We would like to have a quotation for Si wafer <100> Boron 625-725 un thick doped with deposited layers as follows:

- SiO2 (300nm)

- Ti (10nm)

- Pt (100nm)

- PZT (1um)

Can you also provide some suggested recipe/process as to how to etch the PZT?

Do you also provide the properties of the PZT? Are you using sol-gel method?

-

What process did you use to deposit the Ti and Pt layer?

- Is the PZT used is PbZrTio3?

- What process did you use to deposit the PZT material?

Reference #250967 for specs and quantity.

Get Your FAST! Or, Buy Online and Start Researching Today!

PZT or Titanium (Ti) Which Works Best for Energy Harvesting Device?

A research student at IIT requested the following quote:

Currently I am working on MEMS based Energy Harvesting Device which will be made from piezo materials (ZnO or PZT). So please suggest any wafer of 2inch in your stock so that i can order it.

I want 2 inched silicon wafer with different thickness and material deposited in following sequence.

- 2" Silicon wafer p or n type

- Growing of SiO2 on wafer upto

500 nanometer. - Deposition of Titanium up to 500 nanometer above sio2.

- Deposition of PZT or ZnO upto 2 micrometer above Titanium.

- Deposition of Titanium upto 500 nanometer above PZT.

I would like to sputter deposit Ti and ZnO. Please suggest me any other process for same materials so that cost will

be reduced considerably. As i am student i would like to take 5 wafers, so

can you tell me cost for 5 wafers. Also if i deposit different metal

instead of Ti will cost reduced.Reference #120417 for specs and pricing.

PZT Deposited Onto SOI Substrate

A PhD candidate requested a quote for the following:

We need a SOI. Oxide thickness can be anything small such as 1um-2um. Silicon thickness on top of the oxide should be 6um. I also wonder if it is possible to deposit a PZT material such as ZnO. If yes then what would be the price with each PZT?

Reference #137108 for specs and pricing.

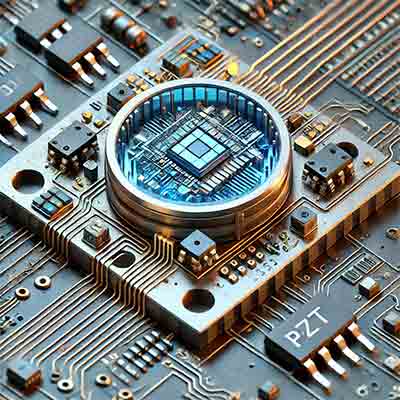

What Is PZT And How Is It Used With Silicon?

PZT, or lead zirconate titanate, is a ceramic perovskite material with the chemical formula Pb(Zr,Ti)O3. It is known for its excellent piezoelectric properties, meaning it can convert mechanical energy into electrical energy and vice versa. This characteristic makes PZT highly useful in a variety of applications, including sensors, actuators, and transducers.

Properties of PZT:

- High Piezoelectric Coefficients: PZT materials exhibit strong piezoelectric

effects, making them highly efficient at converting mechanical stress into electrical signals.

effects, making them highly efficient at converting mechanical stress into electrical signals. - Ferroelectric Properties: PZT has spontaneous polarization, which can be reversed by the application of an external electric field.

- High Dielectric Constant: It has a high dielectric constant, making it suitable for capacitive applications.

- Thermal Stability: PZT maintains its properties over a wide range of temperatures, enhancing its usability in various environments.

Uses of PZT with Silicon:

Integrating PZT with silicon is common in microelectromechanical systems (MEMS) due to the complementary properties of both materials. Silicon provides a robust, flexible platform with excellent electronic properties, while PZT adds functional capabilities through its piezoelectric and ferroelectric properties. Here are some specific applications:

-

MEMS Devices:

- Sensors: PZT-based MEMS sensors can detect pressure, acceleration, and force by converting mechanical deformation into electrical signals. These sensors are used in automotive, aerospace, and consumer electronics.

- Actuators: PZT MEMS actuators can precisely control mechanical movements in micro-scale devices, such as in inkjet printers, micro-pumps, and optical devices.

-

Energy Harvesting:

- PZT materials can be used in energy harvesting devices to convert mechanical vibrations into electrical energy, which can power small electronics or recharge batteries.

-

Ultrasound Transducers:

- PZT-silicon composites are used in medical ultrasound equipment, providing high-resolution imaging by converting electrical signals into ultrasonic waves and vice versa.

-

Optical Devices:

- PZT can be integrated with silicon photonics to modulate light in devices like switches and modulators, benefiting telecommunications and data transfer applications.

Fabrication Techniques:

Integrating PZT with silicon typically involves advanced fabrication techniques, such as:

- Thin-Film Deposition: Methods like sol-gel, sputtering, or chemical vapor deposition (CVD) are used to create thin PZT films on silicon substrates.

- Microfabrication: Standard microfabrication processes, including photolithography, etching, and doping, are employed to pattern and integrate PZT with silicon circuits.

- Bonding Techniques: Wafer bonding or direct bonding methods are used to attach PZT layers to silicon substrates, ensuring good mechanical and electrical contact.

Challenges:

- Compatibility: Ensuring compatibility between PZT and silicon in terms of thermal expansion, chemical stability, and mechanical stress.

- Integration: Achieving high-quality PZT films on silicon without defects or interfacial issues.

- Miniaturization: Managing the challenges of scaling down PZT components for integration into small-scale MEMS devices.

In summary, PZT is a versatile and powerful material when combined with silicon, enabling advanced functionalities in a wide range of high-tech applications, from sensors and actuators to energy harvesters and optical devices.

Thermal Compression Bonding

A university technical director requested a quote for the following:

I would like to know if university wafer can provide thermal compression bonding of

two substrates coated with gold thin film. One substrate is silicon with gold, the other

substrate is PZT with gold. gold layer will be 200nm thick.It will be a au-au bonding, but PZT substrate needs a slow ramping up/down rate.

Reference #180049 for specs and pricing.