I am looking to purchase a couple of Ø50~80mm x 1mm thick wafers with NIST traceable flatness specifications to use as standards in the validation of our Tropel interferometry tool. Do you sell these. I would like each sample to have 2 different WARP values.

Substrates Used for NIST Traceability

NIST Traceable Flatness Specs

A production manager of semiconductor company requested a quote for the following.

Reference #320997 for specs and pricing.

Get Your Quote FAST! Or, Buy Online and Start Researching Today!

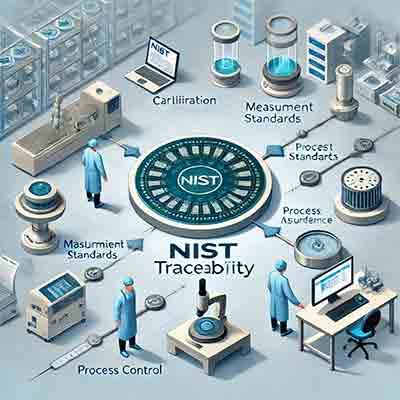

What is NIST Traceability as it Relates to Semiconductors?

NIST traceability in the context of semiconductors ensures that measurements and  standards used in the semiconductor manufacturing process are accurate, reliable, and can be linked back to the National Institute of Standards and Technology (NIST) through an unbroken chain of comparisons. This traceability is critical for maintaining the precision and consistency required in semiconductor fabrication, which involves extremely fine and intricate processes.

standards used in the semiconductor manufacturing process are accurate, reliable, and can be linked back to the National Institute of Standards and Technology (NIST) through an unbroken chain of comparisons. This traceability is critical for maintaining the precision and consistency required in semiconductor fabrication, which involves extremely fine and intricate processes.

Key aspects of NIST traceability in semiconductors include:

-

Calibration of Equipment: Semiconductor manufacturing relies on highly precise equipment for processes like lithography, etching, and deposition. These instruments must be regularly calibrated using standards traceable to NIST to ensure their accuracy.

-

Measurement Standards: Physical measurements such as length, thickness, electrical properties (e.g., resistance, capacitance), and material properties (e.g., purity, composition) must adhere to standards that can be traced back to NIST.

-

Process Control: Precise control of manufacturing processes is crucial in semiconductor fabrication. Traceability ensures that process control measurements are accurate, enabling consistent production of high-quality semiconductors.

-

Quality Assurance: NIST traceability is a fundamental component of quality assurance programs in semiconductor manufacturing. It helps in maintaining product specifications and compliance with industry standards.

-

Research and Development: In R&D, NIST traceability supports the development of new semiconductor technologies by providing reliable measurement standards, ensuring that experimental results are accurate and reproducible.

-

Documentation and Certification: Detailed documentation of the traceability chain, including calibration records and measurement uncertainties, is essential. Certification of traceability provides confidence to customers and regulatory bodies that the semiconductor products meet specified standards.

By ensuring that all measurements and standards in the semiconductor industry are traceable to NIST, manufacturers can achieve the high level of precision and reliability necessary for producing advanced semiconductor devices.