"I use the wafers as test objects to verify my eddy-current measurement setup. As they have a well-defined thickness and homogeneous conductivity, they are ideal for my application."

When were 150mm Silicon Wafers Introduced?

Introduced in 1983, 150mm (5.9 inch, usually referred to as "6 inch") wafers can use the CZ or FZ method for ingot growth.

Let us know what specs we can quote for you!

Get Your 150mm Silicon Quote FAST! Or, Buy Online and Start Researching Today!

150mm Silicon Wafer Growth is Strong

This is impressive growth, supported by a slowly growing variety of applications such as the manufacture of "More Moore's Devices." As long as we continue with the class of equipment mentioned here, it is clear that the future of 150 mm wafer technology is bright.

Mechanical Grade Silicon Wafers Used in Neurobiological Research

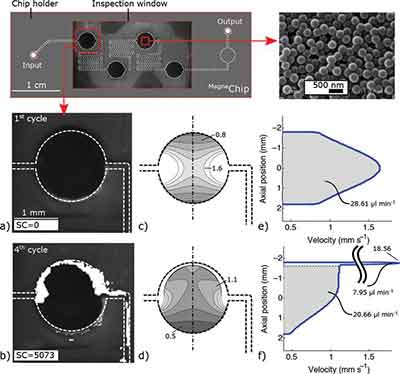

Researchers from the Tata Institute of Fundamental Research in India are using our 150mm, mechanical grade, SSP silicon wafers in their work on Simple Microfluidic Devices.

Silicon Used for Eddy-Current Measurements

A corporate scientist requested the following:

Si Item #1575

100mm P/B <100> 0.01-0.02 ohm-cm 525um SSP Prime

How are Silicon Substrates Used for Eddy-Current Measurements?

Eddy current testing is a nondestructive testing method widely used to examine materials for defects, measure thickness of materials, and inspect conductivity. It's based on the principles of electromagnetic induction.

- Thickness Measurement: One of the primary uses of eddy current measurements on silicon substrates is to measure their thickness.

- Material Defect Analysis: Eddy current testing can also be used to identify defects within the silicon substrate.

- Doping Level and Type Determination: The conductivity of a silicon substrate can be affected by its doping level and type.

What Wafers are Used in Millimeter-Wave Photoconductive Switches?

A university scientist needed help sourcing the correct wafer for their research:

"Our application is millimeter-wave photoconductive switches. We need really low loss silicon for one state, and long carrier lifetime for the other."

UniversityWafer, Inc. Quoted: 150mm Undoped high resistivity silicon >1000 ohm*cm wafers DSP around 500um thick.

Microreactor Array Device

Researchers from University of Arizona used the following 150mm Silicon Wafers for their Microreactor Array Device research: UniversityWafer, Inc. 150mm 675um+/-25um.

150mm (6 Inch) Silicon Wafer Inventory

We have a large selection of 150mm Si wafers in stock and ready to ship. Please fill out the form if you need other specs and quantity. Below is just a small sample of what is in stock.

| Item | Dia | Type | Dopant | Orient. | Res (Ω-cm) | Thick (μm) | Polish | Grade | Description |

|---|---|---|---|---|---|---|---|---|---|

| 478 | 150mm | - | - | N/A | - | 650 | SSP | MECH | Low cost Si Wafer, great for spin coating. |

| 857 | 150mm | P | B | <100> | 0-10 | 620 | SSP | Test | Test Grade Silicon, great for wafer processing studies. |

| 1025 | 150mm | N | - | <100> | 0-100 | 625 | SSP | Test | N-type Test Grade. |

| 2880 | 150mm | P | B | <100> | 0.006-0.012 | 525 | SSP | Test | With Oxide Back Seal. |

| 3071 | 150mm | P | B | <100> | 1-100 | 500 | SSP | Test | 2 SEMI-STD FLATS, PRIMARY <110>. |

| 1383 | 150mm | Undoped | - | <100> | >10,000 | 650 | SSP | Prime | Float Zone (FZ), High Resistivity. |

| 2476 | 150mm | N/P | - | <100> | 2k-10k | 675 | SSP | Prime | Float Zone (FZ). |

| 2312 | 150mm | P | B | <100> | 0.01-0.02 | 675 | P/E | EPI | With EPI layer, Hard wetblast/LTO. |

| UW1972 | 150mm | N | Phos | <100> | 2000-8000 | 320 | P/E | Prime | Float Zone (FZ), Thin. |

| E870 | 150mm | N | Phos | <111> | 0.001-0.014 | 605 | P/P | Prime | Double Side Polished (DSP), FZ. |

150mm Silicon Wafer Dopants Available

- Boron Doped Silicon Wafers

- Antimony Doped Silicon Wafers

- Arsenic Doped Silicon Wafers

- Undoped Silicon Wafers

- Gallium Doped Silicon Wafers

Related Silicon Wafer Resources

- 6 Inch Silicon Wafer Specifications

- Silicon Wafers and Substrates

- Silicon Wafer Orientation Guide

- Czochralski (CZ) Silicon Wafers

- Float Zone (FZ) Silicon Wafers

- Single Side Polished (SSP) Silicon Wafers

- Double Side Polished (DSP) Silicon Wafers

- Prime Grade Silicon Wafers

- Test Grade Silicon Wafers

- Mechanical Grade Silicon Wafers

- Ultra Thin Silicon Wafers