Do you have m-plane (1 0 -1 0) sapphire substrates available? If so, can I get a formal quote?

Wafers for Device Research Labs

What Do Device Research Lab Researchers Buy?

Scientists from device research lab have purchased substrates including the following request for sapphire wafers:

Reference # 270442 for pricing.

What is a Semiconductor Devices Research Laboratory?

A semiconductor device research laboratory is a facility that focuses on the development and investigation of semiconductor devices, which are electronic components that are made from semiconductor materials such as silicon or germanium. These materials have unique electrical properties that allow them to be used as the basis for a wide range of devices, including transistors, diodes, and integrated circuits (ICs).

In a semiconductor device research laboratory, researchers may work on a variety of tasks related to the design, fabrication, testing, and optimization of semiconductor devices. This may involve using computer simulations to model the performance of devices, developing new fabrication techniques to improve device performance, or characterizing devices to understand their behavior and identify ways to improve their performance.

Semiconductor device research is a critical field that plays a key role in the development of new technologies and the advancement of electronic devices. Some of the areas where semiconductor devices are used include computing, telecommunications, and consumer electronics.

In this article, we look at the research performed at the Semiconductor Devices Research Laboratory. In particular, we discuss Molecular doping of semiconductors, the impact of LSMS, and equipment used in the Laboratory. In addition, we briefly touch on the Impact of LSMS on the U.S. semiconductor industry.

Molecular doping of semiconductors

Doping semiconductors involves introducing specific dopants into a semiconductor to control the density of  carriers and other properties. Doping semiconductors affects the carrier diffusion length in solar cells, the open circuit voltage, the contact resistance and the charge recombination rate. This technique is also used in semiconductors used in batteries.

carriers and other properties. Doping semiconductors affects the carrier diffusion length in solar cells, the open circuit voltage, the contact resistance and the charge recombination rate. This technique is also used in semiconductors used in batteries.

One of the key properties of semiconductors is their intrinsic disorder. When impurities are introduced, they increase the density of states (DOS) and generate trap states for charged particles. This phenomenon is called energetic disorder. It is also important to consider the effect of doping on the Fermi level of a semiconductor.

Molecular doping can be used for functional applications, such as p-n junctions and metal-semiconductor contacts. These techniques can also be used to modify semiconductors to increase their properties. Molecular doping is becoming an increasingly popular method for semiconductor research. However, the process has several limitations.

Molecular doping of semiconductors is an important research area for the organic electronics industry. The technique has been shown to enhance the performance of organic semiconductor devices, while at the same time extending the functionality of the devices. Molecular electrical doping of organic semiconductors is still largely unexplored, despite the many advantages it offers.

Molecular doping is a highly versatile process that allows researchers to manipulate the electrical properties of organic materials. It can enhance the density of carriers and improve contact properties of organic semiconductor devices. It can also increase the possibility of direct charge tunneling through a metal/organic semiconductor junction. Molecular doping is an important branch of organic doping techniques, with applications in many areas. The main challenge of molecular doping in organic semiconductors is to increase their doping efficiency.

The chemical doping of p-conjugated organic semiconductors involves a redox reaction between the dopant and its host. This reaction can occur through co-evaporation, co-dissolved solutions, or exposure to a dopant gas. Molecular doping of semiconductors can also be accomplished using an orthogonal solvent. For example, a thiophene-based polymer film can be doped with a metal-organic complex. The metal-organic complexes incorporated in the polymer film are capable of achieving a high-efficiency charge transfer, especially if they reside within lamellae. Further, magnetotransport studies have confirmed that these conducting polymers can achieve band-like transport.

Molecular doping of semiconductors is a process that can be used to produce high-mobility emissive organic semiconductors. This process involves a carefully designed molecular doping strategy.

Impact of LSMS on U.S. semiconductor industry

The United States semiconductor industry is growing in size and importance, and many companies have relocated or expanded to Texas in response to this growth. In the process of doing so, they are sharing a pool of resources such as labor, raw materials, and energy, and are looking to local colleges and job-training programs for talent. But how can these resources help the U.S. semiconductor industry grow?

The semiconductor industry has sought to increase production, despite the large gap between supply and demand. The recent data from the U.S. government suggests that demand in the semiconductor industry is far behind supply. Congress is now considering reshaping the supply chains for semiconductors, a move that may not be entirely detrimental to the U.S. industry in the short term, but could have long-term implications.

It has long been argued that government intervention in the semiconductor industry would improve competitiveness. However, such an approach has not proven to be successful in the long run. In addition, industrial policies tend to require perpetual government assistance. While they might improve the competitiveness of U.S. companies, they do not solve the underlying problem of a monopoly.

Beijing has few options besides implementing a freeze-in-place strategy that targets U.S. semiconductor fabs. As a result, the US government could further exacerbate the issue by restricting exports and implementing an outbound investment screening regime to prevent US companies from contributing to force-multiplying technologies in China. In this way, China could stall the development of new technology, and could potentially harm the competitiveness of the U.S. semiconductor industry.

The US is establishing itself as the de facto regulator for the world semiconductor industry, and it is willing to use extraterritorial measures to force its partners to follow suit. After the presidential election in 2024, the US may be able to compel foreign partners to fall in line and align their control systems independently.

These new controls are far-reaching, targeting key chokepoints in the semiconductor industry. They are meant to thwart Chinese efforts to innovate around US export controls. The US government has granted licenses to US companies and foreign partners to mitigate the immediate costs of these new controls, but further restrictions could be imposed over time.

Research conducted in the Semiconductor Devices Research Laboratory

The Semiconductor Devices Research Laboratory is a dedicated center for the research and development of power semiconductor devices. The lab's research is focused on energy conversion and efficiency applications, such as smart grids and electric infrastructures. Its research also addresses applications in high-speed railway transportation, plug-in electric vehicles, energy-efficient data centers, and zero-energy buildings. Additionally, the laboratory focuses on circuit protection techniques.

Oxide/Quantum Materials Laboratory The research and development of emerging oxide materials will help improve the performance of next-generation semiconductor and energy devices. These materials have distinct properties that are essential ingredients for future technology. These properties include transparency for transparent electronics, ferroelectricity for nonvolatile memory, and high electron mobility for high-speed electronic devices.

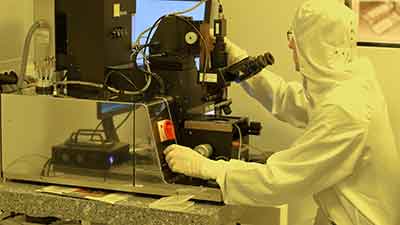

Patrick M. Lenahan Distinguished Professor of Engineering Science and Mechanics conducts semiconductor device and materials research. The lab uses advanced equipment for semiconductor device testing, including a cryostat and probe-stations for wafer-level electrical characterization. The lab also uses numerical simulation and analytic theoretical techniques to analyze the behavior of semiconductor devices and materials.

The Semiconductor Devices Research Laboratory is also involved in research on advanced computer architectures and reconfigurable computing. The lab also focuses on sensors and systems for automotive and industrial applications. The researchers will collaborate with experts at other universities and research labs. The lead principal investigator of the lab, Siddharth Rajan, is a professor in the Department of Electrical and Computer Engineering and Materials Science and Engineering at Ohio State University. Other institutions involved in the project include the Massachusetts Institute of Technology, Sandia National Laboratories, and the University of Arkansas.

The team will explore the properties of semiconductor materials and develop innovative solutions for data-efficient devices. The team will also explore quantum mechanics effects on electron-photon interactions. In addition to these projects, the researchers will conduct research on spintronics and quantum engineering. It is expected that this research will improve the way electronics operate in today's world.

Equipment used by the Laboratory

The semiconductor devices research laboratory employs a variety of equipment. These instruments and facilities are used to investigate the operational physics of semiconductor devices. Currently, Sandia is working on new algorithms for signal processing to improve the quality of electronic signals. This research is aimed at designing new NESP algorithms and examining their performance limit.

The fabrication of semiconductor devices can be expensive, costing millions of dollars to start. Additionally, chemical usage and disposal of waste can be expensive. Because of these costs, few institutions can afford to set up an undergraduate microelectronics laboratory. Although many colleges have acquired used equipment from industry, this is not always a feasible option, especially for smaller colleges.

In the US, semiconductor devices are often made of non-silicon materials. The main technology for preparing these materials is chemical vapour deposition of organometallic compounds. These materials are then deposited onto a monocrystalline semiconductor. This method produces ceramic wafers with unique stacks of semiconductor layers. The materials used for semiconductors must undergo careful characterization before being used in electronic devices.

In the semiconductor devices research laboratory, a variety of materials is processed. Besides silicon and gallium carbide, nitride semiconductors can also be deposited. These materials have diverse physical properties and can be used in a variety of applications, including photonics, sensors, and flexible electronics. These materials are also used in flexible electronics, biosensors, and valleytronics. Lastly, they are used in manufacturing of semiconductor devices for various purposes.

The National Institute of Standards and Technology has been a major supporter of the semiconductor industry for decades. Today, NIST has nearly 50 semiconductor-related programs running at its facilities. These facilities are used to support basic and applied research in this field. The NIST also has two nanofabrication facilities that allow researchers to develop and improve transistors and structures. These devices can be used in the production of electronic products for the consumer market.

The Microelectronics Laboratory includes a wide range of electronics equipment for semiconductor device measurements. The equipment also allows for the analysis of measurement results. This includes the Agilent 4155C, which is a highly accurate instrument for semiconductor device measurement. It features four highly accurate source monitor units and two voltage measurement units. The system can limit output voltage and current to prevent damage to the device under test. The instrument's resolution is 2 uV.