E-Beam Evaporated Metals on Silicon Wafers

E-Beam Evaporated Metals on Your Wafers

A scientist asked for us to quote the following:

"I'm looking to buy 100mm diameter silica wafers. Not picky at all about any of their properties,, they just need to be one side polished. They are going to be used as witness wafers along with other wafers to verify deposition thicknesses during e-beam evaporation of some metals. Basically just looking for cheap flat substrates. If you have any other suggestions other than silica wafers (but they have to be 100m diameter and able to withstand temperatures of 400-500C), I'm open to those to. Please let me know promptly.

Please reference #271422 for the specs and price we quoted.

Our E-Beam evaporation process provides excellent film thickness control and can deposit up to six different materials in-situ. E-Beam evaporation is often used when precious metals deposition is required and is an excellent choice for wafers that require lift-off processing.

In order to ensure the best results for metal lift-off, the underlying wafer and photoresist must be kept cool during metal deposition. This can be difficult to achieve while depositing thick layers. We along with our partners Micro-devices has developed a specialized low temperature E-Beam evaporation process specifically for use during metal lift-off processing.

The surface preparation of patterned silicon and quartz wafers intended for lift-off metal is also extremely important. We include photo-resist bake and O2 descum steps just prior to deposition to improve film adhesion.

Get Your Quote FAST!

Evaporated Metals Available:

- Aluminum

- Chromium

- Copper

- Gold

- Indium Tin oxide

- Platinum

- Nickel

- Silver

- Titanium Tin

What is Electron Beam Deposition?

E-beam evaporation is a process used in the fabrication of electronic devices and other products. It involves the use of a beam of high-energy electrons to evaporate a material, which is then deposited onto a substrate. E-beam evaporation has a number of advantages over other evaporation techniques, including the ability to evaporate a wide range of materials, high deposition rates, and good control over the thickness and uniformity of the deposited film.

Some common applications of e-beam evaporation include:

-

Deposition of thin films: E-beam evaporation can be used to deposit thin films of various materials onto a substrate for use in electronic devices and other products.

-

Metallization: E-beam evaporation can be used to deposit metal films onto a substrate for use in a variety of applications, including the production of electrical contacts and interconnects.

-

Encapsulation: E-beam evaporation can be used to deposit a protective layer over a substrate or device to protect it from the environment or other external factors.

-

Surface modification: E-beam evaporation can be used to alter the surface properties of a substrate or device, such as by adding a coating to increase the surface roughness or to change the surface energy.

Overall, e-beam evaporation is a versatile and widely used technique in the fabrication of electronic devices and other products.

How does Electron Beam Deposition Work?

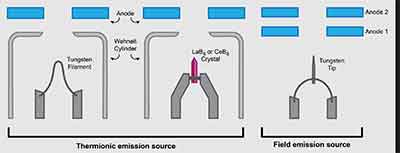

Electron-beam Deposition is a method of depositing thin films of materials onto a substrate. This process involves bombarding a target anode with a high-energy electron beam, given off by a charged tungsten filament. The energy of the beam causes the target atoms to move into a gaseous state. This is the process used in semiconductor manufacturing. Here is a look at how this technique works.

An e-beam evaporation is a form of physical vapour deposition. In this process, the source material is heated above its boiling point and evaporates to produce a thin film on a substrate. This process is perfect for lift-off processes, since it provides a higher density film with increased adhesion to the substrate. In addition, e-beam evaporation uses less energy to deposit thin films than thermal evaporation.

Electron-beam evaporation is a form of physical vapour deposition. The process utilizes a filament to generate an intense electron beam. This beam is steered by electric and magnetic fields, which heat the source material. The energy generated from the beam vaporizes the source material. The atoms of the source material will gain enough energy to escape from the surface, eventually forming a film on the substrate. The evaporating material is then transferred onto the substrate, which can be a sheet of glass, wood, or other material.

This type of physical vapor deposition is a process that utilizes a beam of electrons that is focused onto a filament. During this process, the ingot is held at a positive potential relative to the filament. The beam is guided by a magnetic field, and additional electric fields are often used to steer the beam over the ingot. This is the most common form of ebeam deposition in industry today, and it has several benefits.

The process is a physical vapor deposition method that uses an intense electron beam. The source material is heated above its boiling temperature. The atoms are then transported to the substrate and deposit a film. This method allows for the material to be coated on many surfaces, including optical devices, while maintaining a uniform thickness across a substrate. This type of chemical vapor deposition is ideal for coating large surfaces.

Electron beam evaporation is a form of physical vapor deposition in which the source material is vaporized by an intense electron beam. The energy of the beam is converted into heat. The electromagnets in the source are equipped with electro magnets, which prevent the e-beam from boring a hole in the melt. The e-beam will spit and form large nodules of the source material.

Ebeam Deposition is a physical vapor deposition method. It uses a highly concentrated electron beam to deposit materials. Its evaporation process is controlled with a variety of sweep patterns. For instance, the XY sweep can be used to cover a large area. It can also be used to coat a continuous substrate. A typical working distance for ebeam deposition is 300 mm or one meter.

An e-beam deposition process is a form of physical vapor deposition. It involves bombarding a target anode with an electron beam, which is given off by a charged tungsten filament. The electrons from the beam cause the atoms in the target to become gaseous and precipitate into a solid state. This material can then be deposited on a substrate up to a few millimeters in width.

E-beam evaporation is a form of physical vapor deposition. In this process, an e-beam emits an intense electron beam that vaporizes a source material. The heated source material will eventually lose its thermal energy and leave the surface. The e-beam evaporation method can also be used to coat a substrate. The average working distance is between 300 mm and one meter.

Electron-beam evaporation is a method of depositing materials using an electron beam. This method is a form of physical vapor deposition. A tungsten filament emits electrons with a 100 kV DC voltage source. The evaporation process happens at the point where the beam hits the target material. This process is advantageous because it eliminates contamination from the crucible.

Films Available for Deposition

We offer a wide variety of E-Beam evaporation precious and non-precious metals. Non-precious metals and dielectric materials are available for sputtering.

E-Beam Evaporated Metals

Electron beam evaporation, commonly referred to as e-beam evaporation, is a process used in the production of electronic and optical films and photovoltaics. It is used for the deposition of electronic or optical films for the semiconductor industry and is used in displays and photivoltaics. [Sources: 12, 15]

The high melting point of these materials can be deposited in liquid form and is therefore suitable for the production of electronic and optical films as well as for photovoltaics. However, some materials such as metal oxide nanostructures cannot evaporate because they cannot evaporate and some of them can evaporate with difficulty. The evaporation of the laser beam can facilitate the coating of e-coatings by evaporation. This is achieved by the VLS process, in which metal oxides and nanoscale structures are synthesized from a combination of high and low pressure laser beams. [Sources: 0, 2, 12, 14]

E - Beam Evaporation is capable of transferring pure and precise metal coatings requiring high melting temperatures to substrates at the atomic and molecular level to a substrate at the atomic or molecular level through a variety of applications. The concentration of the electron beam method now makes high-frequency deposition possible, a factor of interest for production-oriented businesses. [Sources: 3, 9]

Of all the vacuum-based processes, the ones that best serve the semiconductor industry are the evaporation and sputtering of electron beams. The vacuum separation techniques listed in the table are listed below, along with their performance and cost-effectiveness. [Sources: 4, 10]

As discussed in an earlier blog, there is an e-jet evaporation process, which is a thermal evaporation process. In the evaporation of the electron beam (e - beam), a material is heated with an electron beam, in contrast to thermal evaporation, in which resistant heating is used. Unlike a resilient boat that flows through a high current, a small portion of the starting material is heated while it is heated in electron beams of the EvAPoration by the electrons generated by tungsten filaments and accelerated by electrons. [Sources: 3, 6, 7]

The beam is directed from a tungsten crucible to the anode, which contains the material deposited at a pH angle. After evaporation, anodes with negative charge apply a large voltage and an electron - focus magnet - to the target source material. The finest filaments are placed in such a way that the electrons from the electron beam collide with the materials and evaporate when applied by the magnet. [Sources: 1, 3]

Due to the intensity of the heat generated by the electron beam, the evaporation tank must be water - cooled to prevent melting. The cooker plate used for electrons - beam separation is advantageous in avoiding thermal loads - produced interactions between copper and cooker and ensured uniform heat distribution from the starting material. We have a single inverted cone ("pocket"), which is used to hold the target material and hold a copper crucible in which the material is melted. [Sources: 3, 5, 9]

Angstrom Engineering Evovac is an electron beam evaporator that can deposit up to 6% of the sample and has the potential to deposit up to 10% in an in situ substrate purification process (performed with an ion mill). The device consists of a vacuum evaporator that houses the electron source that generates electrons, accelerates, deflects with the electron beam, and the crucible hearth that holds the evaporating material. Electron beam separation sources are equipped with an electromagnet that forms and positions the electron flow and a water-cooled copper stove that contains the deposited starting material. We use a single copper plate with a thickness of 1.5 mm to 2 mm, which is applied to a heated substrate after cleaning the substrates by ion mills. [Sources: 5, 6, 8, 14]

The electron beam has a high electricity density and the evaporation of various materials is possible, including sublimating substances. In view of the experimental results, we believe that the high-density electron beams could easily decompose metal oxides and form high partial pressures - low in temperature and oxygen - that can form at low oxygen and partial pressure. The high densities of electrons in the beam could easily decompose metal oxide and easily decompose metal oxides (e.g. copper oxide, nickel oxide). [Sources: 0, 14]

Currently, various processes are used to produce optical thin films, of which the electron beam ions are most commonly used - assisted deposition. As already mentioned, this process is responsible for the deposition of high-temperature metal oxides (e.g. copper oxide, nickel oxide) and their evaporation. Thermal evaporation uses the low melting point of the material during the lifting of an e-beam resistance, which does not produce a stray X-ray that produces an E-beam evaporation. E - Blasting evaporation is oriented to heating the starting material and therefore better from the purity point of view. [Sources: 6, 11, 13]

Sources:

[0]: https://www.ncbi.nlm.nih.gov/pmc/articles/PMC5377458/

[1]: https://www.mdpi.com/2079-6412/10/3/211/htm

[2]: http://article.sapub.org/10.5923.c.materials.201502.04.html

[3]: http://www.semicore.com/news/89-what-is-e-beam-evaporation

[6]: http://lnf-wiki.eecs.umich.edu/wiki/Evaporation

[8]: https://www.utoledo.edu/research/pvic/material_deposition.html

[9]: https://www.tungsten.com/tips/electron-beam-evaporation/

[11]: https://www.findlight.net/blog/2019/06/30/electron-beam-evaporation/

[12]: https://nanomelbourne.com/services/thin-films/

[13]: https://www.reoinc.com/technical-resources/cat/78/technical-tutorials/article/Coating-Process-Tutorial

[14]: https://www.jeol.co.jp/en/science/eb.html

How Does Electron Beam Deposition Work?

The process is relatively simple and requires no auxiliary equipment. The target material is placed in a  vacuum chamber or crucible, with a tungsten filament below it, acting as a negative charge. Electrons are then applied to the tungsten filament by magnets, which focus them on the target material. Next, a substrate is placed over the target, acting as a positive-charge diode.

vacuum chamber or crucible, with a tungsten filament below it, acting as a negative charge. Electrons are then applied to the tungsten filament by magnets, which focus them on the target material. Next, a substrate is placed over the target, acting as a positive-charge diode.

The E-Beam sweeps through the source material, causing it to vaporize. Cooling is necessary due to the high energies that are involved. Water circulating in the crucible reduces impurities in the material, which is why this process requires close attention at each step. The goal is to deposit a thin film of material on a substrate. The process is fast and efficient, so the target substrate may be coated multiple times.

The process also uses a high-energy electron beam. This energy is transferred from the source material to the surface. The energy is lost through secondary electron emission and X-rays, and the source material is evaporated. The material is then coated onto a substrate. The distance between the source and substrate during the process can vary from 300 mm to one meter. This process can be repeated as many times as necessary, and is often performed for high-volume production.

Electron beam evaporation is a highly efficient method for physical vapor deposition. It allows users to deposit materials that would be difficult or impossible to process using standard resistive thermal evaporation. For example, the e-beam process is ideal for lift-off processes. The high energy input is necessary to form a dense film with good adhesion to the substrate. The process requires less energy, which results in a high-density film.

The E-Beam deposition process uses electrons to deposit thin films. The target material is held at a positive potential relative to the filament. An electron beam is directed by a magnetic field. Additional electric fields are used to guide the beam over the ingot's surface. The electron beam is also efficient for optical thin-films. In addition, it can be used to deposit conductive materials.

Electron beam deposition is a highly effective method for creating optical thin films. Its high deposition rate and high material utilization efficiency make it ideal for high-performance automotive and aerospace industries. It can also be used for optical thin films. It is also a powerful method for manufacturing photovoltaic cells. Its advantages are vast and it is worth researching. Its unique features can lead to breakthroughs for your product.

E-Beam deposition is an advanced method of physical vapor deposition. It works by transferring energy directly to the target material. This method is particularly effective for metals with high melting points. The electron beam can bond to a substrate. The vaporized material will be bonded to the substrate. The ingot is held at a positive potential relative to the filament. The filament will be a shield between the ingot and the target material.

Electron beam deposition is a physical vapour deposition method. It is similar to thermal evaporation, with the source material being heated above its boiling point and evaporated. This process yields a higher-density film and a greater adhesion to the substrate. The energy input to the target material is significantly increased compared to the thermal energy input. This method of e-beam deposition also allows the source material to be heated in a high temperature.

The E-Beam deposition method involves direct energy transfer from the source material. This method is perfect for metals with high melting points. It also allows for higher-deposition rates, which range from 0.1 to 100 nm per minute. The film coatings formed by E-Beam is usually much thicker than the previous ones, which means it has better adhesion to the substrate.

When the material is exposed to the electron beam, it evaporates. The electrons are heated to high kinetic energy. The electrons lose their kinetic energy when they hit the evaporation material. When the material is subject to a high vacuum, the evaporation material melts or sublimates, or turns into a molecule of vapor. The vapor can then be deposited onto a surface.

Disadvantages of Electron Beam Evaporation

The advantages of e-beam evaporating materials are its versatility. Unlike resistance heating, it is very effective in evaporating high melting points. It is also used for coatings in a variety of applications, such as optical coatings, thin-film semiconductors, and conductive glass. It can also be used to coat the interior surfaces of complicated geometries. The disadvantages of e-beam etching and evaporation are discussed below.

Electron beam evaporation is an excellent solution for high-performance applications. Its low energy and fast  deposition rates make it ideal for a variety of applications, including aerospace and automotive industries. It is an excellent solution for the deposition of durable hard coatings, chemical barriers, and optical thin films. However, it has a number of drawbacks, which are outlined below.

deposition rates make it ideal for a variety of applications, including aerospace and automotive industries. It is an excellent solution for the deposition of durable hard coatings, chemical barriers, and optical thin films. However, it has a number of drawbacks, which are outlined below.

Electron Beam Evaporation is an effective thin film deposition technique. It uses an electron beam with a very high kinetic energy. The energy transferred by the electrons is converted into thermal energy, which heats the material. When the vacuum is high enough, the material melts or sublimates. The resulting vapor can be used to coat surfaces. Some advantages of e-beam evaporating include a high rate of deposition and less heat generated.

Another disadvantage is the lack of a control over the deposition rate. Electron beam evaporation is faster than sputtering. Generally, the deposition rate is higher, but it is more complicated. It is also prone to damage caused by stray x-rays. Nevertheless, both methods have similar parameters and figures of merit. For example, e-beam evaporation is a faster process than sputtering and resistive thermal evaporation.

The other disadvantages of e-beam aeration are higher deposition rates. This method is not suitable for the production of conductive materials, such as glass. It also requires a high deposition rate and has the potential to damage materials. It is not possible to use thermal evaporation for this purpose, because the process can generate too much heat. Moreover, thermal evaporation is not a safe alternative to evaporation.

One of the disadvantages of e-beam is that it can be expensive. Due to its high deposition rate, it is not suited for production of conductive materials. On the other hand, it is possible to manufacture optical thin films. And unlike resistive thermal evaporation, e-beam evaporation is more efficient for many applications. In addition, the process can be customized.

Although it is a good choice for certain applications, it is not ideal for all applications. The process is too slow and does not produce high-quality films. Aside from its high deposition rate, electrolysis cannot be applied to metals. It also has limited adhesion properties. If you do not want to use electrical components in your products, e-beam evaporation is not the right method for you.

Advantages of Electron Beam Evaporation

Electron beam evaporation is an excellent method for metal deposition. It permits direct energy transfer to the target material, making it ideal for metallization. Compared to regular thermal evaporation, ebeam evaporation allows for higher deposition rates, which result in higher density film coatings. Moreover, the deposition rate is also much higher, which helps the material to adhere to the substrate.

Electron beam evaporation uses a high-energy electron beam to bombard an object, resulting in evaporation. In contrast to thermal evaporation, electron beam evaporation can reach much higher temperatures. The advantages of ebeam evaporator include higher deposition rates, higher density film coatings, and higher adhesion to the substrate. These advantages make ebeam evaporation a superior method of metal deposition.

Electron beam evaporation is more efficient than resistive thermal evaporation, because electrons are created through thermonuclear sources. The current heats filaments and crystals, which then emit electrons. When a solid surface is heated, electrons escape from it. Therefore, ebeam evaporation allows high-temperature materials to be evaporated more easily. Furthermore, electron beam evaporators can deposit thinner and more pure films.

There are several advantages of ebeam evaporator over resistive thermal evaporation. It allows for much faster deposition rates, higher film density, and increased adhesion to the substrate. Another major advantage is the improved energy utilization. In addition to the higher deposition rate, ebeam evaporation also provides high deposition efficiency.

Besides being more efficient than regular thermal evaporation, electron beam evaporation has many advantages over resistive thermal evaporation. The deposition rate is much higher, as the beams can penetrate refractory metals. Lastly, electron beam evaporation can yield thicker films with better purity. These are ideal for manufacturing high-temperature electronics and other parts that require precision and high-quality finishes.

Electron beam evaporation is a method that allows high deposition rates and high material utilization. It is used in aerospace and automotive industries, where it is used for optical thin films. It is useful for coatings made of high-temperature materials. It can also deposit non-metallic films and refractory metals. In general, it is advantageous to choose ebeam evaporation over thermal evaporation, though there are some disadvantages to both processes.

The advantages of ebeam evaporations over thermal evaporation are high deposition rates and high material utilization efficiency. They can be used to create optical thin films, including refractory metals. They also allow for the deposition of refractory metals and nonmetallics. In addition to these, the ebeam evaporation method can be utilised to manufacture various other products.

Compared to thermal evaporation, electron beam evaporation is more effective and produces thin films. It can also evaporate high-temperature materials such as gold and platinum. Additionally, it is easier to control the thickness of a thin film using ebeam evaporation than thermal evaporation. There are several other advantages of ebeam evaporating.

The ebeam evaporation process is an efficient method for the deposition of a small film. The target material can be made of various materials, such as refractory metals and semiconductors. It is also advantageous for evaporating metals with high vapor pressure. The use of ebeam evaporation in laser-based solar cells is also advantageous for the production of optical thin films.

One major difference between thermal evaporation and electron beam evaporation is the fact that the evaporation method involves an electron beam. It uses a filament to generate a highly focused electron beam. During the process, an ebeam evaporation system is cooled with water. After the ebeam evaporation, the evaporated material is transferred to a substrate.

The ebeam evaporation process is more effective than thermal evaporation, which is less expensive. However, the ebeam system requires separate filament and beam current control circuits. It also requires a high-voltage DC source to operate the machine. It is also more efficient than regular thermal evaporation in many applications.