UV Grade Sapphire Window

Ultravioloet Grade Sapphire Wafers

UV Grade Sapphire Windows has outstanding performance in many applications requiring extreme mechanical, optical and thermal durability. With its ability to withstand high temperatures that would otherwise melt or distort other materials; a single crystal of the mineral can be exposed for years without any loss of properties - this is why we often use them as an infrared lens when working with sensors on our aircrafts which need long-term reliability at harsh conditions like those found outside Earth's atmosphere!

A Phd candidate asked for the following UV Grade Sapphire.

UniversityWafer, Inc. Quoted:

Sapphire Window Material: Sapphire, UV Grade Orientation: C-Plane 46.80mm x 46.80mm (+/-0.05mm) Thickness: 1.50mm (+/-0.05mm) Polished Both Sides: 20/10 Scratch/Dig Edges Fine Ground Clear Aperture: 43mm x 43mm Centered Qty: 60pcs

Reference #269892 for pricing

Get Your Quote FAST!

What is UV Grade Sapphire Window?

When buying a sapphire window or sunglass, you should know about the different qualities of the material.  Specifically, you should look for the C-Axis orientation and Hardness. Then, consider how well the sapphire glass resists scratches. You can also check for the UV Grade to make sure the window or sunglass is scratch-resistant.

Specifically, you should look for the C-Axis orientation and Hardness. Then, consider how well the sapphire glass resists scratches. You can also check for the UV Grade to make sure the window or sunglass is scratch-resistant.

UV Grade sapphire glass

One of the key features of a UV Grade sapphire window is that it will not darken when exposed to UV radiation. This characteristic makes it an excellent choice for windows that need to withstand high-intensity light and extreme temperatures. It also has a wide wavelength range, which makes it ideal for a variety of applications.

In addition to being scratch-resistant, sapphire windows are also great for high-pressure environments. This property of sapphire makes it a good choice for use as a safety shield or component in high-tech equipment. During manufacturing processes, it can also be used to protect workers from injuries. For example, commercial ovens often need viewports. Conventional glass can't handle the high temperatures required in these applications, so sapphire is an excellent solution. The high-performance material is also a good option for cryogenic applications. Additionally, it allows ion lasers to pass through the material efficiently.

The process of manufacturing a sapphire window is extremely precise. CNC operations are used to cut these windows to order. This ensures that minimal wastage occurs during the production process. The windows are then subjected to quality check processes in a class 100 clean room environment. Unlike other crystals, sapphire windows are also very thin.

Apart from being perfect for demanding environments, sapphire windows are also ideal for many other applications. They can be used as cover lenses, sensors, pressure windows, and subsea imaging systems. They are also available in a variety of sizes and specifications. Customers can also request custom-made sapphire windows to fit their specifications.

REFLEX Analytical has produced high-quality Sapphire optics. This material has excellent transmission properties from vacuum ultraviolet to infrared wavelengths. Its high-temperature stability is another advantage of this material. In addition, sapphire has low scatter.

C-Axis orientation

An ultra-thin sapphire window can be made by selecting the correct orientation of the sapphire crystal. Sapphire has a refractive index of 1.75 and is slightly birefringent. It is usually cut in a random orientation, but some applications require the sapphire to be cut in a specific orientation. The most common orientation of sapphire is C-Axis, sometimes also known as Zero-degree sapphire.

Sapphire windows are very durable. They can withstand high temperatures and pressure, even in extreme environments. They are also ideal for applications that require high resistance to the effects of ultraviolet light. Moreover, sapphire is extremely scratch-resistant and corrosive-resistant. This makes it suitable for use in medical and research applications.

Another advantage of Sapphire is that it exhibits high optical clarity. Its transmission range extends from the vacuum ultraviolet to the near infrared. This makes it ideal for use in medical and military equipment, as well as skin-contact windows and hair removal lasers. Sapphire is also extremely resistant to shock and chemicals, making it an ideal material for lasers.

While the C-Axis orientation of a sapphire window is more desirable for some applications, it does have its disadvantages. First, sapphire that has been manufactured in an A-axis orientation tends to be more expensive. It has a higher surface area, but it is also less lustrous. Another disadvantage is that it has fewer defects.

Hardness

The Mohs hardness (MOHS) of sapphire is second only to diamond, making it ideal for use as an optical window material. The hardness of sapphire's surface determines how much light can pass through it. It also affects how durable and long-lasting a finished application will be.

The material is available in many colors. A deep blue sapphire, for instance, contains iron and titanium. The orientation of the sapphire crystal depends on a number of physical properties, but the most common orientation is perpendicular to the face of the window. This type of sapphire is also referred to as "Zero-degree sapphire." High-grade sapphire has low lattice distortion and light scatter.

Infrared transmission, thermal conductivity, and intrinsic safety are all important properties of sapphire. It is a highly effective material for use in electronics and semiconductors. It also has exceptional light transmittance. This property makes it ideal for use in electronics and high-voltage switchgear.

Sapphire windows are used in a variety of applications and can be custom made. The material is available in a range of shapes and sizes. The materials can also be cut according to the customer's specifications. These windows are made under high-tech processes that can produce a high-quality product. These windows also undergo a quality check in a cleanroom environment.

Optical grade sapphire windows combine high transmission with mechanical-strength properties at high temperatures. They are also thinner than other optical crystals. In addition, sapphire windows are suitable for applications in high pressure, vacuum, and corrosive environments.

Scratch resistance

The high hardness of sapphire makes it an excellent choice for window coverings and optical assemblies. Second only to diamond, it offers excellent scratch resistance and durability. It can withstand temperatures up to 2030 degrees Celsius. It is also ideal for covering lenses, sensors, and viewports. Moreover, sapphire windows can resist debris and steel splatter, which make them suitable for many applications.

Sapphire window is also ideal for harsh environments and demanding conditions. It is extremely strong, scratch resistant, and chemical-resistant. In addition, it has an excellent transmission range, which makes it ideal for high-performance optical windows. Its high hardness also means that sapphire can withstand high temperatures.

UQG Optics sapphire windows are scratch resistant, hard, and useful for transmitting UV, VIS, and infrared light. Their low coefficient of thermal expansion makes them suitable for a wide range of applications. Additionally, UQG Optics Sapphire windows can be fabricated in any shape or size, making them a great choice for a wide range of applications.

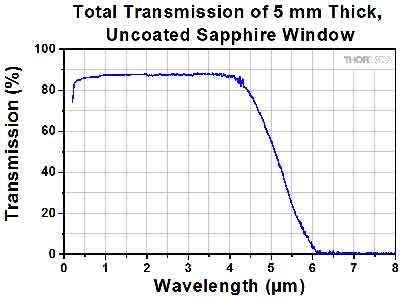

High-quality sapphire optical windows provide excellent transmission, despite their thin profile. They have a wide wavelength range between 0.15 and 5.5um, making them ideal for a wide range of optical needs. In addition, sapphire is not darkened by UV radiation, making it highly versatile for optical applications. It is also resistant to high temperature, high pressure, and high thermal load. That's why sapphire windows are frequently used in IR analytical equipment, lasers, and instruments.

Sapphire is grown in a number of ways. The highest grade sapphire has a lower rate of lattice distortion and less light scattering. The highest grade sapphire is resistant to solarization. It is oriented perpendicular to the surface, which allows it to perform optimally.

IR optical properties

A UV Grade sapphire window has good transmission in the spectral region from 300 to 500 nm. It is a birefringent material and exhibits a wide range of optical properties, depending on its crystalline orientation. Its refractive index changes from 1.796 at 350 nm to 1.761 at 750 nm. Because of its high transmittance, sapphire is commonly used in infrared lens designs.

UV Grade sapphire windows do not darken when exposed to UV radiation. They also exhibit good chemical and thermal properties. They are resistant to corrosive chemicals and do not deform or expand under high heat or pressure. They are also extremely strong and scratch-resistant, which is why they are used in underwater cameras and spectrometers in the marine environment.

These properties make sapphire windows and plates a good choice for high-pressure and vacuum environments. Material transmission and refractive index are important measurements for optical windows, as they describe the amount of light passing through them. As sapphire is an extremely hard material, sapphire's refractive index is a significant factor in the durability and lifetime of the finished application.

Sapphire is a highly versatile material, with a broad spectrum of optical properties, from vacuum ultraviolet to near infrared. This makes sapphire a useful window material in many areas of life, including the medical and military industries. It can protect sensitive equipment from ultraviolet radiation and is resistant to high pressure.

Sapphire glass is available in large sizes and low scatter. It is the ideal material for demanding optical applications, including laser windows. In addition to optical windows, sapphire is also ideal for high-power laser systems and wafers, plasmas, and optics.