Float Zone Silicon Wafers Used In X-Ray Monochromators

A Imaging & Microscopy Researcher requested a quote for the following.

I am looking for Silicon 111 and 220 float zone (preferred) oriented crystals to be used in X-ray Monochromators. I will need the surface lattice planes of the 111 or 220(110) to be as close to zero degree angle as possible, maximum of +/- 1 degree, preferred to be less than 0.2 degrees in one of the directions.

Thickness range between 400-700µm. Minimum diameters is 8 inches silicon wafers. Our major concerns are the orientation being as close to zero as possible, prime grade, polished on at least one side and good flatness will be needed. We will not require any specific resistivity, doplant, or epitaxial layer. We will be sagittally bending this crystal and reflecting off the lattice planes, not doing any depositing on any surface.

Reference #109377 for specs and pricing.

Get Your Quote FAST! Or, Buy Online and Start Researching Today!

What Substrates Are The Most Commonly Used In A Monochromator?

In monochromators, the substrates used for the dispersing elements—such as diffraction gratings or prisms—are chosen based on the wavelength range they need to handle and the specific application. The most commonly used substrates include:

-

Fused Silica/Quartz: Ideal for ultraviolet (UV) to visible light due to its excellent UV transparency, fused silica or quartz substrates are highly durable and are frequently used in both prisms and diffraction gratings.

-

Glass (e.g., BK7): Often used for visible and near-infrared (NIR) applications, BK7 glass is inexpensive, has good optical clarity, and works well for visible light dispersion. However, it does not transmit UV light effectively, so it's typically limited to visible to near-IR wavelengths.

-

Silicon: Silicon substrates are commonly used for infrared (IR) gratings, especially in the mid-IR range. They are effective at transmitting IR light, but not visible light, making them useful in monochromators designed for IR applications.

-

Calcium Fluoride (CaF2): This substrate is valued for its broad transparency range, extending from deep UV to mid-IR. It's used in applications requiring a wide wavelength range, but it’s relatively costly and can be brittle.

-

Germanium: Germanium substrates are used for far-IR or thermal IR monochromators because they are opaque to visible light but transparent in the far-IR range. However, germanium is relatively dense and sensitive to temperature changes.

-

Zinc Selenide (ZnSe): Another IR-compatible material, ZnSe is often used for mid-IR to far-IR applications due to its high transmittance in these ranges. It's common in IR spectrometers and monochromators designed for longer wavelengths.

Each substrate is chosen based on the target wavelength range and the performance characteristics required, such as transmittance, thermal stability, and cost.

What Is A Monochromator?

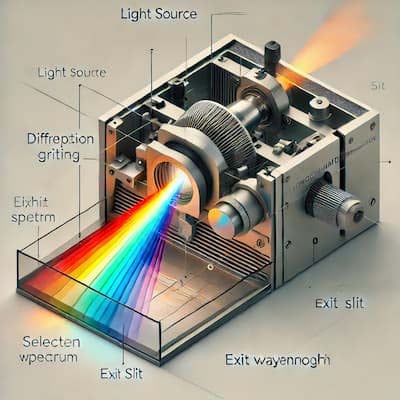

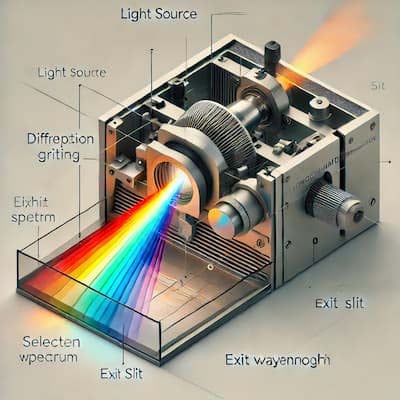

A monochromator is an optical device used to isolate light of a specific wavelength or narrow range of wavelengths from a broader spectrum. It works by dispersing light through a prism or diffraction grating and then selectively allowing only the desired wavelength to pass through an exit slit, effectively filtering out other wavelengths.

Here’s a basic breakdown of how a monochromator works:

- Light Source: White light or a broad spectrum source enters the monochromator.

- Dispersing Element: The light hits a prism or diffraction grating, which disperses the light into its constituent wavelengths (like a rainbow).

- Wavelength Selection: By adjusting the angle or position of the grating or prism, the monochromator can direct only a specific wavelength toward the exit slit.

- Exit Slit: Only the selected wavelength exits the device, while other wavelengths are blocked or directed away.

Monochromators are commonly used in spectrometers, fluorometers, and other analytical instruments where precise wavelength selection is needed, such as in material analysis or optical testing. They are crucial in applications like studying absorbance, reflectance, or emission properties of materials.

Indium Antimonide Substrates for X-Ray Monochromator

A photonics researcher requested a quote for the following.

Please quote for the following: Material: InSb Quantity: 1 - 3 Application: Wafers will be cut as X-ray monochromator crystals Orientation: 111 Comments: we are interested in one side polished undoped wafers with diameters between 2" and 5"; the "perfect" thickness would be 0.75 mm but we can also accept thinner or thicker samples!

Reference #278400 for specs and pricing.

Silicon Wafers For A Monochromator Application

An engineer at an instrument manufacturer requested a quote for the following.

I am seeking a source of Si wafers for a monochromator application. Doping levels, resistivity, doping uniformity, all of the usual wafer characteristics are unimportant to us.

We are seeking wafers cut from an 8" dia 100 ingot axis boule with the following orientations:

2 wafers cut to within 1 deg of the 100 (having the 100 axis within 1 deg of the wafer surface normal)

2 wafers cut to within 1 deg of the 311 (having the 311 axis within 1 deg of the wafer surface normal)

2 wafers cut to within 1 deg of the 422 (having the 422 axis within 1 deg of the wafer surface normal)

All of these orientations can be accessed by rotations about the 110 axis: roughly 17 deg for the 311 wafers and roughly 25 deg for the 422.

The initial order will be for 2 wafers of each orientation with a following order of appriximately 10 of each orientation.

The wafers will be between 0.020" and 0.040" thick (we are still trying to clarify the requirements) and must be polished on both sides.

Reference #168808 for specs and pricing.