundation for a truly superior Quartz Monitor Crystal. By using our six stage proprietary washing process and angstrom level accuracy electrode plating all in clean room conditions we manufacture a truly advanced quality Quartz Monitor Crystal.

Chrome/Gold Plated Quartz Monitor Crystal Specification

| Marking Frequency | 6.000MHz | 6.000MHZ | 5.000MHZ | 5.000MHZ |

| Nominal Frequency | 5.983MHz | 5.983MHz | 4.960MHz | 4.995MHz |

| Adjustment Tolerance | ±7KHz@25°C | ±5KHz@25°C | ||

| Crystal Cutting | AT | IT | AT | AT |

| Oscillation Mode | Foundation Mode | |||

| Resonance Resistance | <15 Ω | |||

| Shunt Capcitance | <7 pF | |||

| Operating Temperature | 0°C ~ +70°C | |||

| Storage Temperature | -40°C ~ +105°C | |||

| Diameter | 13.97mm±0.03mm | 12.45mm±0.03mm | ||

| Electrode of Plane Side | Chrome (Cr) / Gold (Au) | |||

| Electrode of Convex Side | Chrome (Cr) / Gold (Au) | |||

Aluminum/Silver,Chrome /Silver Plated Quartz Monitor Crystal Specification

| Aluminum/Silver | Chrome/Silver | ||

| Marking Frequency | 6.000MHz | 6.000MHz | 5.000MHz |

| Norminal Frequency | 5.983MHZ | 5.983MHz | 4.960MHz |

| Adjustment Tolerance | ±7KHz@25℃ | ±7KHz@25℃ | |

| Crystal Cutting | AT | AT | |

| Oscillation Mode | Foundation Mode | Foundation Mode | |

| Resonance Resistance | <15 Ω | <15 Ω | |

| Shunt Capacitance | <7 pF | <7 pF | |

| Operating Temp | 0℃ ~ +70℃ | 0℃ ~ +70℃ | |

| Storage Temp | -40℃ ~ +105℃ | -40℃ ~ +105℃ | |

| Diameter | 13.97mm±0.03mm | 13.97mm±0.03mm | |

| Electrode of Plane Side | Aluminum (Al) / Silver (Ag) | Chrome (Cr) / Silver (Ag) | |

| Electrode of Convex Side | Aluminum (Al) / Silver (Ag) | Chrome (Cr) / Silver (Ag) | |

Blank Quartz Monitor Crystal Specification:

| Marking Frequency | 6.000MHz | 5.000MHz | |||

| Norminal Frequency | 6.060MHz | 5.010MHz | 5.040MHz | 5.050MHz | 5.050MHz |

| Adjustment Tolerance | ±10KHz@25℃ | ||||

| Crystal Cutting | Top grade Z bar | ||||

| Oscillation Mode | AT & IT/SC | IT/SC | AT | AT | AT |

| Resonance Resistance | <15 Ω <15 Ω | 20 Ω | 20 Ω | 20 Ω | 20 Ω |

| Diopter | Customized | Customized | |||

| Angle | Per Customer or design for Clients | ||||

| Operate Temp | 0℃ ~ +70℃ | ||||

| Storage Temp | 40℃ ~ +105℃ | ||||

| Diameter | 13.97mm | 12.45m | 13.97 | ||

Client asks: Do you have Quartz Monitor Wafers?

Yes, we have Monitor quartz crystals . I attached our general specification for your refer to this URL for quotation for Gold and Alloy.

| Date | Client | Freq | Contour | Diameter | type | 200 | 500 | 1000 |

| 2020/1/17 | U01 | 6M | 3 diopter Plano-Convex | 13.97mm | Alloy | $ /ea | $/ea | $ /ea |

| 2020/1/17 | U01 | 6M | 3 diopter Plano-Convex | 13.97mm | Gold | $ /ea | $ /ea | $ /ea |