What are the substrate requirements for this process? “Monolayer Graphene on Your Substrate?”

Need Graphene‑Coated Substrates?

CVD monolayer graphene on SiO2/Si, Quartz, PET, Cu — or on your substrate. Sizes up to 4" dia. Fast lead times.

- Metal‑free transfer available

- Custom cuts & sheet sizes

- Target specs: ≤120 °C bake, acetone/IPA/H2O compatible

- Reference inquiries welcome (e.g., #198286, #259474)

Trusted by researchers & engineers at universities and industry worldwide.

Graphene for Sale - Products for Researchers

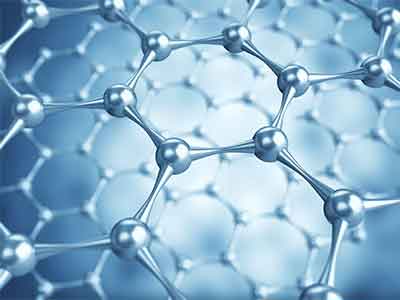

UniversityWafer, Inc. is a leading Graphene Supplier. Graphene has shown to have superior properties that range from mechanical to electronic. Some scientists suggest that graphene's full potential is in unique applications that are designed to work with graphene instead of replacing a traditional material such as silicon.

What Substrates Can Graphene Be Deposited On?

A postdoc asked the following:

We can deposit onto most of the substrates. The maximum size is 4 inches diameter and the substrate must resist acetone, IPA, distilled water and a thermal treatment (around 120ºC).

Reference #198286 for specs and pricing.

Get Your Graphene Quote FAST! Or, Buy Online and Start Researching Today!

The Field of Nanotechnologies

An undergraduate requested help in what he should research:

I am interested in the substance of graphene and would like to learn as much as possible about it so that I can make an informed decision about a move into the field of nanotechnologies. In doing preliminary research, the potential benefits seem to greatly outweigh the current costs of research and development. Graphene holds properties that are unmatched and its potential uses are seemingly endless. It is my goal to learn about the field in general, however, I do not have a technical background. With a history and education degree, my skill set is geared towards analyzing, presenting, and implementing. A good place for me to begin understanding both the graphene market and future is sales. I would be greatly appreciative for any and all information that you might be able to provide me relating to current or anticipated markets and products, as well as other information sources that might be helpful to gaining a better understanding. I realize this request may seem unique, however, I would like to see if this substance is as outstanding as I have been hearing.

Reference #210327 for our answer.

Graphene Keywords

- graphene sheets

- graphene devices

- graphene depends

- graphene buffer

- exfoliated graphene

- dielectric layers

- electron density

- different graphene

- graphene plane

- electronic properties

- hexagonal boron

- absorption coefficient

- original graphene

- hole mobility

- experimental values

Graphene Material Discoveries

Researching two-dimensional materials and their heterostructures, offers the potential for amazing scientific discoveries and the promise of real-world uses that does not require new tooling.

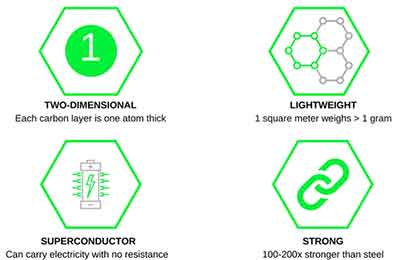

Graphene is lightweight, stiff, and strong. In fact, it’s one of the strongest materials known to man. Graphene properties have many uses including making incredibly strong composite materials such as mixing graphene with plastics that have incredible strength per unit of mass.

Graphene Coating on Silicon Wafers

We are investigating the use of graphene coating on silicon wafers to facilitate the absorption and conversion of light into photovoltaics in the next generation of silicon solar cells. Ultimately, the efficiency of silicon PV cells could be up to 1300%. In order to coat the graphene coatings, they can be dissolved from the substrate with the help of a thin film of water.

Five Cool Graphene Uses Video

One of the most fascinating graphene applications is its use as a bionic implant. In March 2012, the journal Nature featured a study that predicted bionic implants using the material. The study's lead author, Aravind Vijaraghavan, said graphene has the potential to interact with biological systems and talk to cells. While this has not yet been commercialized, this application is already showing promise in many fields.

The materials amazing physical properties mean that they can be combined with other elements. Researchers are already experimenting with graphene in a variety of applications, from antennas to saltwater filters. DNA-sequencing devices are just a few of the technologies using the material. Samsung is investing hundreds of millions of dollars in research into the material. In the near future, we may even see the first cellular phone made from graphene.

Graphene can also be used to create flexible touch-screen displays, rigid metal housing, and energy cells. With its unique structure, graphene can conduct electrical current and heat better than copper and diamond. In addition, it is transparent, which means that it can be used to see through objects. With these amazing properties, graphene is on the verge of revolutionizing many industries. And since there are so many applications for this material, it's only going to continue to grow.

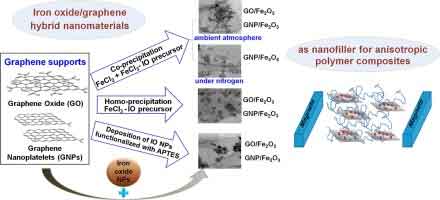

Silicon Wafers for Graphene-Based Nanomaterials Research

Scientists at Northwestern University have used the following Silicon Wafer Item for their following research:

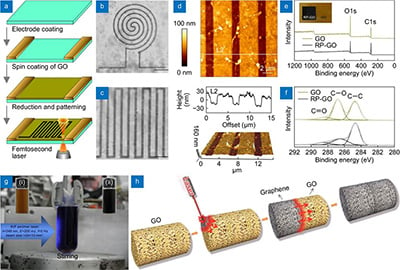

X-ray photoelectron spectroscopy (XPS) was gathered in the Keck II/NUANCE facility at Northwestern University using a Thermo Scientific ESCALAB 250Xi (Al Kα radiation, hν = 1486.6 eV) (Thermo Fisher Scientific Inc., West Palm Beach, FL) equipped with an electron flood gun. Samples for XPS analysis were prepared via LB deposition of GO and GO-PVA onto Si wafers (Item #785, 100 mm diameter, p-type, B-doped, single side polished) purchased from University Wafer, Inc. (Boston, MA). XPS data was obtained from three different locations on the surface of each sample, and was analyzed using Thermo Scientific Avantage Data System software (version 5.923), with a Smart background subtracted prior to peak deconvolution and integration.

What Substrates are used for Exfoliating 2D Materials?

A graduate student requested help with the following:

I wanted to buy 150 mm Si wafers, but confused about the grade specification. Could you please detail me about the prime, mech, test grade wafers. Is it about surface flatness? We want to use the wafers for exfoliating 2D materials, namely, Graphene, Boron Nitride, etc. However, we aren't fabricating any device on theses wafers. For exfoliation, we want the surface to be clean and flat.

We wanted to buy Si wafer with following specs:

Silicon 150mm, Res>= 100 ohm-cm, 625-675 thickness, SSP PRIME w/285nm DRY Thermal Oxide

Qty 10

Could you send me a quote for these spec?

Reference #225883 for specs and pricing

What Graphene Coated Silicon Wafers are Used for Neutron Reflectivity Experiments?

A Post-doctoral Research Associate requested the following quote:

Hello, I will doing a neutron reflectivity experiment this month and would like some graphene coated silicon wafers : quantity 3 The wafers need to be round 4 inch (10 cm) in diameter and ideally 10 mm thick. One side (the side the graphene will be deposited on) will need to be polished to a target rms roughness 0.1 nm (1 Angstrom). The silicon will also need to be n-type doped (phosphorous) with either 110 or 111 Orientation.

I would love a quote for the silicon also! Could you please also provide details of the Si in terms of surface roughness and if it satisfies the requirements I mentioned in the original request?

10 mm thick is right. 4 inches in diameter.

Reflectivity is a temperamental and expensive game unfortunately and thicker substrates actually reduce noise in the measurements. The instrument is called 'Spatz' has a 3 sample changer. Hence why I want 3 substrates.

The substrates should be mostly pure silicon. The surface oxide layer on the polished side should only be a few angstroms.

Reference #258596 for specs and pricing.

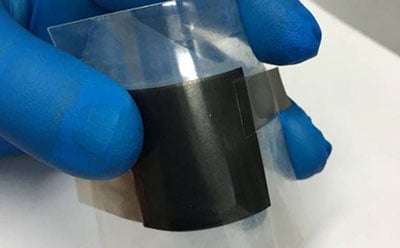

What is The Sheet Resistance of Graphene on PET?

An Assistant Professor Electronic Engineering Dept asked the following:

Question:

Can you provide the sheet resistance of graphene on PET samples, large area especially?

2 questions:

- is 1cmx 1 cm the largest size? Can you provide 5cm x 5cm?

- Is it possible to have lower sheet resistance (around 100 Ohm/sq max)?

UniversityWafer, Inc. Answer:

The Sheet Resistance on PET is 580±50 Ohms/sq (1cm x1cm)

We can make custom size substrates, in this case 5cm2.

Monolayer Graphene M on PET

G/PET/Custom/M-25

Monolayer Graphene (5 cm x 5 cm) on PET

Reference #259474 for specs and pricing.

What is the weight of a Graphene sheet?

A single layer of graphene, which is essentially a two-dimensional material, weighs very little due to its extreme thinness. Graphene is a single layer of carbon atoms arranged in a hexagonal lattice, with a thickness of only one atom.

To estimate the weight of a graphene sheet, we can consider the area of the sheet and the density of graphene. Graphene has a density of about 0.77 mg/m². This means that a one square meter sheet of graphene would weigh about 0.77 milligrams.

For example, if you have a graphene sheet that is 1 square meter in size, it would weigh approximately 0.77 milligrams. For different sizes, you can scale this weight accordingly based on the area of the sheet. However, it's important to note that this is a theoretical calculation and actual weights may vary slightly due to imperfections or additional layers in practical graphene sheets.

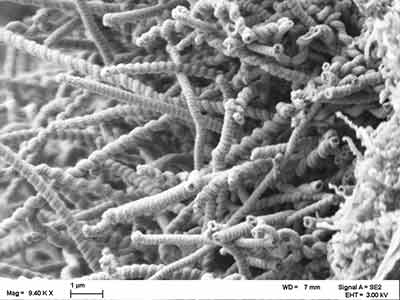

What Catalyst Substrates Can Be Used for Graphene and Carbon Nanotubes?

A corporate researcher requested the following:

I have an urgent requirement for the following wafers .

- 500 nm Cu deposited on Si wafer with 100nm Sio2. Of size 4”

- 500 nm Ni deposited on Si wafer with 100nm Sio2. Of size 4”

- 5nm Ni deposited on Si wafer with 100 nm sio2 + 70 nm TiN of size 4”

- 1nm Fe deposited on Si wafer with 100 nm Sio2+ 70 nm TiN of size 4”

Initially if we would get a quote for some sample wafers of each type which we can use to test our processes for graphene and Carbon Nanotubes. Alternatively if you have experience in supplying catalyst wafers for Graphene and Carbon nanotubes, please send me some data and we will consider a batch order.

I have been having discussion regarding the wafer request I had sent you in order to proceed forward. What we are trying to do is to grow nanotubes and graphene on those substrates and from our experience we find that the process is highly dependant on the source of the catalyst wafers. In order to be confident both from our side that we can offer this to our clients as well as to ensure that this will be a recurring order we were wondering if it would be possible to get one or two wafers of each just for us to test and ensure that they work for us. We will then quickly run our processes on them and follow it up with a larger order.

Reference #198099 for answers, specs and pricing.

What Graphene is used Modelling and Characterization of Photonic Devices?

A PhD student studying nanophotonics, particularly, nanoscale subwavelength optical elements and systems, nanoplasmonics, applications in UV lasers, high efficiency LEDs and solar cells, and ultra-sensitive biosensing, asked the following question.

I am very interested in the Postdoc position in nanophotonics as my PhD project is about modelling and characterization of graphene photonic devices, and my MSc project is about optical sensing. Could you give me more information involving this position? Thanks a lot for your time and information!

Reference #212328 for answer.

Can Graphene Be Transferred Onto a Clean Semiconductor Surface?

A Ph.D and Fellow SPIE researching Quantum Semiconductors requested help with the following project.

Could you please get me more information about:

- Monolayer Graphene on your substrate? What surface area? What substrate? Graphene or graphene oxide?

- Monolayer Graphene on SiO2/Si (1 inch x 1 inch)

Could this graphene be transferred to a clean semiconductor surface?

UniversityWafer, Inc. Answered:

We can transfer Graphene films, not graphene oxide, onto many different substrates, please find attached a short questionnaire regarding your substrates, which we would be grateful if you could complete, in order to know if we can transfer graphene on them. The minimum sheet size we can transfer is 3 mm diameter up to 4 inches diameter wafer.

Regarding the graphene on silicon, I regret to tell you that you can not transfer this graphene on to a semiconductor surface. Anyway, we can transfer our graphene on to your semiconductor. This would be the Monolayer Graphene on Your Substrate. To make a quote we would need you to complete our questionnaire and to know the graphene size you want to transfer.

Reference #216138 for questionnaire.

What is Graphene? Let's Explore Its Mechanical Properties and Reversible Chemistry

What is Graphene? Let us explore its mechanical properties and reversible chemistry. Graphene is the most  abundant natural substance in the world. Its electronic structure makes it one of the most flexible materials. It can be used for electronics, medical implants, and solar panels, as well as in many other applications. The reversible chemistry of Graphene makes it one of the most promising materials for future energy technologies.

abundant natural substance in the world. Its electronic structure makes it one of the most flexible materials. It can be used for electronics, medical implants, and solar panels, as well as in many other applications. The reversible chemistry of Graphene makes it one of the most promising materials for future energy technologies.

Graphene

Graphene is a material made of carbon atoms. In its simplest form, graphene is just one layer. But it's capable of many more things than that. It's extremely strong and is more than a thousand times stronger than copper. Its unique structure allows electrons to flow through the material unhindered. Graphene has a highly pronounced field effect, which allows scientists to control its conductivity.

It's also extremely thin and lightweight, making it ideal for heat-spreading solutions. Graphene-based thermal foils can make LED lights last longer and are becoming increasingly popular in smartphones. Huawei has even begun using graphene-based thermal film on its phones. In addition to being strong and lightweight, graphene also disperses heat more efficiently, so it's a great choice for mobile devices.

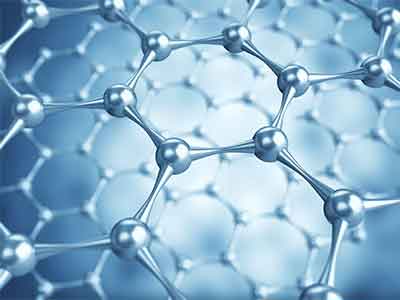

The carbon atoms that make up graphene are connected together using a honeycomb-like structure. Each sublattice is comprised of three atoms; the resulting honeycomb structure mimics the internal angular momentum of subatomic particles. Graphene electrons have the same role as electrons and positrons in quantum electrodynamics. However, their velocity is fractional to the speed of light.

Graphene's electronic properties are dictated by its pi orbitals, which form a valance band and conduction band. These two bands are crucial to understanding graphene's properties. These properties are important for many applications, from making electronics to manufacturing new products. The next step in graphene's development is the manufacture of new products. Once it is ready for the mass market, graphene may even replace some existing materials.

Graphene is a great electrical conductor and has countless uses. It's the basis of solar panels, LCDs and touchscreens. Its strength, transparency, and electrical conductivity make graphene a fantastic material for electronics. Its many applications are virtually limitless, and the potential is truly staggering. If you've ever tried to make graphene, you've probably seen it. Just look at the applications.

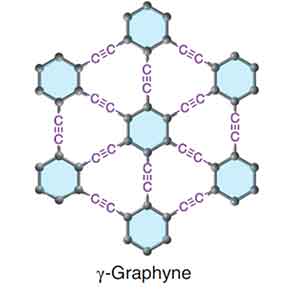

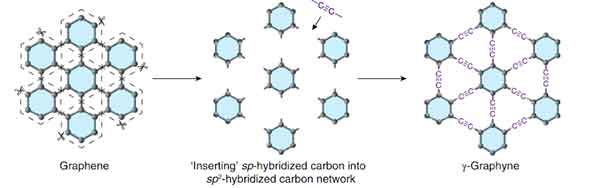

Graphyne

Graphyne is a thermoelectric material that has excellent mechanical properties. However, its properties may be altered by the adsorption of other atoms. Graphyne can prevent mechanical failure caused by thermal expansion or contraction. In a recent study, researchers discovered that a few-layer graphyne exhibits fold edge structure. A single flake of graphyne has a height of 9 nm.

The synthesis of graphene on a copper substrate was successful, as it is composed mainly of elemental carbon. Using energy dispersive X-ray spectroscopy, graphdiyne on copper foil can be distinguished by its characteristic carbon-carbon bonds. The resulting polymer displays acetylenic and aromatic rings. Graphene is a promising material for electronics. However, its production is highly expensive and requires complex equipment.

While one study reported the fabrication of a single-layer graphyne, there is no other study that shows the same results. In contrast, the symmetry of a six-layer graphyne makes it suitable for electrical grating. This property could lead to the development of faster transistors and a variety of other electronic components. In the future, Graphyne may even become an inexpensive material for solar cells.

The mechanical properties of graphene are controlled by strain rate and temperature. Both tensile strength and Young's modulus will decrease significantly when cracks occur in a material. The crack-resistant properties of b-graphyne might be attributed to its triangular structure. If it is possible to create a high-strength polymer, this material will be a useful material for electronic applications.

Graphene's Reversible Chemistry

Graphene's reversibility has led to several interesting discoveries. Among the discoveries that have occurred in recent years are those that reveal how graphene's chemical properties can be controlled. The reversible nature of graphene has enabled researchers to develop nano-scale devices that are able to mimic many of our everyday objects. This property, as well as its unique properties, are the basis for further research.

Graphene can conduct electricity at zero carrier concentration. This property is achieved by the fact that the electrons do not localize or slow down. They simply move around the carbon atoms, interacting with the periodic potential of the graphene honeycomb lattice to produce new quasiparticles. These new particles are massless Dirac fermions, which travel much faster than electrons in other semiconductors.

In addition, graphene can be dissolved in solvents or folded. When dissolved, a single layer of graphene oxide can lose as much as 20% of its carboxylic functionality. As a result, this material is highly thermally unstable. In this case, the chemical reaction between thionyl chloride and graphene oxide can lead to the formation of aromatic and aliphatic amides.

Graphene's reversibility also allows researchers to make a graphene-based device without sacrificing performance. Researchers are studying graphene's reversible chemistry to create high-performing devices that can be worn by humans. The material is also capable of producing a range of next-generation technologies such as ultrasensitive sensors, wearable electronics, and multifunctional coatings and composites. Since its discovery in 2004, graphene research has grown into a vast field with more than 10,000 publications published every year.

What are Graphene's Mechanical Properties?

Graphene is a sheet of carbon atoms, each one atom thick. The atoms in graphene are arranged in a layer with two p-state bands, and these orbitals are responsible for the material's incredible mechanical properties. These properties make graphene the hardest material known to science, and the researchers believe that further exploration of this material will yield many additional applications.

Graphene is so thin that it looks 2D, but it is actually three-dimensional. Unlike other 2D materials, graphene's electronic orbitals are perpendicular to the atomic plane. Because of this, graphene exhibits mechanical properties similar to those of graphite. A recent paper published in Physical Review Letters describes the testing of graphene's mechanical properties.

Graphene's unique structure makes it an ideal host material for electrodes. The structural defects of graphene prevent dendrites, which are branch-like filaments that develop on the electrodes. These dendrites can cause fires and electrical shorts. This material's high surface area means that it can absorb more impact than a typical helmet. Furthermore, graphene's heat dissipation properties make it a better choice for fuel cell catalysts.

As graphene's mechanical properties have been studied, researchers have found a way to detect the defects in the material. Graphene's surface is smooth, so a sand-like grain will have a smooth appearance. Graphene also has excellent optical properties, which makes it a great candidate for sensors and other applications. This material may soon become a common commodity, such as batteries and computer displays.

Although graphene's mechanical properties are excellent, they are not sufficient for flexible electronic devices. Graphene has some defects that can cause it to fracture and break, causing damage to the resultant device. There are effective methods of observing these defects, such as transmission electron microscopy, scanning tunneling microscopy, and atomic force microscopy. Recent research has addressed these issues, including using a process called defect healing.

Graphene's Potential as a Semiconductor

Graphene's high conductivity, thermal stability, and strength make it an ideal candidate for a wide range of applications, including electrical and biomedical ones. The ability to change the behaviour of cells inside the body could prove valuable in biomedical applications, including drug delivery. Today, plastic packaging allows water molecules to enter the product, reducing its shelf-life. Graphene, however, can reduce the absorption of water by millions of times. As such, it can be used as a water-repellent floor, as well as on glass surfaces, textiles, and ship hulls. Full market penetration will probably come within five to ten years.

One of the most fascinating features of graphene is its ability to function as a semiconductor at room temperature. Its zero-gap structure allows the conduction and valence bands to meet at Dirac points. Nanoribbons of graphene are known as graphene, and they are zig-zag in nature. However, they have a non-metal band, which means they are still conductors.

Although graphene is currently available for fabrication, it has to be integrated into the semiconductor industry. It will require a detailed understanding of its properties, as well as a method to implement it in a fabrication environment. Because the semiconductor industry is commercial, any technical challenges must be overcome without disrupting the entire manufacturing process. In addition, graphene must offer a significant performance advantage. However, it is important to note that research in this field is not yet complete.

The ability of graphene to act as an actuator is a key aspect of this material's potential as a semiconductor. The ability to change the dimensions of a material has many applications, including artificial muscles, microelectromechanical systems, and biomimetic nanorobots. Nanoribbons of graphene can be used to create actuators in such systems. The technology is rapidly evolving and a breakthrough will be made soon.

Video: Graphene 101Graphene Materials Inventory

Below are just some of the Graphene materials that we have in stock.

Please let us know what you need.

Monolayer Graphene on SiO2/Silicon (Si)

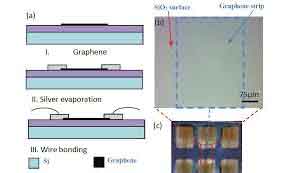

UniversityWafer, Inc’s monolayer graphene (SIO-2-4) substrates is produced by the Chemical Vapor Deposition (CVD) process a two-dimensional (2D) material by a wet transfer to a circular wafer. The CVD method has been used to grow a single layer of graphene. We transfer the Copper (Cu) onto the silicon’s wafer surface using the wet transfer process.

UniversityWafer, Inc’s monolayer graphene (SIO-2-4) substrates is produced by the Chemical Vapor Deposition (CVD) process a two-dimensional (2D) material by a wet transfer to a circular wafer. The CVD method has been used to grow a single layer of graphene. We transfer the Copper (Cu) onto the silicon’s wafer surface using the wet transfer process.

Advantages of Monolayer Graphene on SiO2 Silicon

Graphene is a material with unique optical properties. It is a single layer of atoms that absorbs 2.3% of incident light. When the light strikes the material, it generates electrons and holes. This property makes it different from traditional semiconductors. Its thermal conductivity is high, too. The following are some advantages of this material. It is a promising material for energy storage.

The main advantage of monolayer graphene films is that they are metal-free. This is important for the  development of high-performance graphene-based devices. Current CVD processes suffer from low structural uniformity, poor growth rate, and negligible catalytic activity of dielectric substrates. In this context, a new water-assisted chemical vapor deposition (VACVD) process is developed. Using water, this method is optimized for the growth of monolayer graphene. Furthermore, it lowers the kinetic barrier of the material, enabling rapid and preferential formation of graphene films.

development of high-performance graphene-based devices. Current CVD processes suffer from low structural uniformity, poor growth rate, and negligible catalytic activity of dielectric substrates. In this context, a new water-assisted chemical vapor deposition (VACVD) process is developed. Using water, this method is optimized for the growth of monolayer graphene. Furthermore, it lowers the kinetic barrier of the material, enabling rapid and preferential formation of graphene films.

The production of large-format monolayer graphs is possible through the CVD process and fixing a multilayer graphene film onto a TI adhesive layer. Then, the resulting double bilayer graphene is etched away from the nickel layer, leaving a thin layer of graphene directly on the silicon oxide. The process requires a temperature of 1000degC.

The high-quality graphene products can be made using multiple CVD processes. They can reach 90% coverage and are suitable for product R&D applications. They are also very cheap and can be fabricated using commercial equipment. One of the advantages of monolayer graphene on silicon is its low sheet resistance. The material is transparent, making it an ideal conductor for electronic devices. Moreover, it is compatible with all types of substrates.

For high-performance graphene devices, metal-free growth of monolayer graphene films is necessary. Existing CVD processes, however, are limited by their lack of structural uniformity, slow growth rate, and low catalytic activity. A water-assisted CVD process has overcome these limitations by using water as an additional catalyst. It allows the formation of highly-uniform monolayer graphene films in a much shorter time.

Graphene on silicon is a very dense material that offers high-light transmittance. It is the perfect material for all kinds of applications, including solar cells, battery cells, and transistors. It is highly transparent and has very low density. It is a versatile material that can be used in many fields. This material has many applications and has tremendous potential. It has been demonstrated in a variety of fields, including electrical and optical communications.

A new water-assisted CVD process has the potential to grow monolayer graphene films. This process is a high-temperature technique, and the use of water allows the use of low-temperature synthesizers. Besides, it can be used to create transparent conductors and other electronic devices. Although a new water-assisted CVD process can be used for high-performance device fabrication, it is not yet commercially available.

A CVD process is the most popular way to produce single-layer graphene. This method uses methane, but other carbon-containing compounds can be used. The carbon source is then deposited on a substrate, such as copper foil. This process can also be used to deposit graphene on non-conductive substrates. It is useful for a variety of product R&D applications, including battery manufacturing.

A CVD process that produces monolayer graphene is the most commonly used method for growing monolayer graphene. It requires a gas mixture of methane and oxygen to form monolayer graphene. The gas is then heated to 800-1000degC and the carbon source is deposited on the substrate. In addition, a water-assisted process is preferred for monolayer graphene growth, as it lowers the kinetic barrier and allows a greater extent of morphology and structural uniformity.

In contrast to the traditional CVD process, a single layer of graphene with copper catalyst was grown on quartz substrates. After transfer to the silicon, the graphene films were transferred to Si-SIO-2 via a copper transfer method. The graphene layer was then transferred to a silicon lid by VTD. After this, it was analyzed by SEM to determine the quality of the deposited film.

Monolayer Graphene on Your (Any) Substrate

From glass to silicon to glass, we can deposit graphene monolayer onto it using the Chemical Vapor Deposition (CVD).

From glass to silicon to glass, we can deposit graphene monolayer onto it using the Chemical Vapor Deposition (CVD).

Suspended Monolayer Graphene on Cavities

Graphene in electronics have superior properties to traditional materials. Graphene will be light and stiff. Suspended graphene membranes have can be used optomechanical systems including NEMs. Suspended graphene nanocavities are driven by two horizontal Fabry-Perot cavities and one vertical Fabry-Perot cavity to exploit the standing wave properties of plasmonic resonance.

Graphene in electronics have superior properties to traditional materials. Graphene will be light and stiff. Suspended graphene membranes have can be used optomechanical systems including NEMs. Suspended graphene nanocavities are driven by two horizontal Fabry-Perot cavities and one vertical Fabry-Perot cavity to exploit the standing wave properties of plasmonic resonance.

Suspended Monolayer Graphene on Cavities

Graphene on cavities was first introduced by Graphenea, a company that acts as a provider of graphene. The company has three patent applications and has developed a semi-dry transfer process in which a thin film of a single-layer graphene is placed over holes of up to 500 micrometers in diameter. The research has been successful, and it has led to further advancements in the field. The technology has many potential applications for optical, electrical, and mechanical applications.

Graphenea uses a proprietary PECVD process to grow graphene films on a quartz substrate. They  analyze the surface boundary conditions on the Mg samples deposited in molten quartz, as well as the complex refractive index and electrical conductivity of these materials. They have also shared their publications with world-leading graphene NEMS research groups, which make the materials more accessible to industrial use.

analyze the surface boundary conditions on the Mg samples deposited in molten quartz, as well as the complex refractive index and electrical conductivity of these materials. They have also shared their publications with world-leading graphene NEMS research groups, which make the materials more accessible to industrial use.

Graphenea's suspension monolayer graphene on a cavity material is a promising material for nanoelectromechanical systems (NEMS). These small devices require highly sensitive membranes that are extremely rigid and lightweight. The high Young's modulus and low temperature properties of the materials make them ideal candidates for microsupercapacitors. If you have ever wondered about the performance of such devices, you can now find out how it works.

The new material combines the benefits of conventional carbon and other materials. These new materials form two-dimensional sheets, which are more stable than single-layer graphene. They are conductive and exhibit varying forms of spin ordering. The researchers tested the new material's ability to control electricity with a perpendicular electric field. This new material is the perfect solution for applications in biomedical and medical research.

The new technology has the potential to revolutionize the world of medical devices. Unlike conventional medical devices, monolayer graphene is flexible and thin enough to allow for multiple applications. In addition, its properties also make it an excellent material for the pharmaceutical industry. If you're looking for high-quality, monolayer graphene is a great material for any device that requires electrical properties.

Graphenea has expanded its product line by adding Suspended Monolayer Graphenene on Cavities. These systems are nanoelectromechanical systems (NEMS), which are smaller cousins of MEMS. They are based on tiny, vibrating membranes that can be highly sensitive to small forces. These membranes need to be light and rigid and have a high Young's modulus to be effective.

Graphenea has expanded its product range by adding Suspended Monolayer Graphenene on Cavities. The company also aims to create new products for medical devices. Moreover, this technology can be incorporated into other products. The research will allow scientists to create a new type of device. This technology is an ideal material for use in different fields. It is used in a variety of applications such as sensors, semiconductors, and batteries.

Graphenea's technology is also useful for medical applications. These devices are more durable than MEMS and can be used as implantables. Unlike other materials, these materials are flexible, lightweight, and have high Young's modulus. Furthermore, they can be easily manufactured and shipped. There are no limitations to the potential applications of this new technology. Its use in medical devices is endless.

Graphenea's new technology allows scientists to use graphene as a semiconductor. Its sensitivity is superior to silicon-based MEMS. This material is suitable for a variety of applications. The high-resolution image will allow the semiconductor to be sensitive to electrical signals. Further, the device will be resistant to electromagnetic interference. Besides, the Graphene on the Cavities is suitable for many industrial applications.

Graphene oxide is a promising candidate for producing graphene. It contains flakes and monolayers of graphene. Its water platelets interact with the flakes, which makes it hydrophilic. Its low weight also improves the material's functionality. Moreover, it is a good candidate for industrial applications. These nanoelectromechanical devices are light-weight, and can be made into complex shapes.

Monolayer Graphene on Copper (Cu)

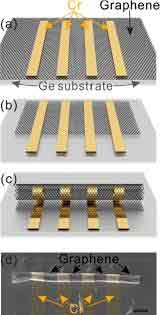

Growing monolayer graphene on Copper (Cu) thin films or Silicon (Si) Wafers works great for the production of massive direct graphene components. Researchers have demonstrated metal-based peeling processing the transfer of monolayers of graphene structures onto copper foil without destroying the base wafer.

Why copper foil? Cu is used for CVD growth because it enables production of large area single-layer graphene.

Monolayer Graphene on Cu (100mm)

Monolayer Graphene on Copper (Cu) (25.4mm x 25.4mm)

Monolayer Graphene on Cu (12mm Dia) Pack 4 Units

Monolayer Graphene on Cu (10mm x 10mm) Pack 4 Units

Monolayer Graphene on Cu with PMMA Coating (10 mm x 10 mm) - Pack 4 units

Monolayer Graphene on Cu with PMMA Coating (25.4mm x 25.4mm)

Monolayer Graphene on Cu with PMMA Coating (12 mm Circular) - Pack 4 units

Trilayer Graphene on SiO2/Silicon

High-quality and uniform graphene films are applied to dielectric substrates to realize large-scale applications of graphene in electronics. The results here make off-axis substrates (Silicon Carbide SiC 0001 ) a good candidate for large-area trilayer graphene producing with favorable amber-splitting.

High-quality and uniform graphene films are applied to dielectric substrates to realize large-scale applications of graphene in electronics. The results here make off-axis substrates (Silicon Carbide SiC 0001 ) a good candidate for large-area trilayer graphene producing with favorable amber-splitting.

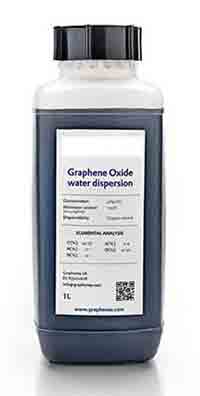

Graphene Oxide

Graphene oxide is one of the most popular 2D materials available and a fascinating nanomaterial that is huge. It is a widely dispersed solution that is bound to aqueous solvents and has useful properties and a wide range of applications in electronics, sensors and optics. Groups of water molecules move through hydrophilic solutions in this way. This forces flakes to form the outer layers of the fibre pack, creating a kind of skin.

Graphene Oxide (4 mg/mL, Water Dispersion 5000 mL)

Graphene Oxide (4mg/mL, Water Dispersion 1000ML)

Graphene Oxide (4mg/mL, Water Dispersion 2500ML)

Graphene Oxide (0.5 mg/mL, Water Dispersion 250mL)

Among other materials in the graphene family, graphene oxide (GO) and its reduced form (reduced graphene oxide or RGO) are of particular interest due to their high surface area, solubility in a variety of solvents, including water and aqueous solutions, and a variety of surface functionalization options for biomedical applications

Among other materials in the graphene family, graphene oxide (GO) and its reduced form (reduced graphene oxide or RGO) are of particular interest due to their high surface area, solubility in a variety of solvents, including water and aqueous solutions, and a variety of surface functionalization options for biomedical applications

Reduced Graphene Oxide (1 Gram)

The reduction of graphene oxide (simultaneous peeling or reduction of graphite oxide) is considered the most promising for the large-scale production of graphene and is referred to as reduced graphene oxide or RGO. RGO is a form of graphene with similar properties to graphene, but with good conductor properties. There are several ways to reduce RGO that are inexpensive and simple. It is popular and attractive as an effective and cost-effective method for those who want to manufacture graphene-related materials such as RGO. The reduction of graphene oxide has proven to be of high quality, as it is practically identical to untouched graphene.

The reduction of graphene oxide (simultaneous peeling or reduction of graphite oxide) is considered the most promising for the large-scale production of graphene and is referred to as reduced graphene oxide or RGO. RGO is a form of graphene with similar properties to graphene, but with good conductor properties. There are several ways to reduce RGO that are inexpensive and simple. It is popular and attractive as an effective and cost-effective method for those who want to manufacture graphene-related materials such as RGO. The reduction of graphene oxide has proven to be of high quality, as it is practically identical to untouched graphene.

A partial reduction can be achieved by treating suspended graphene oxide with Hydrozine Hydrazine for 24 hours at 100 degrees Celsius, by exposing it for a few seconds to hydrogen plasma or by exposing graphene oxide to strong light pulses like xenon flashes. Thermal reduction produces a higher degree of reduction than chemical processes, which leads to higher electrical conductivity. The RGO with strong reduction contains residual oxygen and structural defects caused by chemical oxidation and synthesis of the reducing agents and can be synthesized from inorganic substances such as NAB or organic substances such as phenylhydrazine hydrates and hydroxylamines.

Graphite oxide has aroused great interest as a possible way of producing and manipulating graphene, a material with exceptional electronic properties, on a large scale. Graphite oxide contains flakes or monolayers of several layers of graphene that are interspersed with water platelets and platelet interactions, depending on the carrier medium, thereby reducing surface functionality and improving hydrophilia. The associated high temperatures can lead to damage to individual flakes, a break-down of flakes and the introduction of defects in the structure.

Reduced Graphene Oxide (1 Gram)

In this article, we'll cover the basics of Reduced Graphene Oxide, and discuss  the benefits it offers scientists. As with many new technologies, the process of making RGO is still being refined, but the results of the latest research will definitely change how scientists do their work. Hopefully, we'll see more applications for RGO in the future. If you're interested in learning more, we've compiled some of the most recent research on RGO.

the benefits it offers scientists. As with many new technologies, the process of making RGO is still being refined, but the results of the latest research will definitely change how scientists do their work. Hopefully, we'll see more applications for RGO in the future. If you're interested in learning more, we've compiled some of the most recent research on RGO.

RGO can be manufactured from graphite, a closely related material. Its properties are similar to those of graphene, but are less impressive. Its morphology and chemistry make it a viable material for a variety of applications, including energy storage, composite materials, field effect transistors, and more. In fact, research into the potential applications of RGO will continue for many years to come, so there's no need to wait for its commercial availability.

Various microwave-assisted chemical reduction methods have been proposed, with some results showing a significant improvement over conventional chemical reduction methods. Microwave-assisted reduction methods have been found to produce satisfactory rGO with significantly lower reaction times than conventional heating techniques. However, conventional chemical reduction methods have resulted in unsatisfactory rGO with high oxygen content and a relatively high ID/IG value. These new methods may provide the next step in the development of RGO.

The incorporation of RGO into composites was studied using a variety of methods. For example, using a thermoplastic polyurethane/polypropylene matrix in a melt-mixing process, the researchers were able to synthesize electrically-conductive nanocomposites. Then, they assessed these composites to determine how they may benefit the materials they use. In addition, RGO was found to be more stable than graphite, and a lower concentration of RGO was observed when compared to a control sample.

Monolayer Graphene on PET (10mm x 10mm) Pack 4 units

Researchers are using high-purity monolayer graphene for Chemical Vapor Deposition (CVD) as a growth substrate. Large graphene structures can be cultivated in copper foil for thermal chemical vapour separation and transferred to Polyethylene Terephthalate (PET) by means of hot-pressed lamination. We have high-quality graphene monolayers (PET coated) available for immediate shipment.

Researchers are using high-purity monolayer graphene for Chemical Vapor Deposition (CVD) as a growth substrate. Large graphene structures can be cultivated in copper foil for thermal chemical vapour separation and transferred to Polyethylene Terephthalate (PET) by means of hot-pressed lamination. We have high-quality graphene monolayers (PET coated) available for immediate shipment.

Monolayer Graphene on PET (100mm Wafer)

The production of monolayer large area graphene and wrinkle-free multilayer graphene films, which are transferred to glass substrates, is carried out with graphene sheets, as shown in Fig. High-quality graphene foil monolayers are applied to copper foil by means of chemical vapour deposition (CVD). Similar to other graphene foil products, including single layer graphene foils (Figure 3) manufactured using CVD deposits on round substrates, PET measures a thickness of 1.75 mm during the wet transfer process. Show Source Texts

Based on the CVD method, many large-format monolayer graphs can be produced by fixing and transferring the multi-layer graphene film onto the TI adhesive layer. Figure 4 shows schematic structure of the graphene monolayers prepared and multilayers of graphene foils transferred to the TI glass substrate. Raman spectra of the bare top of graphene were observed when it was detached from the substrate and attached to graphene foil after transfer to the substrate. We assume that the interacting oxygen in the substrate forms a strong O-chemical bond, taking advantage of the concept of transferring wrinkle-free graphene films to different functional substrates by introducing a TI adhesive layer. With this method, high-quality graphene products can be synthesized, resulting in monlayer-graphene coverage of up to 90%.

Monolayer Graphene on PET (25mm x 25mm)

Today, manufacturers are developing high-purity monolayer graphene for chemical vapor deposition (CVD) as a growth substrate. Large graphene structures can be cultivated in copper foil for thermal chemical vapour separation and transferred to polyethylene terephthalate (PET) by means of hot-pressed lamination. Our graphene monolayers (PET coated) are of quality, shape and size for all applications and thus the benchmark products on the graphene market.

Today, manufacturers are developing high-purity monolayer graphene for chemical vapor deposition (CVD) as a growth substrate. Large graphene structures can be cultivated in copper foil for thermal chemical vapour separation and transferred to polyethylene terephthalate (PET) by means of hot-pressed lamination. Our graphene monolayers (PET coated) are of quality, shape and size for all applications and thus the benchmark products on the graphene market.

Monolayer Graphene on Quartz (10mm x 10mm Wafer)

The researchers used a single layer of graphene with a copper catalyst that was grown using the chemical vapour separation method (CVD) and transferred using the chemical etching method to a dielectric substrate (quartz). The growth rate and quality of graphene on quartz substrates showed a remarkable improvement over the conventional CVD process. In TA, BOAT and CU-optimized CVD reactors, SEM images of graphene films at different magnifications transferred to Si-SIO-2 substrate (C) have been delivered to the CU-optimized VDC Rifles at various magnifications. Our single-layer graphene-quartz lid is made by VTD transfer on a circular base of 500 mm thick quartz with wet transfer. Graphene was deposited on the quartz substrate.

The researchers used a single layer of graphene with a copper catalyst that was grown using the chemical vapour separation method (CVD) and transferred using the chemical etching method to a dielectric substrate (quartz). The growth rate and quality of graphene on quartz substrates showed a remarkable improvement over the conventional CVD process. In TA, BOAT and CU-optimized CVD reactors, SEM images of graphene films at different magnifications transferred to Si-SIO-2 substrate (C) have been delivered to the CU-optimized VDC Rifles at various magnifications. Our single-layer graphene-quartz lid is made by VTD transfer on a circular base of 500 mm thick quartz with wet transfer. Graphene was deposited on the quartz substrate.

This situation was confirmed by the investigation of CVD graphene growing in our aging quartz tubes (Figure S3), where SiO2 particles proved to be secondary in the graphene domain, highlighting their role as the preferred additional nucleus. Figure 1 SEM image of contaminated graphene film grown in CVD quartz tubes with copper transfer (Si / SiO 2 at 300 nm C. ) was used to prepare a high quality, uniform single-layer graphene plate with a growth time of 60 seconds using a generic recipe to saturate a Cu substrate with graphene focusing on Cu foil.

Layers of PECVD thickness were used to grow graphene films on quartz. Using THZ-TDS measurements, we examined surface boundary conditions of Mg samples deposited in a molten quartz substrate on both the substrate and in the air to achieve a complex refractive index and electrical conductivity of graphene.

Monolayer Graphene on Quartz (100mm Wafer)

CVD Graphene on Quartz is a type of CVD film made from monolayer  graphene on quartz. This material is fully covered and is easily transferable from a cylinder to a circular substrate through a wet transfer process. This material has many applications in science and technology. Graphene on quartz is a useful material for biosensors. Its atomic layer structure makes it ideal for biosensors.

graphene on quartz. This material is fully covered and is easily transferable from a cylinder to a circular substrate through a wet transfer process. This material has many applications in science and technology. Graphene on quartz is a useful material for biosensors. Its atomic layer structure makes it ideal for biosensors.

To investigate the optical properties of the composite, researchers performed Raman spectroscopy. Using the technique, they were able to see that the graphene layer is a single, uniform layer. Further, they were able to identify the thin film's optical response with the help of scanning electron microscopy. Once this process was finished, they tested the quality of the composite by conducting tests with Raman spectroscopy and other techniques.

Using different samples, scientists measured the transmittance of monolayer graphene on quartz and other substrates. The results indicated that the graphene is highly crystallin and has a large crystallite size. Raman spectra were then measured at 532 nm, which correlated well with the calculated transmittance spectra. The XPS data were then decomposed using an XPS peak fitting software package.

The intensity of the G peak depends on the number of graphene layers. The quality of the fabricated sample can affect the intensity of the 2D peak. For example, the Raman spectra of the transferred MG showed the G (1580 cm-1) and the 2D (2680 cm-1) bands. Both bands were detected, but one was observed a disorder-induced D band, possibly caused by subdomain boundaries and edges.

Suspended Monolayer Graphene on TEM Grids (Quantifoil Gold) Pack 4 units

The first image of Transmission Electron Microscopy (TEM) images of thin graphite samples consisting of a few graphene layers was released by G. Ruess and F. Vogt in 1948. The method of graphene crumpling by adding nanoscale folds to the graphite sample was achieved by applying a layer of graphene oxide on the shrunken film, shrinking and dissolving it. A clean monocrystalline graphene foil was grown in a commercially available copper foil (Alfa Aesar 46365, 25 mm thick) in a low pressure CVD tube furnace (LPCVD) system.

The first image of Transmission Electron Microscopy (TEM) images of thin graphite samples consisting of a few graphene layers was released by G. Ruess and F. Vogt in 1948. The method of graphene crumpling by adding nanoscale folds to the graphite sample was achieved by applying a layer of graphene oxide on the shrunken film, shrinking and dissolving it. A clean monocrystalline graphene foil was grown in a commercially available copper foil (Alfa Aesar 46365, 25 mm thick) in a low pressure CVD tube furnace (LPCVD) system.

Monolayer Graphene on Cu with PMMA Coating (100mm)

The process described here leads to a high yield of suspended, clean graphene films on perforated carbon ribs. In order to etch the copper, graphene is protected by a rich layer of Polymethyl Methacrylate (PMMA). In a modified tube furnace the carbon source and copper matrix are heat independent and the temperature zones and process parameters (growth time and growth temperature) are regulated to control the growth of the graphene film on the copper substrate, which is controlled by low pressure. On the surface of the copper foil form a single layer of graphene film at a growth temperature of 800 degrees Celsius and two layers of graphene film at 600 degrees Celsius and 700 degrees Celsius. After the film is gone, we can transfer the graphene films with PMMA for a distance of 10 minutes into deionized water, or you can transfer the water and wait for up to 20 minutes.

The process described here leads to a high yield of suspended, clean graphene films on perforated carbon ribs. In order to etch the copper, graphene is protected by a rich layer of Polymethyl Methacrylate (PMMA). In a modified tube furnace the carbon source and copper matrix are heat independent and the temperature zones and process parameters (growth time and growth temperature) are regulated to control the growth of the graphene film on the copper substrate, which is controlled by low pressure. On the surface of the copper foil form a single layer of graphene film at a growth temperature of 800 degrees Celsius and two layers of graphene film at 600 degrees Celsius and 700 degrees Celsius. After the film is gone, we can transfer the graphene films with PMMA for a distance of 10 minutes into deionized water, or you can transfer the water and wait for up to 20 minutes.

Monolayer Graphene on Cu with PMMA Coating (60 mm x 40 mm)

Graphene Coated Silicon Wafers

Graphene coated silicon wafers are a promising material for the development of future ![]() semiconductors. These thin layers of graphene are highly friction-resistant and have the ability to reduce the friction of the silicon substrate. In addition, the coatings can also be used in high-end electronics and are being used in many applications, including solar cells and memory devices. These characteristics make them ideal for high-speed ICs.

semiconductors. These thin layers of graphene are highly friction-resistant and have the ability to reduce the friction of the silicon substrate. In addition, the coatings can also be used in high-end electronics and are being used in many applications, including solar cells and memory devices. These characteristics make them ideal for high-speed ICs.

Graphene on silicon wafers are made from a high-quality silicon substrate. This material is conductive, highly transparent, and has a low density, making it a perfect choice for a variety of applications. Graphene-coated silicon has tremendous potential in many electrical devices and is expected to replace silicon in the future. The materials are grown using chemical vapor deposition (CVD).

Researchers have demonstrated that graphene coated silicon wafers have excellent mechanical properties. The material has a high surface area, allowing it to be easily attached to anything. This is why graphene is used in so many applications, from electronics to medical devices. It is even useful in the treatment of wounds, as it is an effective heat dissipator. It also has a wide range of other applications.

The materials produced by Graphenea can be used in various medical applications. For example, they can be used to develop ultra-durable implantable medical devices. In addition, these materials are lightweight and flexible, making them a good choice for medical implants. These materials are cheap to produce and shipping, and the possibilities are virtually limitless. This material has a high energy density and no limitations when it comes to energy storage.

What Is Graphene Used For?

What is graphene used for? Graphene is an ultra-flat material that can be attached to almost anything. Its high surface area makes it a great material to use in composites because it is strong and lightweight. It can be used in electronics and medical applications and can help dissipate heat. This new material has many other applications. In addition to the above, graphene is also being investigated for wound healing.

Graphene is a thin layer of carbon that is formed in a unique way. It was first discovered in 2004, and the scientific community is excited about its future. It is currently in a development stage, but scientists are already developing applications that make it an excellent material. This article will explore some of the most exciting new applications for graphene. However, this article will focus on its properties in a broad sense.

Graphene is a thin layer of carbon that is formed in a unique way. It was first discovered in 2004, and the scientific community is excited about its future. It is currently in a development stage, but scientists are already developing applications that make it an excellent material. This article will explore some of the most exciting new applications for graphene. However, this article will focus on its properties in a broad sense.

Graphene has many applications. For example, it can be used to create superconducting devices. The insulating properties of graphene make it useful for many industries, including the medical field. Graphene can be used to create anti-rust coatings for car parts. It can also be used to create water-proof houses, especially for solar panels. Its properties make it a promising material for use in many industries.

Graphene has many applications. As a barrier to both gas and liquid, it is an excellent choice for protection against corrosion and non-aqueous fluids. Its excellent thermal and mechanical properties also make it an excellent material to use when enhancing toughness, or thermal management. These advantages allow graphene to be a valuable addition to any type of material. So, what is graphene used for?

Graphene is used in water-filtration applications. In Australia, researchers have been using graphene to create filters for the city's water supply. This material is made from graphite and is highly efficient for composites. It also helps in the creation of sensors and electronrics. There are several uses for graphene. If you are wondering what is it used for, here are a few examples.

Graphene can be used in chemical and electrical applications. Its ultra-stretchy properties make it a good material for electrical and optical devices. In addition to electricity and magnets, graphene is an insulator. Its properties also make it a good material for biosensors. It is also a good material for sensors. There are many applications for graphene in the medical industry.

Another example of what is graphene is: A single layer of graphene has the strength of cling film. In order to puncture the cling film with a pencil, a mass equivalent to two kilograms would have to be applied. When you are looking for a way to increase the speed of your electronic circuitry, there are many options. One example is a cellular phone.

Graphene can be used as a superconductor and an insulator. Compared to silicon, it is also more flexible and tensile than cling film. Its tensile strength and flexibility make it a great material for batteries. It can also be used in the construction of ultrafast-charging batteries. It can handle currents that are dozens of times higher than lithium batteries.

Graphene has many applications. Its ultra-sensitive nature means it can be used as an insulator and superconductor. It is an excellent material for sensors. In fact, it is even an insulator. For example, it can be used as a protective layer between two sheets of glass. Its high strength is the reason it can be used in many other applications. It can be used in electrical components.

Graphene can be used in brain implants. It can record and stimulate brain signals on the surface of the brain. This could lead to less invasive neural implant surgeries. Besides, the use of graphene in computers may revolutionize the way electronic components are manufactured. It could also be used as a touch-sensitive coating, as well as extend the life of computers. Furthermore, it is stronger than diamond and a million times thinner than paper.

What Makes Graphene So Strong?

Graphene is a remarkable material that is flat, conductive, transparent, and strong. Scientists from Berkeley Lab developed the first statistical theory of the toughness of polycrystalline graphene. Although polycrystalline graphene is stronger than monocrystalline, it has a lower toughness than graphene. The study is published in Nature Communications. It explains how the graphene structure is strong. If you're wondering what makes graphene so strong, read on.

The structure of graphene is amazing. The carbon atoms are arranged in an  atomic honeycomb pattern. Like chicken wire, each carbon atom is covalently bonded to three other items of carbon. This allows for remarkable strength, while remaining extremely flexible. The resulting material is strong enough to withstand high-strength impacts. It is also a good lubricant. It is so flexible, in fact, that it can slide over other materials.

atomic honeycomb pattern. Like chicken wire, each carbon atom is covalently bonded to three other items of carbon. This allows for remarkable strength, while remaining extremely flexible. The resulting material is strong enough to withstand high-strength impacts. It is also a good lubricant. It is so flexible, in fact, that it can slide over other materials.

One of graphene's main properties is its high strength. The sheet of graphene has four carbon atoms that are bonded together by a single bond. Three of them are shared with neighboring carbon atoms, leaving a fourth electron known as the pi electron. The pi electron moves freely in three-dimensional space and transmits electrical charges across the sheet. This property makes graphene the fastest conductor of electricity at room temperature.

Graphene is very sensitive to the presence of cracks. While steel has great strength and is resistant to crack extension, graphene is more like a window glass. The material's incredible properties make it an excellent material for applications that require great durability. It is also conductive, and flexible. So, it is no wonder that scientists are fascinated by this new substance. These wonders will soon become the stuff of future technology.

Graphene is the strongest material known to man. In a sheet of graphite, the single carbon atom is one atom thick. A mm-thick sheet of graphite contains 3 million layers of graphene. The properties of graphene come from its twop orbitals, which form p-state bands. The sheet is the strongest material known to man. Its strength can be compared to steel, which is a few millimeters thick.

Graphene is a highly elastic material. Its strength is due to the way carbon atoms are bonded. A single carbon atom has four electrons, which are shared with three other atoms in the same layer. Those two atoms are connected through a network of three-dimensional bonds. The sheets of graphene can withstand a huge amount of pressure and are highly elastic.

Graphene is the strongest material known. It is ten times stronger than steel, but has a low fracture toughness. Its fractiousness is the result of small cracks in the material. It has a high elasticity and is less brittle than steel. Its fracture toughness is similar to silicon carbide-based ceramics, but graphene is weaker than steel.

The atomic structure of graphene allows it to conduct electricity. Each carbon atom has four electrons in its outer shell. Of these, three of them are shared with a neighboring carbon atom. The fourth electron, called the pi electron, is free to move in three-dimensional space and is responsible for conducting electrical charges. This property makes graphene the strongest material known to man. If you're wondering how to make a superstrong material, read on.

Graphene has a unique structure that makes it stronger than copper or diamond. Its structure allows it to conduct heat and electrical current more efficiently than other materials, but it also absorbs about two-thirds of the light it reflects. Its atomic structure makes it a strong material for many leading-edge applications. In fact, it is so strong, it's so thin. The thinness of graphene allows it to be used in electronics, batteries, and even in the manufacturing of food and beverages.

Graphene's unique structural properties also make it an excellent material for electronic devices. Its atomic structure enables it to be flexible and strong, and can be formed into any shape desired. Unlike copper, graphene is also one of the cheapest materials in the world. This means that if you want to make a superstrong computer, graphene is the right material to use. However, it's not available in any stores yet.

How Thin Can You Make Graphene?

The question "How thick can you make graphene?" is a fascinating one. Scientists have been working for several years to create the material. It is just one atom thick, and is extremely strong. But how can you make it thicker? This question is a good one for science fiction fans, and it might even be the key to making a super-conductor! Here are some methods:

Graphene is one atom thick. This means that a sheet of this material would weigh less than a gram. However, to cover a football field with graphene, you would need a mass of up to 1500-2,000 tons. Then again, this is the equivalent to the mass of about 1500 cars. The answer is: "About a thousand layers." So the question is, "How thick can you make graphene?"

In 2002, Andre Geim became interested in graphene, and challenged a student to polish a piece of graphite. He succeeded in doing this, but only at a very high level - 1,000 layers! Then, he used a piece of tape to create flaky layered graphene. The more tape peels, the thinner the layer. Andre Geim's experiment was the first step in the process that has made graphene useful for electronics.

In addition to graphene, scientists can create superconducting films that are ten times more efficient than conventional materials. The first one-atom thick transistor was invented by a team of scientists at Manchester University, and another team, led by Geim and Novoselov, were able to produce the first commercially available graphene-based flash memory. The two researchers were awarded the 2010 Nobel Prize for Physics for their research.

To make graphene, you need to first understand the material itself. It is composed of one atom thick layers. A sheet of graphene is one atom thick. If you want to make a graphene-based computer, you need to know how to make it thin. If you want to make a graphite-based chip, you need to use a thin layer of graphite, as this is the only way to create a solid-state electronic device.

To make graphene, you must first make a graphene-based computer. Using the material, you can create a flexible, durable, and super-strong laptop. You can even make a smartwatch out of graphene. Moreover, a graphene-based phone can be used for solar panels. The graphene-based computer could also be used to build solar cells.

To make graphene, you can mix heptane and water. Then, add finely ground graphite powder to the mixture. Then, apply the liquid to a glass plate. After removing the graphite layer, you can deposit the resulting layer onto a clean substrate. You can find a graphene tablet at art stores. Once the layer is ready, you can then put it on a laptop.

The atoms in graphene are just one atom thick, and a sheet of graphene can be as much as one-tenth of a meter in thickness. The graphene sheets can be made in large areas in one go. The soybean oil method is a variation of CVD, which uses ambient air. The advantage of this method is that it requires less energy than other CVD processes.

There are two ways to make graphene. First, you can mix two solvents: heptane and water. Then, you can add finely ground graphite. Then, you can add water. After mixing, the mixture will become transparent. Alternatively, you can also combine these two methods to make graphene. After that, you can deposit it onto any substrate. Once it is hardened, you can store it in a fridge or on a mirror.

The second way to make graphene is to make it with non-water-soluble liquids. This is done by dipping a sheet of graphite in oil. Then, you will add the non-water-soluble liquid into a glass of water. As long as you're using a non-water-soluble liquid, the graphene will float on the water. In this way, you can get a very thick graphene.

How to Make Graphene?

How to Make Graphene is possible using everyday wastes. This research used flash joule heating to turn carbon black and other industrial byproducts into graphene. This material is chemically stable and can be produced with as little as one teaspoon of graphite powder. It can also be obtained from scrap metal or wood. It is important to note that heptane is not available in many chemical supply stores.

The original process to make graphene was invented in the 1950s by Chris Sorensen. He mixed carbon-containing materials with dishwashing liquid and then blended it. This mixture formed a thin layer of graphite that separated from the pencil lead. This process is simple and inexpensive, and could easily be scaled up for industrial use. However, the original method cannot scale up to mass production. This method is still a viable method for the production of graphene, but it's still a long way from commercializing it.

This method is very simple and can be done by almost anyone. You will need a spud gun and PVC pipe. You will also need a spark plug and a quick-sealing endcap. To produce graphene, you will need a large amount of these nanoparticles. You can dry the particles once you've made enough. But be careful not to overdo it, as the process may not be completely reproducible.

Once you've made a graphene-containing solution, you can use the sonication method to remove it. The sonication method is an excellent way to make graphene. This method uses heat to remove the surface layers of carbon. It's an easy and safe method. The benefits are clear. This material is also used in a wide variety of industrial applications. In the end, it can be used in many products.

In addition to using a spud gun, you can also use a spud gun to create graphene. You can make a graphene by heating a potato. This will give you a graphene that is similar to a potato. The spud gun is a device that enables you to vaporize a potato. Eventually, it will form a layer of graphene that is as strong as a single layer of carbon.

To make graphene, you need to mix two different materials. You can purchase heptane and water at most chemical supply stores. A graphite stick is available in art stores. You can also find a graphite ultrasound bath on eBay. You'll need a jar of heptane and water to produce the sheet of graphene. The first two ingredients will produce the graphene.

The first step is to make a thick layer of graphite on a sheet of paper. Then, use a piece of ordinary sticky tape to peel off that layer. After that, use another piece of sticky tape to remove the next layer. Continue until you have created a sheet of graphene that is one to four layers thick. Then, you can use this material for various applications. The layers will get thinner until you have a thin film of graphene.

Graphite is a thin layer of carbon that is made up of atoms. This material is strong enough to be used in high-end electronics. In this experiment, a graphite flake is placed on a microscope slide. Its thin layer of graphene absorbs light, whereas the other layer absorbs light. If you want to see how graphene is made, you will need a lab that is equipped with a micrographer.

The process of making graphene is quite simple. You can simply place a flakes of graphite on a scotch tape and fold them into two. You can then cleave the flake into single atom-thick fragments. This is what we know as graphene. Then, you can put the flake of a graphite on a microscope slide and watch it absorb light.

In order to make graphene, you should first make a solution that contains the graphite oxide. You can do this by adding a spoonful of powdered graphite to a cup of water. Then, add the liquid to the vessel and stir it for a few minutes. Then, let the mixture dry. Once the flakes are dry, you can move on to the next step: the final step.

How to Manufacture Graphene Video?

The Feasibility of Combining Graphene and Iron

Graphene is a material with unique properties that makes it a potential replacement for  steel. Its electrical conductivity is much higher than that of steel, and its insulating and superconducting properties make it an ideal candidate for construction materials. Since most metal parts rust, a combination of graphene and paint could be used to create rust-free surfaces. In addition to this, a combination of graphene and stone or brick can be used to build water-proof houses and other structures.

steel. Its electrical conductivity is much higher than that of steel, and its insulating and superconducting properties make it an ideal candidate for construction materials. Since most metal parts rust, a combination of graphene and paint could be used to create rust-free surfaces. In addition to this, a combination of graphene and stone or brick can be used to build water-proof houses and other structures.

Graphene is made up of carbon, the fourth most common element in the universe. Most people think of materials in terms of molecules or atoms. However, graphene is different from most other materials because it contains no atoms. The carbons in graphene are tightly bound together and are unlike those found in diamonds, graphite, or other metals. Unlike these other materials, it has a hexagonal, flat surface that makes it a great candidate for a solid lubricant.

Graphene is also a promising material for combining with iron in construction. Despite its low cost, it has an impressive range of applications. It can help make steel, concrete, and concrete more durable. It can help protect basements and barrels, as it is more resistant to corrosion and light. It is also better at reflecting and bouncing light, and it's a much safer material compared to kevlar or iron.

While graphene does not display high photoresponsivity, it can be applied as a coating material for glass. While glass is a material with high resistance to corrosion, graphene's chemical inertness and transparency make it an excellent candidate for UV sensors. This new technology is expected to be used in industrial applications and can be incorporated into wearable electronics. When it comes to solar panels, graphene and iron are the ultimate solution.

There are many benefits of combining graphene and iron. The first two are useful in making solar cells. They can also be used to produce fuel. A combination of the two can make it a better fuel for automobiles. This new material is being researched by NASA and other space agencies worldwide. It would improve the life support system on other planets. In addition, the use of a mixture of graphene and iron will enhance its thermoelectric properties and make it more efficient.

Combining graphene and iron is an ideal solution for several purposes. These two materials have high levels of heat absorption and can be used in protective clothing. In addition, a composite made of these two materials is more durable than traditional leather and can withstand more impact. The first advantage of combining graphene and iron is that they are compatible. If you want to create a hybrid between two materials, you will be able to protect your home against the other by preventing the corrosion of the other.

Graphene and iron can combine to create an ideal reinforced material for construction. Because of its superior strength, graphene is an excellent reinforcement material. It is highly durable, and it is a better choice than steel and other materials. In contrast to steel, graphene can be lightweight and can be used for a variety of applications. Moreover, its low-porosity properties make it an ideal replacement for metal.

The initial isolation of graphene from iron requires careful temperature control. But this method will not be cost-effective enough to be widely used in mass production. For the time being, however, it is possible to separate individual sheets of graphene from pencil lead by using adhesive tape. But the process of creating such a composite is unlikely to be automated. The only way to scale this up is by employing a specialized robot.

The combination of graphene and iron is an ideal choice for construction. Graphene has high strength and is a good reinforcement material for iron. In fact, this combination is highly effective in various industries. This material is also transparent and conductive. Its properties make it a perfect choice for various types of glasses, which can be used in eyeglasses and other forms of electronics.

Does Graphene Conduct Electricity?

Does graphene conduct electricity? This is an important question for those interested in  fuel cells. Graphene has a very thin layer of carbon atoms, and they behave like tiny atomic nets. They can detect gases, and can even hold gases that leak. For example, hydrogen is very difficult to store in an environmentally friendly way. Graphene's ability to trap hydrogen could make fuel cells more viable.

fuel cells. Graphene has a very thin layer of carbon atoms, and they behave like tiny atomic nets. They can detect gases, and can even hold gases that leak. For example, hydrogen is very difficult to store in an environmentally friendly way. Graphene's ability to trap hydrogen could make fuel cells more viable.

The electronic band structure of graphene is a hexagonal Brillouin zone in which the conduction and valence bands meet at each of its six vertices to form linearly dispersed Dirac cones. The result of this structure is a zero-gap semiconductor with a high conductivity. This material is called a superconductor because it has a valley degeneracy of 2.

Electrons carrying current in graphene have a pseudospin, meaning that their direction of motion is determined by their group velocity. If the velocity is positive, the electrons move up, while if they are negative, they move down. The chirality of graphene means that the current flows upwards on the A sites and downwards on the B sites. Unlike copper, graphene is the fastest conductor of electricity at room temperature.