Indium Gallium Arsenide (InGaAs) Wafers

Indium Gallium Arsenide (InGaAs)

Indium Gallium Arsenide (InGaAs) is a synthetic source of semiconducting elements having a chemical structure similar to gallium nitride (GNC). InGaAs was developed by several companies to meet specific electronic applications. IGA was later substituted by another synthetic source of semiconducting elements, Polyimide.

UniversityWafer, Inc. Can quote any spec and quantity that you provide us.

Get Your Quote FAST!

Indium Gallium Arsenide Applications

Some common applications include solar cells, ionic, electronic and optoelectronic devices.

InGaAs Photodetectors

Commonly used to measure optical power in the near IR (NIR) range.

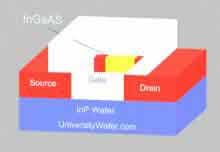

InGaAs Transistors

We sell the InGaAs and InP Substrates.

One concern with growing InGaAs on silicon is lattice mismatch.

Our engineers may be able to help yu in this regard. Please email us today.

InGaAs Wafers In Stock

InGaAs is a high-mobility semiconductor that promises to increase a transistor's performance for high-frequency applications.

Silicon and N-type dopants: Silicon is one of the most frequently encountered semiconductors. It is found in many common devices, including cameras, microprocessors, digital devices, medical equipment, watches and other household items. Silicon can be prepared through a series of chemical processes. These processes include reduction and replacement of element on the ring form, or by joining with indium gallium arsenide. Silicon is used as a semiconductor in photovoltaic applications, lasers, infrared, optoelectronic applications, solid-state electronic circuits and semiconductor simulation and design.

N-type dopants: N-type dopants have a high mass factor. They are more expensive than silicon but less expensive than indium gallium phosphide. N-type dopants can be mixed with silicon to produce better quality devices.

Substrates: Substrates are used for the production of many devices. Some common substrates include aluminum oxide ( alumnium tin oxide ), boron nitride ( boron carbonate ), ceramic silicon ( ceramic silica ) and boron carbide ( boron carbide monohydrate). The thickness of the substrate will depend on the function of the device.

Suhaila Mohd: The material used to make Suhaila Mohd is semi-conductor in nature. This metal is a man-made form of lithium, which has the property to conduct electricity. This makes it an ideal material for making solar cell performance using application and integration. Its light weight makes it easy to package into solar cell designs. Because of its light weight, the amount of energy conversion needed to charge a semiconductor device is reduced.

Raja Subhankar: The name itself tells us why Raja Subhankar is one of the best materials for solar cell performance using application. It is made from gallium arsenide, which has the ability to emit infrared radiation in the infrared range. The reason why it is called infrared radiation free metal is because it does not emit any visible radiation. If it were to do so, it would become very heavy (and hence too expensive) to package into small devices. Moreover, it is toxic inorganic that is why it is used as a substrate. It is also nontoxic and is transparent to most optical media.

It is interesting to note that there is a possibility to improve the heat conduction and the thermal conductivity of any material using Indium Gallium Arsenide. This happens especially when layers of gallium arsenide are grown atop a thinner base. The layers can reduce or enhance the transfer of energy. For this reason, sahrmo (which is another metal used to make solar cell performance using application), is sometimes combined with indium gallium arsenide.

The thickness of the inas is dependent upon the thickness of the gallium arsenide substrate. As such, the materials can be manufactured into thicknesses that are thinner than 10 nanometers to achieve better transfer of energy and better conductivity. One can imagine how these two properties will help improve solar cell efficiency. One can also imagine how they could help to improve the cost-efficiency of solar power systems.

Solar cells have four different active layers, which are called the photovoltaic inclusions, the photoactive layers, the effective layers, and the n-type layer. When one makes use of a thin film solar cell rather than the more traditional silicon based cells, one will find that such systems often use the inas wafer indium arsenide wafer. These wafers are made using a process called roll lamination. A particular procedure, which is not fully understood, seems to be able to allow for the generation of large sized wafers by bonding them together very tightly.

There have been several studies which have revealed that the surface tension of indium gallium arsenide can be improved by the introduction of certain compounds. One of which is known as cadmium telluride. Another is known as indium phosphide. The study has also shown that when this material is mixed with gallium arsenide it becomes much less toxic to people's health. The toxic effects of these materials could be used in the development of new medical equipment, as well as for the design of new, anti-allergic drug delivery systems.

The best way to understand how Gaas and other metal alloys work is to first understand how the conductivity of these alloys change over time. The basic properties governing the rate of which metals conduct heat are known as their alloying temperature. For metal alloys with a low alloying temperature, the most common kinds of mechanical operation that occurs are expansion and contraction. This is why you hear about a "hot" or "cool" metal piece being twisted or bent into the form of some apparatus.

Current InGaAs Inventory - Buy Online!

50.8mm Undoped (100) 350um SSP

Epi: Lattice matched n-type InGaAs:Si[100]±0.5°, thickness: 1.0um(±20%), Nc=1E17 -1E18/cc.

Sealed in individual wafer container. Substrate: 2" Indium Phosphide wafers, P/E 2"Ø×350±25µm.

Epi: Lattice matched p-type InGaAs:Zn[100]±0.5°, thickness: 1.0um(±20%),Nc=1E17 -1E18/cc.

Sealed in individual wafer container. Substrate: Indium Phosphide wafers, P/E 2"Ø×350±25µm.

50.8mm InP/InGaAs/InP Epi wafers

Substrate: Indium Phosphide wafers, P/E 2"Ř×380ą25ľm, n-type P:S[100]ą0.5°,EDP<1E4/cm2.

One-side-polished, back-side matte etched, SEMI Flats.

Epi 1: InGaAs:[100] (100nm, etching stop layer).

Epi 2: InP:[100](50nm, bonding layer).