Is magnetic Hall effect technology dead? How does it compare to TMR technology?

Magnetic Hall effect technology is not dead, but it has been largely supplanted by newer, more sensitive magnetoresistive technologies like TMR (Tunnel Magnetoresistance) and GMR (Giant Magnetoresistance) in high-performance applications.

Comparison of Hall Effect vs. TMR Technology

| Feature |

Hall Effect |

TMR (Tunnel Magnetoresistance) |

| Principle |

Measures voltage induced by Lorentz force on charge carriers in a conductor |

Uses quantum tunneling between two ferromagnetic layers separated by an insulating barrier |

| Sensitivity |

Low (in the mT range) |

High (in the nT to μT range) |

| Power Consumption |

Generally higher |

Lower, due to resistance-based sensing |

| Size |

Can be miniaturized but requires a significant current |

Typically smaller for the same sensitivity |

| Speed |

Fast response |

High-speed, but slightly slower than Hall for some applications |

| Temperature Stability |

Moderate, affected by drift |

Better stability in advanced designs |

| Cost |

Low-cost and widely available |

More expensive but improving with CMOS integration |

| Applications |

Automotive (current sensors, position sensing), industrial, consumer electronics |

Hard disk drives, MRAM, magnetic field sensors, and some biosensors |

Why TMR is Replacing Hall Effect in Many Applications

- Higher Sensitivity – TMR-based sensors can detect much weaker magnetic fields, making them superior for precision applications like data storage and biosensing.

- Lower Power Consumption – TMR sensors work with very small currents and voltages, making them more energy-efficient.

- Better Signal-to-Noise Ratio – Less susceptible to thermal noise and interference.

- Integration with CMOS – TMR sensors are increasingly being integrated into semiconductor processes, which improves performance and scalability.

Where Hall Effect Still Dominates

- Cost-sensitive applications like automotive speed sensors, current sensors, and industrial encoders.

- High-speed applications where response time matters more than sensitivity.

- Simple, robust solutions where extreme sensitivity is unnecessary.

Conclusion

While Hall effect technology is not dead, it is increasingly being phased out in favor of TMR and other magnetoresistive technologies for high-precision, low-power, and compact applications. However, for basic and cost-sensitive applications, Hall effect sensors remain viable and widely used.

What Is TMR (Tunnel Magnetoresistance)?

Tunnel Magnetoresistance (TMR) – Overview

Tunnel Magnetoresistance (TMR) is a quantum mechanical phenomenon where the electrical resistance of a magnetic tunnel junction (MTJ) depends on the relative orientation of the magnetization in two ferromagnetic layers separated by a thin insulating barrier.

How TMR Works

-

Magnetic Tunnel Junction (MTJ) Structure:

- Two ferromagnetic layers sandwiching a very thin insulating layer (typically made of MgO).

- One layer has a fixed magnetic orientation (reference layer).

- The other layer’s magnetic orientation (free layer) can change in response to an external magnetic field.

-

Quantum Tunneling Effect:

- When the free and reference layers are aligned (parallel), electrons can tunnel through the barrier more easily, leading to low resistance.

- When the layers are opposite (antiparallel), tunneling is less probable, leading to high resistance.

-

TMR Ratio:

- Defined as the percentage change in resistance between parallel and antiparallel states.

- Higher TMR ratios mean better sensor performance.

- Modern TMR devices achieve over 500% TMR ratio, compared to only ~10% in GMR.

TMR vs. Other Technologies

| Feature |

TMR (Tunnel Magnetoresistance) |

GMR (Giant Magnetoresistance) |

Hall Effect |

| Principle |

Electron tunneling through an insulator |

Electron scattering in multilayers |

Voltage induced by Lorentz force |

| Sensitivity |

Very high (nT to μT) |

High (but lower than TMR) |

Low (mT range) |

| Power Consumption |

Very low |

Moderate |

Higher |

| Temperature Stability |

Good (MgO-based MTJs are stable) |

Moderate |

Moderate |

| Size |

Can be miniaturized to nanoscale |

Nanoscale possible |

Larger for same sensitivity |

| Applications |

MRAM, HDD read heads, magnetic sensors, biosensors |

HDD read heads, sensors |

Automotive, current sensors |

Applications of TMR

- Magnetic Sensors – High-precision field sensing in robotics, biomedical devices, and industrial automation.

- MRAM (Magnetoresistive RAM) – A non-volatile memory alternative to flash and DRAM.

- Hard Drive Read Heads – Used in high-density HDDs due to their sensitivity.

- Biosensors – Detecting biomolecules tagged with magnetic nanoparticles.

- Wearable & IoT Devices – Energy-efficient magnetic sensing.

Why TMR is Important

- Low power consumption makes it ideal for battery-powered applications.

- High sensitivity enables applications in weak magnetic field detection.

- Scalability with CMOS allows easy integration into semiconductor processes.

TMR is now the dominant technology in next-generation magnetic sensors and memory devices, outperforming both Hall effect and GMR in many applications.

Giant Magnetoresistance (GMR) – Overview

Giant Magnetoresistance (GMR) is a quantum mechanical effect observed in multilayered magnetic structures, where the electrical resistance significantly changes based on the relative orientation of magnetization in alternating ferromagnetic layers. It was discovered independently by Albert Fert and Peter Grünberg in 1988, earning them the 2007 Nobel Prize in Physics.

How GMR Works

-

GMR Structure:

- Consists of alternating thin layers of ferromagnetic material (e.g., Fe, Co, NiFe) and non-magnetic conductive material (e.g., Cu, Ag, Au).

- The thickness of the non-magnetic layer is critical (typically a few nanometers).

-

Spin-Dependent Electron Scattering:

- When the magnetization of adjacent ferromagnetic layers is aligned (parallel), electron scattering is reduced, leading to low resistance.

- When the magnetization is opposite (antiparallel), electron scattering increases, causing high resistance.

- The change in resistance (magnetoresistance ratio) can be as high as 10–50% in standard GMR devices.

Types of GMR

-

Multilayer GMR:

- Alternating ferromagnetic and non-magnetic layers.

- Resistance change is based on spin-dependent electron scattering.

-

Spin-Valve GMR (most common in applications):

- Uses a fixed reference layer and a free layer whose magnetization can be changed by an external magnetic field.

- A small external field is enough to switch the free layer, making it highly sensitive.

GMR vs. TMR (Tunnel Magnetoresistance)

| Feature |

GMR (Giant Magnetoresistance) |

TMR (Tunnel Magnetoresistance) |

| Principle |

Electron scattering in multilayers |

Electron tunneling through an insulator |

| Structure |

Ferromagnetic/Non-magnetic/ Ferromagnetic |

Ferromagnetic/Insulator/ Ferromagnetic |

| Magnetoresistance Ratio |

~10-50% |

>500% (modern TMR devices) |

| Sensitivity |

High |

Very High (better at weak field detection) |

| Power Consumption |

Moderate |

Low |

| CMOS Compatibility |

Moderate |

Better (easier integration) |

| Applications |

Hard drives, magnetic sensors |

MRAM, HDD read heads, ultra-sensitive sensors |

Applications of GMR

- Hard Drive Read Heads – Revolutionized HDD technology by enabling ultra-high storage densities.

- Magnetic Field Sensors – Used in automotive, industrial, and biomedical applications.

- Spintronics – Basis for developing new devices that use electron spin for information storage and logic.

- Biosensors – Detecting magnetic nanoparticles for biomedical diagnostics.

Why GMR Was Revolutionary

- GMR allowed the development of high-density storage (modern HDDs).

- It laid the foundation for spintronics, leading to TMR-based MRAM and advanced magnetic sensors.

- Though TMR has largely replaced GMR in newer applications, GMR is still used where lower-cost, moderate-sensitivity solutions are needed.

Conclusion

GMR was a breakthrough in magnetic sensing and storage technology, but TMR now surpasses it in performance and efficiency. However, GMR is still widely used in hard drives, automotive sensors, and industrial applications where extreme sensitivity is not required.

What is a Hall Effect Sensor?

A Hall Effect sensor is a magnetic device that works by detecting changes in magnetic fields.  The magnet produces an electric field that interacts with ions to cause a change in the electrical resistance of the device. This phenomenon is also known as the Hall effect. This electrical device can also detect other changes in the environment. In this article, we will explore how this type of magnetic sensor works and how it is used in different applications. In addition to being used in electronics, it is also used in the automotive industry.

The magnet produces an electric field that interacts with ions to cause a change in the electrical resistance of the device. This phenomenon is also known as the Hall effect. This electrical device can also detect other changes in the environment. In this article, we will explore how this type of magnetic sensor works and how it is used in different applications. In addition to being used in electronics, it is also used in the automotive industry.

The Hall effect works by measuring a magnetic field, which is produced by a current passing through a conductor. It is used in electronic equipment to detect the current flowing through an electrical circuit. These sensors are inexpensive, requiring no transformers, and can be installed in a variety of applications. Despite being inexpensive, this type of sensor does not use any expensive components. It is not a substitute for other types of sensors, but it is an excellent way to measure the electrical current of a device.

The Hall effect sensor has been used for over fifty years and is one of the most popular types of sensors available. It can detect magnetic fields and their intensity with accuracy. This technology can be used in a variety of applications, including medical devices, automotive sensors, and many more. There are many uses for a hall effect sensor, and you can learn more about its benefits by reading this article. What is a Hall Effect Sensor? What Does It Do?

A Hall Effect sensor works by measuring the magnetic field of a conductor. It can be used for a variety of applications and can be found in many electrical equipment. A Hall Effect Sensor does not require the use of costly transformers and is a great choice for measuring electric currents in electrical systems. It's easy to learn more about this simple sensor by visiting Wikimedia Commons. The Hall Effect in a Wireless Application

A Hall Effect Sensor uses magnetic fields to detect magnetic fields. When a magnetic field passes by the sensor, it produces an output signal. If the magnetic flux density is above a threshold, the Hall Effect is activated, generating a Hall voltage. A Hall Element is made of thin rectangular p-type semiconductor materials, such as gallium arsenide or indium borohydride. These sensors are very sensitive to a magnetic field and can be used in many applications.

The Hall Effect Sensor is used in electrical applications. The output signal of the sensor depends on the magnetic flux density around it. It produces a Hall voltage if the magnetic flux density is above a threshold. This type of electromagnetic sensor is very suitable for current sensing applications. The corresponding graph shows the six steps of commutation. In the image below, a schematic of the Hall Effect Sensor can be seen.

When an electric current flows through a material, electrons move in a straight line. When a magnetic field is applied to a material, the electrons will be attracted to the magnetic field and move in a straight line. The resulting voltage will represent the amount of flux and strength of the magnetic field. Its output voltage is proportional to the magnetic flux density. This makes the Hall Element an excellent choice for detecting changes in the speed of a rotating object.

A Hall-effect sensor is a non-contact device that detects changes in magnetic fields. The Hall-effect switch switches states by sensing the magnetic field of a magnet. It switches to the active state when B OP is opposite to BRP. The same applies to its inactive state. The output voltage of a Hall-effect switch depends on the magnetic field polarity. In the latter case, the magnet will not be affected by the magnet.

The Hall-effect sensor uses a magnetic field to detect changes in the magnetic field. When a magnet is near to the sensor, a small voltage is generated. This voltage is then passed to other electronic devices. The most common example of a Hall-effect sensor is a wheel speed sensor. A car's wheels have a small magnet that is in constant contact with the metal wheel. The movement of the magnet in this case will turn the wheel, generating a current and the voltage will increase.

How Do Hall Effect Sensors Work?

If you're curious about the technology behind hall effect sensors, it's important to understand how they operate. Hall Effect Sensors use a simple electromagnetism principle to detect a magnet's proximity. When a magnet passes close to the Hall Effect Sensor, it generates a small voltage. That small voltage is then sent to an amplifier, where it is amplified to a higher voltage to be used by other electronic devices. One example of a Hall Effect Sensor is a wheel speed sensor. A small magnet is attached to the interior of a wheel, which passes over the Hall Effect Sensor. The movement of the magnet equals the rotation of the wheel, and the information is then passed to a speedometer or odometer unit. In turn, the information is displayed on the speedometer.

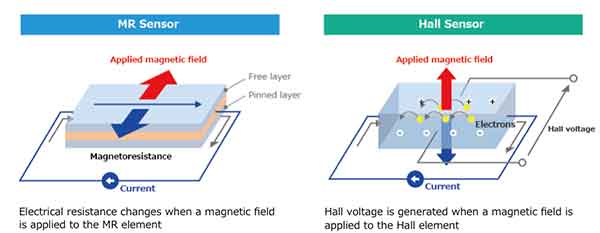

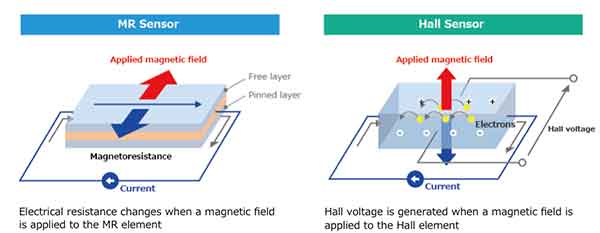

- MR Sensor - Electrical resistance changes when a magnetic field is applied to the MR element

- Hall Voltage is generated when a magnetic field is applied to the Hall Element

Linear Hall Effect Sensors: They measure the strength of a magnetic field and produce a voltage proportional to the measurement. A linear Hall Effect Sensor can also measure the angle a magnet is at. The four different methods for determining an angle can be described by the method used: no calibration, peak calibration, lookup table calibration, and hybrid angle measurement. In addition, linear Hall Effect Sensors measure the direction of a magnet.

Hall Effect Sensors are made up of a single semiconductor that changes the voltage when a magnetic field is applied to it. A conductor's material directly affects the quality of the Hall Effect. Various types of semiconductors are used in Hall Effect devices, with indium arsenide being the most common. The rectangular conductor is ideal for the device because it allows carriers to pool at the edges. If you're curious about how Hall Effect sensors work, this article should help.

The most basic circuit in a Hall Effect Sensor is based on the principle of hysteresis. The hysteresis between the Bnp and BRP makes the switching action more reliable. It allows the Hall Effect Sensor to detect motion as the target moves past the Hall element. The result is that the sensor output changes from a low to a high level when the target moves past the Hall element.

A Hall Effect sensor is used for many different applications. These sensors can detect proximity, speed, and current. They are commonly used on pneumatic cylinders to communicate the position of the cylinder to a PLC or robotic controller. Hall Effect Sensors are also used in the automotive industry, where their magnetic properties make them more resistant to wear and tear than mechanical systems. This is a crucial benefit for car companies who need to monitor car parts.

Hall Effect Sensors operate by detecting mechanical variables using a magnetic field. These sensors don't require any physical elements to operate. Hall Effect Sensors produce either an analogue or digital signal, depending on the type of magnetic field they are exposed to. They can also produce an on and off signal. The basic principle is the same for both bipolar and unipolar Hall Effect Sensors. In addition, they are a great option for remote monitoring.

Video: Hall Effect Explained

Silicon Wafer Hall Effect Sensor Research

As a long-standing and unshakeable specialist in the field of magnetic sensors, Hall effect sensors have played a central role in a wide range of applications in this area for decades. With a portfolio of magnetic sensors that offer industry-leading energy efficiency, built-in, tamper-free, and easy-to-use Hall effect sensors, we are bringing Hall effect sensors into the 21st century with our new silicon wafer halo effect sensor. Lossless, isolated current sensor technology based on the Hall Effect current sensor, which provides the ability to provide the same level of sensitivity and performance as a conventional magnetic field sensor, but without the need for a power source. [Sources: 0, 2, 9]

The Hall sensor's operating principle is based on the Hall effect, which states that the voltage nbsp increases when a conductor carrying current is placed in a magnetic field. The function of a Hall sensor generates reverberation voltage, just like a semiconducting platelet, and is based on the physical principles of the Hall effect. A small plate made of semiconductor material can be used as a "Hall element," as reverberation effects are pronounced in most semiconductors. We can measure current and voltage values of halo sensors with silicon wafers using Hall effects. [Sources: 2, 8, 11]

After the Hall effect sensor [132] is manufactured, an insulating layer [348] is applied to it and then produced on a silicon wafer. [Sources: 1]

They are then mounted side by side, separated by an air gap to form the Hall Effect Sensor. It is then used, as the name suggests, to detect magnets, and the sensor's magnetic field is manufactured in such a way that it is able to manufacture according to the reverberation effect. The Hall sensor is a Hall sensor that was the first of its kind in the world to be produced by producing a magnetic field sensor based on the "Hall effect." In this article we will explain how this sensor works to help us identify possible causes through it. Hall effect sensors are capable of operating under a wide range of conditions, such as high temperatures, low temperatures and high humidity, as shown in Figure [348]. [Sources: 2, 4]

The line 444 is an electrically suspended semiconductor "finger" and acts as the source of the magnetic field of the Hall effect sensor and its resonant effect. line 444, which is the result of a semiconductor finger electrically suspended on the surface of an air gap. [Sources: 6]

Line 442 is the result of a semiconductor "finger" grounded on the surface of an air gap and whose resonance is acting. The AMR sensor circuit (182) consists of the Hall effect sensor circuits (604 - 606), which are formed by the ground semiconductors (linger) and the sensor magnetic field (444 - 444). Line 4 42 is an electrically suspended semicode electrical "finger" anchored in the air gaps (residence gaps) in the center of its circuit and surrounded by a surface gap (Ling). [Sources: 3, 6, 7]

A variety of vertical Hall effect sensors mounted on a toroid semiconductor wafer (12) from a Hall sensor device [10] to build a vertical Hall effect sensor [14]. A plurality in a horizontal Hall effect sensor (13), including an electrically suspended semiconductor finger (line 442) and an air gap in the middle of the sensor circuit (Ling), and a plurality (vertically) in an electric circuit with a Hall effect sensor (14) on top. In this case, the semicurate wafers [12] consist of Hall sensors (10), while the vertical (Hall Effects Sensor) is made up of the toroids of a silicon wadding [13, 14, 15, 16, 17]. [Sources: 6]

This article examines how a solid-state magnetic field sensor is an important component of the smart grid system for smart grids. Hall effect sensors are often used in the automotive industry, and CERN wants to use this sensor to develop a novel magnetic field mapping system. This is a Hall effect sensor that is used to switch proximity switches on and off in the power grid and, if necessary, in power supply systems. October 2015: The efficient operation of a "smart grid" is based on the ability to measure this article. The sensor can work with a variety of different sensor types such as magnetic fields, magnetic resonance imaging (MRI) and magnetometers. [Sources: 2, 5]

In this respect, the magnetic field sensor device includes a variety of vertical Hall effect sensors that interdigitize the electrodes of the Hall effect sensor. In this context, it covers the plurality of vertical and number of positions recorded in 3D. Other examples include the use of magnetic resonance imaging (MRI) and magnetometers, as well as a variety of other applications such as controlling power supply systems. [Sources: 3, 6]

The Dr. Hall Effect sensor, as its name suggests, works on the principle of the Hall effect, and the design of the Hall current sensor is based on this. This can be detected and measured with a so-called "Hall effect sensor probe." The principles of this effect are presented as follows: Where it is used, it uses a magnetic field sensor with two electrodes, one in the middle and one on top. It is then used to detect magnets (as the name suggests) and this module works after the principles for reverb effects have been discovered. [Sources: 2, 10]

Sources:

[0]: https://www.paragraf.com/article/redefining-hall-effect-sensors-with-graphene/

[1]: https://www.google.com.na/patents/US20090137066

[2]: http://pensareseguros.com.br/q4igbfkh/hall-effect-current-sensor-working-principle.html

[3]: https://patents.justia.com/patent/10374004

[4]: https://en.wikipedia.org/wiki/Hall_effect

[5]: https://eepower.com/news/paragraf-and-cern-partner-for-new-hall-effect-sensor/

[6]: http://www.freepatentsonline.com/y2016/0190433.html

[7]: https://www.google.com/patents/EP3039440A1?cl=en

[8]: https://slideplayer.com/slide/9022746/

[9]: https://www.electronicproducts.com/silicon-labs-magnetic-sensors-modernize-hall-effect-switch-and-position-sensing-for-the-iot-era/

[10]: https://www.explainthatstuff.com/hall-effect-sensors.html

[11]: https://www.medicaldesignbriefs.com/component/content/article/mdb/features/technology-leaders/35094

What Turns On and Off a Hall Effect Reed Switch?

What turns on and off a Hall effect reed switch? This article will answer your question on this subject. Learn more about this type of switch and its benefits. Its contactless sensing ensures that it will not get damaged by physical contact, making it a smart choice for many applications. Hall Effect switches are also more durable than reed switches, thanks to their contactless nature.

Why Use Hall Effect Sensor?

The basic idea of a Hall effect sensor is to detect when a target passes in front of it. The Hall element responds to this movement by generating a voltage. The voltage is measured by the comparator and sent to a circuit. Once the switch is activated, the circuit applies a voltage to an NPN transistor. This transistor changes state and opens the circuit. The result is a digital signal.

In order for a Hall effect sensor to work, the device must be in a magnetic field. If a magnetic field is present, the sensor will turn on. When a magnet is removed from the device, it will turn off. This contactless design helps ensure a high mechanical life, durability, and ruggedness. Hall effect switches are often used in industrial applications. If you're looking for a simple switch, check out the features of a Hall effect sensor.

The main differences between linear and bipolar Hall-effect sensors can be easily explained by their different uses. Linear Hall-effect sensors are used for rotary encoding and toggle output only when magnetic polarity is reversed. A bipolar Hall-effect sensor is a more complex design because it needs a magnetic field to work. You can use it for various purposes, including turning on and off a Hall effect switch.

A Hall-effect sensor works by detecting the magnetic field of a material. A magnet creates a magnetic field when it is charged. A magnet placed between poles creates a magnetic field, which deviates the electrons' path. The resulting deviated path is known as a Hall effect. There are various types of Hall-effect switches and they work well in both high-end and low-end products.

What is Hall Effect Latch?

A Hall effect switch is a device that retains its output when a weak magnetic field is applied. It is also called a latch, and the output of a Hall effect switch is either logic high or low. Hall switches are primarily used in magnetic field sensors, such as those used in computers and MRI machines. However, they can also be used in other applications, too. Here's how it works: Multiple magnets are incorporated into a simple structure called a "ring magnet". Each ring magnet has alternating polarity zones. Hall latch devices are adjacent to each ring magnet, and when they rotate, magnetic zones pass through them. The magnetic fields move the Hall latch device past the ring magnets, causing the device to be switched on and off. This process is known as "Hall effect", and is measured in

The first step in a Hall effect sensor is to move the permanent magnet's south pole toward the active area of the Hall effect switch. Once the magnetic field reaches the release point, the Hall effect switch remains "ON". Similarly, a bipolar Hall effect sensor must expose its magnetic north pole to the magnetic south pole. A large power transistor can also be used instead of the LED. Its advantages include switching larger current loads.

The second step is to install a magnet near the sensor. In this way, a magnetic field can be generated. This is known as head-on detection. The magnetic field must approach the Hall effect sensor directly, as opposed to being offset from the sensor. Once the magnet is inside the sensor, the magnetic field produces an output signal that represents the strength and density of the magnetic field. The output voltage is proportional to the strength of the magnetic field.

What is a Hall Effect Reed Switch?

The Hall effect reed switch is an electromechanical device that turns on and off. Its magnetic field is generated by a biasing magnet with a strength of 3 mT. When the magnet is in its active state, it produces a magnetic field that opposes the EMF. This result in contacts that are closed. The switch then remains closed when the BMF is absent.

The magnetic sensitivity of a reed switch is higher than that of a solid-state digital switch. For this reason, high sensitivity is important for designing systems that operate correctly under all operating conditions. A typical reed switch with a sensitivity of 18-22 AT is approximately 20 percent sensitive compared to a micro-power Hall effect sensor that has a sensitivity range of 25-55 Gauss and a nano-power MR sensor that has a sensitivity range of 6-20 Gauss.

Reed switches are low-cost, versatile, and energy-efficient. Reeds can be customized to meet your application's needs and energy-efficiency requirements. Their low power consumption makes them a good alternative for magnetic sensors. They can also be programmed to overcome a reed's weakness. And because they don't require power during their passive state, they are ideal for applications that require high energy efficiency.

Reed switches are safe for use around explosive gases and chemicals, since the sparking from the switching action is contained within the switch housing. They are widely used in security applications, such as speed sensors in automobile gears and bicycle wheels. These switches are also used as proximity sensors in clamshell-style electronic devices. Examples of such devices include flip phones and laptop computers. They can operate under a wide temperature range and in harsh environments.

What are Hall Effect Latches?

A bipolar switch has three transfer functions. The first is a positive (BRP) magnetic field, while the other two are negative (BOP). One of these has a latch-type response, and the third is a bipolar switch. These three types of Hall effect switches are manufactured in the same lot. The Allegro Company provides an application note to help you choose the right one.

The MLX92213 is designed for battery-operated applications and employs an "awake/sleep" strategy for low power consumption. The magnetic flux density is periodically evaluated against a predefined threshold. If it exceeds or falls below the threshold, the device changes state. The MLX92213 is also optimized for extended operating life. To learn more about Hall effect switches, check out the information below!

Bipolar Hall effect sensors are based on the Hall effect. They operate similarly to switches, and provide a switching output when a sufficiently large South Pole magnetic field is present. They remain on until the corresponding North Pole magnetic field is detected. The Hall effect sensors can create 50% duty cycles for measuring speed, and can be used to turn on and off a specific range of movement. If you're thinking about buying a bipolar Hall effect sensor, you may want to look into this one.

Another use for Hall sensors is as a binary switch. They detect the presence of a magnetic field and respond by switching on or off transistors. These devices are great for measuring a variety of parameters, including temperature and pressure. Hall effect sensors are generally divided into analog and digital varieties. They are most commonly used in proximity sensors. And there are many other applications for them in industry. So, whether you're looking for a simple switch or a complex one with countless applications, there's a Hall effect sensor for your application.

What are Hall Effect Sensors Devices?

A Hall effect sensor is a device that detects a magnetic field around a conductor. The Hall effect is a predictable phenomenon that occurs when a current flows through a conductor. It works by detecting magnetic flux density above or below a threshold and producing a Hall voltage. Hall effect sensors are made of a thin rectangular p-type semiconductor material, typically gallium arsenide, indium antimonide, or indium arsenide.

Hall effect sensors work as switches. They switch on or off depending on the presence of a magnetic field. The US5881LUA Hall effect sensor, sold by Adafruit, is normally HIGH and switches to LOW when the magnetic pole of the South is present. Another Hall effect sensor, the US1881, is called a latching Hall effect sensor. It switches to HIGH in the presence of the north magnetic pole, but remains in this state until a south magnetic pole is detected.

In order to trigger a circuit, a resistor is connected to the signal and the collector of an NPN transistor. The target must move past the Hall element for the voltage to be measured. Once the target has passed the Hall element, the non-toothed Hall voltage is measured by a capacitor. A comparator is then used to compare the two voltages. The comparator then sends the voltage signal to a transistor, which changes its state and opens the circuit. The voltage then becomes five volts.

Magnetic Hall effect sensors are used in various applications, including industrial and consumer electronics. They measure the induced magnetic field around a wire and can localize objects. In fact, the modern automotive car contains more than 10 Hall effect sensors, including the windshield wiper and the brake and gas pedals. They also sense the ignition system and can detect the speed of motors. The magnetic Hall effect sensor can be connected to a precision-programmed Speed Switch Meter.

Video: Hall Effect Sensor

How Do You Test a Polaris Hall Effect Sensor?

If your Polaris isn't working properly, you might wonder how to test a Polaris Hall effect sensor. Fortunately, there are several things you can try to make sure your sensor is functioning correctly. These sensors are easy to install and configure in the ECU software, but they are also very sensitive to the Air Gap between the sensor and the trigger material. You can also try troubleshooting a sensor using a CKP, or common electrical connectors.

Reluctor Sensors Are Extremely Reliable

Reluctor sensors are highly reliable in that they measure the actual amount of pressure in the air filter. This is because the signal generated by the reluctor depends on the cranking speed. This is an important aspect because if the cranking speed is too slow, the voltage generated by the reluctor will not be correct. Luckily, many types of reluctor sensors have very reliable voltage outputs, and their performance is excellent.

Reluctor sensors have a very low margin of error, which makes them an excellent choice for many automotive applications. They require a highly accurate sensor mount. The sensor must be mounted precisely, with a small gap between it and the trigger tooth. This ensures trouble-free operation. The sensitivity of reluctor sensors is highly dependent on their mounting accuracy, which is one reason why they are so reliable.

When installed correctly, the reluctor sensor is able to monitor cylinder misfires. The crankshaft position sensor must be installed so that the reluctor ring is at the correct tip of the engine. During the process, the crankshaft position sensor generates a voltage signal corresponding to the tooth on the reluctor ring. The engine management system will set a code in case of misfiring cylinders.

Reluctor sensors are highly reliable, and the most common type of wheel speed sensor is the variable-reluctance magnetic sensor. These sensors contain a permanent magnet pickup core and a coil surrounding it. These sensors are typically found on pre-2003 vehicles, and require a voltage input from the ABS controller. These sensors produce a square-wave signal, and the high signal must be at least 1.93 volts to be considered high. The low signal must cross 0.97V to be considered low.

They are easy to mount and configure in the ECU software

Hall effect sensors are simple to mount and configure in the ECU software, and are compatible with all types of vehicles. They require a 5V, 8V, or 12V power supply, a 0V signal ground, and a Trigger + and - connection. Choosing a hall sensor should be done carefully, as they do not like to get hot and may miss the teeth you want to detect.

To configure a Polaris Hall effect sensor, first install the wiring harness. The wires for the sensor are easily accessible. You should use a small screwdriver to connect the sensor to the electrical connection. Then, connect the power supply to the sensor's power supply's negative terminal. You should then configure the ECU software to match the voltage level. Once the wiring harness is installed and calibrated, you can now mount the sensor in the vehicle.

The Hall Effect Sensors are a common upgrade for Polaris XPs. The Polaris Hall effect sensors are easy to mount and configure in the ECU software. Installing these sensors is quick and simple, and will make your ride more comfortable. They also improve fuel efficiency. This technology can be used to increase horsepower, reduce emissions, and improve the acceleration of your vehicle.

The Polaris Hall effect ABS sensor has a two wire configuration, which means there is no direct ground and a ground wire that is also a signal. The Hall Effect ABS sensor's circuitry is a current regulating system, which means the current flowing through it changes when a tooth passes by. The gap causes the opposite current to flow through the circuit. A voltage is produced by this current through the resistor, similar to the square wave signal produced by the 3 wire Hall Effect ABS sensor.

When you install Polaris Hall effect sensors in your car, you can easily install them in the engine and configure them in the ECU software. They are compatible with many different vehicles and are easy to install. They are compatible with most major brands, and are easy to configure in the ECU software. You'll be amazed at how easy they are to install and configure. You can even do it yourself!

They are extremely sensitive to the Air Gap between the sensor and the trigger material

The Air Gap is the limiting factor in the measurement accuracy of the Polaris Hall effect sensors. They are designed to change the shape of the airspalt during the rotation of the well. This Air Gap must be the same as the gap between the sensor and the trigger material. A strut attached to two opposing points may improve the accuracy of the position measurement. The sensors are also very sensitive to the Air Gap.

Various methods are used to measure the Air Gap between the sensor and the Trigger material. The most popular technique is the use of magnetoelastic materials. These materials can record mechanical stresses without the use of contact. It is difficult to fabricate permanent connections, however. Other methods include measuring the Rotational Angle Offset of the Trigger Material and the Air Gap.

For best results, select a high-quality hall effect sensor that is capable of handling the tooth frequency of the target. Avoid those that have in-built filtering, as this will cause the sensor to miss the teeth it's intended to detect. They are also sensitive to temperature. They should never be used at higher temperatures than 90 degrees Celsius. If possible, mount the sensor with a small Air Gap between the sensor and the trigger material to avoid any problems.

Polaris Hall effect sensors are highly sensitive to the Air Gap between the sensor surface and the trigger material. The Air Gap between the sensor and the trigger material must be small to prevent the sensors from detecting a wide range of objects. This will ensure that the sensor works properly. There are many types of Hall effect sensors, and each one has its own unique characteristics.

Polaris Hall effect sensors are extremely sensitive to this Air Gap, and as a result, the Air Gap between the sensor and the target trigger material is very important. The sensors are usually located on the hub, rotor, drive shaft or hub. A large Air Gap between the sensor and trigger material can affect the accuracy of the measurement. The sensor will then measure the torque with a positive sign, which will make it difficult to miscalculate the torque.

They are easy to troubleshoot a CKP

A CKP sensor monitors the position of the crankshaft and piston to help the computer detect engine misfires and speed. It endures heat and vibration from engine operation, which can lead to a faulty CKP sensor, which can fail as a component or wiring harness. Follow the steps below to troubleshoot your CKP sensor. Once you have identified the problem, check the connector or wiring harness for any signs of damage.

Check the resistance of the CKP sensor with a multimeter. A resistance of 200 to 2000 ohms is typical. If you cannot find this value, refer to your vehicle repair manual or online. However, do not try to read the resistance of a Hall effect sensor by hand as the voltage may damage the internal components. You can also use a multimeter.

You should be able to determine which Hall effect sensor is responsible for the CKP's symptom. It is also helpful to check the coil pack or throttle position sensor, as they can be the culprits for these symptoms. These two parts are usually easily accessible. To troubleshoot a CKP, you should follow the steps outlined in the repair manual. If these steps fail, you should visit the dealership and have it replaced.

Once you have figured out which sensor is responsible for the CKP, you can start troubleshooting it. It is important to take a moment to study the Hall Effect sensor's function. Basically, it produces a voltage transverse to a magnetic field. Hall effect sensors require a voltage feed circuit and an earth circuit. They are usually accompanied by a pulse wheel consisting of 36 or 60 teeth that disturbs the magnetic field of the sensor, modulating the Hall voltage.

You can also use a two-channel oscilloscope to analyze the signal. Its recording function helps you catch glitches that can affect the vehicle's operation. This is an excellent diagnostic tool for diagnosing a CKP sensor. You can even use it to troubleshoot other car problems. It is easy to troubleshoot a CKP sensor if you know what you're doing.

How Do You Make a Hall Effect Sensor?

A Hall effect sensor is an electronic device that detects magnetic fields. They are non-contact magnetometers made from DC amplifiers. If the target moves past the Hall element, the sensor detects the corresponding voltage. The non-toothed Hall voltage is stored on a capacitor. The comparator then compares the two and sends a signal to the trigger circuit, which applies a voltage to the NPN transistor. This transistor is connected to a circuit of resistors in the control unit.

Hall Effect Sensors are Modern Magnetometers

The Hall effect is a type of electromagnetic induction that favors materials with high mobility and low  conductivity. Metals are good candidates for Hall sensors, as they exhibit low mobility and high conductivity. III-V compounds, which combine high carrier mobility and reasonable conductivity, are often used for Hall sensors. Silicon is one such material, with moderate electron mobility and good compatibility with integrated circuit technology. The following section examines the Hall effect and how it works.

conductivity. Metals are good candidates for Hall sensors, as they exhibit low mobility and high conductivity. III-V compounds, which combine high carrier mobility and reasonable conductivity, are often used for Hall sensors. Silicon is one such material, with moderate electron mobility and good compatibility with integrated circuit technology. The following section examines the Hall effect and how it works.

The Hall effect is a nonlinear phenomenon that has enabled scientists to classify chemicals and refine semiconductive materials and measure magnetic fields. Hall effect devices measure magnetic fields by seeing the effects they have on a known current. A magnetic field changes the course of a flowing unidirectional current. This leads to a change in charge that produces a measurable voltage. The voltage increases proportionally to the strength of the magnetic field.

Compared to traditional magnetometers, Hall effect sensors measure magnetic fields in three dimensions. This is useful for determining the position of objects in three dimensions and to identify their relative position to magnetic north. Magnetic sensors, also known as Hall Effect sensors, are used in smartphones, GPS devices, medical scanners, and robotics. Besides determining location and orientation in space, they can also measure distance and speed. These sensors are commonly used in automobiles to help monitor vehicle movements.

Hall Effect Sensors are Non-Contact

Hall effect sensors are non-contact devices that measure current flowing through wires or conductors. They are becoming more common as the technology improves. These sensors integrate both the current path and the Hall element into a single, small package, called a silicon on insulator (SOI) chip. Examples of 8-pin SOICs include the Allegro ACS712 devices. They measure the density of current carriers and detect the presence of a current on a magnetic field.

Hall effect sensors use the magnetic field of an object to measure distance, proximity, and velocity. Because there is no contact with the object being measured, this type of sensor is considered non-contact. They can produce digital, closed-collector, analog, or continuous signals, depending on the size of the magnetic poles. They are also precise sensors, measuring the size of a magnet's magnetic field. However, they are not suitable for measuring temperature.

Hall effect sensors can be used to detect speed and rotation speed. They can be used for anti-lock braking systems and for timing the ignition of an internal combustion engine. They are also used in brushless DC electric motors to detect the position of a permanent magnet. Hall sensors are available in different sizes, from ultra-thin to large ones. They detect both AC and DC currents. Compared to inductive sensors, Hall sensors have a wider range of applications.

Hall Effect Sensors Can Detect a Magnetic Field

A Hall effect sensor is a type of magnetic detector that can measure the strength of a magnetic field. Hall developed this technology more than a century ago and its discovery was a breakthrough. Hall discovered the magnetic field in 1879 and its applications in electrical engineering and physics were a game changer for the time. Hall's work was so revolutionary that it was not widely used until semiconducting materials were understood and developed. Now, though, Hall effect sensors are being used for some interesting applications.

There are two basic methods to detect a magnetic field with Hall Effect sensors. The first method is called "head-on" detection, which involves a magnetic field perpendicular to the active face. The second method, which uses a sideways magnetic field, is called "sideways" detection. This technique is more accurate than head-on detection and allows for more flexibility in the placement of magnets. However, it does not work well in all applications.

One way to troubleshoot a Hall sensor circuit is to check for voltage drops at the power, ground, and output pins. The Hall sensor's voltage regulator is located inside the sensor, so you should measure these three voltages together. However, if you are using a three-pin Hall sensor that has an open-drain configuration, you only need two wires. The voltage drop at the output signal may be due to the voltage regulation in the Hall sensor.

Hall Effect Sensors are made of DC Amplifiers

Hall effect sensors are electronic devices that produce a measurable signal by applying a magnetic field to a metal surface. Different configurations of these devices can be used for different purposes. These devices are a favorite among electronics designers because of their low maintenance, robust design, and non-contact nature. Sealed Hall effect devices are largely immune to water, dust, and vibration. They are also commonly used in automotive systems for detecting speed and distance.

The Hall effect is an electrical phenomenon that occurs when an electric current flows perpendicular to a magnetic field. The voltage induced by this effect is measured in micro-volts and is a measure of the intensity of a magnetic field. Hall-effect sensors are often used in automotive applications, including speed sensors, end-of-travel sensors, and disk-drive index sensors. Hall-effect sensors were first discovered by Edwin Herbert Hall in 1879 at John Hopkins University. In his experiments, he used microvolts to measure the intensity of a static magnetic field.

Hall-effect sensors are a good choice for monitoring a magnetic field. When a magnetic field passes through a metal object, it produces a circular electromagnetic field. This means that this type of sensor can detect electrical current without the need for expensive transformers. The DC amplifiers are very easy to install and use. In addition to being inexpensive, Hall-effect sensors can measure voltage and current without the need for external wiring or expensive transformers.

They Have Logic Switching Circuits

There are two basic modes of operation for Hall effect sensors: head-on and lateral. The head-on mode is relatively insensitive to lateral motion and cannot be used in overextended mechanisms. The head-on mode is also relatively insensitive to changes in flux density due to its shallow magnetic slope. However, this limitation can be overcome by selecting Hall devices with higher operate and release properties. The lateral mode requires higher sensitivity and a higher magnetic flux density than the head-on mode.

Hall effect sensors are typically bipolar, with north and south magnetic poles. The output of this type of sensor is a voltage that varies with the magnetic field's intensity. The Hall voltage is often accompanied by a Schmitt trigger. This mechanism is used in magnetic sensors in applications where a small amount of magnetic field is a concern. The bipolar Hall sensor IC uses both the north and south magnetic poles.

The bipolar latch offers more control over release and operate parameters. Hall integrated circuits operate when the south pole is present, and remain on until the north pole is removed. They release with the north pole and turn off when the south pole is removed. A Hall switch with proper design has a duty cycle that is close to 50%. If you want to avoid hysteresis, a bipolar latch is your best bet.

They are Manufactured in a "U" shape

To make a Hall sensor, you must first manufacture the ring that surrounds the hall effect device. In this way, the sensor will be able to detect a change in temperature. Its current related sensitivity remains relatively stable over a wide range of temperatures. Temperature dependence helps compensate for such variations. There are two kinds of Hall effect sensors: primary and elemental. Each one has its own advantages.

In the current research, a Hall sensor based on AlGaN/GaN heterojunctions grown on silicon (111) substrates was developed. Experimental studies showed that the Hall sensor exhibited high sensitivity over a wide temperature range. Furthermore, the Hall sensor's resistance was measured with a standard kilovoltmeter over a temperature range of 75-500 K. The results also showed that the Hall sensor's current-related sensitivity remains constant across the entire temperature range, compensating for the inevitable temperature variations.

The Hall effect sensor's shape allows it to operate in harsh environments, such as extreme temperatures and radiation. Their applications include space exploration, magnetic diagnosis of thermonuclear reactors, and current sensing in electric vehicles. Advancements in processing technologies and new promising materials continue to propel Hall sensor research. So, the future of Hall sensors is bright. So, what are the advantages of this new device shape?

Hall Effect Sensors can be used for Sensing a Variety of Parameters

Hall effect sensors measure the magnetic field of an object and can be used to design systems with various outputs. These sensors measure the total magnetic field emitted by a magnet in a two-dimensional slice. This magnetic field is measured in units of weber, tesla, and gauss. One tesla is equal to 10000 gauss, while a mT is equal to ten gauss.

The Hall effect is also used to measure various parameters in machinery. The magnetic assembly of the Hall sensor is moved towards the Hall magnet by a spring loaded paddle. The magnetic assembly generates a circular electromagnetic field when it moves within certain limits, which represents distances. Hall effect sensors are widely used in a wide range of applications, including flow measurement and photo processing. You can find them in many places, from a car to a boat.

Integrated 3D Hall effect sensors are particularly effective for industrial applications. They can detect the angle of a mobile robot's wheel or robotic arm. They are also resistant to dirt and moisture, and their coplanar measurements enable highly accurate magnetic field measurements on rotating shafts. It's also possible to install a Hall effect sensor in a high-voltage electrical device. If you're considering purchasing a Hall effect sensor, you can find many benefits for the money you'll spend.

Video: How to make a simple hall effect sensor

The magnet produces an electric field that interacts with ions to cause a change in the electrical resistance of the device. This phenomenon is also known as the Hall effect. This electrical device can also detect other changes in the environment. In this article, we will explore how this type of magnetic sensor works and how it is used in different applications. In addition to being used in electronics, it is also used in the automotive industry.

The magnet produces an electric field that interacts with ions to cause a change in the electrical resistance of the device. This phenomenon is also known as the Hall effect. This electrical device can also detect other changes in the environment. In this article, we will explore how this type of magnetic sensor works and how it is used in different applications. In addition to being used in electronics, it is also used in the automotive industry.

conductivity. Metals are good candidates for Hall sensors, as they exhibit low mobility and high conductivity. III-V compounds, which combine high carrier mobility and reasonable conductivity, are often used for Hall sensors. Silicon is one such material, with moderate electron mobility and good compatibility with integrated circuit technology. The following section examines the Hall effect and how it works.

conductivity. Metals are good candidates for Hall sensors, as they exhibit low mobility and high conductivity. III-V compounds, which combine high carrier mobility and reasonable conductivity, are often used for Hall sensors. Silicon is one such material, with moderate electron mobility and good compatibility with integrated circuit technology. The following section examines the Hall effect and how it works.