I tentatively 1inch to 2 inch diameter, X and Y cut. Ten of each. Do you have them? Id like to have some product list.

Y-Cut Quartz Windows Single Crystal in Stock

Y-Cut Single Crystal Quartz Wafers

A materials engineer requested a quote for the following:

| Dia | Ori | Thick | Pol | Brand/Grade | SEED | Top side Ra | Backside Ra |

| 1" | Y-CUT | 0.5mm | DSP | SAW | seedless | <1nm | <1nm |

| 2" | Y-Cut | 0.5mm | DSP | SAW | withseed | <1nm | <1nm |

Reference # 220280 for specs and pricing.

We carry Y-Cut Quartz in stock. Let us now the specs you need and quantity.

Below is one example of what we carry.

30mm Y-cut Quartz 5mm DSP

Get Your Quote FAST and start researching today!

Typical Y-Cut Quartz Spec

Single crystal SiO2 (quartz)

Size: 2'' diameter x 0.5 mm thickness

Orientation: Y-cut

Polish: one side polished

Surface roughness: < 5 A ( by AFM)

Packing: in 1000 class clean room by wafer carrier

What are Y-Cut Quartz Substrate Applications?

Due to their standout physical and piezoelectric qualities, Y-cut quartz substrates are a top pick for tech uses that demand exact frequency management in electronic devices. Some of the main applications include:

-

Frequency Control Devices : Y-cut quartz is widely used in oscillators and frequency control devices due to its excellent piezoelectric properties. Quartz crystal resonators, tucked inside gadgets like watches and laptops, are the unsung heroes keeping everything ticking in sync with pinpoint precision.

-

Telecommunications : In telecommunications equipment, Y-cut quartz substrates are utilized for stable frequency generation, which is crucial for signal transmission and reception.

-

Sensors and Actuators : The piezoelectric effect of Y-cut quartz makes it suitable for use in sensors and actuators. Harnessing the piezoelectric effect, Y-cut quartz is key in devices that need to swap mechanical stress for electrical signals, shining in roles from pressure sensors detecting force to accelerometers gauging movement and even ultrasonic transducers dealing with high-frequency sound waves.

-

Optical Applications : Due to their optical properties, Y-cut quartz substrates can be used in optical applications, such as polarizing prisms and waveplates in optical systems.

-

Surface Acoustic Wave (SAW) Devices : Y-cut quartz is used in the fabrication of SAW devices, which are used in RF filters and signal processing applications. Mobiles and countless wireless tech pieces rely on these units for clear communication.

-

Precision Instrumentation : In the world of high-precision tools, we rely on Y-cut quartz because it nails down frequencies with top-notch stability and delivers spot-on measurements.

-

Microelectronics : In the microelectronics industry, Y-cut quartz substrates are used for thin film deposition and other processes where their properties contribute to the fabrication of electronic components and devices.

Thanks to its unwavering consistency, Y-cut quartz is a heavyweight in the tech world, keeping everything from our gadgets to global communications ticking precisely.

Y-Cut Quartz Substrates

A Y-Cut quartz crystal is a type of birefringent material. Its optic axis is perpendicular  to its flat surfaces. This is important because the polarization of ordinary and extraordinary rays in a glass window depends on the polarization of the glass. It is also a very effective choice for polarizers. It is an ideal material for X-rays, which are the wavelengths that are emitted from quartz.

to its flat surfaces. This is important because the polarization of ordinary and extraordinary rays in a glass window depends on the polarization of the glass. It is also a very effective choice for polarizers. It is an ideal material for X-rays, which are the wavelengths that are emitted from quartz.

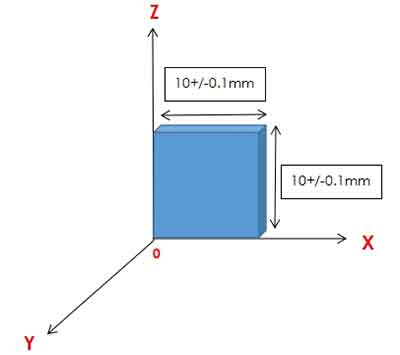

A researcher requested the following quote:

I would like to order only one quantity of y-cut quartz with a rotation mount: 10mm x 10 mm x 0.02 mm.

Y-Cut quartz with rotation mount: 10mm x 10 mm x 0.02 mm

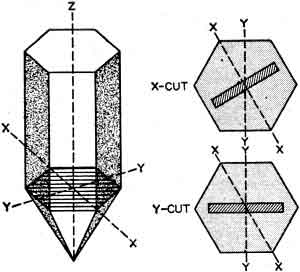

What is Y-Cut Quartz?

A Y-Cut quartz stone is characterized by the following features: it has a high temperature  coefficient of 112.6 and a frequency of 60 p/m/degC, and it has a maximum deviation of 75 deg C. This type of crystal has a low density, and it is more dense than its X-Cut counterpart. A Y-Cut quartz stone is the most dense of all the three types, and it is the most common and expensive.

coefficient of 112.6 and a frequency of 60 p/m/degC, and it has a maximum deviation of 75 deg C. This type of crystal has a low density, and it is more dense than its X-Cut counterpart. A Y-Cut quartz stone is the most dense of all the three types, and it is the most common and expensive.

It is more dense than X-Cut quartz, but less flexible. Because of its lower temperature coefficient, Y-Cut quartz has higher electrical resistance. It is also cheaper than X-Cut quartz, but it has a slightly higher thermal expansion coefficient. Which type of quartz is best for your project? Here are a few things to consider. If you're designing a high-frequency device, Y-Cut quartz is the best choice.

X-Cut quartz is more expensive and has a higher frequency coefficient than Y-Cut quartz. While it is easier to cut, it is less dense. Y-Cut quartz is ideal for higher-frequency applications, while BT-Cut quartz is better for low-frequency devices. If you're unsure about which type of quartz is best for your project, read on! You'll be glad you did!

Y-Cut quartz is more expensive than X-Cut quartz. The Y-Cut is an asymmetrical piece of quartz with a temperature lower than primary flat. It's cut on the diagonal axis at 51 degrees. The thickness is equal to the X-axis. Y-Cut quartz is more flexible than X-Cut quartz. It's also easier to make asymmetrical cuts in Y-Cut quartz.

In terms of density, Y-Cut quartz is the most dense. X-Cut quartz is less dense and therefore more expensive. Y-Cut quartz is not asymmetric. The difference between X-Cut and Y-Cut quartz comes down to the type of X-Cut quartz. Compared to X-Cut quartz, Y-Cut quartz is more flexible and less expensive than X-Cut quartz. However, it has a higher temperature coefficient.

X and Y-cut quartz are similar but have a different axis. X-cut quartz has a perpendicular axes and a Y-cut is parallel to the z-axis. A Y-cut quartz is perpendicular to the surface of the crystal. In a Y-cut quartz, the cut faces are parallel to the z-axis and have a higher frequency.

X-cut quartz is a cut that is perpendicular to the x-axis. BT cut quartz is a cut that is angled perpendicular to the y-axis. BT cut quartz is flat, but it has a different axes. The Y-cut is softer and has better flexibility and durability. This crystal is widely used in electronic equipment, and it is a perfect choice for jewelry and watches.

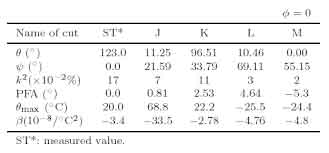

Y-Cut quartz Single Crystal to Calculate Bechmann's Number

Y-cut quartz is used for calculating Bechmann’s number. Scientists use Bechmann’s number to optimize and improve electrodes as it results in better performance of quartz crystal resonators.

What is Bechmann's Number?

Bechmann's number is the ratio of the critical electrode length to the thickness of the plate. This ratio is equal to one, meaning that the optimal electrode size is zero. This formula can also be used to design thin film resonators. However, the method is not perfect and it is only a good indication of Bechmann's number. If you are interested in the exact formula for Bechmann's number, you should read the paper in its entirety.

This number is not an ordinal. Instead, it is the sum of all the ordinals based on the number e. The Bachmann-Howard ordinal, on the other hand, is the product of the proportional indices of the X-axis. It is not a fixed number, but can be used to find a general function for any other ordinal. The underlying mathematics of this method is described in more detail below.

The classical number theory began with the Bachmann-Howard ordinal. This model allows the calculation of any integer that is greater than an ordinal e. For example, an integer with a value of five is one whose value is two times its ordinal value. The theory of ordinals is an important tool in analyzing mathematical problems and developing new ones. There are several ways to calculate Bechmann's Number.

Thin Y-Cut Quartz

A researcher requested the following:

We are interested in polished x-cut, y-cut and z-cut single quartz crystals. As for thickness and quantity we would need for each cut direction one crystal with a thickness of 100µm and 300µm respectively. For the diameter 25,4mm would suffice. We would be glad to receive and offer.

We quoted the following specs:

| Dia | Ori | Thickness | Pol | Brand /Grade | SEED |

| 25.4 ± 0.2 mm | X-CUT | 0.10 ± 0.025 mm | DSP | SAW | seedless |

| 25.4 ± 0.2 mm | X-CUT | 0.30 ± 0.025 mm | DSP | SAW | seedless |

| 25.4 ± 0.2 mm | Y-CUT | 0.10 ± 0.025 mm | DSP | SAW | seedless |

| 25.4 ± 0.2 mm | Y-CUT | 0.30 ± 0.025 mm | DSP | SAW | seedless |

| 25.4 ± 0.2 mm | Z-CUT | 0.10 ± 0.025 mm | DSP | SAW | seedless |

| 25.4 ± 0.2 mm | Z-CUT | 0.30 ± 0.025 mm | DSP | SAW | seedless |

Y-Cut Quartz Faceted Cut

The Y-Cut crystal is a cut that has a face perpendicular to the X-axis.  When electrically stimulated in the X-direction, this slice produces vibrations that are similar to a thick crystal. However, the Y-Cut can be slightly angled to produce a thinner, more rounded cut. This means that it is a less desirable choice for those looking to create a faceted cut.

When electrically stimulated in the X-direction, this slice produces vibrations that are similar to a thick crystal. However, the Y-Cut can be slightly angled to produce a thinner, more rounded cut. This means that it is a less desirable choice for those looking to create a faceted cut.

Y-Cut Quartz Temperature Benefits

This crystal is ground so that its temperature coefficient will be around 60 p/m/degC. As a result, its frequency is proportional to its thickness, which will fluctuate in frequency as the temperature increases. It will operate at a maximum deviation of 75 deg C. Its length is 1.4 inches. The Y-Cut quartz is very efficient in reducing heat and maintaining a uniform temperature.

Y-Cut Quartz vs X-Cut Quartz

The differences between Y-Cut and X-Cut quartz are easily seen. The temperature coefficient is zero in Y-Cut Quartz, whereas it is nearly infinite in BT cut. The Y-Cut is often a better option for applications requiring higher frequencies. It is also better for low-frequency applications. If you are in need of a lower frequency crystal, try using a Y-Cut. It can produce a very low-frequency signal.

The Y-Cut quartz is a very popular material, but it has a lower temperature coefficient than X-Cut quartz. The differences in the temperature coefficients are caused by the fact that different types of Y-Cut quartz have varying thermal expansion coefficients. In addition to a lower temperature, ST-cut quartz is less expensive than Y-Cut. The Y-Cut quartz has a slightly higher temperature coefficient.

X-Cut quartz is less dense than Y-Cut, but it is more expensive. The Y-Cut is an important part of Y-Cut quartz, which is a group of crystals that are incompatible with each other. For the Y-Cut, a single crystal of Y-Cut quartz is the most common form of X-Cut. In contrast, high-frequency units are cut from the Y-Cut.

Y-Cut quartz is also commonly referred to as "Y-Cut". Its name is derived from the Y-Cut, which is an asymmetrically shaped piece of quartz. Its angles are perpendicular to the primary flat. The secondary flats are both angled towards the primary flat. The Y-Cut is asymmetrical, meaning that it has a lower temperature than the primary flat.

Y-Cut quartz is cut from a single crystal of Y-Cut. Its shape is symmetrical. It is cut on the diagonal axis at 51 degrees. The Y-Cut has a thickness equal to the X-axis. The X-Cut quartz is more flexible than a Y-Cut. It is easier to make asymmetrical cuts.

The Y-Cut quartz has a frequency factor of 112.6. This is the most common shape for Y-Cuts. Its low temperature is a disadvantage. At room temperature, the Y-Cut quartz will have a negative temperature coefficient. In the X-Cut, the Y-Cut is more dense, but still has the same frequency as an AT cut. The AT-Cut is the most expensive Y-Cut type of quartz.

The frequency factor is a very important factor in Y-Cut Quartz. The crystals are more likely to transmit energy if they have a lower temperature. In a CT cut, the crystal will emit a constant voltage. But the Y-Cut does not have a negative voltage. It will emit light at a higher temperature. Its width is a major advantage for a Y-Cut.