I’m planning to buy some FZ silicon and CZ-grown Silicon Germanium wafers (Si1-xGex). The information of the required wafers is listed in the table below. The different kinds of FZ silicon and CZ Si1-xGex wafers falling in the listed ranges of resistiviy or Ge contents are all favored. Please give me the related information.

Silicon Germanium Substrates

An associate professor requested a quote for the following.

Reference #220702 for specs and pricing.

Silicon Germanium (SiGe) Wafers

We have 100mm, 150mm and 200mm Silicon Germanium (SiGe) ![]() wafers. SiGe strained silicon provides an alternative substrate for CMOS manufacturing using silicon. SiGe wafers are suitable for mixed-signal circuits.SiGe is much less expensive than Gallium Arsenide (GaAs) heterojunction technologies.

wafers. SiGe strained silicon provides an alternative substrate for CMOS manufacturing using silicon. SiGe wafers are suitable for mixed-signal circuits.SiGe is much less expensive than Gallium Arsenide (GaAs) heterojunction technologies.

Please let us know if you can use our SiGe specs or let us know if you have specs you would like us to quote.

Get Your Quote FAST! Or, Buy Online and Start Researching Today!

SiGe Strained Silicon

Description Prime,Single crystal Silicon

Diameter 100mm, 150mm & 200mm

Thickness Semi Standard

Resistivity 1-100 Ohm.cm

Type P-type/N-type

Polish One side epi polished

Orientation (100)

Epitaxial layer

Composition SixGe1-x

Thickness Upon-requst

Dopant None

Stress state Strained/Relaxed

Silicon Germanium FAQs

Researcher SiGe Question:

Do you supply Si0.1Ge0.9 films on Si Substrates? I am looking for a 2µm thick relaxed film. If yes: Do you know the threading dislocation density on top of the Silicon Germanium SiGe-Film? Is possible to do epitaxy on top of this surface?

Silicon Germanium Answer:

2um thick "Si0.1Ge0.9" film with Ge composition too high and too thick,it not do able.

2um thick Ge on Silicon wafer is ok to supply

What is the pricing on a 4" Silicon Germanium SiGe film?

Researcher Question:

What is the pricing on a 4" SiGe film, 50nm thick, on a Silicon Wafer? Would the price change if the SiGe film was 30nm or 20nm thick?, 50nm thick, on a Silicon Wafer? Would the price change if the SiGe film was 30nm or 20nm thick?

SiGe Film Answer:

Yes,the price will change a little while the SiGe film thickness changes,pls confirm the Ge composition and the order qty. per the item, after this,we shall give you a quote.

Is the Composition of Silicon Germanium (SiGe) Conrollable?

I was wondering is the composition of the thin film controllable? saying SiGe, Si3Ge1 and Si1Ge3.

I am interested in the product of SiGe on Si wafer. I was wondering is the composition of the thin film controllable? saying SiGe, Si3Ge1 and Si1Ge3. Can I get a quotation for the following wafers?

1 um thick SiGe film on Si wafer (4') *2

1 um thick Si3Ge1 film on Si wafer (4') *2

1 um thick Si1Ge3 film on Si wafer (4') *2

100 nm thick SiGe film on Si wafer (4') *2

100 nm thick Si3Ge1 film on Si wafer (4') *2

100 nm thick Si1Ge3 film on Si wafer (4') *2

If the composition is not controllable, please also send me a quotation for the following wafers.

10 um thick SiGe film on Si wafer *4

1 um thick SiGe film on Si wafer *4

100 nm thick SiGe film on Si wafer *4

![]()

SiGe Thin Film Answer:

The composition is controllable, just "Si1Ge3" the Ge composition is high,the SiGe layer thickness can not achieve 100nm,what about "Si2Ge2"?

Si1Ge3, SiGe and Si3Ge means the Si/Ge ratio in the thin film is 1:3, 1:1 and 3:1 respectively. What's the thinnest thickness you can make? Actually we only need 1-2 pieces for each film.

Can you Depost Silicon Germanium (SiGe) film on Silicon wafer?

Researcher asks:

I wanted SiGe film on Silicon wafer, not Si-on-Ge-on-Silicon wafer. Different compositions means different concentrations of Ge in SiGe film. Please take a quick look at the paper attached in which they controlled the Ge concentration to 20, 40, 60 and 80%.Si3Ge: concentration of Ge in SiGe film is 25%

SiGe: concentration of Ge in SiGe film is 50%

SiGe3: concentration of Ge in SiGe film is 75%If 75% Ge is too high for your synthesis, 25 and 50% also work for us.

Hope this makes things clear., not Si-on-Ge-on-Silicon wafer. Different compositions means different concentrations of Ge in SiGe film. Please take a quick look at the paper attached in which they controlled the Ge concentration to 20, 40, 60 and 80%.

Si3Ge: concentration of Ge in SiGe film is 25%

SiGe: concentration of Ge in SiGe film is 50%

SiGe3: concentration of Ge in SiGe film is 75%If 75% Ge is too high for your synthesis, 25 and 50% also work for us.

Hope this makes things clear.

Answer:

We have the following specs. Please fill out the form for pricing.

- Si3Ge: concentration of Ge in SiGe film is 25% , 400 nm thick SiGe film on Si wafer

- SiGe: concentration of Ge in SiGe film is 50% , 30 nm thick SiGe film on Si wafer

- SiGe3: concentration of Ge in SiGe film is 75%, 10 nm thick SiGe film on Si wafer

Do You have Undoped Silicon Germaium (SiGe) Wafers?

Researcher Question:

Do you have the following SiGe spec?

Si+2at%Ge wafers

Wafer diameter : 40- 50 mm

Type: n-type

Orientation [100]

Resistivity: more than 1000 ohm.cm (noncompensated)

Dopant: Phosphorus

Thickness: 0.5 mm

Two-side polished.

Answer:

Yes, we have:

Si+2at%Ge wafers,Si0.98Ge0.02 wafer

Wafer diameter : 100 mm

Type: n-type

Orientation [100]

Resistivity: more than 1000 ohm.cm (noncompensated)

Dopant: Phosphorus

Thickness: 0.5 mm

Two-side polished.

Please ask for pricing.

Could you send me p-SiGe Silicon Germanium wafer estimate?

Diamater: 100 mm, 150 mm

Resistivity: Boron heavily doped

Type: p-type

Composition: x=0.7, 0.6, 0.5

SiGe thickness: 100 nm or 200 nm

Dopant: Boron

Stress state: whatever

Answer Yes! We have the following:

Diameter 100+/-0.25mm

1# SiGe-on-Silicon Wafer,40% Ge Composition

Silicon Substrate

Description Prime,single crystal Silicon

Thickness 525+/-25um

Resistivity 1-10 Ohm.cm

Type P-type(Boron doped)

Polish One side epi polished

Orientation (100)

Si x Ge 1-x Epitaxial layer,x=0.6,1-x=0.4

Composition Si x Ge 1-x

Thickness 100nm

Dopant Boron

Stress state Relaxed

150mm SiGe/Silicon Wafer

2# SiGe-on-Silicon Wafer,40% Ge Composition

Silicon Substrate

Description Prime,single crystal Silicon

Diameter 150+/-0.25mm

Thickness 625/675+/-25um

Resistivity 1-10 Ohm.cm

Type P-type(Boron doped)

Polish One side epi polished

Orientation (100)

Si x Ge 1-x Epitaxial layer, x=0.6,1-x=0.4

Composition Si x Ge 1-x

Thickness 100nm

Dopant Boron

Stress state Relaxed

Do You Carry Silicon Germanium (SiGe) With an Epitaxial Layer

Researcher Question:

Do you have have SiGe with an epitaxial layer?

Answer:

Yes,We can supply Si/Ge 80/20 and 70/30 two different composition

4'' 100mm SiGe/Silicon Wafer

SiGe-on-Silicon Wafer,20% Ge Composition

Silicon Substrate

Description Prime,single crystal Silicon

Diameter 100+/-0.4mm

Thickness 500~550um

Resistivity 1-20 Ohm.cm

Type P-type(Boron doped)

Polish One side polished

Orientation (100)

Thermal Oxide layer 100nm

Si1-xGex Epitaxial layer,x=0.2,1-x=0.8

Composition Si1-xGex

Thickness 100nm

Dopant None

Stress state Relaxed

Could you please let me know the properties of the product that you have, Ge concentration and price/wafer

Researcher Question:

I'm looking for silicon germanium wafers n-type (100) with different Ge concentration.

Answer:

We can supply SiGe with different of Ge concentration:

Diameter 50.8mm, 100mm and 150mm

Type : n-type (100) Silicon germanium

Resistivity: less than 0.1 ohm.cm

One side polished

Please send us your specs!

SiGe Layers can be customized to meet your specific research needs or compare high temperature SiGe to silicon based devices or integrated circuits for performance differences.

The Store of Silicon Germanium in Space

Diced Silicon Germanium Wafers

A professor of physics requested a quote for the following.

Please, let me know if you can make 10x10 mm2 square samples of silicon (germanium) wafers. The samples must have small metal contact pads in four corners for bonding.

Reference #245475 for specs and pricing.

What is Silicon and Germanium For?

The chemical elements silicon and germanium are very similar, but they have very different uses. ![]() For example, silicon is used to make electronics, and it is used to make semiconductors, including transistors. While silicon is a more common semiconductor, it is also useful for other applications. Some of these applications are listed below. How is silicon different from other semiconductors? Read on to learn more about these two elements. Let's explore how these two materials differ.

For example, silicon is used to make electronics, and it is used to make semiconductors, including transistors. While silicon is a more common semiconductor, it is also useful for other applications. Some of these applications are listed below. How is silicon different from other semiconductors? Read on to learn more about these two elements. Let's explore how these two materials differ.

Silicon and germanium are compounds with atomic number 14. They are similar to each other, but they are both used for different things. The main difference between the two is their atomic numbers. The former is 14 while the latter is 32. Neither material is very good for light, so it is not practical for light-based products. The two metals are often abbreviated with Si and Ge, which stands for "silicon" and "germanium."

Silicon is the cheaper metal of the two, but it is more valuable. This is because silicon is much easier to fabricate and has higher thermal resistance than germanium. While the former is cheaper than its rival, germanium is easier to process and is more valuable. Therefore, silicon is more popular for many applications, including electronic devices. The same is true for both materials. These two elements are essential to our society. You've probably wondered what they're used for.

Silicon is a semiconductor, and its compounds are essential for electronic devices. In addition, they are used in cement, ceramics, and glass. Germanium was discovered in 1886 by Clemens Winkler. Its atomic number is 32, and it is located just below Si in the periodic table. It has a diamond-like crystal structure, but is slightly less dense and is grey-white in colour.

While both elements are used in electronics, silicon is a much more pure material than germanium, which makes it a better choice for computer chips. Its insulating properties are important for transistors in electronic devices. In contrast, germanium is more expensive, and it is not as abundant as its counterpart. Despite the differences, they are both useful in electronic products. There are many different applications for both. The main difference is that silicon is more expensive and germanium is a more abundant metal.

Silicon is a semiconductor material and a semiconductor. Its atomic number is 14 and 32. Compared to germanium, silicon has a higher melting point and is therefore better in hot environments. While both of these elements are important, the differences between the two substances are not very important. They both are used in high temperature and mixed-signal circuits. So, if you are planning to design a new product, it is crucial to understand the differences between silicon and the latter.

Aside from their differences, these two elements work well together. While silicon is more affordable than germanium, it is also more pure than its counterpart. Both materials have different applications. For example, both materials work well in computer chips, but one is better than the other in other applications. However, silicon is better suited for computer chips because it works better with light. It is better suited for cell phones and other electronics in the mobile world.

Silicon is less expensive than germanium, but it is more valuable than germanium. It is the lesser of the two. It is more abundant in the crust, and its ICBO can be doubled at any temperature. When compared to these two elements, silicon is more rare, while germanium is more abundant in the outer atmosphere. So, if you are looking for a semiconductor, you can use it in electronics.

In comparison to germanium, silicon is more pure and can be used for computers. This is why it is often used for computers and other devices. As a result, it is more suitable for use in the semiconductor field. And while it is cheaper than germanium, it is less durable than its counterpart. But it can be used in high-temperature applications. In fact, it can work at temperatures up to 150 degrees Celsius, while the Germanium is less durable.

Silicon Germanium Alloys

Researchers have been using indirect bandgap semiconductor materials including cubic silicon (Si), germanium (Ge) and SiGe alloys to achieve efficient light emission from direct-bandgap hexagonal Ge and SiGe alloys.

Please send us your specs for a quote.

Silicon Germanium (SiGe) Based Lasers

For decades researchers have worked hard to fabricate SiGe based lasers that can seemlessly integrate into todays existing chips. This new technology has caught up to Indium Phosphide and Gallium Arsenide currently found in todays chip. The speeds of SiGe based devices could increase by 1000%.

We can provide Blue and Green color,the epi stack structure is "LED MQW epi structure / Silicon epitaxy / SiGe epitaxy / Silicon substrate " at least 3 mode of epi process. Price is dependent on quantity.

Pelase send us your specs!

Polycrystalline Silicon Germanium

We can provide SiGe wafer 4'',6'' and 8'',the price depends on the final requirements. Please send us your specs and quantity for an immediate quote.

New SiGe Transistors Help Transfer Data at Record Speeds Using Light

Researchers from ETH have created a modulator that reduces signal loss during light to data transfer using Silicon Germanium transistors.

![]()

Source: IEF/Springer Nature Ltd.

How would you compare and contrast silicon germanium and gallium arsenide as semiconductor material?

Silicon germanium (SiGe) is an alloy epitaxial wafer, it's has a higher cost for semiconductor IC, etc. Gallium arsenide (GaAs) is a lower cost substrate for LED, LD applications, or related epitaxial growth.

Silicon-Germanium Device Next Step to Fabricate Silicon-Based Lasers

When it comes to microelectronics, it is workhorse transistor technology that drives our information society. There are countless electronic devices we use in our daily lives, such as barcode scanners and laser pointers, that use a variety of semiconductors, from silicon germanium to Gallium Arsenide (GaAs), and so it seems natural to find ways to integrate these different functionalities. Of particular interest in this context are silicon-based components of the laser pointer, which are typically based on gallium arsenids (GaAs). Although a large number of high-performance, low-power silicon-based components can be manufactured today at very low cost, there are other areas where the properties of a semiconductor such as silicon are used technologically. Silicon is used in a wide range of applications, for example in the use of barcodes, scanners, lasers and pointers.

Unfortunately, the physical processes that generate light in GaAs do not work as well as they do in silicon, so finding alternative ways to realize a laser on silicon remains a prime and long-term goal. An international team led by researchers from the Department of Materials Science and Engineering at the University of Illinois at Urbana-Champaign presents an important step towards such a device in the Applied Physics Letters.

In addition, the observed emission is in the terahertz frequency band, which lies between microwave electronics and infrared optics and is of high current interest for a variety of applications. The semiconductor structure is based on GaAs, a material consisting of two different types of band gaps: direct and indirect. In the latter and the former, they are indirect, and electrons recombine in holes in GaAs a band gap, generating light and heat in silicon. Therefore, silicon is used to build a laser based on a GaAs template, as it has nothing to do with the fact that the material is much lighter than silicon and is therefore better suited for use in lasers, "reports the research team from the University of Illinois at Urbana - Champaign, University of Stuttgart.

Therefore, the laser's effect on silicon requires different paths, and its effect on GaAs also requires a different way.

QCLs achieve light emission by tunneling their electrons through a repetitive stack of precisely constructed semiconductor structures in which process potentials are released. The research on this new approach is similar to that of researchers at the Max Planck Institute of Quantum Optics in Garching and the University of California at Berkeley. They are working on the first silicon-based quantum cascade laser with GaAs as the primary material.

Although the QCL paradigm was first demonstrated in 1994 by a team led by Jerome Faist, who was then working at Bell Laboratories in the USA, it was the first time that it was demonstrated in silicon-based materials. The realization of these forecasts is part of an interdisciplinary project funded by the European Commission, bringing together leading experts, characterizing high-quality semiconductor materials and manufacturing them as components at the University of Glasgow. The ETH Group of Scalari and Faists is one of the largest and most advanced research groups in the world in this field.

What are the advantages of Silicon Germanium (SiGe) in semiconductor technology?

Silicon-germanium is an important material that is used for the fabrication of SiGe heterojunction bipolar transistors and strained Si metal-oxide-semiconductor (MOS) transistors for advanced complementary metal-oxide-semiconductor (CMOS) and BiCMOS (bipolar CMOS) technologies. It also has interesting optical properties that are increasingly being applied in silicon-based photonic devices. The key benefit of silicon-germanium is its use in combination with silicon to produce a heterojunction. Strain is incorporated into the silicon-germanium or the silicon during growth, which also gives improved physical properties such as higher values of mobility. This chapter reviews the properties of silicon-germanium, beginning with the electronic properties and then progressing to the optical properties. The growth of silicon-germanium is considered, with particular emphasis on the chemical vapour deposition technique and selective epitaxy. Finally, the properties of polycrystalline silicon-germanium are discussed in the context of its use as a gate material for MOS transistors.

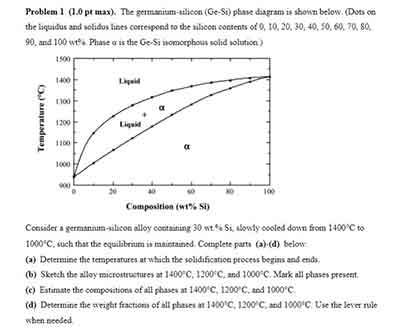

The Silicon-Germanium Phase Diagram

The silicon-germanium phase diagram shows the different phases of the semiconductor. The four  main phases are the n type, p type, and s type. The n type reflects the majority of electrons, while the p type represents the minor-ity. The donor-type impurities are phosphorous, antimony, arsenic, and tin. In the solid-state, electrons contribute more to electrical conductivity than do holes.

main phases are the n type, p type, and s type. The n type reflects the majority of electrons, while the p type represents the minor-ity. The donor-type impurities are phosphorous, antimony, arsenic, and tin. In the solid-state, electrons contribute more to electrical conductivity than do holes.

In the solid-state, the valence electrons move to an acceptor energy level and leave behind an electron hole. This produces additional holes, which are largely responsible for the presence of charge carriers. These electrons are referred to as p types. For a given temperature, the valence electron energy levels of silicon and germanium are similar, although the valence electrons are more abundant. The s and p types have higher densities and are the dominant types of charge carriers in these two materials.

The phase diagram for silicon-germanium shows the initial growth interface, which corresponds to the melting point of the metal. As the silicon displaces from the valence band into the solution, the concentration of local silicon increases. The region with the least solubility is the lowest temperature, and precipitation begins. If the precipitation is allowed to continue, the material is solid. However, this is not an easy process to observe if you want to observe crystallization at its earliest stage.

What is Strained Silicon?

Strained silicon is a layer of silicon that has been manipulated so that the silicon atoms are stretched past their normal interatomic distance. It is made by placing silicon on top of a substrate of either silicon germanium or silicon. This process results in a material that is very thin and very strong, but also very fragile. For this reason, it is very important to know what is strained silicone. To learn more, keep reading.

Straining silicon reduces the effective mass of silicon, which increases the mobility of carriers. It also makes the material more efficient, as it uses less energy to produce a chip. Straining silicon also improves chip performance by reducing the amount of power consumed by the chip. Unlike normal silicon, it is able to handle higher voltages, which means it is more power-efficient. Moreover, strained semiconductors are not susceptible to heat and can be cooled more easily than ordinary materials.

Another key advantage of strained silicon is its reduced effective mass. Straining makes the silicon atoms less mobile, so that they move more readily in response to a voltage. This makes strained semiconductors more energy-efficient. If you're interested in making a semiconductor device, this is the way to go. With a little bit of effort, you can make your own. Just make sure you choose a manufacturer with a track record of producing semiconductors.

Straining silicon changes the lattice constant of silicon by 1%, so it changes the electronic band structure. This modification makes it possible for carrier mobilities to move faster in response to voltage. Several nMOS transistors have been made with this process. If you're interested in a high-performance semiconductor, try out a strained silicon product. It can improve your computer's performance dramatically.

In addition to the advantages of strained silicon, it has a high-quality, reliable semiconductor. A high-quality chip can last for a long time. If you want to reduce power and energy consumption, you should opt for a strained silicon product. In the case of a transistor, it should be strained in two directions. If this is done, it will increase the speed. If you want to improve the reliability of your product, you should try a twisted silicon.

Strained silicon is a type of semiconductor that offers a trade-off between power and speed. It works by lowering two of the six electrons in silicon to a lower energy level, allowing it to achieve the same conductance with less power. However, it requires a perfect homogeneous structure to work. This is why it is important to understand what is strained silicon. The difference between a strained semiconductor is crucial.

Strained silicon is a material that has a higher effective mass than standard silicon. It is not as dense as regular silicon, and it has more mobility than normal silicon. The high-quality crystalline material will not suffer from this disadvantage. The low-quality strained silicon is used for applications like memory and semiconductors. The process does not only result in a strained semiconductor, but is also safer and more effective.

The underlying silicon germanium layer acts as a substrate and provides the necessary support for the silicon film. The silicon atoms are strained by aligning themselves with the underlying silicon germanium layer. This makes the silicon hyperlinks stretch and the crystalline structure become distorted. Because the strain varies with the direction and magnitude of the stress, it has different properties than normal silicon. The distorted crystalline structure is not conducive to damage and it helps reduce the energy consumption.

In the same way as the strained silicon film, it is made by stretching two layers of silicon over a layer of silicon germanium. The silicon atoms are 1% more distorted than the underlying silicon germanium, which improves its mobility and energy efficiency. Because of this, strained silicon is more expensive than standard silicon. Despite the high price tag, the benefits of strained semiconductors are clear. When using a strained silicon film, it is vital to read the specifications carefully.

Strained silicon is a new kind of silicon. The term is an abbreviation for strained silicon. The term'strained silicon' is derived from the Latin word'strained'. The word'strained' refers to the process of stretching a semiconductor. It is an extension of the word'strain.' The result is a strain that stresses the material. When a semiconductor is strained, it becomes brittle. It will not break.

What are Silicon Germanium (SiGe) Substrates Used For?

Silicon germanium (SiGe) substrates are used in a variety of applications in the semiconductor industry. SiGe is a material that combines the electrical properties of silicon and germanium, which can be used to create electronic devices with high-performance characteristics.

One common application of SiGe substrates is in the production of high-speed integrated circuits, such as radio frequency (RF) circuits used in wireless communication devices. SiGe substrates can improve the performance of these circuits by increasing their frequency response and reducing their noise levels.

SiGe substrates are also used in the production of high-performance photovoltaic cells, which are used to convert sunlight into electricity. The addition of germanium to silicon can increase the efficiency of these cells by improving their absorption of light.

In addition, SiGe substrates can be used in the production of high-temperature electronics, such as sensors and power devices, due to their ability to withstand extreme temperatures without degradation.

Overall, SiGe substrates have a wide range of applications in the semiconductor industry, and their unique properties make them an attractive choice for many different types of electronic devices.