I plan to do some electron microscopy on a PN junction. For that, I need to purchase a Si PN junction with metal contacts. Could you recommend any?

Substrates for PN Junctions Fabrication

Electron Microscopy on PN Junction

A graduate student requested the following.

Question:

Answer:

UniversityWafer, Inc. Quoted

Item Qty. Description

IP03. 8 Si PN junction with metal contacts

Both side Al film 250±50nm,

n/p+ Epi wafers:

4" (100.0±0.5mm)Ø×525±25µm

Substrate: p-type Si:B[111], Ro=(0.002-0.003)Ohmcm,

One-side-polished, back-side etched,

EPI Layer: 34±3µm thick, n-type Si:P, Ro=(3.8-5.2)Ohmcm,

Sealed in Empak or equivalent cassette,

Note: wafers will be annealed to create ohmic contacts.

Reference # 318502 for specs and pricing.

Get Your Quote FAST! Or, Buy Online and Start Researching Today!

PN Junction Solar Cell

A government researcher requested a quote for the following.

Need solar wafers for in-house cell fab. Si wafer must be N or undoped with a thin P layer on top (formed by dopant diffusion). Dopant material is unimportant, however thickness must be reasonably small. We intend to "re-dope" the surface n-type in local areas to form contact areas for creation of p-n junction solar cell utilizing back-side illumination. More details may be provided upon request.

Referece #117515 for specs and pricing.

Highly Doped Substrates for P-N Junction

A Post-Doctoral Research Associate requested a quote for the following.

I am wondering whether your company can provide silicon p-n junction.

Details about the junction can be higher-doped n or p layer (5e16-1e18) on top of lower-doped p or n (~5e15) substrate. If yes, could you please give me quote for the product?

The size of wafer diameter does not matter since just small wafer (like a

2 inch) is fine for me. The doping concentration for epilayer and

substrate is a little different from what I mentioned before. However, I

would like to know how much it approximately costs.

UniversityWafer, Inc. Quoted:

Item Qty. Description

AE48. 9 Epi wafers 4"Ø p+/n Substrate: 4"Ø×525±25µm n-type Si:P[100], Ro=(10-30)Ohmcm, One-side-polished, back-side Alkaline etched EPI Layer: 10±1µm thick, p-type Si:B (0.090-0.11)Ohmcm.

AE48b. 9 Epi wafers 4"Ø n+/p Substrate: 4"Ø×525±25µm n-type Si:B[100]±0.5°, Ro=(2.25-2.75)Ohmcm, One-side-polished, back-side Alkaline etched EPI Layer: 10±1µm thick, n-type Si:P (0.04-0.05)Ohmcm.

AE48c. 25 Epi wafers 2"Ø p+/n Substrate: 2"Ø×280±25µm n-type Si:P[100], Ro=(1-5)Ohmcm, One-side-polished, back-side Alkaline etched EPI Layer: 10±1µm thick, p-type Si:B (0.090-0.11)Ohmcm.

AE48d. 25 Epi wafers 2"Ø n+/p Substrate: 2"Ø×280±25µm n-type Si:B[100]±0.5°, Ro=(0.5-2.0)Ohmcm, One-side-polished, back-side Alkaline etched EPI Layer: 10±1µm thick, n-type Si:P (0.04-0.05)Ohmcm.

Reference #108784 for specs and pricing.

What is the Most Common Substrate for PN Junction Research

The most common substrate for PN junction research is silicon. Silicon is widely used because of its abundance, well-understood properties, and established fabrication technologies. It offers good electrical characteristics and is compatible with existing semiconductor processing equipment, making it the standard choice for both research and commercial applications involving PN junctions.

Other substrates are also used in specific scenarios:

- Gallium Arsenide (GaAs): Used for high-speed and optoelectronic devices due to its superior electron mobility and direct bandgap.

- Silicon Carbide (SiC): Often used in high-power, high-temperature applications because of its wide bandgap.

- Gallium Nitride (GaN): Used for high-frequency and high-power electronics, as well as LED applications due to its wide bandgap and thermal stability.

However, for general research purposes, silicon remains the most prevalent substrate.

Epi Silicon Wafers with PN Junction

A PhD student wanted to know about wafers with pn junction and the different types that we carry.

Yes! We can supply Silicon Epi wafers with 10um Epi layer of n-type Si:P on a 500um substrate which is p-type Si:B, or alternately 10um Epi layer of p-type Si:B on a 500um substrate which is n-type Si:P.

You need to specify wafer diameter, thickness, orientation and resistivity of the substrate wafer plus thickness and resistivity of the Epi layer. Do specify how many wafer you need.

We have the following in stock, for quick shipments {these are remains from larger production runs}.

4" EPI Wafers

| Item | Substrate | EPI | Comment | |||||

|---|---|---|---|---|---|---|---|---|

| Size | Type | Res Ωcm | Surf. | Thick μm | Type | Res Ωcm | ||

| E4_71 | 4"Øx525μm | p- Si:B[100] | 0.008-0.020 | P/EOx | 4 | n- Si:P | 15 ±10% | N/P+ |

| E4_23 | 4"Øx525μm | p- Si:B[111] | 0.008-0.020 | P/E | 85 | n- Si:P | 15.2-16.2 | N/P+ |

| E4_33 | 4"Øx525μm | p- Si:B[100] | 0.008-0.020 | P/E | 100 | n- Si:P | 45 ±10% | N/P+ |

| E4_31 | 4"Øx525μm | p- Si:B[111] | 0.008-0.020 | P/E | 105 | n- Si:P | 32 ±10% | N/P+ |

| Item | Substrate | EPI | Comment | |||||

|---|---|---|---|---|---|---|---|---|

| Size | Type | Res Ωcm | Surf. | Thick μm | Type | Res Ωcm | ||

| E3_50 | 3"Øx381μm | p- Si:B[111] | 0.008-0.020 | P/E | 35.5 | n- Si:P | 4.5 ±10% | N/P+ |

| E3_52 | 3"Øx381μm | p- Si:B[111] | 0.008-0.020 | P/E | 75 | n- Si:P | 20 ±10% | N/P+ |

Reference #100643 for pricing.

What is a PN Junction?

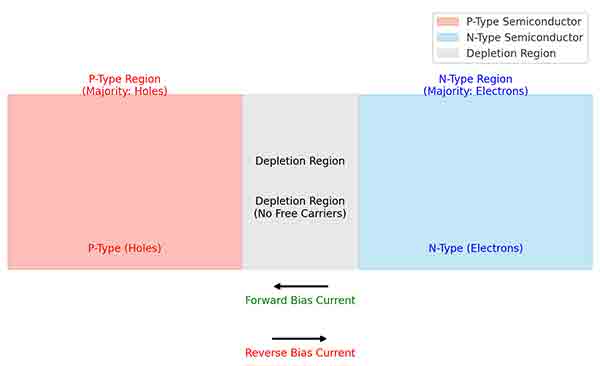

A PN junction is a fundamental building block in semiconductor electronics, formed by joining a p-type semiconductor (which has an abundance of holes as majority charge carriers) with an n-type semiconductor (which has an abundance of free electrons as majority charge carriers). This junction forms a boundary between the two types of materials and has unique electrical properties that make it useful in various applications like diodes, transistors, and solar cells.

When a PN junction is created, electrons from the n-type region diffuse into the p-type region and recombine with holes, while holes from the p-type region diffuse into the n-type region. This process creates a depletion region near the junction, which acts as an insulating barrier, preventing further charge carrier movement.

The electrical behavior of a PN junction depends on the applied voltage:

Forward Bias: When a positive voltage is applied to the p-side relative to the n-side, the depletion region narrows, allowing current to flow easily through the junction.

Reverse Bias: When a positive voltage is applied to the n-side relative to the p-side, the depletion region widens, inhibiting current flow.

The PN junction forms the basis for diodes, which allow current to flow in one direction while blocking it in the opposite direction, among other semiconductor devices.

P-N Junction for Silicon Wafers

A undergrad requested a quote for the following.

Do you have any chance of n-type doped silicon wafer, with one side doped to be p-type, which means a p-n junction for the silicon wafer ( can be polycrystalline or single crystalline). Please let me know. /article>

UniversityWafer, Inc. Quoted:

| Item | Substrate | EPI | Comment | |||||

|---|---|---|---|---|---|---|---|---|

| Size | Type | Res Ωcm | Surf. | Thick μm | Type | Res Ωcm | ||

| 7137 | 3"Ø×381μm | p- Si:B[111] | 0.004-0.008 | P/E | 44.5 ±1.0 | n- Si:P (Top) | ~1.1 | n/p+ |

| A305 | 4"Ø×525μm | p- Si:B[111] | 0.002-0.003 | P/E | 34 ±3 | n- Si:P | (3.8-5.2) | n/p+ |

The wafers are ready for immediate delivery.

Reference #135726 for specs and pricing.

What is the most Common University Research for PN Junctions

The most common university research topics involving PN junctions include:

-

Solar Cells and Photovoltaics: Studying the behavior of PN junctions under light to improve the efficiency of solar cells. This research focuses on understanding the conversion of light into electrical energy, optimizing junction design, and experimenting with new materials.

-

Diode Applications and Improvements: Research on different types of diodes (e.g., Zener, LED, and Schottky diodes) to enhance performance characteristics like breakdown voltage, light emission efficiency, and switching speed. This also includes studying temperature dependence and material properties.

-

Semiconductor Material Studies: Investigating alternative materials for PN junctions, such as gallium nitride (GaN), silicon carbide (SiC), and perovskites, to achieve higher efficiency, increased power handling, or other desirable electrical characteristics.

-

Nanoelectronics and Miniaturization: Exploring PN junctions at nanoscale dimensions, such as in nanowires or thin-film semiconductors, to understand quantum effects, enhance device performance, and improve scalability for future electronic devices.

-

Power Electronics: Research on PN junctions in power devices such as diodes, transistors (e.g., IGBTs), and thyristors, focusing on improving efficiency, reducing power losses, and increasing the robustness of high-power and high-voltage applications.

-

Optoelectronics: Studying PN junctions in optoelectronic devices, such as LEDs, lasers, and photodetectors. Researchers focus on improving light emission, detection efficiency, and spectral response by exploring different semiconductor materials and junction structures.

-

Thermoelectric Devices: Researching PN junctions for thermoelectric applications, where they can be used to convert heat into electricity. The focus is on improving thermoelectric efficiency using PN junction structures.

-

Modeling and Simulation: Developing models and simulations to better understand the behavior of PN junctions under different conditions, including electric fields, temperature, and frequency. This helps in optimizing designs and predicting the behavior of new materials and structures.

These topics are central to improving semiconductor devices and developing new technologies, ranging from renewable energy to telecommunications and consumer electronics.