What Scientific Research are Silicon Wafers Used For?

How fast Can Silicon Wafers be Delivered?

UniversityWafer, Inc is the leading silicon wafer distributor to universities and research centers internationally. We can delivery next day and if in Boston, same day. Just let us know how fast you need the wafers!

Researcher Testimonial:

"The (silicon) wafers have arrived today, and we really pleased with them! Thumbs up to your production crew!"

Researcher from University of Exeter

Free Technical Assiatance on All Substrates!

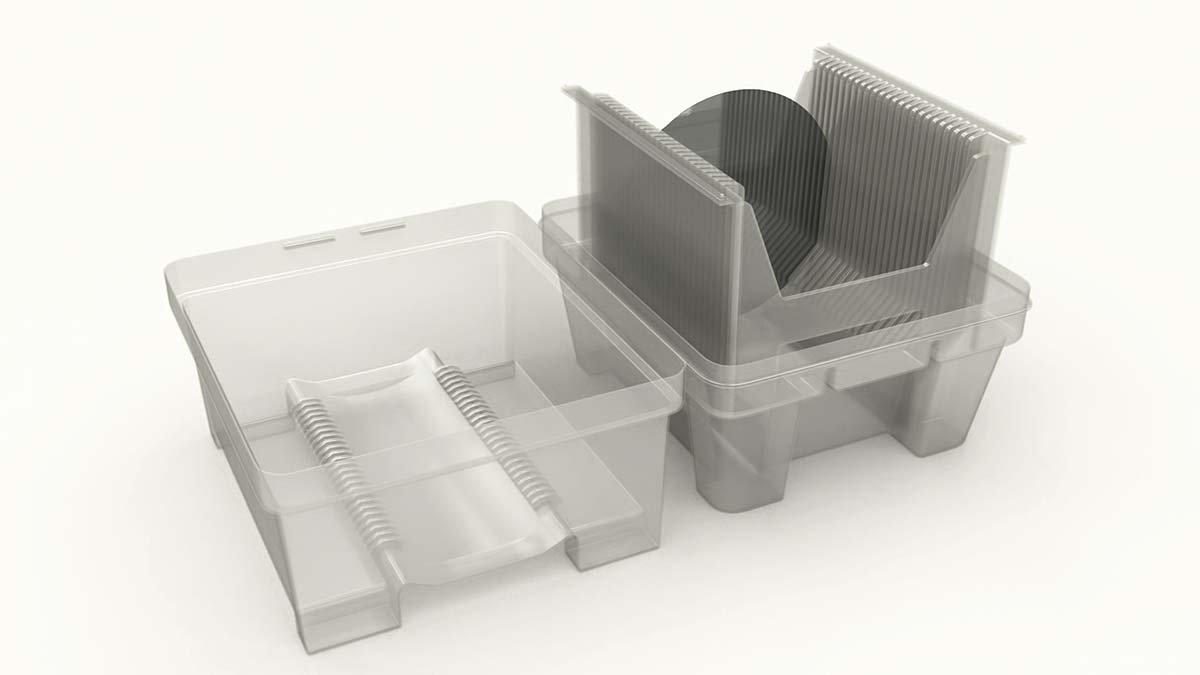

What Silicon-Wafer-Diameters do you Have in Inventory

We have all diameters in inventory. Below is just a sample of our ready to ship inventory. We can also dice any wafer into a dimension or diameter that you need in small and large quantities. Belwo are just some examples of what we carry.

Ultra-thin Silicon 100mm P/B (100) 1-10 ohm-cm 25um 2um thin Silicon also available!

1" Undoped Si (100) >1,000 ohm-cm 250um DSP

2" P-type Boron (100) 1-10 ohm-cm 280um SSP

3" N-type Phosphorus (100) 0.01-0.02 ohm-cm 380um DSP

4" Undoped/Intrinsic Silicon (100) >20,000 ohm-cm 500um DSP

6" P/B (111) <1 ohm-cm 300um SSP

8" undoped (100) >5,000 ohm-cm 750um SSP

12" P/B (100) 10-20 ohm-cm DSP 850um

We have plenty of silicon wafers at a low price and small quantities of partial cassettes so you can buy less than 25 wafers and as few as one Si wafer.

Silicon Wafer Sale!

We carry a large selection of Silicon Wafers with the following specifications:

Researchers commonly search for specific silicon wafer specifications to match their experimental needs. Below are the ten most sought-after specifications:

-

Diameter

Standard sizes include <25.4mm (1 inch), 50.8mm (2 inches), 76.2mm (3 inches), 100 mm (4 inches), 125mm (5 inches) 150 mm (6 inches), 200 mm (8 inches), aand 300mm (12 inches), chosen based on the scale of the project and equipment compatibility. -

Thickness

Wafer thickness depends on the diameter, typically ranging from 525 µm for 100 mm wafers to 775 µm for 300 mm wafers. Accurate thickness ensures mechanical stability and compatibility with processing tools. -

Crystallographic Orientation

Common orientations such as ⟨100⟩, ⟨110⟩, and ⟨111⟩ influence etching behavior and electronic properties. The orientation is selected to suit specific fabrication techniques. -

Doping Type and Resistivity

Wafers are doped with boron (p-type) or phosphorus (n-type), with resistivity (measured in Ω·cm) determining electrical properties. This specification is critical for device performance. -

Surface Finish

Wafers may be single-side polished (SSP) or double-side polished (DSP). A high-quality surface is essential for processes like lithography and thin-film deposition. -

Flatness and Warp

Parameters such as Total Thickness Variation (TTV), bow, and warp are crucial for uniformity during processes like lithography and etching, affecting the precision of device fabrication. -

Surface Roughness

Measured in nanometers (nm), smoother surfaces enhance the adhesion of photoresists and the quality of deposited films, making this a vital parameter for high-precision applications. -

Oxide Layer Thickness

Some wafers include a silicon dioxide layer with a specific thickness, used for insulation in electronic devices. The oxide layer's thickness is tailored to the application. -

Carrier Lifetime

This indicates the time charge carriers (electrons and holes) persist before recombination. It's a critical factor in applications like solar cells and high-speed electronics. -

Contamination Levels

High-purity wafers with minimal impurities, particularly metals, are essential to reduce defects and improve device reliability.

How do Silicon Wafers make Computer Chips

Silicon wafers start as pure silicon crystal ingots, grown from a single seed crystal and melted silicon through the Czochralski process. These cylindrical ingots are sliced into thin, disc-shaped wafers and polished to a mirror finish.

The wafer manufacturing process, called photolithography, is like taking a photograph. Light-sensitive chemicals (photoresist) are applied to the wafer, then exposed to ultraviolet light through a template (photomask) containing the circuit pattern. Areas exposed to light undergo chemical changes, allowing selective removal of material layers.

Multiple layers are built up through repeated cycles of:

- Depositing materials (metals, insulators)

- Applying photoresist

- Exposing to UV light through masks

- Etching away unwanted material

- Implanting dopants to modify electrical properties

This creates a complex 3D network of transistors and interconnections. Each wafer contains many identical chips (dies) that are later cut apart and packaged into the processors and memory chips we use in electronics.

Modern chips can have billions of transistors in layers less than 5 nanometers thick.

What do Researchers Use our Silicon Wafers for?

Researchers use silicon wafers in a wide range of applications across various scientific and technological fields. Here are 10 common uses:

- Microelectronics and Semiconductors Silicon wafers are the foundation of microchips, used in integrated circuits (ICs) for computers, smartphones, and other electronic devices.

- Photovoltaics High-purity silicon wafers are employed in solar cells to convert sunlight into electricity, forming the basis of many solar panel technologies.

- Micro-Electro-Mechanical Systems (MEMS) Wafers are used as substrates for MEMS devices, including accelerometers, gyroscopes, pressure sensors, and microfluidic devices.

- Optical MEMS Devices Silicon wafers serve as substrates for fabricating optical MEMS components like mirrors and waveguides, essential for fiber-optic communication systems.

- Quantum Computing Ultra-pure silicon wafers are used to build quantum processors and to study qubit dynamics.

- Sensors Researchers use silicon wafers to fabricate sensors for temperature, humidity, gas, and biosensing applications.

- Nanotechnology Silicon wafers act as substrates for growing nanostructures such as carbon nanotubes, nanowires, and quantum dots.

- Thin Film Deposition Studies Wafers provide a controlled surface for researchers to study deposition techniques such as physical vapor deposition (PVD) and chemical vapor deposition (CVD).

- Optical Coatings Silicon wafers are used as substrates for fabricating optical coatings, such as antireflective layers and filters.

- Biomedical Applications Researchers fabricate lab-on-a-chip devices, biosensors, and other biomedical platforms using silicon wafers for diagnostic and therapeutic applications.

Let me know if you'd like details on any of these applications!

What 100mmm and 200mm silicon wafers are used by researchers

-

Microfabrication Research

- Fabrication of prototypes for MEMS, microelectronics, and photonic devices.

- Ideal for exploratory device designs before scaling up to larger wafers.

-

Thin Film Studies

- Deposition and characterization of thin films (e.g., metal, oxide, nitride).

- Used for studying wetting, adhesion, and chemical vapor deposition (CVD) processes.

-

Material Science Experiments

- Growing nanostructures (e.g., carbon nanotubes or nanowires).

- Characterizing the thermal, optical, or electrical properties of silicon.

-

Optical MEMS Development

- Used for developing micro-mirrors, waveguides, and other optoelectronic components.

-

Lithography Testing

- Calibration and testing of photolithography equipment and processes.

200 mm (8-inch) Silicon Wafers

Larger wafers are preferred for more advanced research and applications requiring more surface area or compatibility with modern semiconductor tools.

-

Semiconductor Device Research

- Fabrication of transistors, diodes, and other microelectronics.

- Studies of new semiconductor materials (e.g., SiGe or strained silicon).

-

Integration of MEMS and CMOS

- Research into the integration of MEMS devices with CMOS circuitry on a single wafer.

-

Photonics and Optoelectronics

- Prototyping photonic integrated circuits (PICs) and optical MEMS devices.

- Used for developing devices like lasers, modulators, and photodetectors.

-

Solar Cell Research

- Studying processes for high-efficiency crystalline silicon solar cells.

- Used in tandem or bifacial cell designs.

-

Advanced Packaging Research

- Studies in wafer-level packaging (WLP), fan-out wafer-level packaging (FOWLP), and through-silicon vias (TSVs).

-

Quantum Computing

- Research into silicon qubits and quantum dot arrays.

-

Chemical Mechanical Polishing (CMP) Studies

- Testing and developing CMP techniques for smoothing and planarizing wafers.

-

High-Volume Manufacturing (HVM) Simulation

- Used to test manufacturing processes and tools designed for high-volume production.

-

SOI-Based Research

- Fabrication of advanced devices using silicon-on-insulator (SOI) wafers.

-

Wafer Bonding Experiments

- Research into wafer-to-wafer bonding for 3D integration or MEMS encapsulation.

What Silicon Wafer are used for Nanoparticle Formation

1. Native Oxide Silicon Wafers:

- Usage: Native oxide layers (~1-2 nm) naturally form on silicon wafers and can serve as a basic platform for nanoparticle nucleation, especially for studies in physical vapor deposition or wet chemical growth.

2. Thermal Oxide Silicon Wafers:

- Usage: Wafers with thick oxide layers (e.g., 100-500 nm) provide an insulating surface, useful for growing or depositing nanoparticles without electrical interference.

3. Polished (DSP or SSP) Wafers:

- Usage: Polished wafers with smooth surfaces allow precise control over nanoparticle deposition via techniques like chemical vapor deposition (CVD) or physical vapor deposition (PVD).

4. Doped Silicon Wafers:

- Usage: For applications where electrical conductivity is necessary, doped silicon wafers (e.g., n-type or p-type) are used, particularly in nanoparticle-based sensors or electronic applications.

5. Patterned Silicon Wafers:

- Usage: Wafers pre-patterned with features like wells or ridges guide nanoparticle self-assembly for photonic or catalytic applications.

6. Silicon-on-Insulator (SOI) Wafers:

- Usage: These wafers are valuable for precise control of the surface and underlying properties, ideal for optoelectronic or MEMS-related nanoparticle studies.

Selecting the appropriate wafer depends on factors like particle synthesis method, substrate reactivity, and end-use application.

As a (silicon) substrate for nanoparticle formation in ionic liquids. The nanoparticles are for fuel cell investigations."

Item# 2218 - Silicon 25.4mm P /B <100> ANY 400um SSP

What Silicon Wafer Coatings are Available?

What is Thin Film Deposition on Silicon Wafers

We have fast return on Sputtering, E-Beam Evaporation and more.

What are Other Silicon-Wafer Services

We also provide the following serviecs: Wafer dicing, Silicon wafer lapping, Silicon wafer polishing, Wafer bonding

What is a Silicon Material Safety Data Sheet (MSDS)

A Material Safety Data Sheet (MSDS) for silicon wafers is a critical document that provides detailed information about the safety, handling, storage, and disposal of the material. Although silicon wafers themselves are generally considered non-hazardous, their MSDS is important for the following reasons:

1. Hazard Identification

- While silicon wafers are typically safe, the MSDS highlights potential risks associated with their processing (e.g., dust generation during dicing or grinding).

- It ensures that users are aware of any chemical coatings, residues, or dopants (e.g., boron, phosphorus, or arsenic) that might present health or environmental risks.

2. Safe Handling Procedures

- The MSDS provides guidelines on proper handling to avoid damage to the wafers and to minimize risks to personnel.

- For example, precautions for handling wafers with sharp edges or brittle structures are specified to prevent cuts or breakage.

3. Storage Guidelines

- Silicon wafers must be stored in clean, controlled environments to avoid contamination or degradation.

- The MSDS outlines suitable storage conditions, such as maintaining specific temperature and humidity levels.

4. Personal Protective Equipment (PPE) Requirements

- Recommendations for PPE (e.g., gloves, safety glasses) are provided to protect workers, especially during wafer dicing, polishing, or other operations where particulate matter could be generated.

5. First-Aid Measures

- If a worker is exposed to hazards associated with wafer handling (e.g., silicon dust inhalation or eye irritation), the MSDS outlines immediate first-aid steps.

6. Environmental Considerations

- Silicon wafers can generate hazardous waste during manufacturing (e.g., slurry, chemicals, or doped silicon dust). The MSDS addresses proper waste disposal practices to minimize environmental impact.

7. Compliance with Regulations

- The MSDS ensures compliance with occupational health and safety regulations, such as OSHA (Occupational Safety and Health Administration) in the U.S. or similar agencies in other countries.

- It provides documentation required during inspections and audits.

8. Emergency Response Information

- In case of accidents, such as chemical spills from cleaning agents used with the wafers, the MSDS includes emergency response protocols and contact information.

9. Worker Education and Training

- The MSDS serves as a resource for training employees on material-specific risks and safe handling practices, fostering a culture of safety in labs or production facilities.

10. Documentation for Downstream Users

- If your company is brokering silicon wafers, the MSDS is critical for informing downstream users (your clients) about any safety and handling requirements, ensuring that your business maintains transparency and compliance.

In summary, while silicon wafers may appear benign, their MSDS plays a vital role in ensuring safety across the entire supply chain—from manufacturing to end use. It is also a key document for regulatory compliance and risk management.

What Are The Applications of Silicon Wafer Diameters?

We have the following silicon wafers in stock and ready to ship! 25.4mm, 50.8mm, 76.2mm, 100mm, 125mm, 150mm, 200mm, 300mmm, 450mm

What Silicon Wafers use in the day-to-day Scientific Research?

1. Standard Test Wafers

- Diameter: (Item #452 is our best seller!) 100 mm (4-inch) and 200 mm (8-inch) are most common for research labs.

- Use: General-purpose experiments like lithography testing, thin film deposition, and etching.

- Benefits: Readily available, cost-effective, and compatible with standard lab equipment.

2. Silicon-on-Insulator (SOI) Wafers

- Structure: Thin silicon layer on top of a silicon dioxide insulating layer, with a bulk silicon substrate underneath.

- Use: MEMS devices, photonics, and advanced device prototyping.

- Benefits: Excellent for isolating devices from substrate effects, improving performance.

3. Single-Side Polished (SSP) Wafers

- Surface Finish: One polished side for deposition and fabrication, with the other side unpolished.

- Use: Thin film studies, wet etching, and sensor development.

- Benefits: Smooth surface for precise processing.

4. Double-Side Polished (DSP) Wafers

- Surface Finish: Both sides polished for high flatness and parallelism.

- Use: Optical applications, double-sided deposition, and advanced MEMS.

- Benefits: Reduced bow and warp, essential for high-precision work.

5. Doped Silicon Wafers

- Types:

- Use: Electrical testing, device fabrication, and photovoltaic experiments.

- Benefits: Tailored resistivity for specific applications.

6. Undoped/Intrinsic Silicon Wafers

- Use: Optical and electrical studies requiring minimal interference from doping.

- Benefits: High purity, ideal for photoconductivity and basic material studies.

7. Oxidized Wafers

- Surface: Pre-grown silicon dioxide layer of varying thickness (e.g., 100 nm, 300 nm).

- Use: Research in dielectric layers, passivation, and interface effects.

- Benefits: Provides a controlled oxide layer for experiments without requiring in-house oxidation equipment.

8. Prime Grade Wafers

- Surface Quality: High-quality wafers with minimal defects, often used for advanced research.

- Use: Lithography, nanofabrication, and high-precision experiments.

- Benefits: Ensures reliability in demanding applications.

9. Dummy Wafers

- Use: Equipment testing and process calibration (e.g., for deposition or etching tools).

- Benefits: Dummy substrates Lower cost compared to prime wafers, preserving resources for critical experiments.

10. Thick Silicon Wafers

- Use: Applications requiring mechanical stability, such as in bulk micromachining or as substrates for high-power devices.

- Benefits:Thick silicon wafers offer better durability during handling and processing.

Why These Wafers are Popular in Daily Research

- Versatility: Silicon wafers serve as substrates for experiments in electronics, photonics, MEMS, and more.

- Availability: Standardized sizes and specs make them easy to procure.

- Cost-effectiveness: Researchers can choose between high-grade and test-grade wafers based on their needs.

Let me know if you’d like a deeper dive into specific wafer types or suppliers!

What Kind of Silicon Is Used To Fabricate SOI Wafers?

1. Bulk Silicon Substrate

- Type: Typically high-resistivity silicon or low-resistivity silicon, depending on the application.

- Doping: Can be either p-type (boron-doped) or n-type (phosphorus-doped), chosen based on the electrical requirements of the final device.

- Orientation: Crystallographic orientations such as ⟨100⟩ or ⟨111⟩ are selected based on compatibility with specific fabrication processes.

- Thickness: Generally thicker than the device layer to provide mechanical support and stability.

2. Device Layer Silicon

- Type: Ultra-high-purity, single-crystal silicon is used for the thin device layer.

- Thickness: Can range from a few nanometers to several micrometers, depending on the application.

- Doping: Lightly doped or intrinsic silicon is common to ensure high-quality electrical properties.

- Orientation: Often ⟨100⟩ for CMOS applications or ⟨111⟩ for MEMS and photonics.

3. Buried Oxide Layer (BOX)

- Material: High-quality thermally grown silicon dioxide (SiO₂).

- Thickness: Typically between 100 nm and 3 µm, depending on the level of isolation needed and the target application.

- Purpose: Electrically isolates the device layer from the substrate, reducing parasitic capacitance and improving performance.

4. Silicon for Wafer Bonding

For bonded SOI wafers, both the handle wafer and the donor wafer (providing the device layer) are made of:

- High-quality, single-crystal silicon.

- Matched or complementary crystallographic orientations to ensure proper bonding.

Processes to Create SOI Wafers

SOI wafers are fabricated using specialized methods, such as:

-

Smart Cut™ Process

- A hydrogen ion implantation process is used to define the device layer on a donor wafer.

- The implanted donor wafer is bonded to a bulk substrate wafer with an oxide layer, and the device layer is cleaved from the donor.

-

Bonded and Etched-Back SOI (BESOI)

- Two silicon wafers are bonded together, one with an oxide layer. The donor wafer is then thinned by etching to form the device layer.

-

Separation by IMplantation of OXygen (SIMOX)

- High-dose oxygen implantation into bulk silicon followed by annealing creates a buried oxide layer.

Applications of SOI Wafers

- Microelectronics: For high-speed and low-power CMOS devices.

- MEMS: For sensors and actuators requiring high isolation.

- Photonics: For optical waveguides and integrated photonic circuits.

- Power Electronics: For devices like insulated-gate bipolar transistors (IGBTs).

- Radiation-Hardened Electronics: For aerospace and defense applications.

The choice of silicon for each layer in an SOI wafer ensures the final product meets stringent electrical, mechanical, and thermal performance requirements. Let me know if you'd like details on specific applications or suppliers!

What Silicon Wafer Dopants are Available?

Silicon wafers are available with various types of doping to tailor their electrical properties for specific applications. The doping process introduces controlled impurities (dopants) into the silicon, which can either add free electrons (n-type) or create holes (p-type) in the material.

Common Silicon Wafer Dopings

-

N-Type Doping (Electron Donors)

- Phosphorus (P): The most common n-type dopant; used for general semiconductor applications.

- Arsenic (As): Produces similar n-type properties as phosphorus but is less prone to diffusion at high temperatures; used in precise doping profiles.

- Antimony (Sb): Rarely used but offers high resistivity control and minimal diffusion.

- Applications: Transistors, diodes, and sensors requiring electron conduction.

-

P-Type Doping (Hole Donors)

- Boron (B): The most common p-type dopant; easily diffuses and integrates into silicon lattices.

- Gallium (Ga): Used when deeper doping profiles are needed, though less common than boron.

- Applications: Solar cells, CMOS technology, and devices requiring hole conduction.

-

Undoped or Intrinsic Silicon

- Contains no intentional doping, providing very high resistivity and purity.

- Applications: Optical experiments, research on material properties, and devices needing isolation from conductive effects.

Resistivity Ranges

- Doping levels determine the wafer’s resistivity, typically measured in ohm-centimeters (Ω·cm).

- Resistivity can range from:

- Low (0.001–0.1 Ω·cm): Heavily doped for high conductivity.

- Moderate (1–10 Ω·cm): Common for electronic devices and MEMS.

- High (>100 Ω·cm): Lightly doped or intrinsic silicon for isolation and specific research applications.

Specialty Doping

-

Gradient-Doped Wafers

- Wafers with varying doping concentrations across the surface or thickness.

- Applications: Power devices and experimental studies on doping effects.

-

Compensated Doping

- Combines p-type and n-type dopants to achieve precise resistivity or electrical neutrality.

- Applications: Custom-designed devices with specific conductivity needs.

-

Epitaxial Wafers (Epi Wafers)

- A thin, lightly doped silicon layer grown on a heavily doped substrate.

- Applications: High-voltage or high-frequency devices.

-

SOI Wafers

- The silicon device layer can be lightly doped or intrinsic, depending on the application.

- Applications: CMOS, MEMS, and photonic devices.

How Doping is Chosen

- Type of Device: For example, solar cells use p-type substrates with an n-type emitter layer.

- Resistivity Needs: High-resistivity wafers are used for radio-frequency (RF) and photonic devices, while low-resistivity wafers suit high-power devices.

- Thermal Stability: Dopants like arsenic or antimony are chosen when minimal diffusion is required at elevated temperatures.

Doping in Applications

- Microelectronics: Lightly doped wafers for CMOS and heavily doped wafers for contacts.

- MEMS: Doping controls conductivity for sensors and actuators.

- Photonics: High-resistivity intrinsic silicon minimizes absorption losses.

- Solar Cells: Typically boron-doped p-type wafers with an n-type emitter layer.

Let me know if you need more details on selecting a doping type or supplier options!

What Are Ultra-Thinned Silicon Wafers and what is their application?

Ultra-thinned silicon wafers are wafers that have been processed to achieve an extremely thin thickness, often ranging from <100 µm to as thin as 5 µm or less. These wafers are made by thinning down standard silicon wafers using methods like grinding, chemical mechanical polishing (CMP), or etching.

Key Features of Ultra-Thinned Silicon Wafers

- Extreme Thinness: Typically <50 µm, sometimes as thin as a few microns.

- Flexibility: Extremely thin wafers can exhibit a degree of flexibility, making them suitable for applications like flexible electronics.

- High Surface Quality: The polished surface ensures smoothness for subsequent processing, such as deposition or bonding.

- Compatibility: Can be bonded to carriers for added support during processing.

Applications of Ultra-Thinned Silicon Wafers

-

Flexible Electronics

- Used in flexible displays, wearable devices, and bendable sensors.

- The thinness allows for mechanical flexibility while retaining electronic functionality.

-

Advanced Packaging (3D Integration)

- Used in through-silicon vias (TSVs) for 3D stacked integrated circuits (ICs).

- Thin wafers reduce the height of stacked devices, improving heat dissipation and electrical performance.

-

Power Electronics

- Thinned wafers are used in IGBTs (Insulated-Gate Bipolar Transistors) and MOSFETs to minimize resistance and improve performance in high-power and high-frequency applications.

-

Photovoltaics

- In high-efficiency solar cells, ultra-thinned silicon reduces material usage while maintaining efficiency.

- Used in bifacial or tandem solar cells where light absorption occurs on both sides.

-

Micro-Electro-Mechanical Systems (MEMS)

- Ideal for fabricating thin, lightweight sensors and actuators.

- Used in accelerometers, gyroscopes, and pressure sensors.

-

Bioelectronics

- Flexible, ultra-thin wafers are used for implantable biosensors and neural interfaces due to their biocompatibility and adaptability to biological tissues.

-

Thermal Management

- Thinned silicon wafers are used in applications requiring thermal conductivity while minimizing the volume of material, such as in high-power LED substrates.

-

Optoelectronics

- In devices like photonic chips, thin wafers can improve optical alignment and reduce losses in optical circuits.

-

Displays

- Used in micro-LED and OLED displays, where thin silicon substrates support lightweight, compact designs.

-

Wafer Bonding Applications

- Thinned wafers are often used as a donor layer in bonded SOI wafers or in other wafer bonding techniques.

Advantages of Ultra-Thinned Silicon Wafers

- Material Efficiency: Significant reduction in silicon usage compared to thicker wafers.

- Improved Heat Dissipation: Thinner wafers have better thermal properties for certain applications.

- Compact Devices: Essential for miniaturization and portable technologies.

- Flexible Integration: Enables the creation of devices with curved or irregular shapes.

Challenges

- Fragility: Thinner wafers are more prone to breaking during handling and processing.

- Complex Processing: Requires advanced techniques for thinning and bonding to carriers for support.

- Higher Costs: Processing thin wafers is more expensive compared to standard wafers.

Ultra-thinned silicon wafers are an enabling technology for cutting-edge advancements in electronics, MEMS, photonics, and more, offering unique capabilities for next-generation devices. Let me know if you need further details or sourcing options!

What Silicon Wafers Do Scientist Use in Day-to-Day Scientific Research?

Silicon wafers are essential in scientific research and are chosen based on the requirements of specific experiments or applications. Here are the types of silicon wafers scientists use in day-to-day research, categorized by common research purposes:

1. Standard Silicon Wafers

- Purpose: General experiments and as substrates for testing.

- Details: Typically <100> orientation, 500–700 µm thickness, and low resistivity (<1 ohm-cm) for mechanical robustness and electrical testing.

2. High-Resistivity Wafers

- Purpose: Electrical and optical experiments requiring low leakage currents.

- Details: Resistivity >10 ohm-cm to several kΩ-cm, often used in radio-frequency (RF) applications or photonics.

3. Silicon-On-Insulator (SOI) Wafers

- Purpose: Microelectromechanical systems (MEMS), sensors, and high-performance electronic circuits.

- Details: These have a thin silicon device layer separated from the bulk wafer by an insulating layer (SiO₂).

4. Ultra-Flat Wafers

- Purpose: Lithography, optical alignment, or high-precision device fabrication.

- Details: Double-sided polished (DSP) wafers are used for their excellent surface flatness and low bow/warp characteristics.

5. Oxidized Wafers

- Purpose: Experiments involving passivation, dielectric studies, or as a base for additional coatings.

- Details: Wafers with thermal oxide (e.g., 300 nm or 1 µm SiO₂) to act as an insulating layer.

6. Doped Wafers

- Purpose: Studies of conductivity, doping effects, or photovoltaic research.

- Details:

- P-type (Boron-doped): Positive carriers (holes), used for solar cells and some sensors.

- N-type (Phosphorus/Arsenic-doped): Negative carriers (electrons), used in many electronic device studies.

7. Patterned or Etched Wafers

- Purpose: Testing specific device structures or studying etching techniques.

- Details: Pre-patterned wafers with trenches or other microstructures.

8. Specialized Wafers

- Purpose: Advanced research in optics, quantum computing, or materials science.

- Examples:

- SOI wafers for photonics: Thin device layers for waveguides.

- Ultra-high resistivity wafers: For applications like particle detectors or terahertz experiments.

- Orientation-specific wafers (e.g., <110>, <111>): For anisotropic etching or specific crystal plane studies.

9. Thin or Flexible Wafers

- Purpose: Micro and nanofabrication requiring less bulk.

- Details: Wafers thinned to less than 200 µm, often with a support wafer during processing.

10. Specialty Coated Wafers

- Purpose: Optical experiments or testing adhesion properties.

- Details: Wafers with specific coatings such as silicon nitride, polyimide, or metallic films.

Selection Criteria for Day-to-Day Research:

- Size: Common sizes include 4-inch (100 mm) and 6-inch (150 mm); sometimes 8-inch for advanced setups.

- Polishing: Single-sided polished (SSP) or double-sided polished (DSP) for precision applications.

- Cleanliness: Semiconductor-grade wafers (ultra-clean) for contamination-sensitive experiments.

If you need recommendations for specific types or vendors, let me know! Si Item #453 - 100mm P/B <100> 0-100 ohm-cm 500um DSP Test Grade Si Item #589 - 100mm N-type Phosphorous Doped <100> orient

What Silicon Wafer

We have sed for Nanoimprint Processes?

**1. Substrate Type

- Material: Single-crystal silicon wafers are most commonly used due to their smooth surface, thermal stability, and ability to withstand high pressures.

- Orientation: Generally <100> orientation for uniformity, though <110> or <111> may be used if anisotropic etching or specific crystallographic properties are needed.

2. Surface Flatness

- Purpose: Nanoimprint requires ultra-flat surfaces to maintain pattern fidelity.

- Specifications:

- Total Thickness Variation (TTV): As low as possible, typically <2 µm for standard processes.

- Bow and Warp: Minimal, often <10 µm, to prevent uneven patterning or defects.

- Polishing: Double-sided polished (DSP) wafers are preferred for excellent flatness.

3. Oxidized Silicon Wafers

- Purpose: Used as molds or templates for nanoimprint patterns.

- Details:

- Thermal Oxide Coating: Thickness ranging from 100 nm to 1 µm for additional hardness or to serve as a functional layer.

- Reason: Oxide layers improve the anti-sticking properties and reduce damage during imprinting.

4. Doped or Undoped Wafers

- Undoped (Intrinsic):

- Used for general nanoimprint applications requiring pure silicon with minimal electrical conductivity.

- Doped Wafers:

- P-type (Boron-doped) or N-type (Phosphorus/Arsenic-doped) may be selected if electrical conductivity or specific electronic interactions are needed for downstream applications.

5. Wafer Thickness

- Standard Thickness:

- 500–700 µm for 4-inch or 6-inch wafers.

- Thin Wafers:

- Thickness <200 µm for flexible or non-standard setups, though they require support during imprinting.

6. Specialty Coatings

- Anti-Sticking Layer (ASL):

- A fluorosilane-based or similar coating is often applied to the wafer mold to prevent the resist from adhering to the mold during imprinting.

- Metal Coatings:

- Gold or chromium layers for specific optical or plasmonic experiments.

7. Wafer Size

- Common Sizes:

- 4-inch (100 mm), 6-inch (150 mm), or 8-inch (200 mm) wafers are used depending on the nanoimprint equipment.

8. Mold Wafers

- Purpose: Fabricated wafers act as the master mold for the imprint process.

- Details:

- Pre-patterned using electron beam lithography (EBL) or focused ion beam (FIB) to create nanoscale features.

- Hard materials like silicon carbide or quartz may be used instead of pure silicon for high durability.

9. Requirements for NIL Process

- Thermal Stability: The wafers must withstand high temperatures used for thermal nanoimprint lithography (e.g., 200–400°C).

- Mechanical Durability: Strong enough to handle the pressures applied during imprinting (up to several MPa).

- Surface Cleanliness: Ultra-clean surfaces to avoid contamination or defects in nano-patterns.

Recommended Types

- SOI (Silicon-On-Insulator) Wafers:

- For precise depth control in etching or imprinting processes.

- Silicon Wafers with Pre-Deposited Oxides:

- Enhances mold durability and adhesion properties.

- Quartz Wafers:

- Alternative to silicon for transparency and high thermal resistance in optical NIL.

If you’re planning a specific nanoimprint process, I can recommend suitable wafer specifications or vendors. Let me know your application!

Silicon Wafers vs Alternative Materials Comparison

Silicon dominates in cost-sensitive and large-scale applications, while alternatives like GaAs, SiC, Ge, and GaN are chosen for niche applications requiring high performance in power, optoelectronics, or RF domains.

| Criteria | Silicon Wafers | GaAs (Gallium Arsenide) | SiC (Silicon Carbide) | Ge (Germanium) | GaN (Gallium Nitride) |

|---|---|---|---|---|---|

| Material | Silicon | Gallium Arsenide | Silicon Carbide | Germanium | Gallium Nitride |

| Cost | Moderate | High | High | High | High |

| Thermal Conductivity | Moderate | High | Very High | Moderate | High |

| Electrical Conductivity | High | Very High | High | Very High | Very High |

| Band Gap | 1.12 eV | 1.43 eV | 2.36 eV | 0.66 eV | 3.4 eV |

| Applications | Microchips, Solar Panels, Electronics | High-frequency, Optoelectronics | High-power devices, LEDs | Fiber optics, Infrared optics | Power electronics, RF devices, LEDs |

Get Your Silicon Quote FAST! Or, Buy Online and Start Researching Today!

How do Silicon Anodes Speed Up Electric Vehicle (EV) Charging

New anode technology that uses a thin film of porous pure silicon could lead to less-expensive lithium-ion batteries for electric vehicles that charge in just a few minutes and provide over 200 mile range. The technology could help increase an EV’s range by 30 percent or more. Li15Si4 is the new material that combines silicon with lithium. UniversityWafer, Inc. can help researchers source the material for their lab.

Silicon The Element Defined in Detail

However, the latest results confuse what we know about the element and the individual elements on its surface. To be sure, researchers should know all about silicon by now, but they don't, at least not yet. Silicon was first identified in 1824 by Swedish chemist Jons Jacob Berzelius, but it has been worshipped by a number of other chemists and physicists over the last two centuries, from the late 19th century to the early 20th century. Interest in silicon increased in the late 1970s and early 1980s, when silicon transistors were developed to replace vacuum tubes in electronic devices such as computers, televisions, and mobile phones. It has since become the preferred material for electronic devices because it can make small circuits and integrate them into small chips. Silicon ushered in the so-called silicon revolution, which has changed society and permeated every corner of daily life. When we speak of semiconductor technology, we are talking about silicon crystals, which are normally cut from larger crystals to form thin wafers. This has enabled enormous computing capacity, which has reshaped the world by processing huge amounts of data and continuously accessing valuable information. While crystalline silicon has long been studied, the surface of the thin silicon layer has played an important role in the development of computer chips, as it is a key component in many of its applications. There is no doubt that the basic properties of the silicon surface are still unknown and widely discussed. He joined IBM's Thomas J. Watson Laboratory to help develop and apply new surface inspection techniques. PhD student, has been working with metal surfaces since his doctorate and continues to work well with them and understand them well, as well as facilitating the development of new techniques. At the time, I was an outsider in silicon surface research, so Mr. Cary asked me why I wasn't interested in silicon surfaces. When the opportunity came up to do a new kind of measurement that no one had done before, I saw an opportunity and thought, "Why not? The new attempt to study silicon surfaces involves understanding Si (111), which has been widely studied since 1957 but whose surface structure has never been understood. refers to the fact that the crystal is halved and a flat plane of atoms remains on the surface. To measure this, a surface must be cleaned and heated to remove dirt, with its atoms arranged like marbles in different configurations. The annealed Si (111) surfaces exhibit a diffraction pattern of 7x7, which is derived from the unusual atomic structure they possess. This pattern fascinates everyone who looks at it, and it has undoubtedly become one of the most widely studied semiconductor surfaces, if one excludes none. The latest discovery, which will be discussed later in this article, is based on initial studies of Si11 surfaces. The new temperature-dependent measurements of 7x7 show many interesting electronic transitions that were not observed before. Normally, if a surface is a semiconductor, it would be expected to become an insulator at low temperatures, but more importantly, it would be insulated at lower temperatures (about 50 K). In 1983, a theoretical model of the 2x1 structure was proposed and established, but the structure and chemical composition of a 7X7 surface was much more complex and elusive. In the 1980s, a new method of studying silicon surfaces - the Si (111) diffraction pattern - was developed, which allowed us to study other properties of this pattern. What people knew at the time was that if you broke a crystalline silicon rod in 111 directions, you would get a simple diffraction pattern of 2X1, and if the 2X2 surface were heated, the surface would form the 7Z7 pattern and be very stable at high temperatures. In general, such behaviour has a specific temperature dependence, but in 7x7 we found another temperature dependency. The surface is neither semiconducting nor metallic, so it is a very unusual effect to create electrons on the surface of the metal isolate, depending on how the electrons are aligned. This was proposed in 1985 to accommodate diffraction experiments, but the problem was that the calculated structure was always metallic, which contradicted the experiments. The 1985 7x7 structure, which was confirmed as the lowest energy and most stable structure, was revealed in the 1990s, when calculations were mature and could be performed to predict the complex structures of the 7X7 surface. This became the unsolved paradox of the silicon surface and the subject of a so-called scanning tunnelling microscope, for which he and other IBM colleagues received the Nobel Prize in Physics in Zurich in 1986. The paradoxes of 7x7 were rediscovered in the 1990s, this time by Bob Kowalski and colleagues at IBM, using a new device designed to perform electron spectroscopy on silicon surfaces at atomic resolution. The high stability of the STM design made it possible to see the electron clouds in different places on different surfaces and atoms and to dissolve their energy into atomic solvents. However, the theory did not predict the surface conditions observed at atomic resolution in 1983 and 1986. Initially, experimental measurements and their interpretation were a valid form of simplified calculations. Several researchers confirmed the new electronic state at the time, but again, no one had a clear explanation. In the insulation of floors, the paradox of the 7x7 surface became the basis for the development of a new type of high-temperature, low-energy electronic state of silicon. I left the lab in 1993 to pursue other interests and retired in 2005, completely in the paradise of my surroundings in Florida. I # ve never played so many rounds of golf in a year, caught so many fish in a single day, or played and played so long, at a time when the game of golf seemed to be getting worse, not better. That's when I decided to write to my grandchildren about why I became a scientist and what it means to be a scientist. Even then, I remembered all that and was kind of confused about what I was ever going to be. After two years of studying the results of the past and consulting the literature, I discovered two also more recent paradoxes and why they arose. To my surprise, despite many new studies, they have never been resolved, and there are many structures proposed over the years that would not fit either. These discoveries were made by attempting a reverse engineering process, taking into account certain features that an alternative structure might take into account. They are all based on many experiments, which today tell us much more than theoretical calculations and the state of the art. To my surprise, I found a new structure that takes into account these unusual paradoxes, but not in the same way as the previous ones. The trick is that in a very complex system, there can be different arrangements of atoms that look like structures from one angle but are connected by icicles stacked upright on a tray. When you look at it from the side, you see that you are actually standing on the cone, and when you look down, it is like a ball. At close range, each rung can have a different shape, such as a triangle, a circle or a cone with different shapes and sizes. The original structure in 1985 was proposed as a two-dimensional (2D) structure, similar to that in the atom, but the details of the new structure gave it distinctly different properties. The electrons behave very differently when they are in this new 2d frame, and there are now bonds. In the 2000s, everyone in the scientific community still believed that the original 1985 structure was correct. Now, however, it has been proposed again, this time with a different structure. In 2008, many of the researchers working on the surface switched to studying graphene, which is best known for its use as a surface for the production of high-performance electronics. Graphene is one of two materials based on carbon, but whose atoms are arranged in a hexagonal structure. As a result, graphene has a number of properties, the most striking being a very high electron mobility, which is important for electrical devices. The discovery of graphene was awarded the Nobel Prize in Physics in 2010 for its role in the development of high-performance electronics and its use in materials science. For some time now, there have been efforts to adapt other 2D structures for electrical devices. However, graphene formation on substrates has proved problematic as its formation in the substrate is crucial for highly integrated applications such as electronic devices and electronic components. The role of silver surfaces is called into question, however, as the 2D character of silicon atoms in silver must be preserved, especially as the silicon layers become thicker. Researchers at the University of California, San Diego School of Engineering have discovered in a promising new electronic material that silicon can be used to form a 2d structure similar to graphene. They succeeded in this by cultivating a monolayer of silicon on a silver surface. The monolayer of 2D silicon grown on silver has several properties that correspond to those of graphene, such as a high surface area and strong electrical conductivity, which silicon requires as an ideal material for use in electronic devices and electronic components.

What is Electron Configuration for Silicon?

Silicon Electron Configuration The electron configuration of Silicon (Si) is: 1s² 2s² 2p⁶ 3s² 3p² This configuration shows 14 electrons arranged as follows: 1s²: 2 electrons in the 1s orbital 2s² 2p⁶: 8 electrons filling the second shell (2 in 2s, 6 in 2p) 3s² 3p²: 4 electrons in the third shell (2 in 3s, 2 in 3p) This arrangement gives silicon four valence electrons, contributing to its properties as a semiconductor material.

How Many Valence Electrons Does Silicon Have?

Silicon has four valence electrons. This is because it belongs to Group 14 (or Group IV) in the periodic table, which indicates it has four electrons in its outermost shell. Explanation: Silicon’s atomic number is 14, meaning it has 14 electrons in total. The electron configuration of silicon is 1s² 2s² 2p⁶ 3s² 3p². The outermost shell (3rd shell) has four valence electrons in the 3s and 3p orbitals. Importance of Silicon's Valence Electrons: These four valence electrons allow silicon atoms to form covalent bonds with other atoms. In its crystalline form, silicon atoms connect in a lattice structure by sharing their valence electrons with neighboring atoms. This lattice structure gives silicon its properties as a semiconductor, making it an ideal material for electronic devices.

Silicon Protons Neutrons Electrons

Silicon is an element with the following subatomic particles: Protons: Silicon has 14 protons. The number of protons defines it as the element silicon on the periodic table, with an atomic number of 14. Neutrons: The most common isotope of silicon is silicon-28, which has 14 neutrons. Other isotopes, like silicon-29 and silicon-30, have 15 and 16 neutrons, respectively. Electrons: A neutral silicon atom has 14 electrons to balance the 14 protons. These electrons are arranged in shells around the nucleus, with four electrons in the outermost shell (valence shell). Summary for the most common isotope (Silicon-28): Protons: 14 Neutrons: 14 Electrons: 14 The balanced numbers of protons and electrons make silicon electrically neutral in its ground state, and its four valence electrons allow it to form covalent bonds in crystal structures.

Silicon Melting Point

The melting point of silicon is 1,414°C (or 2,577°F). This high melting point makes silicon suitable for high-temperature applications and is one of the reasons it’s widely used in electronics and semiconductor manufacturing. Silicon’s thermal stability at elevated temperatures is crucial in devices that operate under conditions where heat resistance is important

Silicon Bohr Model

The Bohr model of a silicon atom illustrates its atomic structure, focusing on the arrangement of electrons around the nucleus in distinct energy levels or "shells." Silicon has 14 protons and 14 neutrons in its nucleus, with 14 electrons orbiting in defined shells. Here’s a breakdown of the Bohr model for silicon: Structure: Nucleus: Contains 14 protons and 14 neutrons. Electron Shells: 1st Shell: 2 electrons (closest to the nucleus) 2nd Shell: 8 electrons 3rd Shell: 4 electrons (valence shell) Diagram Summary: In the Bohr model, the electrons are arranged in shells around the nucleus: The first shell can hold up to 2 electrons, and it is fully occupied in silicon. The second shell can hold up to 8 electrons, and it is also fully occupied. The third shell, the outermost shell for silicon, has 4 electrons, which are the valence electrons responsible for bonding and giving silicon its semiconductor properties. This arrangement explains why silicon has four valence electrons and is commonly found in materials used for electronic applications.

Silicon Mass Number

The most common mass number of silicon is 28. This corresponds to the isotope silicon-28 (⁴⁴Si), which has: 14 protons 14 neutrons Silicon has other isotopes with different mass numbers, such as silicon-29 (with 15 neutrons) and silicon-30 (with 16 neutrons). However, silicon-28 is the most abundant, making up about 92% of naturally occurring silicon.

What Are The Applications of Silicon Wafer Diameters?

Silicon wafers come in a range of diameters, and their size plays a significant role in their applications. The diameter affects the cost, compatibility with processing tools, and scalability of production. Below are the common wafer diameters and their typical applications: 1. 50 mm (2-inch) Silicon Wafers Applications: Research and development in material science and thin-film studies. Early-stage prototyping of small-scale MEMS and sensors. Basic optical coatings and experimental testing in labs. Advantages: Cost-effective for small-scale experiments. Easy handling and minimal material usage. 2. 100 mm (4-inch) Silicon Wafers Applications: MEMS and microelectronics prototyping. Photolithography calibration and process development. Carbon nanotube and nanowire growth studies. Research in semiconductor devices and thin-film deposition. Advantages: Most common size for academic and small-scale research labs. Affordable and widely supported by lab-scale fabrication equipment. 3. 150 mm (6-inch) Silicon Wafers Applications: Intermediate-scale MEMS and microelectronics production. Photonic and optoelectronic device research. Solar cell prototyping and advanced coating processes. Wafer-level packaging (WLP) and TSV (Through-Silicon Via) research. Advantages: Larger area supports more devices per wafer. Compatible with older industrial and academic equipment. 4. 200 mm (8-inch) Silicon Wafers Applications: Semiconductor device fabrication for research and pilot-scale production. MEMS and CMOS integration. Photonics, optical MEMS, and waveguide-based device research. Development of power electronics and RF devices. Advantages: Balances cost with a sufficient number of devices per wafer. Widely used in advanced research and pre-commercial fabrication. 5. 300 mm (12-inch) Silicon Wafers Applications: High-volume manufacturing of advanced ICs (integrated circuits), including processors and memory chips. Solar cell manufacturing for high-efficiency photovoltaic modules. Cutting-edge MEMS and advanced power devices. Advantages: Economies of scale: More devices can be fabricated per wafer. Supported by modern semiconductor processing tools. 6. 450 mm (18-inch) Silicon Wafers (Emerging Technology) Applications: Research in next-generation wafer processing and high-volume semiconductor production. Advanced logic and memory chip manufacturing (still experimental). Advantages: Potential for further cost reduction per device. Large surface area allows high device yield. How Diameter Affects Application Device Yield: Larger wafers (e.g., 300 mm) support more devices per wafer, making them ideal for high-volume production. Smaller wafers are suited for R&D and small-scale prototyping. Cost Considerations: Smaller wafers are less expensive and minimize material waste in exploratory research. Larger wafers offer better cost efficiency in mass production but require more advanced equipment. Equipment Compatibility: Labs and older fabrication facilities are typically equipped to handle 100 mm or 150 mm wafers. Industrial fabs use 200 mm and 300 mm wafers for modern semiconductor manufacturing.

Comparison of Applications by Diameter

| Wafer Diameter | Primary Use | Example Applications |

|---|---|---|

| 25.4 mm | Basic Research/Testing | Academic labs, material studies, basic sensors |

| 50.8 mm | Research/Prototyping | Thin films, sensors, basic coatings |

| 100 mm | R&D/Small-Scale Prototyping | MEMS, photolithography, basic electronics |

| 150 mm | Intermediate-Scale Production | Photonics, MEMS, solar cells |

| 200 mm | Advanced Research/Pilot Production | CMOS, RF devices, TSV packaging |

| 300 mm | High-Volume Manufacturing | ICs, advanced solar cells, power devices |

| 450 mm | Experimental | Future IC fabrication, next-gen manufacturing |

Summary

Silicon wafer diameter determines its suitability for specific applications based on cost, processing requirements, and yield. Smaller diameters are preferred in research and prototyping, while larger diameters dominate commercial semiconductor manufacturing. Let me know if you’d like further details on any specific size or application!