For our research of the electrodes for organic

solar cells, we need silicon wafers with elevated conductivity as the substrate for the

grow of carbon nanotubes from deposited nano-nuclei of gold on the

surface of the wafers. The wafers should have dimensions about 15x15

to 25x25 mm. Please, can you send me the proforma account for 50 - 100.

Substrates for Organic Solar Cells

Silicon Wafers for Organic Solar Cells Research

A professor for materials for electrical engineering researching electrodes for organic solar cells requested a quote for the following.

tem Qty. Description

Q98b. 3/6 Silicon wafers, per SEMI, P/E 4"Ø×525±25µm, p-type Si:B[100], Ro=(0.010-0.020)Ohmcm, One-side-polished, back-side Alkaline etched, SEMI Flats (two), Each wafer diced into at least 20 of 16×16mm squares, sides parallel to [110], Shipped on dicing tape, in single wafer cassettes.

Reference #93970 for specs and pricing.

Thin Glass Wafers for Organic Solar Cells

A molecular photonics researcher requested a quote for the following.

Would it be possible for you to provide me with a few ultrathin glass slides for carrying some tests. I am looking to produce glass panels coated with fluorescent films to use with organic solar cells. I would very much like to try your slides so if you could provide a few free samples I would be happy to arrange some trials.

Reference #253292 for specs and pricing.

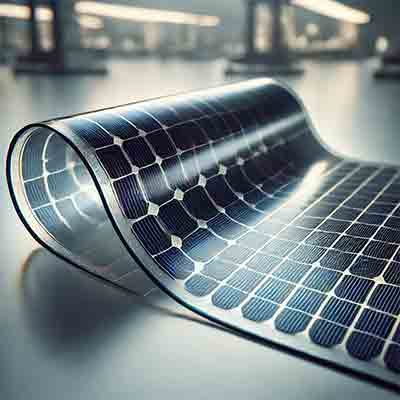

What Are Organic Solar Cells?

Organic solar cells (OSCs) are a type of photovoltaic device that use organic molecules or polymers as the active material to convert sunlight into electricity. Unlike traditional silicon-based solar cells, which are inorganic, organic solar cells are made from carbon-based materials. These materials can be small molecules, polymers, or a combination of both.

Key Features of Organic Solar Cells:

-

Lightweight and Flexible: Organic materials are generally lightweight and can be

processed onto flexible substrates, making them suitable for applications where flexibility and lightweight properties are desirable.

processed onto flexible substrates, making them suitable for applications where flexibility and lightweight properties are desirable. -

Low-Cost Manufacturing: The fabrication process for organic solar cells can be less expensive compared to traditional solar cells, as they can be produced using solution-based techniques such as printing and coating.

-

Tunable Optical Properties: The optical properties of organic materials can be tuned by altering their chemical structure, allowing for the optimization of light absorption and the efficiency of the solar cells.

Common Substrates Used in Organic Solar Cells:

-

Glass: Often used as a substrate for rigid organic solar cells due to its transparency and stability. Glass substrates are commonly coated with a transparent conductive oxide (TCO) layer, such as indium tin oxide (ITO), which acts as the anode in the device.

-

Plastic (Polymer) Substrates: Flexible substrates like polyethylene terephthalate (PET) and polyethylene naphthalate (PEN) are used for producing flexible organic solar cells. These substrates allow for roll-to-roll processing, which is beneficial for large-scale manufacturing.

-

Metal Foils: Metals like aluminum or stainless steel can be used as substrates for organic solar cells. These substrates are durable and can provide additional mechanical strength.

-

Textile-Based Substrates: There is ongoing research into integrating organic solar cells into textiles, allowing for wearable energy-harvesting devices.

Fabrication Process:

Organic solar cells are typically fabricated through techniques such as spin-coating, inkjet printing, or vapor deposition. These processes allow for the creation of thin, uniform layers of organic materials on the chosen substrate.

Overall, organic solar cells offer a promising alternative to traditional photovoltaic technologies, particularly for applications where flexibility, lightweight, and cost-effectiveness are important considerations. However, they generally have lower efficiency and stability compared to silicon-based solar cells, which is a major area of ongoing research and development.