I am interested in your InP wafers with item# HQ20. What does the A in [111A] stand for? Is this a cubic crystal wafer.

Is Indium Phosphide A Cubic Crystal Wafer?

A graduate research associate of materials science and engineering asked the following question:

Item Qty. Description

HQ20. 5/10/30 Indium Phosphide wafers, P/E 2"Ø×350±25µm,  Undoped InP [111B]±0.5°,

Undoped InP [111B]±0.5°,

Nc<3E16/cc, Bow<30µm,Warp<30µm.

One-side-polished, back-side matte etched, EJ Flats, Surface roughness<15A.

Sealed under nitrogen in single wafer cassette.

Q1) What does the A in [111A] stand for?

A1) In face is polished and P face is etched and adequately for [111B] P face is polished and In is face etched

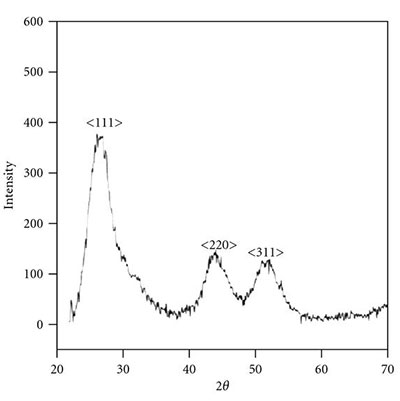

Q2) Is this a cubic crystal wafer?

A2) Yes, it is cubic crystal wafer

Reference #268498 for specs and pricing.

Get Your Quote FAST! Or, Buy Online and Start Researching Today!

Indium Phopshide (InP) Benefits

InP's exceptional electron velocity over silicon and gallium arsenide substrates is used in high-power and high-frequency electronics.

Indium Gallium Arsenide (InGaAs) are used in pseudomorphic heterojunction bipolar transistor that operate at 604 GHz.

InP's direct bandgap makes it into optoelectronics devices like laser diodes that are used in the optical telecommunications industry, to enable wavelength-division multiplexing.

Indium Phosphide (InP) Applications

Indium Phosphide (InP) wafers are often used as substrates for growing infrared (IR) laser and LED heterostructures.

How Do You Test for InP Wafer Defects?

Defects in substrates are generally specified as a dislocation density, but the inhomogeneity of their distribution and the range of sizes is not known from one wafer to the next. When growing a new device on such a wafer, it is imperative to understand how the substrate defects affect the heterojunctions above them that comprise the active layers of the device. At a minimum, the quality of the wafers should be measurable in order to determine whether they are of sufficient quality to be used in the production of reliable devices with near-zero latent defects.

Indium Phosphide Based HEMT Video

How to Grow III-V Materials on Silicon Wafers

A Clean Energy Technology Researcher requested help with the following:

We are working on a project at NREL to grow III-V materials on silicon wafers with different levels of polishing. I'm doing cost analysis to try to understand the potential benefit of growing on rough or lightly polished (lapped) surfaces compared to traditional epi-ready wafers with a mirror polish. I couldnt find this on your website, but do you have quotes for similar wafers with different levels of polishing that you might be able to provide so we can better understand how much different levels of polishing add to cost? Ideally, wed like to compare as-cut to lapped and then to single-side polished, epi-ready wafers. We are trying to model what the cost savings would be in high volume production to evaluate potential for commercialization, but quotes for any volumes you are able to provide would be very helpful. In the lab, we would be doing this in much lower volume.

UniverityWafer,Inc. Answered:

The following are the steps in producing an One-side-polished silicon wafer and estimated cost break-down as a percentage of total

1. 28% Silicon ingot (with Flat)

2. 12% Slicing (by Diamond ID Saw)

3. 3% Edge rounding

4. 12% Lapping

5. 2% Etching

6. 28% Polishing

7. 5% Cleaning

8. 5% Inspection

9. 5% Packing

100%

Above are based on my estimates - I do not have data to support them.

After Slicing and Lapping the surface is "damaged", which means that it is not monocrystalline. You might as well grow a film on a polycrystalline wafer, as on lapped monocrystalline wafer. The Etching removes the damaged layer, restoring the surface to a monocrystalline condition, but creating a surface that is a collection of regular pyramids several microns high.

An alternate, is to slice monocrystalline ingot with and abrasive wire saw. This minimizes surface "damage" and such surface is commonly used for making Solar Cells.

From what I know, the only III-V semiconductor that you are likely to grow successfully, as an Epitaxial layer on a Silicon substrate, is GaP. I am interested in this topic. I would be happy to cooperate with your in trying to grow GaP on Silicon substrates.

Reference #225505 for specs and pricing.

Highly Doped Indium Phosphide Used as a Low Temp NMR Magnetometer for ALPHA experiment on Antimatter

A associate professor at a University Physics and Astronomy department asked for the following quote:

Hi Chris, after "years" of receiving your updates, with no action on my

part, I finally have a real request!!

Do you have any highly doped InP material? When I look on-line, it seems

that sulphur doped material (n-type) has the highest carrier concentrations

e.g. 1-10 X 10^18 . I am looking for the very highest concentrations

possible.

Just in case you are wondering why we want the highest possible doping:

we will be using the InP as a low temperature NMR magnetometer. The sample

would be in the approximate form of a millimeter sized rod and we would do

NMR on the phosphorus nuclei of the sample in a 1 Tesla magnetic field, at

liquid helium temperatures (4.2 Kelvin). Unless there are lots of free

carriers, at the low temperatures the nuclear spins (of the phosphoruous

atoms) take an excessively long time to recover after interacting with the

applied RF magnetic field.

We think that 10^19 carriers/cc will be enough, but so far no one gives accurate values of the doping. Soooo, we just have to try samples with the "highest" dopings available and try them out.

Any wafer that is, say, aproximately 0.4 mm thick will do. We could cut our

little squares and glue them together. actually, we would probably cut out a

number of discs to produce a short rod, of diameter 1mm and length also

about 1mm. So, just about any wafer thickness and shape would do!

Just in case you are curious, if suitable, the samples would be used for ALPHA experiment on antimatter.

Let me know what you have available in InP, and I will get back to you.

UniversityWafer, Inc. Quoted:

Item #H357

2" N/S (100) 400um SSP US Flats; Epi Ready

Its Certificate of conformance indicates that the Nc was actually measured as 8.24E18/cc. Sulfur doped InP wafers are normally made with Nc=(3-8)E18/cc although I have seen material as high as 9.3E18/cc

Reference #226058 for specs and pricing.

How to Grow Epitaxially Thin Film on Indium Phosphide Wafers?

A postdoc researcher requested a quote for the following InP substrates.

Could you send me your latest quotation of undoped (100) InP?

By the way, how do I clean the

surface? Since we need

epitaxially grow thin film on

it, the surface need to be very

clean. Could you give me some

instruction on cleaning

procedure? Is there any native oxide layer on it? Do I need do extra cleaning with water or alcohol before use?

UniversityWafer, Inc. Answered and Quoted the following:

There is No native oxide on the InP wafers.

We offer:

Item #EF54b. Indium Phosphide wafers

P/E 2"Ø×350±25µm,

n-type InP:-[100]±0.5°,

Nc < 1E16/cc, u > 3,500cm²/Vs, EPD<5,000/cm²,

One-side-polished, back-side matte etched, EJ Flats (two),

Sealed under nitrogen in single wafer cassette.

Reference #211633 for more specs and pricing.

What is Indium Phosphide (InP)?

Indium phosphide is a semiconductor that is a binary compound of indium and phosphorus. It has a face-centered cubic crystal structure and is similar to GaAs in structure. In addition to its similarity to GaAs, it is a common component of many III-V semiconductors. Unlike most III-V semiconductors, indium phosphide contains no metal.

Despite its small size, indium phosphide is useful in photonic devices, such as those that rely on  wavelength-division multiplexing. It is also a substrate for indium gallium arsenide-based optoelectronic devices. These components produce electromagnetic waves with high frequency and optical qualities, which make them suitable for many applications. In addition to enabling photonic integrated circuits, indium phosphide is also an important material in lasers.

wavelength-division multiplexing. It is also a substrate for indium gallium arsenide-based optoelectronic devices. These components produce electromagnetic waves with high frequency and optical qualities, which make them suitable for many applications. In addition to enabling photonic integrated circuits, indium phosphide is also an important material in lasers.

Indium phosphide is a popular material used in microelectronics. Its name derives from the Latin word indicum, which means "violet." Its broad applicability makes it an attractive option for solar cells. However, it has a high price tag. It is often difficult to find a supplier of indium phosphide. In this article, I will discuss some of its benefits.

The advantages of indium phosphide are numerous. This semiconductor has a large emitter, high-collector capacitance, and low current density. Its sensitivity to radiation is excellent, making it a suitable material for photovoltaic applications. Nevertheless, the downsides of indium phosphide may be that it is not scaled for mass production. In the past, indium pyridide was widely used in solar cells and is very expensive.

Among the most important issues that can be addressed with indium phosphide is its ability to cause pulmonary edema and weight loss. While it is not as harmful as lead, it can lead to problems with liver, kidney, and even brain. In addition, it can damage bones and can cause leg paralysis. There are many more risks associated with indium phosphide, which include: ‘The metal is a poison.

Indium phosphide is a semiconductor that is used for high-speed communications. Aside from being highly sensitive, it also is used in a wide range of other applications. In addition to these uses, indium phosphide is an ideal material for high-speed switches. These materials are also effective for lasers and photodetectors. There are two types of indium phosphide: a type that is highly conductive, and one that is an insulator.

Indium phosphide is a compound semiconductor that is used in many different applications. In addition to being used in high-speed communications, indium phosphide is a semiconductor that can be used in a wide range of applications. Various types of indium phosphide can be found in lasers, semiconductors, and in different forms. They are both important materials in the development of electronic systems.

Indium Phosphide Direct BandGap

The indium phosphide is a semiconductor that has a face-centred cubic crystal structure. It has a direct band gap and is used in high-frequency electronics. It is a member of the III-V family of semiconductors. Its electron velocity is much higher than that of indium nitride, which is a group III-V semiconductor. A crystalline indium phosphide wafer has a low-energy quantum of indium.

Indium phosphide is a chemical compound. Its name is indium gallium arsenide. It is a chemical compound. This compound has similar characteristics to GaAs, except that it has a high-frequency bandgap and a phosphate group. Compared to indium gallium arsenide, indium phosphide is an alloy of gallium and indium.

Difference Between Indium Phosphide and Gallium Arsenide

Indium phosphide has the same structure as GaAs, but is more expensive. Its nanocrystalline surface is obtained by thermal decomposition of indium iodide. It has a much better electron velocity than Gallium Arsenide (GaAs), but has a high material fragility. Indium phosphide is an important component of indium iodide. This compound can be prepared by a variety of ways, including sputtering, electrochemical etching, and sputtering.

Indium phosphide is a chemical compound composed of two elements, indium and phosphorus. The indium phosphide layer is very thin and has a low electrical resistance. It can be synthesized from a white phosphorus powder. The white phosphorus in indium phosphide layers is a source of energy and serves as an electron donor. Indium chromium is the most abundant element in nature and has the highest atomic number.

What Substrate Should I Use for THz modulation?

A scientist asked the following:

I am interested in using them for THz modulation. I basically need a semiconductor with low bandgap, in order to use infrared light (1030 nm) to photo-excite carriers, but at the same time I'd need it to be almost dispersionless and with low absorption in the THz region. I am currently using Germanium, but I would like to explore other possibilities. Would have any suggestions, by any chance?

UniversityWafer, Inc. Quoted:

Lowest Energy Gap Semiconductors

For Indium Phosphide we suggest the following. I would suggest Gallium Antimonide (GaSb) and Indium Antimony (InSb), for these are the lowest energy gap semiconductors.

For THz modulators people also use InP. We have the following cubes of InP that were prepared specifically for such use.

Description: All sides polished, 8.0×4.0mm is (001), 4.0×3.5mm is (110), 8.0×3.5mm is (1,-1,0) |

|||||||||

| Item | Material | Orient. | Diam (mm) | Thck(μm) | Pol | Resistivity Ωcm | Nca/cm³ | Mobil cm²/Vs | EPD/cm² |

|---|---|---|---|---|---|---|---|---|---|

| D745 | SI InP:Fe cube | [100] | 8×4 | 3,500 | P/P | 2.50E+07 | 1.30E+08 | 2,330 | 6.80E+04 |

In Stock Indium Phosphide

| Item | Material | Orient. | Diam (mm) |

Thck (μm) |

Surf. |

|---|---|---|---|---|---|

| 5176 | InP:S+Zn | [100] | 2" | 400 | SSP |

| 5243 | SI InP:Fe | [100] | 2" | 350 | SSP |

| C745 | SI InP:Fe cube | [100] | 8x4 | 3,500 | DSP |

| D745 | SI InP:Fe cube | [100] | 8×4 | 3,500 | DSP |

| 5052 | undoped InP:- | [100] | 2" | 350 | SSP |

| F745 | undoped InP:- Seed crystal | [100] | 16x16 | 75,000 | |

| G745 | undoped InP:-Seed crystal | [100] | 8x8 mm | 75,000 | |

| K661 | undoped InP:- | [111A] ±0.5° | 2" | 350 | SSP |

| B745 | n-type InP:S | [100] | 2" | 2,000 | SSP |

| L206 | InP:(S+Zn) Ingot | [100] | 2" | ||

| J206 | n-type InP:S Ingot | [100] | 2" | 133,400 | |

| 2206 | n-type InP:S Ingot | [100] | 2" | 117,490 | |

| O206 | p-type InP:Zn Ingot | [100] | 2" | 31,750 | |

| P206 | InP:(S+Zn) Ingot | [100] | 2" | 33,500 | |

| N206 | n-type InP:S Ingot | [100] | 2" | 114,300 | |

| M206 | n-type InP:S Ingot | [100] | 2" | 95,000 | |

| R206 | n-type InP:S Ingot | [100] | 2" | 101,600 | |

| S206 | n-type InP:S Ingot | Poly | 2" | 20,000 | |

| H206 | n-type InP:S Ingot | [100] | 2" | 54,000 | |

| K206 | n-type InP:S Ingot | [100] | 2" | 63,500 | |

| I206 | n-type InP:S Ingot | [100] | 2" | 28,600 | |

| Q206 | n-type InP:S Ingot | [100] | 2" | 158,750 | |

| P050 | n-type InP:(S+Zn) | [100] | 2" | 400 | SSP |

| P040 | n-type InP:S | [100] | 2" | 350 | SSP |

| 41 | n-type InP:S | [100] | 2" | 400 | SSP |

| P041 | n-type InP:S | [100] | 2" | 400 | SSP |

| P029 | n-type InP:S | [100] | 2" | 400 | SSP |

| 474A | n-type InP:S | [100] | 2" | 400 | SSP |

| 474 | n-type InP:S | [100] | 2" | 400 | SSP |

| 636 | n-type InP:S | [115] | 2" | 400 | SSP |

What is Indium Phosphide (InP) Band GaP?

Indium phosphide is a metal with a direct bandgap and is an ideal material for photonic integrated circuits. The bandgap makes it possible to use wavelength-division multiplexing. It is used for photonic integrated circuits by companies such as Infinera. Indium phosphosphide also serves as a substrate for epitaxial indium gallium arsenide devices. It is a good candidate for applications in lasers, spectroscopy, and photonics. Indium phobiasphide exhibits properties that are suitable for high-frequency, optical, and non-linear electromagnetic waves.

The metal electrodes' Fermi level is aligned with the lower edge of the InP bandgap. The dopant introduces an energy level in the middle of the bandgap, which is called the bandgap. The thickness of the metal electrodes and the space charge layer are related, and the concentration of the dopant affects the thickness of the film.

Indium phosphide is an excellent material for high-frequency, high-power electronic devices. The bandgap is narrow and reflects the electrons' energy, a feature that makes InP a good candidate for high-performance devices. Its ZB crystal structure allows for low carrier concentration and low resistance. This characteristic makes it useful in optical and bioelectronic applications.

Indium phosphide semiconductors are highly versatile and useful for high-frequency devices. The low bandgap of InP allows for efficient lasers and sensitive photodetectors. It is used for conversion of laser signals. Indium phosphate is available in wafer diameters of up to four inches. Its wavelength regime is ideal for gas spectroscopy, sensing, and the conversion of light to electricity.

Indium phosphide is a binary semiconductor, which means it is composed of indium and phosphorus. Its crystal structure is face-centered cubic. Its nanocrystalline surface can be visualized with a scanning electron microscope, which is an important tool in semiconductors. In addition to its superior electron velocity, indium phosphide is an excellent material for high-speed electronics.

Indium phosphide is a common material for photovoltaics. It is used in high-powered applications. In addition to photovoltaics, indium phosphate is an ideal material for semiconductors. Its wide bandgap opens a previously unexplored range of electromagnetic frequencies. Its advantages can be seen in a variety of different applications.

Indium phosphide is a highly versatile material with numerous applications. Its high speed, radiation tolerance, and low cost make it an excellent choice for photovoltaics. It also makes a great base material for a variety of high-speed electronic applications. There are many in-demand InP NWs, so there is a need for further research in this area.

Indium phosphide bandgaping is a common process for manufacturing semiconductors. The higher the temperature of the semiconductor, the lower its bandgap. It is used in a wide range of electronics, from high-frequency to high-power. Its direct bandgap makes InP an ideal material for a wide variety of applications. In addition, indium phosphosphide is a popular component of LED heterostructures, as it is compatible with a variety of materials.

Indium Phosphide vs Gallium Arsenide Band Gap Performace

Indium phosphide is a semiconductor containing the elements Indium and Phosphorus. This semiconductor is used in high-frequency, power electronics, and photovoltaic devices. Its direct bandgap also makes it a suitable substrate for LEDs and IR lasers. The indium phosphide has a cubic crystal structure, which is identical to GaAs.

The bandgap of InP is the key characteristic that determines the material's optical properties. Its size and position of valence and conduction bands determine its optical and mechanical characteristics. This means that it is a good candidate for solar cells. The indium phosphide bandgaptide structure is a highly desirable semiconductor. It is also a useful material for LEDs.

A high-frequency indium phosphide solar cell is an example of a high-power, high-frequency semiconductor. The InP bandgap is a characteristic that helps distinguish between indium phosphide and gallium arsenide. A larger AMO means that indium phosphorus has a higher permeability to light than gallium.

Indium Phosphide (InP) Semiconductors

The first commercial applications of the InP semiconductor came in high-speed data communication. The bandgap of the InP material matches the transmission window of optical fibre. The use of this semiconductor crystal as a light source and lossless transmission method facilitated the connection of computers. However, this process had several drawbacks. For example, it was difficult to control the recombination of carrier ions, which may compromise the optical and electronic properties.

The indium phosphide compound semiconductor can emit wavelengths greater than 1000 nm. It is widely used in fibre optic communication devices. Manufacturers are developing and introducing new communication technologies that will use the InP semiconductor in many applications. In addition to its numerous applications, the InP semiconductor is expected to become an increasingly important component in future electronics. XAFS calculations were used to determine the electronic structure properties of the InP semiconductor material.

In addition to Gallium Arsenide (GaAs) and InP semiconductors, ion-implanted wafers can be annealed. The annealing process requires that the ion-implanted surface of the semiconductor be covered by a flat, nonreactive surface. The covering material can be identical to the semiconductor material or may have a similar general smoothness. The top form may be polished to the same level of smoothness as the unannealed semiconductor.

Indium phosphide solar cells have recently been investigated for use in space. They exhibit high conversion efficiencies and are simpler to manufacture than GaAs and silicon solar cells. Compared to other semiconductors, the InP semiconductor offers superior radiation resistance. Its high level of recombination allows it to be used for solar cells. There is also a possibility that the InP semiconductor could be used in space, where radiation exposure is a critical factor.

Key Indium Phosphide Terms

Below are some of the key terms associated with semiconductors made from Indium Phosphide.

- semiconductor nanomaterials

- inp nanocrystals

- inp semiconductors

- attractive semiconductor

- indium aluminium

- perfect semiconductor

- InP wafers

- compound semiconductor

- semiconductor compounds

- photon detectors

- integrated nano

- trialkyl indium

- indium compound

- laser diodes

- many semiconductors

What are Semi Insulating Indium Phosphide (InP) Applications?

emi-insulating Indium Phosphide (InP) is widely used in high-frequency, optoelectronic, and high-power applications due to its high electron mobility, direct bandgap, and excellent thermal properties. Here are some of its key applications:

1. High-Frequency & RF Applications

- MMICs (Monolithic Microwave Integrated Circuits): InP is used for making high-performance MMICs for radar, satellite communications, and 5G networks.

- High Electron Mobility Transistors (HEMTs): Used in RF and microwave applications requiring high-speed signal processing.

- Low-Noise Amplifiers (LNAs): InP-based LNAs provide superior noise performance in applications like radio astronomy and military radar.

2. Optoelectronics & Photonics

- Laser Diodes: InP-based lasers operate in the infrared (1.3–1.55 µm) range, making them ideal for fiber-optic communications.

- Photodetectors & Avalanche Photodiodes (APDs): Used in optical receivers for high-speed data transmission and LiDAR systems.

- Optical Modulators: Integrated with photonic circuits for high-speed optical communication networks.

3. Quantum and Advanced Computing

- Quantum Dots & Single-Photon Detectors: Used in quantum computing and secure communications.

- Terahertz (THz) Technology: Semi-insulating InP is useful in developing THz devices for imaging and spectroscopy.

4. Power & Radiation-Hardened Electronics

- High-Power Transistors: InP-based HBTs (Heterojunction Bipolar Transistors) are used in power amplifiers.

- Space Applications: Radiation-resistant InP devices are used in satellite and deep-space communication systems.

5. Sensing & Imaging

- Infrared Sensors: InP photodetectors are used in night vision and thermal imaging applications.

- Gas Sensors: InP-based devices detect gases using infrared absorption techniques.