Silicon Substrate Orientation

Not all orientations are created equal. You need to make sure you have the right flat and notch orientations for your project.

Solution:

UniversityWafer, Inc. carry all the popular orientations so you can find the perfect one for your needs. With our selection of flats and notches, you'll be able to get your project up and running in no time.

If you have silicon wafers and you are not sure of the orientations then you can actually use a hammer and nail to find out! Your wafer's flat location should be enough to determine orientation. But ocassionaly the flats are not representative of the silicon orientation.

Get Your Quote FAST! Or, Buy Online and Start Researching Today!

What is My Wafer's Flat Orienation?

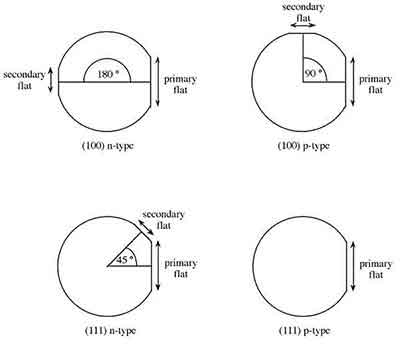

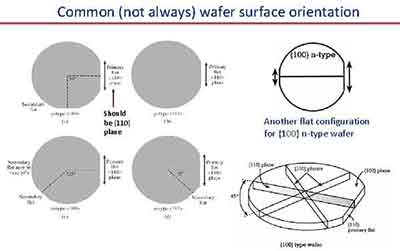

What is my flat orienation? A common question. Below are some diagrams to help explain it. How to identify your wafer orientation by the flat position and dimensions for n-type wafer and p-type wafers.

Orientation is defined by the Miller indexwith (100) or (111) faces being the most common for silicon. Silicon has an orientation

to determine the wafers properties when measured in different directions or anisotropic.

On the right of the diagram are Silicon p-type wafer flats.

Cleaving a wafer to determine a wafer's orientation is an easy way to determine the silicon's crystal direction.

So if you buy silicon wafersand lose the specification sheet, you can sacrifice a wafer to determine it's orientation!

Miller Indices Calculator

Other questions include, "what is a wafer?"

What is the Difference Between (100) (110) and (111) Silicon Wafer Types?

Watch https://www.youtube.com/embed/iktLutyh4W8

Breaking Silicon to Determine Silicon Wafer Orientation

How to Determine a Silicon Wafer's Crystal Orientation

Below is an image of what happens to two wafers when a hammer hits a nail at the wafer's center. On the left are (100) oriented silicon. When struck the wafer split into four equal parts. If you then do the same to the pieces, those pieces will also split into four pieces. (100) oriented silicon wafers are more efficient for making integrated circuits (IC).

The wafer on the right are (111). That wafer shatters into many different pieces. Thus this is an easy way to find out the orientation of your silicon wafer cassette.

![]()

The orientation of the silicon happens during the silicon wafer manufacturing process while the silicon is in the crystal boule. We aslo have wafer notch orientation specs on notched substrates.

Silicon Wafer Orientation, What you Need to Know

Silicon wafers are thin slices of semiconducting material widely used in the production of electronics and micromechanical devices. Integrated circuits are often manufactured with a silicon wafer on which a layer of silicon insulator (SOI) is placed. SOIs are used to electronically isolate the fine layers of monocrystalline silicon from the rest, and integrated circuits can be manufactured in a much more efficient way than would be used in a normal silicone wafer. Silicon on Insulator, or SOI, on the wadding resemble silicon chips because they have buried an oxide layer under the surface of crystalline silicon. [Sources: 0, 2, 4]

The aim of this invention is to produce a paschal theatre head by precisely aligning adjacent 100% silicon wafer subunits. The wafers have orientation notches as shown in FIG. 1, in which the wires running in each direction are in the range of A (5Adeg (001)) in this direction. [Sources: 7, 10]

The direction of the notch N is not fixed, but can be formed in 1 - 10 directions and then, with crystal orientation, form notches N. The silicon wafers in the first embodiment of FIG. 1 are shown as shown on the right side of this image, in a vertical orientation of N = 1. [Sources: 8]

The crystal growth of the melt corresponds to this initial orientation until the last large single crystal acquires a known crystal orientation. [Sources: 13]

In fact, the load depends on crystal orientation, and mobility itself depends on this orientation. The 40% orientation is important because 100 - 111 are very anisotropic silicon species, which are most common in crystalline form. This orientation is defined by the Miller index, with the 100 and 111 faces being the most common in silicon. It defines orientation in relation to its orientation in relation to the 50% and 60% orientations, of which 100-111 species are the most common of all silica species. [Sources: 5, 9, 14, 15]

The second layer is not always used, but it is used for doping detection and for a variety of other purposes, such as measuring the temperature of a silicon wafer. [Sources: 1]

According to previous findings, conventional optical orientation sensors are not able to reliably measure the orientation of gallium wafers. The different orientation of the wafer suggests that the material that adheres to its surface must be reconstructed in different orientations. Accordingly, we are interested in developing an improved "wafer orientation sensor" that can detect the different orientation properties of waves that, according to the researchers, have different properties, including those of a galaxy ice. [Sources: 3, 4, 6]

Today's inventors produced 110 silicon wafers by cutting them open with a wire - and confirmed that the wafer is capable of disassembling in time when cut, compared to a conventional 100% silicon wafer. The cutting process performs so much cutting that all the wires travelling in all directions account for about 200-110% of the produced silicon wafer. [Sources: 7]

The crystal orientation of the Si is 100%, splits at 60 ° and bites off at 100 °, and the split piece is 111%. The crystal orientation of Si is 100 - 110% and splits at 120 ° C. Cut-offs are 110 - 120% of their original shape, with a gap of 60 °. [Sources: 2]

When you cut a bar, the flat surface is aligned in several relative directions, called orientations, and when it is cut, the bars are aligned in several directions. [Sources: 0]

This orientation influences how the silicon wafer is etched, and therefore the primary flat silicon wafers are often used as a reference for all types of wafer orientations. Wafers smaller than four inches uses two notches at different angles to indicate the orientation of the flat surface and the two-notch angle between them. [Sources: 0, 11, 12]

They report that they have found that this orientation is mainly used to produce MEMS structures, but not for other types of silicon wafer orientation. [Sources: 12]

Using an X-ray diffraction unit mounted on a mask aligner, they were able to determine the exact crystallographic direction of the silicon wafer. The crystalline silicon layer, called the 111 layer by craftsmen, is located in the middle of a single layer of silicon with a surface of 1.5 mm. Next, they measured the thickness of each layer, calculated on the basis of measured values, and the number of layers per square meter. [Sources: 8, 10, 12]

If wafer 12 is completely blocked by the light beam 110, the orientation and center sensor cannot detect the edge of wafer 112. Thus, an epitaxial film deposited on the 111-oriented wafer will assume a 111-oriented orientation. [Sources: 3, 9]

What Are (110) Oriented Silicon Wafers?

If 110 silicon wafers are produced according to the present invention, the single crystal silicon ingots, which have a flat alignment, are disposed of by conventional wire saws with a tilting mechanism. Instead of producing a 110 silicon wafer, they can be cut with a diameter of 300% using the Czochralski method. [Sources: 7]

It is understood the Orient wafer uses the "wafer transfer handle device" that requires this. The wafers rotate in the desired orientation and then rotate back and forth with the orientation of the silicon ingot. [Sources: 3]

Sources:

[1]: https://www.halbleiter.org/en/waferfabrication/wafer/

[3]: https://www.freepatentsonline.com/6489626.html

[5]: https://en.wikipedia.org/wiki/Wafer_(electronics)

[6]: https://onlinelibrary.wiley.com/doi/full/10.1111/jmi.12654

[7]: https://www.google.com/patents/EP1955813B1

[8]: https://www.google.ch/patents/US8152919

[9]: https://cleanroom.byu.edu/ew_wafer_specs

[10]: https://patents.google.com/patent/EP0430593A2/en

[12]: https://link.springer.com/article/10.1186/s40486-018-0066-1

[14]: http://large.stanford.edu/courses/2007/ap273/chensl1/

[15]: https://www.wikidoc.org/index.php/Wafer_(electronics)

Wafer Flat Dimensions

Below are the semicondcutor standard flat dimensions.

| Spec. | 2” | 3” | 100mm | 125mm | 150mm | 200mm | 300mm |

| Diameter | 2.000+/-.015” | 3.000+/-.025” | 100+/-.5mm | 125+/-.5mm | 150+/-.2mm | 200+/-.2mm | 300+/-.2mm |

| 50.8+/-.38mm | 76.2+/-.63mm | ||||||

| Thickness | 0.011+/-.001” | 0.015+/-.001” | 525+/-20 um | 625+/-20um | 675+/-20um | 725+/-20um | 775+/-20um |

| 279+/-25um | 381+/-25um | or | or | ||||

| 625+/-20um | 625+/-15um | ||||||

| Primary | 0.625+/-.065” | 0.875+/-.125” | 32.5+/-2.5mm | 42.5+/-2.5 | 57.5+/-2.5mm | Notch | Notch |

| Flat Length | 15.88+/-1.65mm | 22.22+/-3.17mm | |||||

| Secondary | 0.315+/-.065” | 0.44+/-.06” | 18.0+/-2.0mm | 27.5+/-2.5 | 37.5+/-2.5mm | ||

| Flat | 8+/-1.65mm | 11.18+/-1.52mm | |||||

| Length | |||||||

| Primary Flat Location | {110}+/-1 deg. | {110}+/-1 deg. | {110}+/-1 deg. | {110}+/-1 deg. | {110}+/-1 deg. | {110}+/-1 deg. | {110}+/-1 deg. |

What are Advantages and Disadvantages of Different Silicon Wafer Orientations

The basic process of producing a silicon wafer is based on an X-ray diffraction method. A diffraction pattern is a picture of a crystal with a specified crystal orientation. In the case of silicon, the X-ray pattern is the best means for verifying the crystal orientation during the machining process. An X-ray diffraction system allows you to achieve a standard accuracy of 0.5 degrees.

The basic process of producing a silicon wafer is based on an X-ray diffraction method. A diffraction pattern is a picture of a crystal with a specified crystal orientation. In the case of silicon, the X-ray pattern is the best means for verifying the crystal orientation during the machining process. An X-ray diffraction system allows you to achieve a standard accuracy of 0.5 degrees.

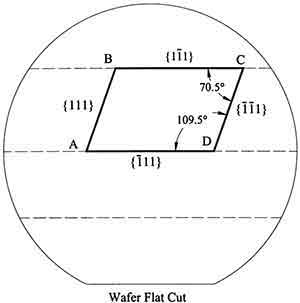

(100) oriented wafers usually break along the (110) plane (actually Si cleaves naturally along the (111) plane, which meet the surface at an angle of 54.7 degrees, the angle between (001) and (111).

Sometimes (100) wafers break along the (100) plane. (100) = (100) + (010) + (001)

The silicon wafer orientations used in manufacturing silicon devices may have different effects on heat dissipation. The flat substrates are often marked with a black stripe, which prevents heat from conduction through flat surfaces. The resulting heat energy is redirected to the interior of the component. Non-silicon wafers are popular in applications requiring extreme temperatures. This enables a component to be oriented in the desired manner for optimum performance.

How to Choose a Silicon Orientation?

Choosing between flat, diamond, planar, and membrane silicon wafers is essential in semiconductor processing. The orientation of silicon wafers is important because of the way that the silicon wafers interact with each other. A thin stripe, also known as a "flat", can prevent heat from penetrating the silicon surface. This feature makes non-silicon wafers a popular choice for applications requiring high temperatures.

The silicon wafer orientations have an impact on heat dissipation. Non-silicon alloys have a black stripe along the surface that prevents heat from conduction through flat surfaces. This prevents heat from permeating the surface and is redirected towards the interior of the component. Because of this advantage, these types of semiconductors are preferred in applications involving extreme temperatures.

Another important consideration when selecting silicon wafer orientations is heat dissipation. For example, a flat wafer is more likely to resist heat than a non-silicon one. It is crucial in applications where it is required to function at extreme temperatures. This makes the silicon wafer an excellent choice for temperature-sensitive components. However, it can also lead to defects. Therefore, it is important to choose the right substrates for the application you are developing.

Other advantages of using silicon wafers include heat dissipation and surface symmetry. The (111) orientation is easier to cleve than the (100) orientation. These differences make it important to choose the proper silicon wafer for your application. Once you've selected the right orientation, you'll be on your way to producing better performing devices and components. So, if you're looking for a new chip, you'll need to consider the following tips to improve your productivity and save money.

Which Silicon Orientation is the Best Option for Semiconductor Fabrication?

Optimum orientation is critical for semiconductor manufacturing. The (100) orientation is the best option for most applications. The (111) silicon orientation is more difficult to cleve. The 100 orientation is easier to cleve. There are other factors that will determine the best silicon wafer orientation for your needs. It's important to remember that the silicon wafer is a semiconductor and it will be used in the same way as other semiconductors.

Choosing the right silicon wafer orientation is very important for semiconductor production. Optimal silicon wafer orientation will maximize the potential of your semiconductor. It will make it possible for you to make devices with maximum efficiency. Using a high-quality substrate ensures that you'll get the best results for your money. The higher the quality of the material, the higher its cost. You can also choose a silicon wafer that has an optimized silicon wafer orientation.

The best silicon wafer orientation is based on the intended use of the semiconductor. During the manufacturing process, silicon is cut into wafers with different orientations. A c-shaped silicon wafer is oriented in a different way. The 111-oriented silicon is easy to cleve, while a 100-oriented one is hard to cleve. For notched substrates, it is easy to cleve.

The X-ray diffraction of silicon wafers is the most common optical technique to determine the crystallographic plane of a silicon wafer. Various kinds of crystallographic planes can be identified with this method. For instance, the thickness of a thin-film silicon semiconductor can be determined by analyzing its structure with x-ray diffraction. This is a non-destructive method and does not require sample preparation.

What Is Silicon Wafer Orientation?

If you're in the semiconductor industry, then you must know what is silicon wafer orientation. The  correct silicon orientation will increase the yield of your semiconductors. You can get the desired yield by cleaving your wafer in the proper orientation. The best way to cleave a silicon wavefer is the same way it was oriented before manufacturing. Unless you're making a superconductor, you can't do it in any other way.

correct silicon orientation will increase the yield of your semiconductors. You can get the desired yield by cleaving your wafer in the proper orientation. The best way to cleave a silicon wavefer is the same way it was oriented before manufacturing. Unless you're making a superconductor, you can't do it in any other way.

Silicon wafer orientation affects the way heat is dissipated. The most effective way to ensure that a crystal is oriented is by examining its X-ray diffraction pattern. This method is highly accurate, and allows for a standard accuracy of 0.5 degrees. In addition, it is more cost-effective than re-machining a wafer to make the same component. This can save you money in the long run.

Orientation refers to the surface alignment of the silicon wafer. You can have it perpendicular to the substrate, horizontally or vertically. This means that the edges are clean or wavy. The wavy edge provides an easier cut to make. Aside from preserving face flatness, this surface orientation provides better face-to-cut contact times. This is an important factor in semiconductor manufacturing.

Besides the cleaving efficiency, another important factor for silicon wafer fabrication is the ability to dissipate heat. The non-silicon wafer has an inner surface that is oriented differently than the outer surface. These materials are more expensive to cleave than their silicon counterparts, but they are very useful for high-temperature applications. This is the primary reason why they are used in semiconductor production.

Silicon wafers are grown on regular crystal structures. As a result, their surface is oriented in the same direction as the crystal structure of the silicon wafer. The orientation of silicon wafers is important because it affects the electronic properties. Similarly, the orientation of the silicon wafers affects the amount of ion implantation, which affects the path of the heat. If you want to use a crystalline silicon chip, you must consider its orientation and its application.

The main difference between 100- and 110-oriented silicon wafers is the degree of impurity removal. A semiconductor can be fabricated with a wide variety of orientations. In general, the two most common types of wafer orientations are c-shaped and flat. The 111-oriented silicon wafers are easier to cleave, but they are more difficult to fabricate. A square or rectangular angled substrate is easier to cleave.

There are many advantages to using 100-oriented silicon wafers. The resulting silicon is a cleaner product with no impurities. However, it does not have the high cost of a crystalline silicon chip. You can find the same type of semiconductor in almost any price range, but it will be much more expensive. This is why it is important to use the right kind of orientation. You can also consider the benefits of the different orientations of a chip.

Orientation is important for semiconductors. Unlike a regular flat, the silicon surface has a diamond-like structure. It is more stable and more durable. It is also easier to process. When you're designing a chip, you'll need to consider the orientation. Usually, the oriented silicon has higher crystalline density, while a non-orientable flat has a higher density of silicon.

Orientation is important for semiconductors. It can affect the conductivity, thermal resistance, and optical properties. The Miller index is a formula for defining the orientation of crystalline silicon. Using this index can help you determine whether you're making the right chips. The optimum orientation depends on your particular requirements. The most common types of orientations are described below. Listed below are the major differences between the three types of wafers.

Optimal silicon wafer orientation is important for semiconductor production. It will help you get the best results from your semiconductors. By selecting the right silicon wafer orientation, you will be able to maximize the efficiency of your semiconductors. So, you've made the right choice. Now, you can make the best products. The first step is to find the right substrate. When buying a silicon wafer, you need to choose one that is compatible with the manufacturing process.