I am a PhD student working in one of the research

groups of Electrical

Engineering department. I am looking for

4'' (100mm) quartz wafers

(dielectric constant < 4,

resistivity > 10^17 Ohm*m) with

thickness of ~0.5 mm Could you

please provide a quote for 25

wafers order from an academic

research group? How quickly can you ship it?

Z-Cut Quartz Single Crystal for Research & Production

Z-Cut Quartz to Fabricate MEMS

A PhD student requested the following quote:

Reference #220663 for specs and pricing.

Z-Cut Single Crystal Quartz Wafers

We have a large selection of in stock quartz single and double side polished. We can also custom make your specs. Below are some recent z-cut quartz windows we've manufactured.

- 50.8mm Z-cut Quartz 0.05mm DSP SAW Grade Seedless

- 5mm x 5mm +/-0.5mm Z-cut Quartz 0.05mm DSP SAW Grade Seedless

- 50.8+/-0.2mm Z-cut 0.15mm DSP Quartz Crystal SAW seedless Roughness <1nm

Get Your Quote FAST! Or, Buy Online and Start Researching Today!

Z-Cut Quartz for Optical Applications

A PhD Candidate of Electrical Engineering Department requested the following quote:

We are looking for crystal quartz wafers with a z-cut and 100 mm diameter for optical applications.

We want to process these wafers in an ASML stepper tool that is very sensitive to dimension of the wafer; with a diameter of 100 +- 0.5 mm and primary flat length of 32.5 +- 2.5 mm (Image attached). So, our question is whether your wafers are cut to the SEMI M1.5 specifications?

We previously bought silicon and oxide wafer from you and the specs were great and worked for ASML steppers. If the cut for the quartz wafer are the same as your silicon wafers, would you please send me a quotation for 10 wafers.

Reference #225553 for specs and pricing.

Z-Cut Single Crystal SiO2 (quartz)

Size: 25.4mm, 50.8mm, 76.2mm, 100mm diameter x 0.5 mm thickness

Orientation: Z-cut

Polish: one side polished

Surface roughness: < 5 A ( by AFM)

Packing: in 1000 class clean room by wafer carrier

Some uses for Single crystal quartz wafers include microwave filters for wireless communication.

How to Bond Thin Z-Cut Quartz to Silicon Substrate

A Post-Doctoral Scholar requested a quote for the following:

I wanted a 50 um thick quartz wafer 2 inch in diameter, z cut and dual side polished temporarily wafer bonded to a 2 inch silicon carrier wafer. The silicon carrier wafer can be thick 270 - 350 um thick. Do you sell this? If so, could you please give me a quote for qty: 10?

It needs to be clean and flat like any other standard wafers that you sell. I plan to do photolithography on it. The quartz should be fully transparent. But no other special specs than the ones that I have already mentioned. Can you give me an approximate price now?

UniversityWafer, Inc. Quoted:

We can supply the 2" quartz wafer with 50um thickness, the surface finish is DSP.

Reference #273118 for specs and pricing.

Z-Cut Quartz for RF Circuit Patterns

A Radio Frequency Engineer requested the following quote:

Reference #274174 for specs and pricing.

What Z-Cut Single Crystal Quartz to Fabricate Quartz Resonator?

A researcher requested the following based on a previous order.

I recently placed an order with University Wafer for item 2298 (100mm Z-cut quartz, 500 um). Is it safe for me to assume that the flat is aligned with the x-axis of the quartz? Second, please tell me if this is a possibility for you, and if so, a very rough estimate of cost and lead time (if possible). 3 or 4-inch wafer, Z-cut quartz (with flat aligned to X-axis within 0.25-degrees), 75 um thick, DSP. Volume would likely only be ~10 wafers.

Reference #273856 for specs and pricing.

What is Z-Cut Quartz?

A scientist asked me recently what is Z cut quartz. He was trying to use quartz wafers in research. He wanted to know the orientation of the off-cut crystal. The most common cuts are Y and X. The angle at which the crystal is cut affects the orientation of the crystal. It is important to know the differences between the two. We'll explore some examples below. This is the most common cut of quartz.

The X and Y cut is perpendicular to the surface and results in a crystal with a thickness of 4.118 +/- 0.003 mm. The resulting crystal is a Z cut. In an open resonator, it measures at 36 GHz. The result is e' = 4.435 +/- 0.007 and tan d = (37 x 10).

The AT cut is perpendicular to the z-axis and produces a frequency constant of 2.536 MHz/mm. The BT cut is perpendicular to the x-axis and is often used in electronic instruments. However, its frequency limit is lower than the AT cut. The BT type uses a width extensional mode of vibration. If you are looking for high-frequency performance, this cut is best for you.

The Z cut is a birefringent material. This means that it is transparent to the visible spectrum, but it doesn't change the polarization of light. It's the ideal material for polarizers, wave plates, windows, and other similar applications. A Z cut quartz crystal can be X and Y or right handed. It's a perpendicular cut, which is the best type of quartz for wave plate and polarizers.

This cut is the most common cut for quartz. It is the most commonly used type. It is the best material for wave plates, window, and polarizers. It is also more durable than most other materials. What's more, it is a great choice for windows and polarizers. The X and Y cuts of quartz are perpendicular to the surface. The Z cut allows the crystal to direct a single path through the crystal.

This cut is also used for oscillators. Its symmetrical shape allows it to block out rays from the opposite polarity. The Z cut has a symmetrical symmetry and is often used as an oscillator. The symmetry of the Z cut allows it to be a useful tool in many applications. This quartz crystal can also be a wave plate. There are many advantages of a Z-cut.

This cut is a type of quartz crystal that uses a perpendicular angle. It uses a 49-degree z-cut to make the crystal's thickness. The IT cut has a higher temperature coefficient than the AT cut, but it's the most versatile cut. It is also useful for wavelengths above 50um. If you're looking for a unique quartz piece, then you'll want to choose a Z cut.

The thickness of a Z cut quartz crystal is 4.118 mm. This is a standard measurement of quartz in an open resonator at 36 GHz. Hence, this cut is an optical window for 60 kbar. Its size is determined by its tan d. In addition to its thickness, the Z-cut quartz crystal is the best material for wave plates and polarizers. You can find this type of crystalline glass in many jewelry shops.

This type of quartz crystal has a thickness of 4.118 mm. It is ideal for optically cutting and using in polarizers. The material is conductive and can also be used for wave plate applications. The Z-cut quartz crystal is available in a variety of different shapes, including X-cut and Y-cut crystals. Its symmetry makes it suitable for waveplates and windows. The simplest quartz is the right-handed one.

Various applications require a quartz crystal with a Z-cut. This is a type of "cut" in a crystalline crystal. It is a type of cutting that requires the cutting of the crystal along a specific axis. There are two types of resonators: resonators made of Z-cut quartz and a Z-cut quartz. The first is used in manufacturing the simplest electronic components. The other is the Z-cut.

What Are The Most Common Z-Cut Quartz Applications?

Z-cut single crystal quartz has several common applications due to its unique properties. Some of the most common applications include:

Oscillators and Frequency Control: Quartz crystals are widely used in electronic devices as oscillators and  frequency control components. Their excellent piezoelectric properties allow them to vibrate at a precise frequency when an electrical voltage is applied. This makes them crucial for accurate timekeeping in watches, clocks, and various electronic devices.

frequency control components. Their excellent piezoelectric properties allow them to vibrate at a precise frequency when an electrical voltage is applied. This makes them crucial for accurate timekeeping in watches, clocks, and various electronic devices.

Sensors: Quartz crystals are used in various types of sensors due to their high sensitivity to changes in temperature, pressure, and acceleration. They are commonly found in pressure sensors, accelerometers, and temperature-compensated crystal oscillators (TCXOs) used in electronic equipment.

Filters and Resonators: Z-cut single crystal quartz is utilized in the fabrication of filters and resonators for controlling specific frequencies in electronic circuits. Quartz crystal filters are commonly used in communication systems, audio devices, and radio frequency (RF) applications to remove unwanted frequencies and improve signal quality.

Microelectronics: Quartz wafers, derived from z-cut single crystal quartz, are used as substrates in the manufacturing of integrated circuits and microelectromechanical systems (MEMS). Their high purity, mechanical stability, and excellent electrical properties make them ideal for supporting and interconnecting electronic components on a microscopic scale.

Optics and Laser Technology: Z-cut single crystal quartz is employed in optical components and laser systems. Its high transparency to ultraviolet (UV) light makes it suitable for UV applications, such as ultraviolet photolithography used in semiconductor manufacturing. Quartz crystal is also used as a material for making polarizers, waveplates, lenses, and prisms in various optical instruments.

Piezoelectric Transducers: Quartz crystals are widely used as piezoelectric transducers for generating and detecting ultrasonic waves. They are utilized in medical imaging devices like ultrasound scanners, as well as industrial applications such as non-destructive testing, cleaning, and distance measurement.

Scientific Research: Z-cut single crystal quartz is commonly used in scientific research, particularly in physics and materials science. Its exceptional stability, low thermal coefficient of expansion, and high mechanical Q-factor make it an ideal material for experimental setups, resonators, and high-precision measurements.

These applications highlight the versatility and importance of z-cut single crystal quartz in various industries, ranging from electronics and telecommunications to optics and scientific research.

What Z-Cut Quartz Used for MEMS Resonant Devices Fabrication?

Single crystal z-cut quartz wafers are used to fabricate quartz resonators. The resonator is a device that vibrates at a certain frequency, and uses that vibration to send information. It is used in many applications, such as clocks, watches, radios, phones, computers, and many other devices. Quartz resonators are made of quartz crystal. They are very accurate because they vibrate at a very specific frequency. The resonator is usually attached to a circuit board. The whole circuit board might be put into another device that has an oscillator on it. The oscillator is the thing that makes the resonator vibrate at its specific frequency. The quartz resonators are used in tiny devices called microelectromechanical systems (MEMS). MEMS are used in many different types of devices, such as computer mice and keyboards, cell phones, video cameras, and automobile airbags. In these applications the MEMS are used as sensors to measure things like acceleration or position.

Recently, a few micromachining processes such as laser beam machining, abrasive jet machining (and electrochemical discharge machining have been studied for realizing micro-structures on quartz substrate.

Z-cut quartz etching used deep reactive ion etching (DRIE) system (GDE C200, China, Beijing), which has two high-density 13.56 MHz plasma sources (inductively coupled plasma (ICP) and capacitive coupled plasma (CCP), designed to etch materials which are infeasible to etch using conventional reactive ion etching (RIE) or ICP sources, such as silicon oxide, silicon nitride, aluminum oxide. The ICP source was a planar electrode on the top of the reaction chamber with a spiral coil. The ICP energy was supplied by electromagnetic inductions with a frequency of 13.56 MHz. The CCP source had the same frequency and was placed at the bottom of the reaction chamber. The cooled chuck with electrostatic clamping and helium backside cooling was served as a stage in which the target wafer was kept. The internal diameter of the reactor was 500 mm and the distance from the substrate chuck to the top of the reaction chamber was 150 mm. In this system the ICP produced the plasma of ions, while the CCP was applied to accelerate the ions onto the cathode. In order to guarantee the stability of the etching process, a chiller was used to control the temperature.

Some Z-Cut Quartz Applications

A scientists conducting research on PbSe Infrared Detectors. The scientist had the following question. The material that has been used in our industry for about 50 years is a “Z” cut single crystal quartz. The end product is used as cold as -50C so that is the “cut” that everyone has used as the Z cut allegedly has least expansion coefficient characteristics. The industry has used the same vendor all those years and my thought is that there would be a possibility that things may have changed over time. My fixtures to manufacture are based on 1.25” squares and as I mentioned we use over 2000 substrates a year. To explain the problem, I have a final product that the “chip” of quartz is about 1.5mm X 12.5mm on it are detectors that are 40 microns wide and 450 microns long, there are 256 of those detectors in a linear row along the 12.5mm… Over temperature some of the detectors do what we call “drift” where the electrical output does not stabilize… The odd thing is some drift for long periods of time, most detectors stabilize much quicker. When these detectors are packaged there is over $1500 of material and labor and with this “drift” problem they are useless. If the drift were happening with every part it would mean the problem was somewhere else but the fact that some do and some don’t in my mind points to substrate variation.. This question has come to the surface again as we sell just the array chips to a customer who packages them and they are seeing the same phenomenon which tells me that it is unlikely that we both have the same packaging problem…. I have been chasing this problem for 25 years and I want to try a different single crystal quartz to see if there is a difference. I appreciate you time looking at this….

UniversityWafer, Inc. Answer

PbSe films will not grow on silicon. 4” Z cut single crystal quartz will work.

We did discuss this internally, we think the angle of Z cut is the good choice for the lower cost, however, there is another angle cut called SC (double side rotation ) it's also a good cut for keeping the temperature no change . the short-come is the cost is high there is another possibility is happened while the fab of the wafers to lower the performance of the wafers

1) the tolerance of z- cut is too large , what's your specification at the tolerance of Z cut?

2) the parallelism of the 31.75X31.75 square wafer is not so good, this could damage the Z-cut angle's tolerance

Could you give a look of your specification, and we study if the tolerance your setup is right.

PbSe infrared detectors

Companies that manufacture PbSe infrared detectors use single crystal z cut quartz over temperature ranging from 25C to 50C One of the longtime problems is what we call drift when the material is operated a cold temperatures This drift is a real problem with linear arrays with as many as 256 elements 40 microns wide and 450 microns long Where the real problem comes in is that some of these arrays drift forever and never stop changing and some are rock solid after a few hours of operation I suspect that there is something in the substrates that is different that might be causing this phenomenon One of the things I would like to try is to grow the material on single crystal quartz that is manufactured in a different way than the 50 year old method our industry has used since the 1960s Because of the specialty equipment to checkverify the wafers we can never know if we or anyone in our industry is getting the same material every time At this point and in the past there was no way for our industry to know what the effect of polaritypolarity or perpendicular to or parallel to the z axis to the final product We use approximately 1500 to 2000 125 wafers a year This is a problem for the last 25 years that I have been involved with this industry and hope to find the solution.

A scientist recently asked about which quartz wafers they should use for their Research.

Researcher:

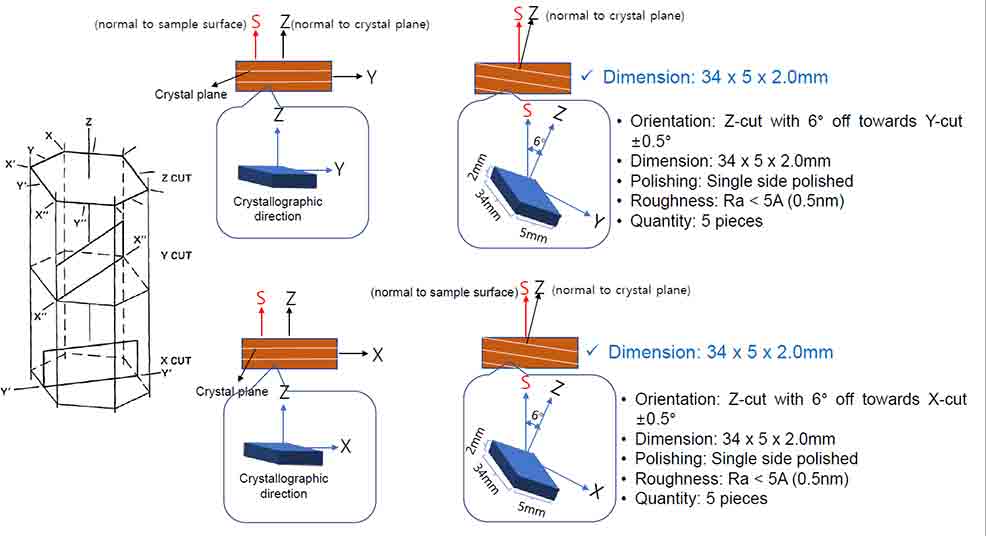

I wonder whether you can customize the off-angle(6 degrees) of Quartz(SiO2) substrate, that is, "Z-cut with 6° off toward X-cut" and "Z-cut with 6° off toward Y-cut" or not. If possible, I want to get your quotation. Quartz(SiO2) single crystal substrate Orientation: "Z-cut with 6° off toward X-cut" or "Z-cut with 6° off toward Y-cut" Dimension: 34x5x2.0mm Polishing: Single side polished or Double side polished

If possible, please let me know how to confirm the orientation of the off-cut crystal after cutting

Z-cut with 6° off towards Y-cut or Z-cut with 6° off towards X-cut.

We quoted and the client purchased the following:

| Dia | Ori | Thick | Pol | Material | Brand /Grade | SEED |

| 34x5mm | Z-cut with 6° off toward X-cut | 2.0mm | SSP | Quartz Crystal | SAW | seedless |

| 34x5mm | Z-cut with 6° off toward X-cut | 2.0mm | DSP | Quartz Crystal | SAW | seedless |