Indium Gallium Nitride Multiple Well

A doctoral candidate requested a quote for the following:

We would like to get information about your "InGaN" stocks (price, specialities, etc)?

Here are the specialities that we want:

InGaN: Multiple quantum well, consruction diode that gives light (LED) and the amount we want is 8.

Reference #88298 for specs and pricing.

Get Your Quote FAST! Or Buy Online Here!S Start Researching Today!

P-GaN Quantum Well N-GaN

A scientist researching GaN FET and GaN LED requested a quote for the following.

We want to inquire price of the 4inch Gallium Nitride epitaxy wafer on sapphire wafer. The structure is P-GaN/Quantum well/N-GaN.

UniversityWafer, Inc. Quoted:

- 100mm GaN epitaxy wafer

GaN Epi-wafer,C-Plane Sapphire With 4.0um Thick GaN Epi-layer On FSS Sapphire Substrate 650um Thickness

- 100mm GaN epitaxy wafer

GaN Epi-wafer,C-Plane Sapphire With 6.0um Thick GaN Epi-layer On PSS Sapphire Substrate 650um Thickness

Reference #176462 for more specs and pricing.

Fabricating Gallium Nitride Quantum Wells

A quantum well researcher requested a quote for the following:

I am looking for a supplier capable of producing the following Wafers, generic structure: TopLayer: GaAs Quantum Well(s): InGaAs Spacer Layers: GaAs Bragg-reflector: AlAs/GaAs quarter wafe Wafer: SI-GaAs (SI=Semi-Insulating) can you offer these?

Reference #192945 for specs and pricing.

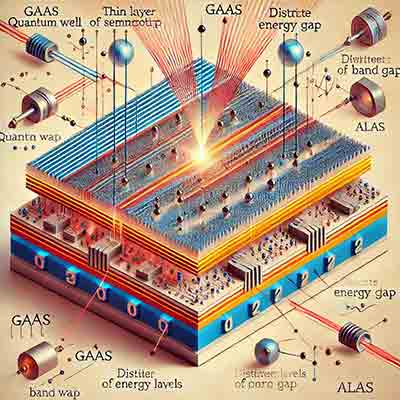

What are Quantum Wells?

Quantum wells are nanometer-scale structures that confine particles, such as electrons, in one dimension, allowing them to move freely in the other two dimensions. This creates a potential well where the energy levels of the particles become quantized. Quantum wells are typically made by sandwiching a thin layer of a semiconductor material between two layers of another semiconductor with a larger band gap.

Key Points:

-

Structure: A thin layer of semiconductor material (e.g., GaAs) is placed between two layers of a material with a larger band gap (e.g., AlAs). This creates a potential well where electrons or holes are confined.

-

Energy Levels: The confinement leads to discrete energy levels within the well, similar to the quantization of energy levels in an atom. Electrons can only occupy specific energy states.

-

Applications:

- Lasers: Quantum wells are used in semiconductor lasers, such as those in CD players and

barcode scanners, because they can produce very pure and intense light.

barcode scanners, because they can produce very pure and intense light.

- Transistors: They improve the performance of high-electron-mobility transistors (HEMTs), which are used in RF and microwave applications.

- Solar Cells: Quantum wells can enhance the efficiency of solar cells by allowing for better absorption of sunlight and conversion to electricity.

-

Advantages:

- Increased efficiency in electronic and optoelectronic devices.

- Enhanced control over the electronic and optical properties of materials.

-

Fabrication: Quantum wells are typically fabricated using advanced techniques like molecular beam epitaxy (MBE) or metal-organic chemical vapor deposition (MOCVD), which allow for precise control over the thickness and composition of the layers.

In summary, quantum wells are crucial components in modern electronics and photonics, providing enhanced performance and enabling new technologies through the manipulation of quantum mechanical properties.

What Substrates are used to Fabricate Quantum Wells?

To fabricate quantum wells, specific substrates are chosen based on their compatibility with the semiconductor materials used in the quantum wells. Here are some commonly used substrates:

-

Gallium Arsenide (GaAs):

- GaAs is widely used as a substrate for quantum wells made of materials like GaAs/AlGaAs.

- It provides good lattice matching, minimizing defects and dislocations.

-

Silicon (Si):

- Silicon substrates are common for integrating quantum wells with existing silicon technology.

- Si/SiGe quantum wells are an example, where SiGe forms the quantum well layer.

-

Sapphire (Al2O3):

- Sapphire substrates are used for quantum wells made of materials like GaN/InGaN.

- They offer good thermal conductivity and mechanical stability.

-

Indium Phosphide (InP):

- InP substrates are used for quantum wells composed of materials like InGaAs/InP or InGaAsP/InP.

- They are particularly useful for optoelectronic devices operating at longer wavelengths.

-

Silicon Carbide (SiC):

- SiC substrates are suitable for quantum wells made of materials like GaN/AlGaN.

- They provide excellent thermal and electrical properties.

-

Zinc Selenide (ZnSe):

- ZnSe substrates are used for quantum wells composed of II-VI semiconductor materials, like ZnSe/CdSe.

- They are beneficial for optoelectronic applications in the visible spectrum.

-

Germanium (Ge):

- Germanium substrates are sometimes used for quantum wells involving SiGe, especially in high-speed electronics.

- Ge offers good lattice matching with silicon and other materials.

Each substrate has its own advantages and is selected based on the specific requirements of the quantum well structure, such as lattice matching, thermal properties, and the desired application of the final device.