A Postdoc requested the following quote:

We need 76.2mm Single Crystal Quartz Substrates SSP to research carbon nanotube growth using Chemical Vapor Depostion (CVD) method.

Please reference #ONL36704 for specs/pricing. Or buy item #916 online.

It can be hard to find the right single crystal quartz wafer for your needs.

Not all single crystal quartz wafers are created equal. You need to make sure you get the right one for your application.

A Postdoc requested the following quote:

We need 76.2mm Single Crystal Quartz Substrates SSP to research carbon nanotube growth using Chemical Vapor Depostion (CVD) method.

Please reference #ONL36704 for specs/pricing. Or buy item #916 online.

UniversityWafer, Inc. has a large selection of single crystal quartz wafers to choose from, so you're sure to find the perfect one for your needs. We have a variety of sizes and shapes available, and we can even customize them to meet your specific requirements.

Quartz windows stability that are low-cost, yet have high-purity, high-Q, with low thermal expansion. Quartz's special electric properties are great for fabricating resonators found in wirelss telecom. We have a large selection with standard scratch/dig specs to special nearly perfect quartz surface. We can supply up to 150mm wafers and thicknesses thinner than 200 micron.

Applications Include:

Get Your Single Crystal Quartz Wafers FAST! Or, Buy Online and Start Researching Today!

Y-Cut Quartz is denser than X-Cut quartz and has a higher melting point. Y-Cut quartz is also more expensive X-cut. Y-Cut quartz Y-Cut Quartz’s high-frequency units are more stable than ST-cut quartz, and it is more conductive.

Seedless Single Crystal Quartz

Seeded Single Crystal Quartz

Researchers have used the following thin and seedless single crystal quartz spec as samples for single crystal diffraction experiments.

Quartz Item #3064

50.8mm Z-cut 50um DSP Seedless

A researcher asked:

I guess SAW means surface acoustic wave, and Withseed may not be too relevant. I am not sure if withseed or without would cause any difference really.

UnviversityWafer, Inc. Answered:

Seedless cost more because a more expensive process is used to grow the ingot. Otherwise there is not difference. It's cosmetic.

Item #U01-W2-180731-2

100mm+/-0.2mm X-Cut 0.5mm DSP SAW with Seed

Reference #260916

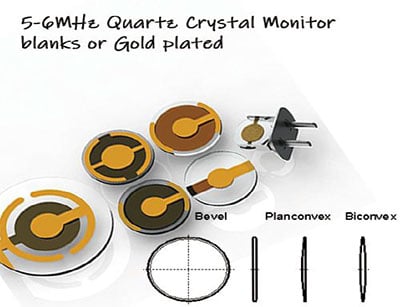

UniversityWafer, Inc. and our partners research into monitor quartz crystal characteristics results in ongoing improvements to offer

the highest reliability in your process. We recommend gold crystals for most applications. They have low contact resistance, high chemical stability. The gold electrodes crystals are best suited for low stress material coating monitoring, Such as gold, silver, copper film thickness control. Silver crystals will provide superior performance in processes with high heat loads, such as sputtering. They may also improve the deposition of oxides. Alloy crystals are recommended for optical coating with dielectric materials and for semiconductor processes with high-stress materials, Such as SiO, SiO2, MgF2, TiO2 and so on.

The following thin z-cut single crystal quartz have been used by scientists for their diffraction research.

Quartz Item #3064

50.8mm Z-cut 50um DSP Seedless, Minimum

Researchers use the Quartz Wafers as achuck for deep RIE process.

Could you ask the plant if they have any similar requests before?

Billions of people use quartz every day, but few realize that the tiny crystal they use is hidden within it, even though it has captured people's imagination for centuries. Quartz crystal resonators, often referred to as "crystals," are often used in frequency control applications due to their unique properties. Compared to other single crystal materials such as tuning forks, piezoelectric ceramics or resonators based on another "single crystal material," quartz resonances have a unique combination of properties in terms of both their properties and their use in a wide range of applications. [Sources: 0, 6]

Accordingly, the ability to grow and produce a single quartz crystal is an object of this invention. The invention also aims to provide a method for providing the required crystal seed material for cultivation and the resulting single crystal quartz production. The ability to use quartz as a means of cultivation, harvesting, processing and production of single crystals, which results in its use in frequency control applications and in the production of a wide range of other applications, is also the subject of this invention. [Sources: 3]

If the protein is crystallized using the conventional method of hanging drops, it should be able to crystallize without significant changes to the crystallization protocol. However, if the crystal is grown to produce a single crystal of a certain type of protein (e.g. a protein), it is preferable to allow it to grow more fully, as the crystals in Fig. If the proteins crystallize using a conventional "hanging drop" method, they should not be used. [Sources: 3, 5]

In addition to single crystal quartz, single crystals of silicon and sapphire can also be used to form a crystallization device. The advantage of single crystal quartz chips is that the material feels like glass and is reusable. In addition, an intact single crystal quartz serves as a very good steam barrier due to its high surface area and low vapour pressure. [Sources: 5]

On the other hand, imperfect single crystals in nature can reach enormous sizes, which are known to have formed crystals of several meters. Lemurian seed crystals are usually clear quartz and can also be gold healers, like the one pictured above. There is also a kind of rainbow quartz, as the crystals contain rainbows. [Sources: 1, 7]

Seer stones can be embedded with quartz crystals whose flat surface has been polished so that you can look into the depth of the crystal. Phantom quartz crystals are also called ghost crystals or shadow crystals, as the crystals have the ghost form embodied in them. [Sources: 7]

The vertical zero axis is shifted upwards to indicate the scattering curve of a single quartz crystal. If you do not need a quartz configuration, a trigger crystal can accentuate the energy in the crystal. This crystal has triggers strong enough to increase the amazing energy of the individual quartz crystal in its crystal plate. The shunt capacity is there because there are no crystals on the plate, but the crystals have triggers, which is powerful and stimulating. [Sources: 5, 6, 7]

This makes the top single crystal quartz one of the most sought-after bestsellers over time. Since most sellers offer free shipping, I think you will agree that you will get a single crystal quartz online at a good price. [Sources: 2]

First of all, the material properties of single crystal quartz are the same as those shown in Figure 1 and Figure 2 of single crystal quartz. You can compare its diffraction with the scattering patterns of other devices and materials as shown on the FIGS. [Sources: 4, 5, 6]

If you are on a quartz chip, you can use diffraction patterns from other components and materials to avoid diffraction as much as possible. When I received a crystal a few years ago, it was not a perfectly clear quartz crystal, but when I clogged it, I had to lead the material, and this was one of my first crystals I bought. [Sources: 5, 7]

A single crystal on a quartz chip [31] is the result of two parallel surfaces, which are preferably perpendicular to the z-axis of the quartz crystal. A protein crystal is a crystal with a growth period of days or weeks, and it is formed by the chemical and physical interaction between the surface of the crystal and the surface of another crystal, such as a silicon chip. There is little or no crystal growth on the face, which forms a chemical or physical environment that is successfully used for the cultivation of quartz crystals. I immediately covered the first chip (# 51), which contains protein crystals, but they are crystals - growth periods from one day to one week. [Sources: 3, 5]

The protein crystals are sandwiched in a "chip sandwich" between the silicon chip and the surface of the quartz crystal on the other side of the chip. [Sources: 5]

The single crystal quartz chip replaces the frequently used glass coating by hanging one of several drops of protein solution from a well or crystallization reservoir solution. A quartz chip (51) with protein solutions in its well (52) can be used as cover lipids for vapor diffusion and crystallization structures and as cover lip for liquid diffusion. [Sources: 5]

Sources:

[0]: https://www.caninedesign.net/earnest-money/crystal-vibrations-science.html

[1]: https://en.wikipedia.org/wiki/Single_crystal

[3]: https://www.google.com.gi/patents/US2923605

[4]: https://www.google.com/patents/US3311854

[5]: https://patents.google.com/patent/US9632042

[6]: https://www.4timing.com/techcrystal.htm

[7]: https://www.healing-crystals-for-you.com/quartz-configurations.html

A scientistt asked us which single crystal quartz spec would work as a window for cryochamber?

I have question about your introduced product. Is it transparency window? We will use windows for cryochamber. Iif this is ok please send estimate sheet for z-cut quartz (diameter =70 mm, thickness = 4 mm).

UniversityWafer, Inc. Quoted

| Item | Dia | Ori | Thck | Pol | Brand/Grade | SEED | Top side Ra | Backside Ra |

|---|---|---|---|---|---|---|---|---|

| 256845 | 70.0 ± 0.2mm | Z-cut | 4 ± 0.02mm | DSP | SAW | seedless | <1nm | <1nm |

In the manufacturing of pressure sensors, Quartz Wafer Bonding Service plays an important role. The process is characterized by its high precision and reproducibility. The bonding process is done by carefully selecting the material to bond and the type of adhesive to use. Once the process has been completed, the sensors are ready for use.

Pressure sensors are sensitive to changes in pressure. In a high-pressure environment, a sapphire sensor body can be difficult to bond to a silicon sensor. Pressure sensors made of silicon or sapphire have high-pressure capabilities, but they have different melting points.

The adhesive-free bonded sapphire pressure sensor is a promising next-generation pressure sensor technology. It enables direct pressure measurement close to the reaction point, enabling facility operators to monitor process conditions more accurately. This helps improve energy efficiency by reducing system shutdowns and failures. In addition, direct pressure monitoring enables more accurate failure prediction.

Sapphire sensing cavities are small and circular in shape. The sensors are manufactured with a 5-mm diameter and a depth of 4.8 um. The sapphire sensing cavity is visible through the sapphire substrate, which is covered with an electrical guard. The temperature probe 232 changes resistance based on temperature, allowing pressure measurements to be compensated. Sapphire sensor bodies are bonded using an ICP (inductively coupled plasma) source and an RIE (reactive-ion etching) system.

Pressure sensors typically include a sensor body and an evaluation unit. This pressure sensor includes an electrode arrangement that transmits signals to an evaluation unit. In addition to the sensor body, a sapphire sensor body may also have a stress isolating structure, which is directly exposed to the process fluid.

Sapphire sensor body 310 is bonded to a pressure sensor. This technique is known as fusion bonding. The fusion bond between the pressure sensor housing and the pressure transmitter housing can be achieved at temperatures of 65-95 percent absolute temperature or higher.

The sapphire sensing cavity is 4.8 um deep and 5 mm in diameter. It was created by bonding two sapphire pieces in direct contact. The resulting sensor structure does not exhibit interference rings outside the central cylindrical cavity, which indicates tight bonding. In this study, the researchers used an adhesive-free bonding process to create the sensor.

The sensor is expected to function well at very high temperatures. It also exhibits good corrosion resistance. The sapphire material is a good candidate for optical sensors because of its high melting point and low optical loss. It is also able to resist plastic deformation at high temperatures. Therefore, it is a promising material for temperature sensors.

This sensor is fabricated from two commercially available sapphire wafers that are bonded together. The sapphire sensor contains a Fabry-Perot cavity that acts as a pressure transducer. Its monolithic design is compatible with high-temperature packaging and a variety of applications. In addition, sapphire sensors are suitable for use in extreme environments such as those found in the energy and transportation industries.

The measurement of the pressure-pressure response of sapphire sensors involves the measurement of the standard deviation of the output of a sapphire sensor under constant pressure. The calibration curve of the sensor reveals a linear response over a pressure range of 0.03 to 3.45 MPa. The sensor has a high degree of linearity and has a low hysteresis, which is below the measurement resolution. The sensor response is best described by a second-order polynomial, and the agreement between experimental results and the regression is excellent. The sensor data were then fitted with a quadratic regression curve. This calibration curve matched the measured sensor data to that of an electronic pressure gauge.

The sapphire sensing cavity is made of a vacuum-sealed sapphire wafer using inductively coupled plasma etching. The process involves a series of steps, including plasma surface activation, high-temperature annealing, and direct bonding. The tensile strength of the bonded sapphire-sapphire interface is 7.2 MPa, which is much greater than the minimum bond strength recommended for MEMS devices.

Solder compression during quartz wafer bonding is a crucial process for high-quality pressure sensors. It significantly affects the gap between substrate surfaces. In this study, the gap was measured at consistent locations across the entire wafer by using a Zygo profilometer. Using the same measurement technique on two different quartz wafers, the researchers were able to confirm that solder compression was directly related to the gap size.

The amount of solder that flows during the bonding process will depend on the seed metal pattern. If the seed metal is thin, the solder will be better able to seal the area. Sometimes, the entire seed layer can be consumed during the bonding process. This will produce a eutectic composition. During the bonding process, liquid solder is compressed and floods the fresh areas of the seed layer.

The solder melts at a specific temperature, which varies with the thickness of the seed metal. The melting point of the solder will depend on the amount of Au in the seed metal. In this device, the lower and upper wafers have micromachined devices and CAP wafers with solder rings. During bonding, the solder must wet both wafers, forming a mechanical bond and a hermetic seal.

Solder compression during quartz wafer bonding is a vital process for high-quality pressure sensors. It is a critical process and requires precision in order to achieve reliable pressure sensors. The melting temperature of the solder must be controlled to ensure the highest reliability. The eutectic temperature should be 278degC. The bonding process should be precise to ensure that the process does not lead to any significant stress.

Solder compression during quartz wafer bonding process improves the uniformity of the inter-wafer electrical connections. The process also provides good planarization capabilities. The bonding process requires excellent control of the bond gap and excellent bond strength.

In the pressure sensor industry, XPS and EELS techniques are used to characterize a quartz wafer's bonding mechanism. In XPS, the imaginary component of the scattering coefficient decreases monotonically with increasing energy. The x-rays produced by these techniques are usually derived from the energy of a synchrotron light source, which has a conversion efficiency of about 0.01 and a high energy cutoff filter of about 200 meV.

The microstructure and composition of the bonding interface were investigated using XPS and EELS techniques. XPS data revealed that an amorphous layer with an average thickness of 15 nm is formed at the interface between the two materials. The amorphous layer is made up of SiC and AlN. On the AlN side, there was a high amount of oxidation. This oxidation is considered a possible failure mechanism.

XPS and EELS have been used to understand the bonding mechanism between quartz and silicon in pressure sensors. They can also be used for material characterization. The XPS method can measure the oxygen and nitrogen atoms on the surface of the silicon substrate. EELS can also measure the surface tension of the silicon-based pressure sensors.

The alumina ceramic material is a promising material for high-temperature pressure sensors. This material can be used to fabricate sensitive cavities that can detect pressure parameters under high pressure. By using a direct bonding technique, alumina ceramic substrates are bonded together to form a sensitive cavity. The fabricated pressure sensor has a capacitance element and an inductor integrated on its ceramic substrate. It was tested using a system test platform.

A type K thermocouple was used to control the process temperature by detecting the core temperature of a reference sample. The reference sample was identical in material and geometry and was positioned in the center of the furnace. The resulting time-temperature-curve (Figure 3) is indicative of the corresponding temperature profiles. Minor deviations were noted between the target temperature profile and the actual temperature. The temperature rate during the brazing cycle was about 5 K min-1.

High-temperature brazing of the pressure sensor to the flanged alumina insert is a process that requires a high temperature. The temperature of the brazed joints must be at least 600 degrees Celsius in order to meet the mission's requirements. The joints should also be able to withstand repeated thermal cycling from -40 to 200 degrees C.

The results from high temperature brazing show a perfect blend between the Crofer and the metal-braze filler. In addition, the joint is characterized by no pores or defects. There is a reaction layer visible at the Crofer interface. This layer is between five and seven micrometers thick and is light black. Moreover, the silver alloy well bonds to the aluminum oxide surface.

High-temperature brazing of the pressure sensor to the flanged alumina insert was successfully carried out in this experiment. The temperature was raised by 5 K min-1 until the desired brazing temperature was achieved. After brazing, the brazed samples were allowed to cool down to ambient temperature.

A large international chemical firm requested a quote for the following:

Question:

About single crystal quartz for optical applications. As the substrate for optical measurement, we expect that the single crystal quartz is fully transparent between 190 nm to 25 um (from UV to IR). Maybe the z-cut quartz is suitable for our purpose. Do you have any recommendation of the products from University Wafer, Inc. of single crystal quartz?

Answer:

The single crystal quartz is transparent between 190 nm to 2500nm (from UV to IR), over 90% transmission. Please refer to the transmittance curve below. And, yes, Z-cut is normally used for optical applications.

Reference #259596 for specs/pricing. Or, buy online.

A university research professor requested the following quote:

We would like to acquire substrates that are both optically transparent and that can withstand a temperature of 1000 °C for a pyrolysis process, so we were thinking of fused silica or single crystal quartz. Also, it would be helpful if the substrate have low fluorescence too. What do you suggest? and can you send me a quote for 25 units of each substrate (fused silica, quartz, and suggestions)?

Reference 205196 for specs and pricing.

A Ph.D. In Materials Science and Engineering, requested help with the following question:

Question:

I am interested in the single crystal quartz substrates you offer and would like to inquire about their chirality. Could you confirm whether they are left-handed or right-handed quartz? Additionally, regarding the Z-cut substrates, is the cutting direction perpendicular to the C-axis? I would appreciate any clarification you can provide.

Answer:

All of our single quartz wafers are right-handed quartz if no special indicates.

Of corse, left-handed quartz is available too. Meanwhile, Yes, regarding the Z-cut substrates, the cutting direction is perpendicular to the C-axis

Reference #320291 for specs and pricing.

Chirality refers to a property of an object or a molecule that makes it non-superimposable on its mirror image. A classic example is human hands—your left and right hands are mirror images, but no matter how you rotate them, they cannot be perfectly aligned on top of each other.

In chemistry, chirality is particularly important in organic molecules. A molecule is chiral if it has a chiral center, usually a carbon atom bonded to four different substituents. The two mirror-image forms of a chiral molecule are called enantiomers.

Beyond chemistry, chirality appears in physics and materials science:

Would you like an example related to your work with carbon nanotubes or silicon-based devices?

Below are just some of the single crystal quartz substrates that we have in stock. Please let us know which specs you'd like us to quote.

| Dia | Orien | Thick | Polish | Brand/Grade | SEED |

|---|---|---|---|---|---|

| 76.2mm | ST&AT&Z | 0.15mm | DSP | SAW | withseed |

| 76.2mm | 42.75ST | 0.35mm | SSP | SAW | withseed |

| 76.2mm | X&Y&Z | 0.35mm | SSP | SAW | withseed |

| 76.2mm | 42.75ST | 0.50mm | SSP | SAW | withseed |

| 76.2mm | X&Y&Z | 0.50mm | SSP | SAW | withseed |

| 76.2mm | 42.75ST | 0.35mm | DSP | SAW | withseed |

| 76.2mm | X&Y&Z | 0.35mm | DSP | SAW | withseed |

| 76.2mm | 42.75ST | 0.50mm | DSP | SAW | withseed |

| 76.2mm | X&Y&Z | 0.50mm | DSP | SAW | withseed |

| 100mm | ST&AT&Z | 0.20mm | DSP | SAW | withseed |

| 100mm | ST-CUT | 0.35mm | SSP | SAW | withseed |

| 100mm | X&Y&Z | 0.35mm | SSP | SAW | withseed |

| 100mm | ST-CUT | 0.50mm | SSP | SAW | withseed |

| 100mm | X&Y&Z | 0.50mm | SSP | SAW | withseed |

| 100mm | ST-CUT | 0.35mm | DSP | SAW | withseed |

| 100mm | ST-CUT | 0.50mm | DSP | SAW | withseed |

| 100mm | X&Y&Z | 0.50mm | DSP | SAW | withseed |

| 25.4mm | AT&Z-CUT | 0.05mm | DSP | SAW | seedless |

| 50.8mm | AT&Z-CUT | 0.10mm | DSP | SAW | withseed |

| 76.2mm | ST&AT&Z | 0.15mm | DSP | SAW | withseed |

| 150mm | Z-Cut | 0.675mm | SSP | SAW | Seedless |

Single crystal quartz is a natural material that can be found in many different forms. It is used for a wide range of purposes including diffraction experiments, frequency control, and frequency selection. Its properties make it an excellent material to work with. Listed below are some of its most common uses. Let's discuss each of them in greater detail. - What is single-crystal quartz? — And what are its properties?

- It is used for optical components. It is a perfect DUV component, and is often used in UV systems. It can also be used for THz diapason. The characteristic transmission curves of single crystal quartz are shown in Figures 1 and 2. They are made from a sample with a thickness of 8.6 mm and a pressure of 1000 atm. - What is single-crystal quartz?

- What is polycrystalline quartz? The answer is two-fold. First, single-crystal quartz is a polycrystalline material, which means that it can grow as a monocrystalline material. Secondly, monocrystalline quartz is a monocrystalline material. This means that it has a symmetry in the X-axis. Third, it can be grown in an autoclave at temperatures of 340degC and 1000 atm.

- What is single-crystal quartz? This substance is used to make sensors, resonators, and other complex objects. It is not easy to process because it is a soft material. Luckily, several new technologies have made the process easier. One of them is quartz-on-silicon technology, which involves bonding silicon and quartz. After bonding, the quartz is then thinned and polished. Then, a thin quartz wafer can be fabricated on the silicon substrate.

The most common way to grow single-crystal quartz is to grow it in an autoclave. This type of material is used to make optical filters, windows, and prisms. Manufacturer cultured quartz crystals are right-handed. The X-axis has three axes: Y-axis, Z-axis, and X-axis. Moreover, it is very difficult to cut a piece of single-crystal quartz.

The most common use of single-crystal quartz is in the manufacturing of microwave filters. Hence, it is a good substrate for such technologies. The price of single-crystal quartz is very low, which is a significant advantage. It can also be used in high-end instruments. Aside from optical devices, single-crystal quartz can also be used in medical equipment. These applications include the semiconductor industry.

The X-ray directional instrument is used to identify quartz crystals. The angle of quartz crystals should be oriented according to the needs of the manufacturing. If the quartz crystals are symmetrical, the two axes should match up. Then, the material should be free from defects. Finally, single-crystal quartz has excellent mechanical and electrical properties. So, the material is a valuable source for the development of electronics and medical devices.

It is used in many electronic applications. It is also used in medical devices. Its electrical properties make it a very important material for electronic equipment. It is free of electrical and optical twinning. When compared to other materials, quartz has excellent optical and mechanical properties. This makes it a very valuable material for medical devices. In fact, it is a very valuable material for semiconductors. The use of single crystal quartz in many different industries is expanding.

It is also used in microwave filters. It is a great substrate for microwave filters. It is also used in research and production. And what is single crystal quartz? If it's single-crystal quartz is a good material for your application, then it's worth the money. Its price is lower than other quartz, which is a good thing. If you're unsure about the quality of a material, you can contact the manufacturer and ask for a sample.

The IEC-G grade is the highest quality of single crystal quartz. It is the highest quality of quartz and it has the lowest amount of inclusions. It has been used in high-tech applications for many years. It is an excellent material for medical applications. It is also used in jewelry. It is a very versatile material for electronics. Moreover, it is a natural material for electronics. It is a great choice for jewelry, as it can be easily shaped.

Watch https://www.youtube.com/embed/NfbbrZcUMCM

To create a single crystal quartz device, a special seed must be used. Different cut types result in the seeds being at different locations. Some cut types are BT, Z, and AT. These cuts will vary in the crystal's surface flatness. This is important for various applications, such as frequency control or optical transmittance. The polishing designations are used for improving the transmission properties of the quartz and reducing its electronic resistance.

One way to obtain a quartz single crystal is to cut a large piece of quartz in the direction that the  user needs it to have a certain electrical field. The crystal will then grow on this seed crystal. Once the crystal is cut, it will retain its mechanical and electrical characteristics. This is what makes single crystal quartz so important. Its properties make it a valuable material for electronics. It is also widely used in medical devices.

user needs it to have a certain electrical field. The crystal will then grow on this seed crystal. Once the crystal is cut, it will retain its mechanical and electrical characteristics. This is what makes single crystal quartz so important. Its properties make it a valuable material for electronics. It is also widely used in medical devices.

The quartz is cut into thin slices. The resulting quartz wafer is then cleaned and polished. The thickness of the wafer can affect the resistance to vibration. The process of deep etching is more effective because it removes the loose surface layer. The process is repeated until the desired shape and size is obtained. The crystal is then examined for electrical twinning. Afterward, it is examined for optical twinning.

The process begins with the cutting of the sample bar. After this, the quartz wafer is etched in ammonium biflouride. This removes the etching channels and marks the pure-Z region of the slice. The number of etch channels in each grid area is determined by microscopic visual examination. This data is then converted into density and units. Manufacturer cultured quartz crystals do not contain electrical twinning. To detect optical twinning, a bright incandescent light is used to illuminate the quartz.

After the samples are etched, the manufacturer cultures the crystals. The process produces high-quality quartz, which is free of electrical twinning. It also has a high refractive index, which makes it an excellent material for solar cells and computer chips. After twinning, the manufacturer cultured quartz will be transparent to electrical current and light. This crystal is usually more expensive than other quartz, but it is worth the money.

When the single crystal quartz is ready to be used, it will be tested to ensure that it does not have any electrical twinning. In this way, researchers can confirm the quality of the material and identify the inclusions that have been present. In some cases, the quartz is also tested for its ability to produce radioactive twinning. However, in some instances, the production of single crystal quartz is very expensive. The process will take years to complete, but the results will be high-quality.

When the single crystal quartz is ready, the manufacturer will etch it. In this process, the crystal is etched in ammonium biflouride to determine its electrical properties. Then, the etched slice is analyzed by microscope to find electrical and optical twinning. This is an important step in manufacturing a single crystal quartz. The process will take between six to eight weeks and cost several thousands of dollars.

After the quartz wafer is cut, it is cleaned and polished to ensure its perfect shape. The thickness of the quartz crystal has an impact on the frequency and resistance of the crystal. Therefore, the thickness of the quartz wafer is important for the quality of the single-crystal quartz. A quartz that is thicker will have better diffraction properties, but it will not have as high of a resistance as a thin wafer.

After the quartz wafer has been cut, it is cleaned and polished. The thicker the crystal, the more it will be resistant to vibrations. The thin-crystal quartz will have more resistance. In addition, thin-crystal quartz will not have optical or electrical twinning, but it will still produce a single crystal with high optical and mechanical properties. There are several different methods to produce single crystal quartz.

Watch https://www.youtube.com/embed/lzHqhNoyx2o

All single crystal quartz should be grown from one special seed.

And the different cut type will cause the different seed location.

One type is inside the wafer names "with seed", the other type is not inside the wafers, so names "seedless".

Orientation

1.AT & BT & SC etc such orientations are for many frequency control application which will be used for many electronic and space application, such as mobile phone and satellite etc 2.Z cut is for some optical application, such as some windows and lens etc. meanwhile, general speaking, the polishing designations are for reducing the electronic resistance or enlarging the optical transmittance.

Seeded and Seedless Quartz Single quartz crystal is grown from one special seed and then is divided into three zones, x/y & z zones.

Seedless means the wafers are in the pure x /y or z zone.

| Item | Dia | Ori | Thk | Pol | Specs |

|---|---|---|---|---|---|

| 1153 | 50.8mm | Z-Cut | 100 μm | DSP | Thin |

| 566 | 76.2mm | ST-Cut | 350 μm | SSP | Ang:42°45' Seeded (WITH-SEED) |

| 547 | 100mm | ST-Cut | 350 μm | SSP | Seeded Angle 42°45'±15', With-Seed. ST cut. |

| 2298 | 100mm | Z-Cut | 500 μm | DSP | Z-Cut Seedless Wafer |

We have the following large diameter quartz crystal wafers available. All the wafers below have one primary SEMI-Std flat.

Our R&D is active at developing and researching from big material to process 8” quartz wafer or more.

| Dia | Ori | Thickness | Pol | Brand/Grade | SEED | TTV | Top side Ra | Backside Ra | S/D |

|---|---|---|---|---|---|---|---|---|---|

| 150 ± 0.3mm | ST-Cut | 500 ± 20 um | DSP | SAW | withseed | <10 um | <1.2 nm | <1.2 nm | 60/40 |

| 150 ± 0.3mm | AT-Cut | 500 ± 20 um | DSP | SAW | withseed | <10 um | <1.2 nm | <1.2 nm | 60/40 |

| 150 ± 0.3mm | Z-CUT | 500 ± 20 um | DSP | SAW | seedless | <10 um | <1 nm | <1 nm | 60/40 |

| 150 ± 0.3mm | 42.75 ST-cut | 500 ± 20 um | SSP | SAW | withseed | <10 um | <1 nm | GC#1000 | 60/40 |

| Material | Quartz Crystal | |||

|---|---|---|---|---|

| Cutting Angle | X/Y/Z/AT32, 33, 36/BT/ST42.75°-cut etc | |||

| Diameter/size | 3" (76.2mm) | 4" (100mm) | 6" (150mm) | 8" (200mm) |

| Tol (±) | <0.20 mm | |||

| Thinnest Thickness | 0.08mm Min | 0.10mm Min | 0.20mm Min | 0.35mm or more |

| Primary Flat | 22mm | 32mm | 42.5mm | 57.5mm |

| LTV (5mm×5mm) | <1 μm | |||

| TTV | <3 μm | |||

| Bow | -30 <bow< 30 | |||

| Warp | <40 μm | |||

| PLTV (<0.5μm) | ≥95% (5mm×5mm) | |||

| Orientation Flat | All available | |||

| Surface Type | Single Side Polished / Double Side Polished | |||

| Polished side Ra | <0.5 nm | |||

| Back Side Criteria | General is 0.2–0.5 μm or as customized | |||

| Edge Criteria | R=0.2mm or Bullnose | |||

| Material Property | ECD | Better than grade 4 | ||

| Inclusion | Better than grade II | |||

| Q-Value | Better than grade C | |||

| Wafer Surface Criteria | Particles Ø>0.3 μm | ≤ 30 | ||

| Scratch, Chipping | None | |||

| Defect | No edge cracks, scratches, saw marks, stains | |||

| Packaging | Qty/Wafer box | 25 pcs per box | ||

| Cut | Frequency range | Mode | Angles |

|---|---|---|---|

| AT | 0.5–300 MHz | thickness shear (c-mode, slow quasi-shear) | 35°15', 0° (<25 MHz) |

| 35°18', 0° (>10 MHz) | |||

|

The most common cut, developed in 1934. The plate contains the crystal's x axis and is inclined by 35°15' from the z (optic) axis. The frequency-temperature curve is a sine-shaped curve with inflection point at around 25–35°C. Has frequency constant 1.661 MHz⋅mm. Most (estimated over 90%) of all crystals are this variant. Used for oscillators operating in wider temperature range, for range of 0.5 to 200 MHz; also used in oven-controlled oscillators. Sensitive to mechanical stresses, whether caused by external forces or by temperature gradients. Thickness-shear crystals typically operate in fundamental mode at 1–30 MHz, 3rd overtone at 30–90 MHz, and 5th overtone at 90–150 MHz; according to other sources, they can be made for fundamental mode operation up to 300 MHz, though that mode is usually used only to 100 MHz and the upper limit for fundamental frequency of the AT cut is limited to 40 MHz for small diameter blanks. Can be manufactured either as a conventional round disk, or as a strip resonator; the latter allows much smaller size. The thickness of the quartz blank is about (1.661 mm)/(frequency in MHz), with the frequency somewhat shifted by further processing. The third overtone is about 3 times the fundamental frequency; the overtones are higher than the equivalent multiple of the fundamental frequency by about 25 kHz per overtone. Crystals designed for operating in overtone modes have to be specially processed for plane parallelism and surface finish for the best performance at a given overtone frequency. |

|||

| SC | 0.5–200 MHz | thickness shear | 35°15', 21°54' |

| A special cut (Stress Compensated) developed in 1974, is a double-rotated cut (35°15' and 21°54') for oven-stabilized oscillators with low phase noise and good aging characteristics. Less sensitive to mechanical stresses. Has faster warm-up speed, higher Q, better close-in phase noise, less sensitivity to spatial orientation against the vector of gravity, and less sensitivity to vibrations. Its frequency constant is 1.797 MHz⋅mm. Coupled modes are worse than the AT cut, resistance tends to be higher; much more care is required to convert between overtones. Operates at the same frequencies as the AT cut. The frequency-temperature curve is a third order downward parabola with inflection point at 95°C and much lower temperature sensitivity than the AT cut. Suitable for OCXOs in e.g. space and GPS systems. Less available than AT cut, more difficult to manufacture; the improvement of parameters is traded for an order of magnitude tighter crystal orientation tolerances. Aging characteristics are 2 to 3 times better than of the AT cuts. Less sensitive to drive levels. Far fewer activity dips. Less sensitive to plate geometry. Requires an oven, does not operate well at ambient temperatures as the frequency rapidly falls off at lower temperatures. Has several times lower motional capacitance than the corresponding AT cut, reducing the possibility to adjust the crystal frequency by attached capacitor; this restricts usage in conventional TCXO and VCXO devices, and other applications where the frequency of the crystal has to be adjustable. The temperature coefficients for the fundamental frequency is different than for its third overtone; when the crystal is driven to operate on both frequencies simultaneously, the resulting beat frequency can be used for temperature sensing in e.g. microcomputer-compensated crystal oscillators. Sensitive to electric fields. Sensitive to air damping, to obtain optimum Q it has to be packaged in vacuum. Temperature coefficient for b-mode is −25 ppm/°C, for dual mode 80 to over 100 ppm/°C. | |||

| BT | 0.5–200 MHz | thickness shear (b-mode, fast quasi-shear) | −49°8', 0° |

| A special cut, similar to AT cut, except the plate is cut at 49° from the z axis. Operates in thickness shear mode, in b-mode (fast quasi-shear). Has frequency constant 2.536 MHz⋅mm. Has poorer temperature characteristics than the AT cut. Due to the higher frequency constant, can be used for crystals with higher frequencies than the AT cut, up to over 50 MHz. | |||

| IT | thickness shear | ||

| A special cut, is a double-rotated cut with improved characteristics for oven-stabilized oscillators. Operates in thickness shear mode. The frequency-temperature curve is a third order downward parabola with inflection point at 78°C. Rarely used. Has similar performance and properties to the SC cut, more suitable for higher temperatures. | |||

| FC | thickness shear | ||

| A special cut, a double-rotated cut with improved characteristics for oven-stabilized oscillators. Operates in thickness shear mode. The frequency-temperature curve is a third order downward parabola with inflection point at 52°C. Rarely used. Employed in oven-controlled oscillators; the oven can be set to lower temperature than for the AT/IT/SC cuts, to the beginning of the flat part of the temperature-frequency curve (which is also broader than of the other cuts); when the ambient temperature reaches this region, the oven switches off and the crystal operates at the ambient temperature, while maintaining reasonable accuracy. This cut therefore combines the power saving feature of allowing relatively low oven temperature with reasonable stability at higher ambient temperatures. | |||

| AK | thickness shear | ||

| A double rotated cut with better temperature-frequency characteristics than AT and BT cuts and with higher tolerance to crystallographic orientation than the AT, BT, and SC cuts (by factor 50 against a standard AT cut, according to calculations). Operates in thickness-shear mode. | |||

| CT | 300–900 kHz | face shear | 38°, 0° |

| The frequency-temperature curve is a downward parabola. | |||

| DT | 75–800 kHz | face shear | −52°, 0° |

| Similar to CT cut. The frequency-temperature curve is a downward parabola. The temperature coefficient is lower than the CT cut; where the frequency range permits, DT is preferred over CT. | |||

| SL | face-shear | −57°, 0° | |

| GT | 0.1–3 MHz | width-extensional | 51°7' |

| Its temperature coefficient between −25..+75°C is near-zero, due to cancelling effect between two modes. | |||

| E, 5°X | 50–250 kHz | longitudal | |

| Has reasonably low temperature coefficient, widely used for low-frequency crystal filters. | |||

| MT | 40–200 kHz | longitudal | |

| ET | 66°30' | ||

| FT | −57° | ||

| NT | 8–130 kHz | length-width flexure (bending) | |

| XY, tuning fork | 3–85 kHz | length-width flexure | |

| The dominant low-frequency crystal, as it is smaller than other low-frequency cuts, less expensive, has low impedance and low Co/C1 ratio. The chief application is the 32.768 kHz RTC crystal. Its second overtone is about six times the fundamental frequency. | |||

| H | 8–130 kHz | length-width flexure | |

| Used extensively for wideband filters. The temperature coefficient is linear. | |||

| J | 1–12 kHz | length-thickness flexure | |

| J cut is made of two quartz plates bonded together, selected to produce out of phase motion for a given electrical field. | |||

| RT | |||

| A double rotated cut. | |||

| SBTC | |||

| A double rotated cut. | |||

| TS | |||

| A double rotated cut. | |||

| X 30° | |||

| A double rotated cut. | |||

| LC | thickness shear | 11.17°/9.39° | |

| A double rotated cut ("Linear Coefficient") with a linear temperature-frequency response; can be used as a sensor in crystal thermometers. Temperature coefficient is 35.4 ppm/°C. | |||

| AC | 31° | ||

| Temperature-sensitive, can be used as a sensor. Single mode with steep frequency-temperature characteristics. Temperature coefficient is 20 ppm/°C. | |||

| BC | −60° | ||

| Temperature-sensitive. | |||

| NLSC | |||

| Temperature-sensitive. Temperature coefficient is about 14 ppm/°C. | |||

| Y | |||

| Temperature-sensitive, can be used as a sensor. Single mode with steep frequency-temperature characteristics. The plane of the plate is perpendicular to the Y axis of the crystal. Also called parallel or 30-degree. Temperature coefficient is about 90 ppm/°C. | |||

| X | |||

| Used in one of the first crystal oscillators in 1921 by W.G. Cady, and as a 50 kHz oscillator in the first crystal clock by Horton and Marrison in 1927. The plane of the plate is perpendicular to the X axis of the crystal. Also called perpendicular, normal, Curie, zero-angle, or ultrasonic. | |||

A research scientist asked the following:

UniversityWafer, Inc Quoted:

I quoted price as below with Gold 6M QCM crystal. If you need another spec please feel free to let me know.

| Client | Freq | Contour | Diameter | Type |

|---|---|---|---|---|

| U01 | 5M | Plano-Convex | 13.97mm | Gold |

| 6M |

QCM is an acoustical transducer that converts mass changes on the surface of an oscillating quartz crystal resonator into an electronic signal. It has been widely used in such areas as vapor deposition of metals, and over the last decade it has become more widely used in biosensor applications.

| Basic Materials Characteristics | Value |

|---|---|

| Density, g/cm³ | 2.65 |

| Melting point, °C | 1467 |

| Thermal Conductivity, W/(m·K) (T=25°C) | 10.7 (parallel to axis Z), 6.2 (perpendicular to axis Z) |

| Hardness (Mohs) | 7 |

| Dielectric constant at 30 MHz | 4.34 (parallel to axis Z), 4.27 (perpendicular to axis Z) |

| Young's modulus E, GPa | 97.2 (parallel to axis Z), 76.5 (perpendicular to axis Z) |

| Chemical Stability | Insoluble in water |

Product specification List: Bevel plano-plano/Plano-convex/Bi-convex

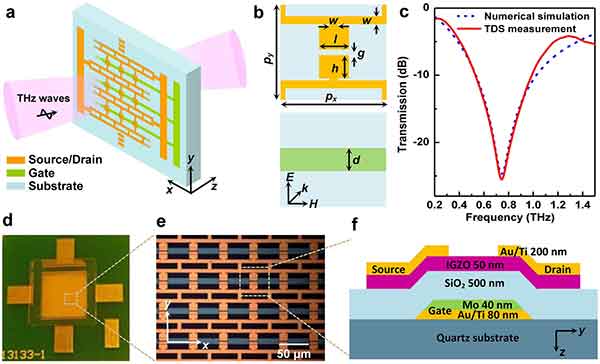

The use of quartz windows for Terahertz (THz) measurements is becoming more common in the field of radio astronomy. THz is a high-frequency electromagnetic radiation and therefore, the polarization of light within it is of primary importance. There are several reasons for this, but the basic reason is that water is highly attenuating to THz. For this reason, it is essential to use windows made of z-cut crystal quartz.

The use of quartz windows for Terahertz (THz) measurements is becoming more common in the field of radio astronomy. THz is a high-frequency electromagnetic radiation and therefore, the polarization of light within it is of primary importance. There are several reasons for this, but the basic reason is that water is highly attenuating to THz. For this reason, it is essential to use windows made of z-cut crystal quartz.

TPX is a hard, solid material that is mechanically shaped into optical components. It suppresses the pump radiation from terahertz sources. Because of its high sensitivity, it is used in cryostats. It is also not affected by temperature, and its refractive index is only 3.0*10-4 K-1 for temperatures between 8 and 120 K. It also shows excellent optical properties in vacuum and is commercially available.

The use of quartz windows for Terahertz measurements is a crucial step in the development of a tunable terahertz detector. This new technology requires a crystal with a high complex refractive index, a special feature that allows Terahertz experiments to be performed on it. The first steps to constructing the windows for Terahertz measurements were performed by S. Dhillon, E. H. Linfield, and Matthias C. Hoffmann, who presented the technology in a technical paper published in Nature Communications.

To create a terahertz detector, researchers must first determine which wavelength of light to use for the experiment. The first method, called Fourier spectroscopy, uses a quartz window that has a high refractive index. The other method is to produce a z-cut quartz window, which aligns the optic axis of the crystal with a flat surface. The z-cut technique enables the ordinary and extraordinary rays to follow the same path through the crystal.

The optical properties of quartz are characterized by their transparency and resistance to high-frequency light. This material has a high-temperature coefficient of refraction of just 0.015. The complex refractive index of quartz is used to measure a wide range of frequencies. The TPX-cutted glass provides a better transverse-to-vertical mirror. Infrared waveplates have a narrow lateral symmetry, and their thickness is sufficient for accurate terahertz measurement.

The transmission characteristics of TPX-cut quartz windows are similar to those of the corresponding optical components. The TPX-cut quartz window is ideal for terahertz measurements. The corresponding IR-cut glass window is also a good choice. The TPX-cut glass is used for terahertz research. It is often more expensive than the other window material, and it has a higher cost.

TPX-cut glass windows are a perfect solution for cryostats. Unlike glass windows, TPX-cut windows can be mechanically shaped to minimize interference from external sources. Moreover, the TX-cut glass can be fabricated with a SU-8 photoresist. Infrared glasses are used to avoid refract light. The thickness of the glasses is 1mm.

TPX-cut quartz windows are an excellent substitute for Picarin lenses. Moreover, TPX-cut windows are inexpensive and commercially available. ZEONEX-cut quartz is a great alternative for a wide range of terahertz measurement applications. The cyclo olefin polymer exhibits excellent mechanical properties, chemical stability, and low outgassing in ultrahigh vacuum. The thickness of these glasses is less than a mm.

Infrared-cut quartz is also a good choice for terahertz measurements. Unlike quartz, TPX is not affected by temperature, making it possible to make it a versatile window. This material is especially well suited for a wide range of applications. Further, compared to quartz windows, TPX-cut quartz does not need any special maintenance. In fact, it requires minimal maintenance.

Single-crystal a-quartz wafers are an excellent choice for terahertz measurements. The glass's thickness is critical. The thinner the quartz window, the better. In addition, the a-quartz window should be a thicker material than standard quartz. The thinness of a-quartz windows is critical for terahertz measurement. This material is much more expensive than quartz.

Watch https://www.youtube.com/embed/osNXI61c_dA

What is quartz substrate? It is a substance that is both rigid and transparent. It is also used as a semiconductor material. The melting point of this substance is high, and it is widely used in electronics and lasers. It is used in the production of fused quartz, which is an excellent resonator material. It is also used in glass instruments, including historical glass harmonicas, wine glasses, and verrophones.

Fused quartz is a type of crystal that can be metallised and etched. It is widely used as a microwave circuit substrate. Its high temperature stability makes it an excellent choice for demanding applications such as ultra-high-end semiconductors. It is also extremely durable and is useful in laboratory equipment and narrowband filters. Its low dielectric constant makes it a great choice for telecommunications applications. It is also used in the production of high-temperature furnace crucibles.

Fused quartz is often used as a semiconductor substrate. Its properties make it a suitable material for many applications. It is ideal for telescope mirrors, as it behaves in a predictable manner and allows for a smooth polishing. In optics, it has been used to make individual uncoated lens elements for special-purpose lenses, including the Zeiss 105mm f/4.3 UV Sonnar, which was formerly used in Hasselblad cameras, and the Nikon PF10545MF-UV.

Another application for fused quartz is in the microwave industry, where it can be metallised and etched. The material is also suitable for optical circuits, with good thermal stability and low water content. Because it is a semiconductor substrate, it can be shaped and patterned in a variety of ways. For example, the optical characteristics of these materials are very similar. They can be etched, fabricated, or etched to a very high degree, making it an ideal choice for use in the semiconductor manufacturing industry.

The properties of quartz are unique and versatile. It is the perfect choice for optical components, such as lasers. Its high translucency makes it ideal for a variety of applications, from ultra-high-speed fibers to medical imaging. In addition to optics, it is also useful for semiconductors, lasers, and infrared sensors. Its low thermal expansion makes it the ideal choice for many different applications.

Other applications include high-precision microwave circuits. In addition to this, it also has good thermal stability. It is an excellent substrate for high-precision optical components. It is a valuable starting material for optical fiber, which is used in telecommunication. You can find these materials in your kitchen, or at your local laboratory. Aside from these uses, they're also used in optical devices. If you need to produce a crystal, then quartz is the right choice for you.

It is the best choice for optical components. This material is perfect for use in telecommunications and is a popular choice in lasers. It is also used in radio astronomy. As a result, it has a high-transmission range. But this is not the only benefit of quartz. The material's amorphous structure means that it is highly prone to thermal shock. As a result, it is a popular choice for telecommunications.

Quartz is an excellent choice for high-precision optical devices. The material is resistant to heat and is a good choice for a variety of applications. It is also used in optical components. Some types of quartz are used in lenses to make lenses more accurate. These lenses are often made of fused quartz. Unlike many other materials, quartz is very light-sensitive, and they are useful in lasers. It also helps in the fabrication of crystalline products.

Quartz glass is a substance of silicon and oxygen. It has a low-refractive index and high-transmittance. Its optical properties are similar to those of other materials and it can also be used for high-temperature furnace crucibles. In addition, quartz is a great choice for semiconductors, which is why it's so popular in the semiconductor industry. Its low thermal expansion makes it one of the best materials for telecommunications.

A research client requested the following quote:

Hi, do you have the a-quartz substrate with left handedness? I found you can provide the right-handed quartz. But, I also need the left-handed. Thank you!

UniversityWafer, Inc. Quoted the following. Reference #267571 for pricing.

| Dia | Ori | Thick | Pol | Quartz Crystal | Brand/Grade | SEED |

|---|---|---|---|---|---|---|

| 12×12mm | X-Cut | 0.5 ± 0.03mm | DSP | left-handed | SAW | seedless |

| 5×5mm | X-Cut | 0.5 ± 0.03mm | DSP | left-handed | SAW | seedless |

| 12×12mm | X-Cut | 0.5 ± 0.03mm | DSP | right-handed | SAW | seedless |

| 5×5mm | X-Cut | 0.5 ± 0.03mm | DSP | right-handed | SAW | seedless |

The axes/indices of individual minerals determine the handedness of a form. Although crystals are not symmetrical in structure, handedness is a characteristic that can be observed on specific crystal faces. Figure 5 depicts a left-handed quartz crystal. This form exhibits a similar frequency to a right-handed quartz crystal. The faces can be either s or m-shaped. Right-handed quartz has x-faces, while s-faces are orange and blue.

Another way to determine whether a crystal is right or left-handed is to look at the x or z-faces. These faces are often paired together to create a more beautiful shape. While it is possible to find right-handed quartz crystals in nature, you should not expect them to be right-handed. The left-handed quartz face is more common than the right-handed one. However, it is rare to find a crystal that has both s and x-faces.

Another way to determine which quartz crystals are right-handed is to observe the optical rotation of each crystal. Left-handed quartz contains a levorotatory l-shaped crystal, whereas right-handed quartz has a symmetrical d-shaped crystal. Regardless of the symmetry of these quartz crystals, their appearances can be determined by their morphology. And if you are looking for the perfect gift for a loved one, you can get right-handed quartz in just a few clicks.

As crystals grow, they lock in the enantiomorphic properties of their unit cells. While the enantiomorphic xtals have a left-handed and right-handed counterpart, this is not the case with quartz. Therefore, you can't tell if a crystal is left-handed or right-handed by looking at its symmetry. However, it may be the case if the xtals have an unconstrained spiral axis.

The symmetry of a crystal is a critical factor for its stability. Quartz crystals have the same angles on all faces and are therefore equally stable. Hence, it is essential to specify the face specification correctly in order to get the right-handed form. If you don't specify the right-handed crystal specification, the symmetry operators won't be able to generate it. It is possible to produce a crystal with two faces but not both, but you must know which one you want to get.

What is Synthetic Quartz?

There are two types of synthetic quartz crystals: right-handed and left-handed. While both types of quartz are found in nature, the majority of them are optically right-handed. The handedness of a crystal is determined by the seed crystal used to grow it. However, there are some companies that specialize in left-handed quartz. Here are some tips for determining the hand of your synthetic quartz. Listed below are several benefits of buying right-handed crystals.

The first reason why synthetic quartz is right-handed is that the unit cell of the crystal is spiral-shaped, so it is impossible for the other shard to be formed without the opposite-handed symmetry plane. The spiral feature of quartz crystals explains why right-handedness occurs in synthetic quartz, while opposite-handedness is not common. The presence of the right-hand face identifies it as a particular xtal, and this attribute prevents the other hand from forming.

The second distinguishing characteristic of right-hand synthetic quartz is its low birefringence. Quartz is not a highly reflective material, and it also has strong optical activity. The outer ring of color is characterized by isochromes and follows the Newton's Rings. Because of this, synthetic quartz is often used to make bracelets. By observing the shape of a crystal, you can determine its quality. This is very helpful when choosing the right crystal for your needs.

Natural quartz is a better choice for faceting than synthetic quartz. Natural quartz is softer and less likely to have bubble lines, while lab-grown quartz has a standard flaw - bubble lines. The differences between natural quartz and synthetic quartz are not significant, however, because the right-hand version is more desirable for faceting. Regardless of how you decide to grow your crystals, make sure you choose a material with high purity.

To determine whether your crystal has the correct face structure, look at its face configuration. Then, identify whether it has a positive or negative symmetry. Both symmetry faces of synthetic quartz are identical. A positive symmetry axis is an equilateral triangle. If you have a

When light passes through a stone, it has some unusual physical properties. For example, when light passes through a stone that is left-handed, its polarization plane rotates differently than a right-handed one. This odd behavior is caused by the crystalline nature of the stone. Different minerals have different degrees of anisotropy, and quartz exhibits a number of different types of anisotropy.

In terms of crystal structure, there are two types of quartz: left-handed and right-handed. They are both nearly pure SiO2 and can accommodate cations. However, some quartzes are colored because of impurities linked to cations. Examples of these colored quartzes include Dauphine and Brazil twins, which can be distinguished from one another by their c-axis orientations.

The crystallographic structure of quartz has a trigonal trapezohedron, which indicates the handedness of the crystal. Positive trapezohedra are present on some quartz crystals but are not present on all. These trigonal tetrahedra are found in the trigonal bipyramid. This makes it easy to distinguish between a left-handed and right-handed quartz crystal.

Other physical properties of left-handed quartz include a tendency to wear or crack under stress. The crystal structure of the stone is made up of tetrahedrons of silicon and oxygen, which can be damaged under mechanical stress. Moreover, the central silicon atom carries two positive and one negative charge. This means that if a left-handed quartz crystal breaks, it will likely be broken in a few days.

The X-ray reflection of left-handed quartz can be detected by using a technique called multi-wave spectroscopy. This method is used to identify a particular quartz sample by its multiple-wave peaks. The intensity of the reflection varies according to the crystal form, and circularly polarized x-rays are required to determine the differences. The right-handed sample is more likely to exhibit the strongest peaks.

In a laboratory experiment, two quartz crystals were examined for their 001 polarization. These crystals were cut perpendicular to the screw axis and had one-cm2 areas. All crystals had been optically pre-tested and had known absolute structures. The 001 reflection intensity for both the left-handed and right-handed quartz samples was compared to the results from the calculations.

The twinning is a result of the interpenetrant nature of quartz. The two types of quartz crystals fit together perfectly. The right-handed portion is connected to the left-handed one by its principal axis. A fourth type of twinning is a phenomenon that occurs across a plane passing through a pyramid's edge. The faces on either side of the edge make equal angles. This produces a curious effect: two quartz crystals joined at right angles. These crystals have been found in Japan and France.

A new technique called electron crystallography can be used to determine the chirality of a crystal. It is more sensitive than optical methods, and the data obtained can be used to refine the definition of a left handed crystal. In addition, x-ray technique can be used to determine a crystal's chirality. This technique is preferred by many physicists as it is applicable to non-transparent materials such as quartz.

When light passes through a stone, it has some unusual physical properties. For example, when light passes through a stone that is left-handed, its polarization plane rotates differently than a right-handed one. This odd behavior is caused by the crystalline nature of the stone. Different minerals have different degrees of anisotropy, and quartz exhibits a number of different types of anisotropy.

In terms of crystal structure, there are two types of quartz: left-handed and right-handed. They are both nearly pure SiO2 and can accommodate cations. However, some quartzes are colored because of impurities linked to cations. Examples of these colored quartzes include Dauphine and Brazil twins, which can be distinguished from one another by their c-axis orientations.

The crystallographic structure of quartz has a trigonal trapezohedron, which indicates the handedness of the crystal. Positive trapezohedra are present on some quartz crystals but are not present on all. These trigonal tetrahedra are found in the trigonal bipyramid. This makes it easy to distinguish between a left-handed and right-handed quartz crystal.

Other physical properties of left-handed quartz include a tendency to wear or crack under stress. The crystal structure of the stone is made up of tetrahedrons of silicon and oxygen, which can be damaged under mechanical stress. Moreover, the central silicon atom carries two positive and one negative charge. This means that if a left-handed quartz crystal breaks, it will likely be broken in a few days.

A young graduate student asked the the meaning of quartz saw grade with the following specs Quartz z cut 4inch wafer one box?

UniversityWafer, Inc. Quoted

| RFQ# | Quote No. | Diameter | Orientation | Thickness | Surface Finish | Material | Brand/Grade | SEED | Top side Ra | Backside Ra |

|---|---|---|---|---|---|---|---|---|---|---|

| 269701 | U01-220922-2 | 100 ± 0.2mm | Z-CUT | 0.50 ± 0.03mm | DSP | Quartz Crystal | SAW | seedless | <1nm | <1nm |

SAW grade means Surface Acustic Wave grade, just is electric grade.