We are looking for substrates for Infrared Spectroscopy measurements. Please send us a quotation for 5 CaF2 wafers (thickness cca 1mm, and a large diameter as we anyway intend to cut them later ourselves). Is there some other material that you could recommend to us? Thank you in advance.

Substrates Used for Infrared (IR) Spectroscopy

CaF2 Wafers for IR Spectroscopy Measurements

A PhD candidate requested a quote for the following:

Reference #122834 for specs and pricing.

Get Your Silicon Wafer Quote FAST! Or, Buy Online and Start Researching Today!

What Silicon Substrates for Fourier Transform Infrared Spectroscopy

A graduate student requested assistance for the following.

I would like to inquire do you think which kind of Si subtrate can be used for FTIR (Fourier transform infrared spectroscopy) and spectroscopy. I think for both cases I need double side polished Si substrate, I am really not sure which kind of Si substate can works for this specific experiments. Thus I would like to ask do you have any options that which kinds of substrate can work, or transparency in Near-infared ~ mid-infared range?

Answer:

By selecting a high-quality, double side polished intrinsic silicon substrate, you can ensure optimal performance for your FTIR and general spectroscopy experiments.

Reference #132068 for specs and pricing.

For Fourier Transform Infrared (FTIR) spectroscopy and general spectroscopy, the choice of silicon (Si) substrate is crucial due to its transparency and optical properties in the desired wavelength range. Here are some key considerations and options:

Key Considerations:

-

Transparency Range:

- Near-Infrared (NIR) to Mid-Infrared (MIR): Silicon is generally transparent in the range of approximately 1.2 µm to 8 µm (8333 cm⁻¹ to 1250 cm⁻¹), making it suitable for NIR to MIR applications.

-

Polishing:

- Double Side Polished (DSP): Double side polished substrates are preferred for spectroscopy because they ensure minimal scattering and interference from surface irregularities, providing clearer and more accurate spectral data.

-

Thickness:

- Thickness of the Substrate: The thickness of the silicon substrate can affect the path length of the IR beam. Thinner substrates are generally preferred to minimize absorption losses and maximize transmission.

-

Doping:

- Doped vs. Undoped: Undoped (intrinsic) silicon is preferred for IR spectroscopy to avoid free carrier absorption that can occur in doped silicon.

Recommended Silicon Substrates:

-

Intrinsic Silicon (Undoped) Double Side Polished:

- Ideal for most IR spectroscopy applications due to its high transparency and minimal absorption in the NIR to MIR range.

- Available in various thicknesses (e.g., 500 µm, 250 µm, etc.) depending on specific experimental needs.

-

High Resistivity Silicon:

- High resistivity (undoped) silicon wafers with double side polishing are excellent for minimizing free carrier absorption and ensuring high transparency.

- Resistivity values typically greater than 10,000 ohm-cm are preferred.

-

Float Zone (FZ) Silicon:

- Float zone silicon substrates are highly pure and have minimal oxygen content, providing better IR transparency.

- Double side polished FZ silicon is a good option for high-quality spectroscopy.

Suppliers:

- University Wafer: Offers a variety of silicon wafers, including intrinsic and high resistivity, with double side polishing.

Far Infrared Spectroscopy

A chemical engineering PhD candidate requested help with the following specs.

I am looking for high resistivity Si wafers for the purpose of Far infrared spectroscopy (CZ or

float zone purified might be best, but other low doping ones might also work). I don"t care much

about the diameter of the wafer, while the thinner ones should be better. Could you please send me a

quote of all wafers that fit those requirements?

Reference #170919 for specs and pricing.

Wat Silicon Wafers are used for Transmission-Based Infrared Spectroscopy Studies

A graduate student needed help with the followng.

I wanted to know if a certain Double Side Polished (DSP) Prime Silicon wafer from you all is Infrared(IR) transparent. I need to know this because we are doing transmission-based Infrared spectroscopy studies. I'm attaching the wafer we are thinking to buy with this mail. You can also suggest other DSP Silicon wafers which are IR transparent (to my knowledge, double sided polished Si wafers with resistivity around 31-40 is IR transparent). For your information, we can use wafers with any kind of doping. Another important property we are looking at is minimum surface roughness (we are doing nanometer level deposition). That's why we are preferring prime wafers. Specifications of the wafer we are planning to buy from you all (ID # 515).

UniversityWafer, Inc. Answered:

I suggest using FZ (Float - Zone) silicon for the experiment. Differently to Czochralski (CZ) silicon, FZ Si has much less bulk impurities due to mono-crystals growth technique.

Reference #312742 for specs and pricing.

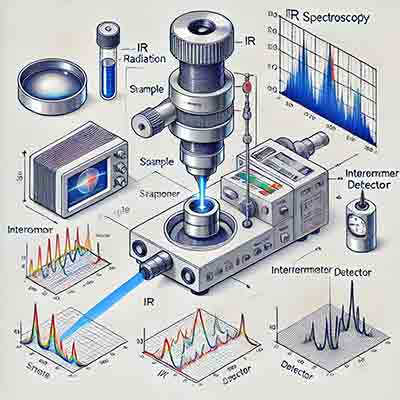

What is Infrared (IR) Spectroscopy?

Infrared (IR) spectroscopy is a technique used to identify and study chemicals through the interaction of infrared radiation with matter. Here's a detailed breakdown of what it involves and how it works:

Basics of Infrared Spectroscopy:

-

Principle:

- Absorption of IR Radiation: Molecules absorb specific frequencies of

infrared light that cause changes in their vibrational energy levels.

infrared light that cause changes in their vibrational energy levels. - Molecular Vibrations: Different bonds within a molecule vibrate at characteristic frequencies. These vibrations can be stretching (changing bond lengths) or bending (changing bond angles).

- Absorption of IR Radiation: Molecules absorb specific frequencies of

-

IR Spectrum:

- Wavenumber: The x-axis of an IR spectrum is usually expressed in wavenumbers (cm⁻¹), which is the reciprocal of the wavelength in centimeters.

- Absorbance/Transmittance: The y-axis shows the absorbance (or transmittance) of light. Peaks in the spectrum indicate the frequencies at which the sample absorbs IR radiation.

Types of Vibrations:

-

Stretching Vibrations:

- Symmetric Stretch: Both bonds lengthen and shorten simultaneously.

- Asymmetric Stretch: One bond lengthens while the other shortens.

-

Bending Vibrations:

- Scissoring: In-plane bending where two atoms move towards and away from each other.

- Rocking: In-plane bending where the atoms move in the same direction.

- Wagging: Out-of-plane bending where atoms move in the same direction.

- Twisting: Out-of-plane bending where atoms move in opposite directions.

Applications:

- Identification of Functional Groups: Different functional groups (e.g., -OH, -NH, -CO) have characteristic absorption bands.

- Quantitative Analysis: Concentration of a compound can be determined by the intensity of the absorption bands.

- Structural Elucidation: Information about the molecular structure can be inferred from the pattern of absorption bands.

- Material Characterization: Used in polymer science, biochemistry, and other fields to characterize materials.

Instruments:

-

Fourier-Transform Infrared (FTIR) Spectrometer:

- Interferometer: Splits and recombines the IR beam to produce an interference pattern.

- Fourier Transform: Converts the interference pattern into a spectrum.

- Advantages: Faster data collection, better signal-to-noise ratio, and higher resolution.

-

Dispersive IR Spectrometer:

- Monochromator: Separates different wavelengths of IR light.

- Detector: Measures the intensity of transmitted or absorbed light.

Process:

-

Sample Preparation:

- Solid Samples: Often ground and mixed with a matrix like potassium bromide (KBr) and pressed into a pellet.

- Liquid Samples: Placed between two IR-transparent windows.

- Gaseous Samples: Contained in a gas cell with IR-transparent windows.

-

Data Collection and Analysis:

- Spectrum Acquisition: The IR spectrum is collected by passing IR radiation through the sample and measuring the absorbed frequencies.

- Interpretation: The resulting spectrum is analyzed to identify functional groups and molecular structure.

Infrared spectroscopy is a powerful tool in analytical chemistry, allowing scientists to gain detailed information about the molecular composition and structure of a wide variety of substances.

What Substrates are Used for GD Spectrometry?

A glow discharge product manager requested help with the following.

We do GD spectrometers for elemental depth profile analysis.

So for me the main parameter is the sample size (we have a destructive technique and do quite large spots !), I do not care too much for other issues.

I would love large pieces on which I can do multiple spots and for each piece a relatively precise (10% fine) knowledge of composition and thickness (thus I can use this sample for semi quant calibration of similar samples) - this for each of the layers you can deposit,

Cadmium Telluride (CdTe) is surely of interest but essentially all PV materials are of interest. My problem is that I have similar stuff from our customers but due to confidentiality agreements I cannot use their samples : so I garantee you in addition a good advertisment if your samples are fine !

Suitable Silicon Substrates for GD Spectrometry:

-

Large Size Silicon Wafers:

-

Double Side Polished (DSP) Wafers:

- DSP wafers are essential to minimize surface irregularities, which can affect the consistency and accuracy of the spectrometry results.

-

High Purity Intrinsic Silicon:

- High purity intrinsic (undoped) silicon is ideal to avoid interference from dopants, which can affect the accuracy of the depth profiling.

-

High Resistivity Silicon:

- High resistivity silicon (typically >10,000 ohm-cm) is preferred for minimizing free carrier absorption, ensuring better transparency and consistency in results.

Thickness and Composition:

- Thickness: The wafers should be thick enough to provide a stable platform for multiple spots of analysis, typically around 500 µm or more.

- Composition: Intrinsic silicon with a low level of impurities and defects to ensure accurate depth profiling and calibration.

PV Material Substrates:

- Cadmium Telluride (CdTe):

- CdTe is a common PV material. It is critical to have a precise knowledge of its composition and thickness for semi-quantitative calibration.

- Other PV Materials:

- Similar considerations apply to other PV materials, ensuring large, pure, and polished substrates for effective GD spectrometry analysis.

Recommended Suppliers:

- University Wafer: Offers a variety of high-quality silicon wafers, including large sizes and high purity options.

Relevant Information from the Provided Document:

The attached document discusses the applications of GD-OES (Glow Discharge Optical Emission Spectroscopy) and LA ICP-MS (Laser Ablation Inductively Coupled Plasma Mass Spectrometry) in thin film analysis, emphasizing their advantages in depth profiling and contamination analysis. The key points include:

- GD-OES: Suitable for surface and bulk analysis with high depth resolution and the ability to analyze conductive and non-conductive materials without charging issues.

- LA ICP-MS: Provides high sensitivity and the capability to analyze metals and semi-metals, with a spot size significantly smaller than GD-OES, suitable for deep profiling.

- Sample Requirements: For effective GD-OES analysis, the sample size should be large enough to accommodate multiple analysis spots, and the material composition should be well-characterized for calibration purposes.

With this information, selecting a large, high-purity, double side polished silicon wafer will ensure optimal results for your GD spectrometry applications in analyzing PV materials.

Reference #134413 for specs and pricing.