GaN High Electron Mobility Transistor (HEMT) on Silicon Carbide

HEMT Grown on SiC Substrates

HEMTs made from silicon carbide have the potential to revolutionize the power electronics industry by providing a higher-performance alternative to silicon transistors.

Silicon carbide (SiC) is a semiconductor material with very high electron mobility, which makes it attractive for use in high-frequency and power electronics.

SiC has been known as a potential replacement for silicon in these applications for many years, but the material has been held back by its low yield and high cost.

Send us your specs for an immediate quote!

What is High Electron Mobility Transistors (HEMTs)

High Electron Mobility Transistors (HEMTs) are a type of transistor that can be made from SiC. HEMTs have the potential to revolutionize the power electronics industry by providing a higher performance alternative to silicon transistors. We can help you!

High Electron Mobility Transistors (HEMT) grown on Silicon Carbide (SiC) Wafers

Silicon carbide [SiC] is an alternative to silicon, but GaN generally has more attractive basic material properties and it is worth understanding the applications in which it excels. Both have different properties and some parts are not yet comparable to silicon carbide in this area. Silicon carbide and gallium nitride transistors have the same basic properties as gallium nitride, such as high electronic mobility and low power consumption. However, they are not comparable in their electronic properties.

Below is just one option. Let us know what specs we can quote for you?

| HEMT on SiC | |

|---|---|

| Substrate | SiC |

Thickness of GaN buffer(um) |

1.8± 0.25μm |

| AlGaN compostion(%Al) | 20, 23 or 26± 1.25% |

| AlGaN thickness (nm) | 21±1nm |

| AlN thickness | 1±0.5nm |

| Sheet resistivity (ohms/sq) | <420 ohms/sq |

| Mobility (cm2/V-sec) | >1200 cm2/V-sec |

| Sheet concentration (/cm3) | >1e13/cm3 |

| Bow | <60um |

| Buffer layer resistivity (ohms/sq) | >1e5ohms/sq |

| Substrate resistivity (ohms/sq) | >10000ohms/sq |

| particulates or other defects | 90.00% |

HEMT Gallium Nitride (GaN) on Sapphire

HEMT Silicon Wafers

High-Electron Mobility Transistors Silicon Carbide

A team of researchers at the University of Illinois has developed a new approach to optimizing the composition of the semiconductor layers that make up these devices. They have taken the next step in the development of high-performance, low-power, ultra-thin transistors by optimizing their chemical composition. A team Of course, this has a number of advantages over other approaches, such as the use of silicon carbide. [Sources: 5, 15]

Working with industry partners Veeco and IBM, the team has developed a process that will grow to wafer sizes larger than industry standards. Together with its industrial partner Ve ecoCoelco, IBM has developed an approach to the development of high-performance, low-power, ultra-thin transistors with a chemical composition similar to that of silicon carbide, although the process is reduced to smaller than larger wafers according to industry standards. Together with its industrial partner VecoEco and IBM, they have developed a different approach to the creation of a transistor with higher - than - industry standard, super - low performance. [Sources: 5]

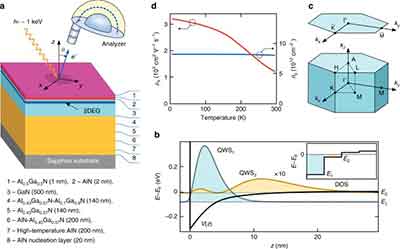

The GaN HEMT structure is designed to be compatible with existing CMOS manufacturing processes and suitable for high-performance, low-power, and ultra-thin transistors. Silicon carbide also has a very high thermal conductivity, so that the heat dissipation of the substrate is not as limited as with this sapphire-shaped device. [Sources: 6, 11]

GaN's electron mobility is also a key factor in making it suitable for high-performance, low-power, and ultra-thin transistors. A particularly interesting component is the high-electron mobility transistor (HEMT), also known as a field effect transistor, in which modulation is doped by modulation. The cascode circuit consists of two silicon-controlled amplifiers, one for each side of the transistor. These have properties similar to thyratron tubes, but are solid - like a transistor - but consist of a single transistor instead of an array of three. [Sources: 2, 9, 11, 13]

These may include gallium nitride-based transistors with high electron mobility, as described in this paper. According to the embodiment of the present invention, the silicon carbide nozzle, which contains at least one trench, thus provides an ideal substrate for the buffer layer of a high electron mobility transistor. The trench is disposed of in the silicon region - carbides die according to a region on its surface. On the substrate [11], the aluminum-nitride layer [12] is a 12% substrate and provides a buffer zone of 1.5 micrometers in diameter and 0.1 micrometer in thickness. [Sources: 8, 11]

By using HEMT - doped modulation, induced transistors with high electron mobility generate different electron densities, which can be adjusted by the induced charge carrier in the 2degree plane or by the formation of doping on them. In order to reduce the scattering of ionizing impurities, electrons from doping and broadband gap semiconductors may originate from the silicon carbide layer [12, 13, 14, 15, 16]. [Sources: 4, 11]

As shown in Figure 1, SiC offers a higher thermal conductivity because it has a high band gap and electron mobility. The arrangement of the silicon carbon atoms in the lattice makes it a broadband gap semiconductor (WBG), because the electrons are able to move through it. Compared to conventional silicon (Si) materials, GaN has much higher electron mobility than silicon and a lower dielectric field strength [13, 14, 15, 16]. In the meantime, the binary material Ga n III - V has up to ten times the dielectric field strength due to the electron mobility of silicon [17]. [Sources: 10, 12, 14]

Gallium nitride (GaN) is a high-band gap material that allows devices to operate at high temperatures and withstand high voltages compared to silicon. Gallium arsenide can be used for transistors with higher frequencies due to its high electron mobility and thermal conductivity, while its ability to move electrons through semiconductor materials is an avalanche breakthrough. There are also a number of semiconductor technologies to bridge the gap between the performance of silicon and silicon carbide. One of the most promising and advanced silicon carbide technologies is bile nitride [17]. [Sources: 0, 9, 13]

Therefore, the goal of our present invention is to develop a transistor with high electronic mobility (HEMT) that utilizes the electronic properties of group III nitride and does so at a higher frequency than existing devices [17, 18, 19]. The present inventions relate to radio frequency transistors and contain a silicon carbide-based active layer on a gallium arsenide substrate. The transistor [10] consists of a semi-insulated substrate made of 4H polytype silicon carbide as the preferred embodiment. [Sources: 11]

Silicon carbide [sic] is an alternative to silicon, but GaN generally has more attractive basic material properties and it is worth understanding the applications in which it excels. Both have different properties and some parts are not yet comparable to silicon carbide in this area. Silicon carbide and gallium nitride transistors have the same basic properties as gallium nitride, such as high electronic mobility and low power consumption. However, they are not comparable in their electronic properties [19, 20, 21, 22, 23]. [Sources: 0, 1, 3, 7]

Sources:

[0]: http://www.ivwkr.com/vertical-gan-devices-the-next-generation-of-power-electronics/

[1]: https://resources.altium.com/p/what-you-need-know-about-gan-and-sic-fets

[2]: https://www.ncbi.nlm.nih.gov/pmc/articles/PMC6567103/

[3]: http://dprkp.palembang.go.id/jlni/epi-wafers.html

[4]: https://en.wikipedia.org/wiki/High-electron-mobility_transistor

[5]: https://www.everythingrf.com/News/details/3466-Advances-in-GaN-on-Silicon-Technology-to-Enable-Scalable-High-Electron-Mobility-Transistors

[6]: https://www.electronicspecifier.com/products/component-management/gan-on-silicon-tech-optimises-high-electron-mobility-transistors

[7]: https://www.powerelectronictips.com/sic-outperforms-gan/

[8]: https://www.google.com.pg/patents/US20100012952

[9]: https://rogerscorp.com/power-electronics-solutions/blog/2019/how-does-gallium-nitride-fit-into-the-next-generation-of-high-performance-electronics

[10]: https://encyclopedia.pub/371

[11]: https://patents.google.com/patent/US6486502

[12]: https://blog.st.com/silicon-carbide-cars-wide-bandgap-semiconductor/

[13]: http://portlandstadiumdistrict.mmdccompany.com/cdcz/avalanche-transistor.html

[14]: https://semiengineering.com/power-semi-wars-begin/

[15]: https://www.nanowerk.com/nanotechnology-news/newsid=45542.php

Types of High Electron Mobility Transistor

A high electron mobility transistor is a semiconductor device that controls the flow of electrons with a high degree of mobility. The device is made from a semiconductor material with a low band gap and no donor atoms, which makes it possible to achieve high switching speeds. The device is made up of many individual transistors, each with its own unique characteristics. This article will discuss the different types of high electron mobility transistors and their properties.

InAlN/GaN HEMTs, the sheet charge is 2.6 x 1013 cm-2 in a lattice-matched condition. This high sheet charge density is limited by the poor crystal quality of InAlN due to phase segregation. It is also reduced when the barrier is compressed. A lattice stress relief method maintains the high sheet charge density. This device can be used in electric cars, locomotives, power transmission, and other applications that require high-voltage switching.

High electron mobility transistors are also known as heterostructure FETs or modulation-doped FETs. These transistors incorporate an heterojunction in their channels, which enhances their high electron mobility. The material combination used in making HEMTs varies widely, but typically comprises GaAs/AlGaAs. Materials with more indium are preferred for high-frequency applications, while gallium nitride is preferred for high-power applications.

Another HEMT material is AlGaN/GaN, which has the same layered structure as GaAs. This material does not need intentional doping, but is made up of AlGaN/GaN layers. These devices have a higher carrier concentration and have better RF performance. A high electron mobility transistor is a valuable device that is widely used in high-frequency and power applications. The latest research in this area focuses on the AlGaN/GaN HEMTs.

Video: HEMT Explained