Do you have anything like a PIN Epi Silicon wafer available?

PIN Epi Silicon Wafers

An electrical engineering graduate student requested a quote for the ![]() following:

following:

Reference #274681 for specs and pricing.

Get Your Epi-Silicon Wafer Quote FAST! Or, Buy Online and Start Researching Today!

Epi Silicon Wafer for Solar Cell Research

A graduate student requested a quote for the following.

We want to order some epi silicon wafer for the solar cell. Here's the specification.

substrate: Monocrystalline silicon wafer for solar cell degradation

layer 1: P+ layer (near to the substrate) doping 5*10^19 cm^-3 thickness 1um

layer 2: P- layer (on the top) doping 5*1015 cm^-3 thickness 3um

quantity: 5

Question:

Before we quote the Epi wafers you request, we need information about the substrate. Please answer the following:

- What diameter are you looking for

- What thickness so you need for the substrate?

- What is the orientation you need?

- Are the wafers to be one-side or double-side polished?

- What is the dopant and resistivity you need for the substrate?

We need this information before we can quote.

Answer:

I don't mind the diameter, thickness and resistivity of the substrate. It will be great if you can find the cheapest substrate for us.

We need <100> orientation p dopant substrate and the wafers should be one-side polished.

Could you give me a quote on that? Thank you and have a good day.

UniversityWafer, Inc. Quoted:

We offer:

Item Qty. Description

AL62. 5 Epi wafers 2"Ø P+/P-/N+ Substrate: 2"Ø×250±25µm n-type Si:P[100]±0.5°, Ro=(1-100)Ohmcm, One-side-polished, back-side Alkaline etched, SEMI Flats EPI Layer 1: P+ layer, 6±1µm thick, p-type Si:B doping density 5E19/cc EPI Layer 2 (top layer): P- layer, 5±0.5µm thick, p-type Si:B, doping density 5E15/cc

Reference #115190 for specs and pricing.

Epi Ready Silicon Wafers

We offer many epi-ready silicon wafers for various research applications and projects. These substrates are made from various materials, such as boron, silicon, gallium arsenide, and gallium nitride.

We also provide structural defect characterization data on bare epi-ready wafers based on ELBA used for FTIR thickness uniformity mapping and AFM surface morphology.

What Are Epi-Ready Wafers Used For?

Finished epitaxial silicon wafers are used to construct semiconductor chips found in most technology and gadgets worldwide. The n-type and p-type silicon materials that make up these wafers provide the wireless, photonic, and electronic performance required for these devices and systems.

When a new layer of epitaxial silicon is constructed on a recycled substrate, the result is a repurposed wafer with built-in technical potential to yield results far superior to what would be possible on an unrecycled virgin wafer. The repurposed wafer also benefits from the fact that it can be fabricated at significantly lower than the cost of producing a new, raw substrate wafer.

The process starts with polishing a single-crystal silicon wafer, then exposing it to low-temperature conditions. This treatment helps remove the oxide and ensures that the surface is clean and ready for a thin film of dopant to be applied. This dopant will establish the p-type or n-type silicon properties for the new epitaxial layer to be grown on the wafer.

The dopant can be either boron or phosphorus, which are the most commonly employed dopants in the production of silicon wafers. Once the substrate is prepared for epitaxial growth, the process can be initiated using various methods. These include chemical vapor deposition (CVD), liquid phase epitaxy, and molecular beam epitaxy.

The Most Common Applications and Research

Epitaxial wafers are used in a wide range of applications and research areas. The most popular applications include various semiconductor devices, including highly integrated semiconductor elements (ICs), transistors, diodes, and photovoltaics. They are also commonly utilized as the substrate for lithography, lasers, and light-emitting diodes (LED). As the demand for LED lights continues to grow, so does the need for high-quality, wide-bandgap silicon carbide (SiC) substrates.

SiC substrates offer a higher operating temperature range than other substrate materials and are well-suited to short-wavelength optoelectronic devices, high-temperature electronics, and power/high-frequency electronic devices. They also have a much wider bandgap than GaAs and Si, which allows them to be used in power electronics where current density is important.

The most common method for preparing SiC wafers is through the chemical vapor deposition of an EPI layer. The EPI process involves using a quartz reaction chamber and a silicon susceptor to support the wafers and create a uniform environment for epitaxial growth. This process can be achieved using various epitaxial growth techniques, including chemical vapor deposition CVD, liquid phase epitaxy LPE, and molecular beam epitaxy (MBE).

Another popular application for epi-ready silicon wafers is the foundation for photovoltaic device production. The high quality of the epi-ready surface, coupled with gettering to improve carrier lifetimes, makes these wafers a great alternative to standard Czochralski (Cz) substrates.

The Process of Epitaxial Deposition

Epitaxy creates a crystalline foundation layer on which to build semiconductor devices. This can be accomplished by depositing a thin film of a material engineered to have particular electrical properties or by placing an underlayer in a specific Ori to create either compressive or tensile strain that improves electrical conductivity.

A variety of techniques are used for epitaxial deposition, including vapor phase epitaxy (VPE), molecular beam epitaxy (MBE), and liquid phase epitaxy (LPE). All of these methods use a combination of chemical vapor deposition and thermal expansion to form atomic layers of material.

The growth process is usually conducted in a UHV environment, and all of the elemental sources are kept under a vacuum to prevent contamination, thus making it possible to monitor the atomic-level formation of an interface with an extremely high degree of accuracy.

The image above shows TEM images of Si cap (10 nm)/SiGe blanket and Si buffer (5 nm) multi-stack layers on a P/E wafer grown with wet DHF pre-cleaning followed by H2 bake at 700 deg C. HRXRD was performed to characterize the strained layer, which had a Ge concentration of 32% and an Ori of (011 / 2). Applied’s advanced epi technology allows for highly uniform and precise placement of dopant atoms across the film's surface, along with deficient defect levels and high crystalline quality.

The Benefits of Epitaxial Wafers

Besides being a cost-effective option, epi-ready silicon wafers help manufacturers produce more powerful semiconductor devices. They can be used to make silicon chips that are used in many electronic products, including computers, consumer electronics, telecommunications devices, and even self-driving cars. As a result, the demand for these wafers is expected to increase.

In addition, a key benefit of using these wafers is that they can be used to improve the reliability of IC devices by reducing the amount of crystal-originated particles (COP). Imperfections in polished wafers cause COPs and can cause device failure. Fortunately, by using the Epi process on P/E wafers, manufacturers can avoid these defects and provide superior product performance.

The Epitaxial growth process is a great way to create a layer of material that can be patterned on top of the bare silicon substrate. This process can be used to create a wide range of semiconductor devices, such as transistors, diodes, and photodiodes. The high-quality films that are produced by this method are also very stable and can withstand an extensive range of temperatures.

The global market for compound semiconductor epitaxial wafers is divided into several segments by the end user. These segments include digital economy, industrial and energy & power, defense/security, transport, and consumer electronics.

Growing Dual Epi Layers on Substrate

A Semiconductor Device Engineer requested the following quote:

Can you guys grow dual epi layers on 4 inch N+ substrate? Please see below for details.

UniversityWafer, Inc. Quoted:

We offer:

Item Qty. Description

HJ48. 25/50/100 p/n/n+ Epi wafers, 4" (100.0±0.5mm)Ø×420±25µm

Substrate: n-type Si:As[111-4°]±0.5°, Ro=(0.0015-0.0030)Ohmcm,

TTV<5µm, Bow<40µm, Warp<40µm, TIR<6µm,

One-side-polished, back-side etched, 1 SEMI Flat, Edges: rounded,

Backside seal: 17.5±2.5µm Si monolayer by mass transfer (necessary to prevent autodoping),

EPI Layer 1: 20±2µm thick, n-type Si:P, Ro=4.6±0.4Ohmcm,

EPI Layer 2 (top layer): 25.0±2.5µm thick, p-type Si:B, Ro=0.0100±0.0001hmcm,

Overall: SF<10/cm², Slips<0.15 (Edge exclusion 3mm) , LPD≤5 @>20µm, Total LLS≤16@>0.5µm, Haze, foreign matter, scratches, edge chips: all none, Others per SEMI, Sealed in Empak or equivalent cassette.

Reference #260691 for specs and pricing.

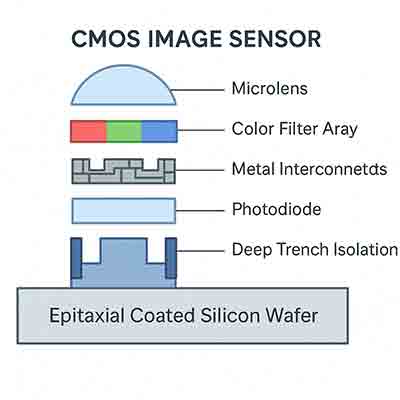

UniversityWafer, Inc. offers Epitaxial Coated Silicon Wafers tailored for applications demanding  ultra-clean, defect-free active layers. These wafers are ideal for high-performance CMOS image sensors, power devices, and RFICs where precise control of doping profiles is critical.

ultra-clean, defect-free active layers. These wafers are ideal for high-performance CMOS image sensors, power devices, and RFICs where precise control of doping profiles is critical.

Our epi wafers are grown using chemical vapor deposition (CVD) on a heavily doped monocrystalline silicon substrate, delivering superior electrical performance and device reliability.

-

CMOS Image Sensors – Low dark current, high dynamic range

-

Power Devices (IGBTs, MOSFETs) – Improved breakdown voltage and switching speed

-

RF and Microwave Circuits – Enhanced signal isolation and linearity

-

Photodetectors and Photodiodes – Low defect densities, high purity layers

-

MEMS Devices – Compatible with deep trench and high-aspect ratio etching

📐 Specifications

| Parameter | Typical Values |

|---|---|

| Wafer Diameter | 100 mm, 150 mm, 200 mm, 300 mm |

| Orientation | <100>, <111> |

| Epi Layer Thickness | 2 µm – 20 µm |

| Epi Layer Resistivity | 5–25 Ohm·cm (custom available) |

| Substrate Resistivity | 0.01–0.05 Ohm·cm |

| Doping Type | P- or N-type (Bor, Phos, Arsenic) |

| Surface Finish | DSP, SSP, Prime Grade |

📦 Available Formats

-

Prime Grade

-

Test Grade

-

DSP (Double Side Polished)

-

Ultra-flat & Low TTV Options

🌍 Why Buy from UniversityWafer?

-

Decades of experience supporting university & industrial R&D

-

Global shipping with fast turnaround

-

Responsive technical support

-

Competitive pricing for small and bulk quantities

Silicon Epi Wafers Sale - Many More Available! Just ask!

6" Epitaxial Silicon Wafers

| Item | Qty in Stock | Substrate | EPI | Comment | |||||

|---|---|---|---|---|---|---|---|---|---|

| Size | Type | Res Ωcm | Surf. | Thick μm | Type | Res Ωcm | |||

| G541 | 150 | 6"Øx675μm | n- Si:P[100] | 0.001-0.002 | P/EOx | 0.016 | n- Si:P | 0.32-0.46 | n/n+ |

4" Epitaxial Silicon Wafers

| Item | Qty in Stock | Substrate | EPI | Comment | |||||

|---|---|---|---|---|---|---|---|---|---|

| Size | Type | Res Ωcm | Surf. | Thick μm | Type | Res Ωcm | |||

| D274 | 6 | 4"Øx360μm | n- Si:Sb[111] | 0.005-0.020 | P/E | 20 | n- Si:P | 360 - 440 | n/n+ |

| E4_151 | 8 | 4"Øx400μm | p- Si:B[111] | 0.01-0.10 | P/E | 6.5 22±1.5 |

p- Si:B p- Si:B |

3.6±10% 300±50 |

P/P/P+ |

| E4_134 | 7 | 4"Øx525μm | p- Si:B[111] | 0.01-0.02 | P/E | 8.1±1 6.85±0.75 |

p- Si:B p- Si:B |

4.5±10% 0.75±0.15 |

P/P/P+ |

| E4_104 | 6 | 4"Øx380μm | p- Si:B[111] | 0.008-0.020 | P/EOx | 10.5 | p- Si:B | 570±10% | p/p+ |

| E4_22 | 3 | 4"Øx440μm | p- Si:B[111] | 0.008-0.020 | P/E | 20 | p- Si:B | 0.15 ±10% | P/P+ |

| E4_106 | 4 | 4"Øx440μm | p- Si:B[111] | 0.008-0.020 | P/E | 20 | p- Si:B | 0.25±10% | P/P+ |

| E4_105 | 7 | 4"Øx525μm | p- Si:B[111] | 0.001-0.005 | P/E | 20 | p- Si:B | 175±10% | P/P+ |

| E4_26 | 10 | 4"Øx440μm | p- Si:B[111] | 0.008-0.020 | P/E | 21 | p- Si:B | 150 ±10% | P/P+ |

| E4_107 | 8 | 4"Øx380μm | p- Si:B[111] | 0.008-0.020 | P/EOx | 23 | p- Si:B | 200±10% | P/P+ |

| E4_108 | 9 | 4"Øx380μm | p- Si:B[111] | 0.008-0.020 | P/EOx | 23 | p- Si:B | 80±10% | P/P+ |

| E4_42 | 4 | 4"Øx440μm | p- Si:B[111] | 0.008-0.020 | P/E | 32 | p- Si:B | 600 ±10% | P/P+ |

| E4_109 | 8 | 4"Øx440μm | p- Si:B[111] | 0.01-0.02 | P/E | 32.5 | p- Si:B | 100±10% | P/P+ |

| E4_21 | 5 | 4"Øx380μm | p- Si:B[111] | 0.008-0.020 | P/EOx | 40 | p- Si:B | 550 ±10% | P/P+ |

| E4_133 | 3 | 4"Øx525μm | p- Si:B[111] | 0.01-0.02 | P/E | 14 10 |

n- Si:P p- Si:B |

2.5±0.3 15 |

N/P/P+ |

| E4_135 | 2 | 4"Øx525μm | p- Si:B[111] | 0.01-0.02 | P/E | 14 10 |

n- Si:P p- Si:B |

2.5±10% 9±10% |

n/p/p+ |

| E4_113 | 8 | 4"Øx525μm | n- Si:As[111] | 0.0010-0.0035 | P/E | 20 10 |

p- Si:B n- Si:P |

10±1.5 5.5±0.7 |

P/N/N+ |

| E4_127 | 5 | 4"Øx381μm | n- Si:As[111] | 0.0010-0.0035 | P/E | 33 10 |

p- Si:B n- Si:P |

12±10% 4±10% |

P/N/N+ |

| E4_147 | 9 | 4"Øx525μm | n- Si:As[111] | 0.0010-0.0035 | P/E | 33±5 9 |

p- Si:B n- Si:P |

12±2 4 |

P/N/N+ |

| E4_128 | 6 | 4"Øx525μm | n- Si:As[111] | 0.0010-0.0035 | P/E | 37 16.5 |

p- Si:B n- Si:P |

35±10% 12.5±10% |

P/N/N+ |

| E4_124 | 7 | 4"Øx525μm | n- Si:As[111] | 0.0010-0.0035 | P/E | 45 7±1 |

p- Si:B n- Si:P |

13±10% 12±10% |

P/N/N+ |

| E4_144 | 6 | 4"Øx525μm | n- Si:As[111] | 0.0010-0.0035 | P/E | 45 7 |

p- Si:B n- Si:P |

14.5±10% 12±10% |

P/N/N+ |

| E4_132 | 8 | 4"Øx525μm | n- Si:As[111] | 0.002-0.005 | P/E | 88 88 |

p- Si:B n- Si:P |

80.5±10% 27±10% |

P/N/N+ |

| E4_145 | 7 | 4"Øx380μm | n- Si:As[111] | 0.002-0.005 | P/E | 105 26 |

p- Si:B n- Si:P |

0.0035±10% 5±10% |

P/N/N+ |

| E4_122 | 5 | 4"Øx525μm | n- Si:As[111] | 0.0010-0.0035 | P/E | 10.15 6.8±0.8 |

n- Si:P n- Si:P |

3.8±0.5 0.55±0.15 |

N/N/N+ |

| E4_84 | 9 | 4"Øx380μm | n- Si:As[111] | 0.004-0.008 | P/EOx | 16.5 | n- Si:P | 35 ±10% | N/N+ |

| E4_143 | 8 | 4"Øx508μm | n- Si:As[111] | 0.002-0.005 | P/E | 19±1.3 54.5±3.6 |

n- Si:P n- Si:P |

25±5 4.4 |

N/N/N+ |

| E4_68 | 9 | 4"Øx380μm | n- Si:As[111] | 0.001-0.005 | P/EOx | 20 | n- Si:P | 270 ±10% | N/N+ |

| E4_90 | 8 | 4"Øx400μm | n- Si:As[111] | 0.001-0.005 | P/E | 20 | n- Si:P | 0.09 ±10% | N/N+ |

| E4_10 | 25 | 4"Øx400μm | n- Si:As[111] | 0.001-0.005 | P/E | 20 | n- Si:P | 90±10% | N/N+ |

| E4_89 | 9 | 4"Øx400μm | n- Si:As[111] | 0.001-0.005 | P/E | 20 | n- Si:P | 0.07 ±10% | N/N+ |

| E4_91 | 9 | 4"Øx400μm | n- Si:As[111] | 0.001-0.005 | P/E | 20 | n- Si:P | 0.13 ±10% | N/N+ |

| E4_92 | 11 | 4"Øx400μm | n- Si:As[111] | 0.001-0.005 | P/E | 20 | n- Si:P | 0.15 ±10% | N/N+ |

| E4_93 | 7 | 4"Øx400μm | n- Si:As[111] | 0.001-0.005 | P/E | 20 | n- Si:P | 0.19 ±10% | N/N+ |

| E4_30 | 7 | 4"Øx525μm | n- Si:As[111] | 0.001-0.005 | P/E | 20 | n- Si:P | 65 ±10% | N/N+ |

| E4_116 | 5 | 4"Øx525μm | n- Si:As[111] | 0.0010-0.0035 | P/E | 20 10 |

n- Si:P n- Si:P |

7±10% 2±0.4 |

N/N/N+ |

| E4_69 | 8 | 4"Øx380μm | n- Si:As[111] | 0.001-0.005 | P/EOx | 21 | n- Si:P | 150 ±10% | N/N+ |

| E4_117 | 11 | 4"Øx525μm | n- Si:As[111] | 0.0010-0.0035 | P/E | 22.5 28.5 |

n- Si:P n- Si:P |

12±10% 2±10% |

N/N/N+ |

| E4_129 | 9 | 4"Øx525μm | n- Si:As[111] | 0.0010-0.0035 | P/E | 26 11 |

n- Si:P n- Si:P |

18±10% 2±10% |

N/N/N+ |

| E4_54 | 9 | 4"Øx525μm | n- Si:As[111] | 0.001-0.005 | P/E | 27 | n- Si:P | 220 ±10% | N/N+ |

| E4_52 | 15 | 4"Øx525μm | n- Si:As[111] | 0.001-0.005 | P/E | 27.5 | n- Si:P | >250 | N/N+ |

| E4_53 | 9 | 4"Øx525μm | n- Si:As[111] | 0.001-0.005 | P/E | 28 | n- Si:P | 165 ±10% | N/N+ |

| E4_125 | 14 | 4"Øx525μm | n- Si:As[111] | 0.0010-0.0035 | P/E | 28 8 - 12 |

n- Si:P n- Si:P |

11±10% 1 - 3 |

N/N/N+ |

| E4_120 | 19 | 4"Øx525μm | n- Si:As[111] | 0.0010-0.0035 | P/E | 28 9 - 11 |

n- Si:P n- Si:P |

8 - 11 1 - 3 |

N/N/N+ |

| E4_111 | 20 | 4"Øx525μm | n- Si:As[111] | 0.0010-0.0035 | P/E | 30 15 5 |

n- Si:P n- Si:P n- Si:P |

11±10% 4±10% 1.5±10% |

N/N/N/N+ |

| E4_123 | 10 | 4"Øx525μm | n- Si:As[111] | 0.0010-0.0035 | P/E | 39.5 12 |

n- Si:P n- Si:P |

29±10% 4±10% |

N/N/N+ |

| E4_81 | 20 | 4"Øx380μm | n- Si:As[111] | 0.004-0.008 | P/EOx | 41.5 | n- Si:P | >300 ±10% | N/N+ |

| E4_77 | 18 | 4"Øx380μm | n- Si:As[111] | 0.004-0.008 | P/EOx | 41.5 | n- Si:P | >200 | N/N+ |

| E4_17 | 2 | 4"Øx380μm | n- Si:As[111] | 0.004-0.008 | P/EOx | 43 | n- Si:P | 600 ±10% | N/N+ |

| E4_79 | 8 | 4"Øx380μm | n- Si:As[111] | 0.004-0.008 | P/EOx | 43 | n- Si:P | >200 | N/N+ |

| E4_16 | 1 | 4"Øx380μm | n- Si:As[111] | 0.004-0.008 | P/EOx | 43 | n- Si:P | 340 ±10% | N/N+ |

| E4_115 | 6 | 4"Øx525μm | n- Si:As[111] | 0.0010-0.0035 | P/E | 50 15 |

n- Si:P n- Si:P |

36±4 5.4±0.7 |

N/N/N+ |

| E4_24 | 10 | 4"Øx525μm | n- Si:As[111] | 0.001-0.005 | P/E | 75 | n- Si:P | 66 ±10% | N/N+ |

| E4_59 | 9 | 4"Øx525μm | n- Si:As[111] | 0.001-0.005 | P/E | 78 | n- Si:P | 25 ±10% | N/N+ |

| E4_5 | 15 | 4"Øx525μm | n- Si:As[111] | 0.001-0.005 | P/EOx | 78 | n- Si:P | 20 ±10% | N/N+ |

| E4_94 | 5 | 4"Øx525μm | n- Si:As[111] | 0.001-0.005 | P/E | 80 | n- Si:P | 17.5 ±10% | N/N+ |

| E4_112 | 4 | 4"Øx525μm | n- Si:As[111] | 0.0010-0.0035 | P/E | 80 10 |

n- Si:P n- Si:P |

60±10% 2±1 |

N/N/N+ |

| E4_146 | 7 | 4"Øx525μm | n- Si:As[111] | 0.0010-0.0035 | P/E | 80 10 |

n- Si:P n- Si:P |

70±10% 2±1 |

N/N/N+ |

| E4_137 | 8 | 4"Øx525μm | n- Si:Sb[111] | 0.008-0.020 | P/E | 22.5 15 |

p- Si:B n- Si:P |

15±10% 6±0.9 |

P/N/N+ |

| E4_136 | 7 | 4"Øx525μm | n- Si:Sb[111] | 0.008-0.020 | P/E | 38 18 |

p- Si:B n- Si:P |

55±10% 10±10% |

P/N/N+ |

| E4_9 | 4 | 4"Øx525μm | n- Si:Sb[111] | 0.005-0.020 | P/E | 14 | n- Si:P | 4.25 ±10% | N/N+ |

| E4_55 | 4 | 4"Øx525μm | n- Si:Sb[111] | 0.005-0.020 | P/E | 15 | n- Si:P | 90 ±10% | N/N+ |

| E4_27 | 10 | 4"Øx525μm | n- Si:Sb[111] | 0.005-0.020 | P/E | 18 | n- Si:P | 0.25 ±10% | N/N+ |

| E4_56 | 6 | 4"Øx400μm | n- Si:Sb[111] | 0.005-0.020 | P/E | 20 | n- Si:P | 75 ±10% | N/N+ |

| E4_57 | 8 | 4"Øx400μm | n- Si:Sb[111] | 0.005-0.020 | P/E | 20 | n- Si:P | 136 ±10% | N/N+ |

| E4_58 | 3 | 4"Øx400μm | n- Si:Sb[111] | 0.005-0.020 | P/E | 20 | n- Si:P | 101 ±10% | N/N+ |

| E4_98 | 5 | 4"Øx400μm | n- Si:Sb[111] | 0.006-0.020 | P/E | 20 | n- Si:P | 300±10% | N/N+ |

| E4_97 | 9 | 4"Øx400μm | n- Si:Sb[111] | 0.006-0.020 | P/E | 21 | n- Si:P | 400±10% | N/N+ |

| E4_100 | 15 | 4"Øx525μm | n- Si:Sb[111] | 0.005-0.020 | P/E | 22.5 | n- Si:P | 12.5±10% | N/N+ |

| E4_2 | 16 | 4"Øx400μm | n- Si:Sb[111] | 0.005-0.020 | P/E | 25 | n- Si:P | 0.08 ±10% | N/N+ |

| E4_14 | 2 | 4"Øx400μm | n- Si:Sb[111] | 0.005-0.020 | P/E | 25 | n- Si:P | 0.04 ±10% | N/N+ |

| E4_66 | 5 | 4"Øx360μm | n- Si:Sb[111] | 0.005-0.020 | P/E | 37.5 | n- Si:P | 270 ±10% | N/N+ |

| E4_95 | 10 | 4"Øx400μm | n- Si:Sb[111] | 0.006-0.020 | P/E | 37.5 | n- Si:P | 85±10% | N/N+ |

| E4_138 | 4 | 4"Øx525μm | n- Si:Sb[111] | 0.008-0.020 | P/E | 58 15 5 |

n- Si:P n- Si:P n- Si:P |

60±10% 8±10% 3±10% |

N/N/N/N+ |

| E4_148 | 9 | 4"Øx460μm | n- Si:Sb[111] | 0.007-0.020 | P/E | 60 20 |

n- Si:P n- Si:P |

40.5±4.5 10±2 |

N/N/N+ |

| E4_60 | 9 | 4"Øx525μm | n- Si:Sb[111] | 0.005-0.020 | P/E | 60 | n- Si:P | 60 ±10% | N/N+ |

| E4_12 | 10 | 4"Øx525μm | n- Si:Sb[111] | 0.005-0.020 | P/E | 60 | n- Si:P | 58.75 ±10% | N/N+ |

| E4_19 | 6 | 4"Øx525μm | n- Si:Sb[111] | 0.005-0.020 | P/E | 70 | n- Si:P | 60 ±10% | N/N+ |

| E4_61 | 9 | 4"Øx525μm | n- Si:Sb[111] | 0.005-0.020 | P/E | 75 | n- Si:P | 125 ±10% | N/N+ |

| E4_44 | 6 | 4"Øx525μm | n- Si:Sb[111] | 0.005-0.020 | P/E | 100 | n- Si:P | 420±10% | N/N+ |

3" Epitaxial Silicon Wafers

| Item | Qty in Stock | Substrate | EPI | Comment | |||||

|---|---|---|---|---|---|---|---|---|---|

| Size | Type | Res Ωcm | Surf. | Thick μm | Type | Res Ωcm | |||

| K827 | 4 | 3"Øx508μm | p- Si:B[111] | 0.008-0.020 | P/E | 12.5 140±10 |

p- Si:B n- Si:P |

2.35 33.60 |

p+ |

| 8611 | 50 | 3"Øx381μm | n- Si:As[111-4°] | 0.001-0.005 | P/E | 5.5 | n- Si:P | 0.31 - 0.33 | n/n+ |

| F667 | 120 | 3"Øx525μm | n- Si:P[111] | 0.001-0.005 | P/E | 4.5 | n- Si:P | 1.1 - 1.4 | n/n+, Sealed in cassettes of 24 wafers |

| E3_32 | 18 | 3"Øx381μm | n- Si:As[111] | 0.001-0.005 | P/E | 5.5 | n- Si:P | 1.06±10% | N/N+ |

| E3_40 | 5 | 3"Øx381μm | n- Si:As[111] | 0.001-0.005 | P/E | 11 | n- Si:P | 17.5±10% | N/N+ |

| E3_2 | 9 | 3"Øx381μm | n- Si:As[111] | 0.001-0.005 | P/E | 12 | n- Si:P | 16±10% | N/N+ |

| E3_54 | 8 | 3"Øx381μm | n- Si:As[111] | 0.001-0.005 | P/E | 12 | n- Si:P | 2.1±10% | N/N+ |

| E3_55 | 12 | 3"Øx381μm | n- Si:As[111] | 0.001-0.005 | P/E | 12 | n- Si:P | 1.7±10% | N/N+ |

| E3_24 | 18 | 3"Øx381μm | n- Si:As[111] | 0.001-0.005 | P/E | 12 | n- Si:P | 1.3±10% | N/N+ |

| E3_38 | 15 | 3"Øx381μm | n- Si:As[111] | 0.001-0.005 | P/E | 12 | n- Si:P | 1.3±10% | N/N+ |

| E3_62 | 14 | 3"Øx381μm | n- Si:As[111] | 0.001-0.005 | P/E | 12 | n- Si:P | 1.8±10% | N/N+ |

| E3_30 | 15 | 3"Øx381μm | n- Si:As[111] | 0.001-0.005 | P/E | 13 | n- Si:P | 1.35±10% | N/N+ |

| E3_48 | 9 | 3"Øx381μm | n- Si:As[111] | 0.001-0.005 | P/E | 15.5 | n- Si:P | 9.5±10% | N/N+ |

| E3_22 | 12 | 3"Øx381μm | n- Si:As[111] | 0.001-0.005 | P/E | 15.5 | n- Si:P | 9.5±10% | N/N+ |

| E3_42 | 4 | 3"Øx381μm | n- Si:As[111] | 0.001-0.005 | P/E | 18 | n- Si:P | 0.05±10% | N/N+ |

| E3_3 | 20 | 3"Øx381μm | n- Si:As[111] | 0.001-0.005 | P/E | 22 | n- Si:P | 4.8±10% | N/N+ |

| E3_5 | 18 | 3"Øx381μm | n- Si:As[111] | 0.001-0.005 | P/E | 22 | n- Si:P | 4±10% | N/N+ |

| E3_27 | 5 | 3"Øx381μm | n- Si:As[111] | 0.001-0.005 | P/E | 22 | n- Si:P | 4±10% | N/N+ |

| E3_63 | 20 | 3"Øx381μm | n- Si:As[111] | 0.001-0.005 | P/E | 28 | n- Si:P | 16.5±10% | N/N+ |

| E3_17 | 6 | 3"Øx381μm | n- Si:As[111] | 0.001-0.005 | P/E | 28.5 | n- Si:P | 4±10% | N/N+ |

| E3_25 | 9 | 3"Øx381μm | n- Si:As[111] | 0.001-0.005 | P/E | 28.5 | n- Si:P | 20±10% | N/N+ |

| E3_53 | 8 | 3"Øx381μm | n- Si:As[111] | 0.001-0.005 | P/E | 30 | n- Si:P | 4.5±10% | N/N+ |

| E3_15 | 15 | 3"Øx355μm | n- Si:As[111] | 0.001-0.005 | P/E | 34 | n- Si:P | 9.5±10% | N/N+ |

| E3_16 | 15 | 3"Øx355μm | n- Si:As[111] | 0.001-0.005 | P/E | 34 | n- Si:P | 12±10% | N/N+ |

| E3_51 | 8 | 3"Øx355μm | n- Si:As[111] | 0.001-0.005 | P/E | 34 | n- Si:P | 11±10% | N/N+ |

| E3_4 | 9 | 3"Øx355μm | n- Si:As[111] | 0.001-0.005 | P/E | 36 | n- Si:P | 4±10% | N/N+ |

| E3_23 | 5 | 3"Øx381μm | n- Si:As[111] | 0.001-0.005 | P/E | 37.5 | n- Si:P | 0.6±10% | N/N+ |

| E3_1 | 20 | 3"Øx381μm | n- Si:As[111] | 0.001-0.005 | P/E | 41 | n- Si:P | 25±10% | N/N+ |

| E3_41 | 9 | 3"Øx381μm | n- Si:As[111] | 0.001-0.005 | P/E | 42 | n- Si:P | 20.5±10% | N/N+ |

| E3_19 | 18 | 3"Øx381μm | n- Si:As[111] | 0.001-0.005 | P/E | 42.5 | n- Si:P | 17±10% | N/N+ |

| E3_14 | 8 | 3"Øx355μm | n- Si:As[111] | 0.001-0.005 | P/E | 52.5 | n- Si:P | 12.5±10% | N/N+ |

| E3_56 | 19 | 3"Øx381μm | n- Si:As[111] | 0.001-0.005 | P/E | 56 | n- Si:P | 12±10% | N/N+ |

| E3_45 | 8 | 3"Øx508μm | n- Si:As[111] | 0.001-0.005 | P/E | 70 | n- Si:P | 73±10% | N/N+ |

| E3_33 | 10 | 3"Øx508μm | n- Si:As[111] | 0.001-0.005 | P/E | 72 | n- Si:P | 12.5±10% | N/N+ |

| E3_7 | 19 | 3"Øx508μm | n- Si:As[111] | 0.001-0.005 | P/E | 73 | n- Si:P | 84±10% | N/N+ |

| E3_44 | 8 | 3"Øx508μm | n- Si:As[111] | 0.001-0.005 | P/E | 75 | n- Si:P | 13±10% | N/N+ |

| E3_49 | 18 | 3"Øx508μm | n- Si:As[111] | 0.001-0.005 | P/E | 75 | n- Si:P | 11±10% | N/N+ |

| E3_12 | 8 | 3"Øx508μm | n- Si:As[111] | 0.001-0.005 | P/E | 80 | n- Si:P | 12±10% | N/N+ |

| E3_10 | 15 | 3"Øx375μm | n- Si:As[111] | 0.001-0.005 | P/E | 85 | n- Si:P | 22.5 ±10% | N/N+ |

| E3_34 | 10 | 3"Øx508μm | n- Si:As[111] | 0.001-0.005 | P/E | 85 | n- Si:P | 19.5±10% | N/N+ |

| E3_20 | 20 | 3"Øx508μm | n- Si:As[111] | 0.001-0.005 | P/E | 85 | n- Si:P | 66±10% | N/N+ |

| E3_59 | 18 | 3"Øx508μm | n- Si:As[111] | 0.001-0.005 | P/E | 90 18 |

n- Si:P n- Si:P |

41±10% 5±10% |

N/N/N+ |

| E3_43 | 18 | 3"Øx508μm | n- Si:As[111] | 0.001-0.005 | P/E | 96 | n- Si:P | 30±10% | N/N+ |

| E3_11 | 19 | 3"Øx508μm | n- Si:As[111] | 0.001-0.005 | P/E | 100 | n- Si:P | 16 ±10% | N/N+ |

| E3_13 | 2 | 3"Øx508μm | n- Si:As[111] | 0.001-0.005 | P/E | 100 | n- Si:P | 12±10% | N/N+ |

| E3_21 | 10 | 3"Øx508μm | n- Si:As[111] | 0.001-0.005 | P/E | 100 | n- Si:P | 20±10% | N/N+ |

| E3_8 | 5 | 3"Øx508μm | n- Si:As[111] | 0.001-0.005 | P/E | 100 | n- Si:P | 21±10% | N/N+ |

| E3_37 | 14 | 3"Øx508μm | n- Si:As[111] | 0.001-0.005 | P/E | 135 | n- Si:P | 35±10% | N/N+ |

| E3_39 | 4 | 3"Øx508μm | n- Si:As[111] | 0.001-0.005 | P/E | 140 | n- Si:P | 31±10% | N/N+ |

| E3_29 | 10 | 3"Øx508μm | n- Si:As[111] | 0.001-0.005 | P/E | 145 | n- Si:P | 38±10% | N/N+ |

| E3_26 | 18 | 3"Øx508μm | n- Si:As[111] | 0.001-0.005 | P/E | 145 | n- Si:P | 25±10% | N/N+ |

| E3_9 | 3 | 3"Øx508μm | n- Si:As[111] | 0.001-0.005 | P/E | 150 | n- Si:P | 44±10% | N/N+ |

| E3_28 | 15 | 3"Øx508μm | n- Si:As[111] | 0.001-0.005 | P/E | 158 | n- Si:P | 67±10% | N/N+ |

| E3_31 | 10 | 3"Øx381μm | n- Si:Sb[111] | 0.005-0.020 | P/E | 8 | n- Si:P | 0.63±10% | N/N+ |

| E3_35 | 15 | 3"Øx381μm | n- Si:Sb[111] | 0.005-0.020 | P/E | 22.5 | n- Si:P | 0.07±10% | N/N+ |

| E3_6 | 12 | 3"Øx381μm | n- Si:Sb[111] | 0.005-0.020 | P/E | 30 | n- Si:P | 6.75±10% | N/N+ |

| E3_64 | 10 | 3"Øx330μm | n- Si:Sb[111] | 0.005-0.018 | P/E | 75 25 |

n- Si:P n- Si:P |

40±10% 2.5±10% |

N/N/N+ |

100±10 N/PHn 40 - 60 ohm-cm n/p+, Back-side polished after Epi deposition

certificate available

100mm P/B (111) 400μm .01-0.10 ohm-cm SSP

6.522±1.5 p- Si:B p- Si:B .6±10% 300±50 P/P/P+

76.2mm N/As (111) 0.001-0.005 ohm-cm SSP

75 n- Si:P 11±10% N/N+