150mm Substrates to Create Mechanical Parts

A mechanical engineer requested a quote for the following.

I am interested in a quote containing lead-time and availability information for: Quantity: 5 Description: 6" P(100) 10-20 ohm-cm SSP 650um Prime Grade Silicon Wafer I am flexible in material quality. If you have additional 6” wafers available please include them in the above quote. (The wafers will be used to create mechanical parts.

Mechanical Grade wafers seem like the perfect choice to make interposers.

You don’t forsee any issues with this material (voids, inclusions, etc.) that would prohibit it from being thinned to .004” and diced into interposers (final size .004” x .016” x .200”).

Reference #115041 for specs and pricing.

Get Your Quote FAST! Or, Buy Online and Start Researching Today!

Substrates to Fabricate Glass Interposer

A process engineer requested a quote for the following.

- We are purchasing the borosilicate glass plates because its CTE matches silicon the best. Please confirm if your glass plates are borosilicate or not, and send us a detailed specification list, including its chemical composition and physical (mainly optical obsorptance) properties if you have.

- Please provide us the quotation on 0.5mm & 0.4mm borosilicate glass plates for 10 pieces in size of 4” and 6”. Finally, please do let us know if there are some standard products, compliant with our requirements, in your stock, so that we can send you the formal order as soon as possible.

We are trying to develop glass interposer manufacturing in our factory. Before HVM, experimental fabrication is to be carried out.

For our application, coefficient of thermal expansion (CTE) is one of the most critical considerations. After checking the properties of borofloat glasses, we find its CTE is around 3.25E-6 /K, which is close to silicon. However, real experimental data is missing for your product. Further, the optical absorption spectrum of the glass material is also important since laser drilling is supposed to be applied to fabricate holes in it. If you can provide these information, it will be the best.

Another thing is that, we may need such glass panels in 100mm x 300mm panel form in HVM after successful test fabrication. Did you provide such products instead of glass wafers?

Reference #129159 for specs and pricing.

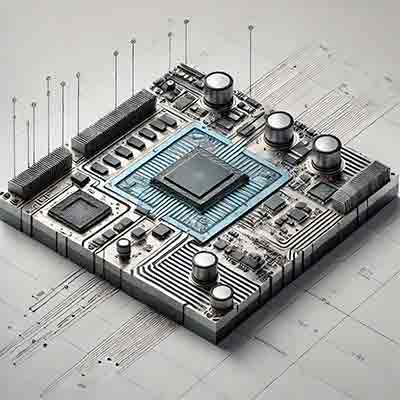

What Is A Silicon Interposer?

A silicon interposer is a semiconductor device that acts as an intermediate layer, typically in advanced electronic packaging, enabling electrical interconnections between different integrated circuits (ICs) or components. It serves as a "bridge" that links multiple dies or chips on a single substrate, facilitating data transfer, power distribution, and thermal management. Here are some key aspects of silicon interposers:

-

Structure: Silicon interposers are made from silicon and can be as thin as a few hundred micrometers. They contain through-silicon vias (TSVs), which are vertical electrical connections that pass through the silicon, allowing signals to be transmitted from one side of the interposer to the other.

-

Functionality: By integrating multiple dies or components (e.g., processors, memory chips) on a silicon interposer, high-speed data communication between components is achieved with reduced parasitics (unwanted electrical effects). This improves signal integrity and power efficiency compared to traditional multi-chip interconnections.

-

Applications: Silicon interposers are widely used in 2.5D and 3D IC packaging, where several dies or chips are assembled in close proximity or stacked. They're common in high-performance computing, graphics processors, and other applications where multiple components need to communicate quickly and efficiently.

-

Benefits: Silicon interposers allow for higher density and bandwidth in packaging while reducing power consumption and improving signal performance. They also contribute to better thermal management by spreading heat across the interposer surface.

In essence, silicon interposers help achieve miniaturization and performance optimization in complex electronic systems, which is crucial for advanced computing and high-performance applications.

Silicon Interposer