Are Test Grade Silicon Wafers Good for My Research?

A scientist asked us the following:

I have questions about the quality of Si wafers. So we want wafers that will help us determine dep rate, unif, etc. but only need quality good enough to accurately measure results repeatably. I am assuming TEST wafers good enough for that?

See below for the answer!

Get Your Quote FAST! Or, Buy Online and Start Researching Today!

Test Grade Wafer Answer

A scientist asked us the following:

I have questions about the quality of Si wafers. So we want wafers that will help us determine dep rate, unif, etc. but only need quality good enough to accurately measure results repeatably. I am assuming TEST wafers good enough for that?

These would be run using a variety of processes, from sputtering, to PECVD, etc. Why would someone need to get PRIME grade silicon?

Also, we are going to use a number of wafers for dummies in a LCPVD process, where they will be going in and out of the chamber for a number of runs. For that, should we be using TEST wafers? Or MECHANICAL grade good enough there? In the dummy case, no measurements will be done on the wafers. They will just get thicker and thicker coatings over time, until they get replaced. Please advise

A couple of different things we are using the wafers for.

1 . we need some for verifying Dep Rates and RI of films on Si. So the quality there needs to be good enough for that. So is TEST wafer sufficient, or do we need PRIME for that? If so, why?

2. We need dummy wafers to put into LPCVD tool to take up spare slots during deposition. We won't do any measurements on these, and they will go in multiple times, maybe for up to 6 months so long they are not flaking. Are MECH grade wafers good enough for that, or will they flake more quickly than TEST wafers. If so, why?

If you can answer these questions for us, we will place an order for 2 different types of Si wafers.

UniversityWafer, Inc. Replied:

SEMI standards are the specifications covering the physical and chemical characteristics of Silicon wafers.

SEMI defines Prime and Test grades of wafers. According to SEMI, the two grades are the same, except that Test wafers are allowed to have some polishing imperfections, most notably scratches and surface dust particles. Chemically they are the same. Test grade was established for the very purpose that you plan to use the wafers, that is to be the monitor wafers for doping and film deposition processes.

In common usage, Test grade wafers are those that have any polishing imperfections or those that have been on the shelf for a long time. Old wafers have an extra thick layer of "native oxide" that forms over time and shows up as "haze" during inspection. One needs to check into the nature of the imperfections to make sure that they do not affect deposition rates in LPCVD or PECVD reactors and Refractive index measurements. In most cases commonly named Test grade wafers are entirely adequate as monitor wafers.

In common usage, Mechanical grade wafers can have any crystallographic orientation and any kind and degree of doping, as long as they conform to geometric specifications. One needs to check if the dopants or dust particles on such wafers can contaminate the process. For example, Arsenic can easily evaporate from such wafers when they are heated in vacuum. In most cases commonly named Mechanical grade wafers are adequate as spacer wafers.

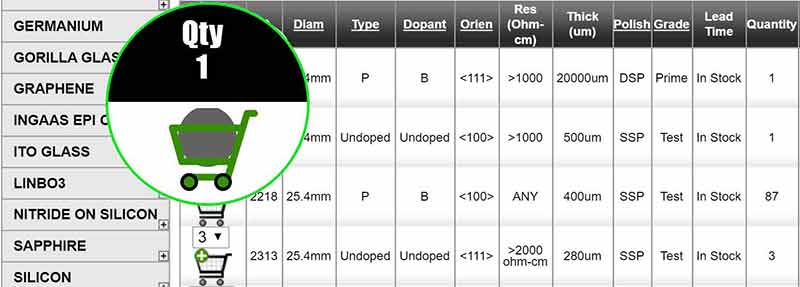

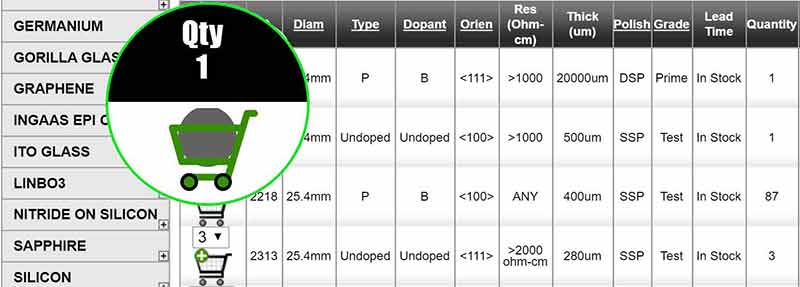

Click the image below to visit our store. Buy as few as one wafer!

Silicon Wafers Used for Wrinkled Surface Adhesion Research

For the study reported here, the glassy thin films are high molecular weight, atactic polystyrene (PS) (Mn

¼ 1100 kg mol�1,

PDI ¼ 1.15, Polymer Source, Inc.) spuncast from toluene (Fisher

Scientific) onto ultraviolet/ozone (Jelight 342 UVO system)

treated silicon wafers (University Wafer). By varying the

concentration and spin speed, film thicknesses ranging from

20 nm to 300 nm as measured by white light interferometry

(Filmetrics) are obtained.

Scientists have used the following wafer to research the mechanics of wrinkled surface adhesion.

Si Item #452

100mm P(100) 0-100 ohm-cm SSP 500um Test Grade

What is Wrinkled Surface adhesion?

Wrinkles are examples of surface buckling instabilities. The wrinkles cover large areas and modify the adhesion of surfaces. But the effects of wrinkles are not well understood quantitatively. To measure the effects of wrinkles on surface adhesion, researchers fabricate aligned polymers with different amplitudes. These wrinkles vary in amplitude from 0.3 to 11.4 mm. In addition, the researchers also studied the effect of UV exposure and plasma treatments on the adhesion of wrinkled surfaces.

Cell attachment to wrinkled particles

We have observed that the cells attached to wrinkled particles climb onto their surfaces and cover the surface area. This is confirmed by confocal microscopy studies. Our data show that cells adhere to the surface of wrinkled particles in 75.1% (SD) of cases and 17.6% in the other cases. Cells adhere to the surfaces of the particles only to the extent that they have a large surface area. Our findings suggest that cell attachment to wrinkled particles can be an important mechanism for regulating drug delivery.

We created bio-based wrinkled films by combining FE and HRP-catalyzed surface reactions. We then plated 3T3 cells on the wrinkled film and cultured them with DMEM. Our findings show that 3T3 cells attached to the wrinkled particles had better survival and attachment rates compared to the control group. Further, the film's biocompatibility in mice supports its potential application as a biomedical mechano-structural cue.

We used two methods to determine cell attachment to wrinkled particles. First, we determined the extent of HUVEC attachment to the particles. Secondly, we measured the proliferation of HUVECs on the particles in a bioreactor. In both cases, the samples were processed for 4 hours, the time period which encompasses the highest binding capacity of HUVECs. Flow cytometry data was also used to confirm cell attachment. The flow cytometry data obtained from the experiments are shown in Figure 5.

Effects of UV exposure

Increasing the exposure time to ultraviolet light can modify the polymer conversion rate and thus control the thickness of the PCP layer. These parameters determine the wavelength of wrinkles after plasma treatment. Figure 2 illustrates the morphology of wrinkled particles and their wavelengths after plasma treatment and washing with 5% PEG-DA solution. The wavelength decreases from a micron scale to a submicron scale as UV exposure time increases.

Exposure time had an effect on the amplitude of wrinkles. Exposure time reduced wrinkle morphology from a continuous to a discontinuous pattern. Time of exposure was studied by measuring the skin's elasticity. The wavelengths of UV light were chosen to reduce wrinkle amplitude. In addition, the time of UV exposure increased from 300 ms to 1000 ms.

In addition, repetitive exposure to UVB and UVA causes degeneration of skin elasticity. Elastic fibers undergo a tortuous deformation upon repeated UV irradiation. The reduction in elasticity is closely related to the activity of elastase and matrix metalloproteinases. However, p-MCX treatment did not prevent the decline. In addition, UVB and UVA exposure induces sagging.

Effects of plasma treatment

Low-pressure plasma was shown to improve wrinkle surface features. This plasma was generated from argon, oxygen, and nitrogen. Depending on the gas, low-pressure plasma can generate a wide range of wrinkle structures. When applied to wrinkled skin, the resulting plasma enhances the optical and mechanical properties of the wrinkled surface. However, it is difficult to evaluate its efficacy without human intervention.

The wavelength of wrinkles increased with the increase in the plasma treatment time. After 90 s, the wrinkle to fold transition started. This transition occurred as the accumulated stress in the two-layer system increased and the deep fold formed. This transition was observed after a total of 365 s of plasma treatment. In a subsequent study, an increase in the wavelength caused the wrinkle to shrink by more than half.

Low-pressure plasma is also used to treat textiles. This process uses proprietary gas blends to inhibit arcing. Because it is non-thermal, low-pressure plasma treatment is an energy-efficient method to modify textile surfaces. Plasma treatment can be applied to any shaped object with a single side. The technique is suitable for modifying textiles and polymers without the need for a separate treatment area.