I am looking for a SiO2 waferfor FET fabrication having an oxide thickness of 90-100 & 300nms. 1. P-type Silicon wafer (CZ wafer growth) <100> 2. Resistivity 0.0005-0.001 ohm-cm 3. Dry thermal oxidation. 4. Oxide thickness 90-100nm & 300nm. 5. Polished front surface 6. Diced substrate depends on our dimension (1cmx1cm) 7. Back side gold contact Note: Wafer should be suitable for field-effect transistor fabrication having low roughness and low leakage current. If you have any standard oxide wafers for OFET fabrication please send me the details for that along with the requested wafer in different sizes (4", 6" & 8").

Silicon Dioxide Wafers for Field Effect Transistor Fabrication

A PhD candidate requested a quote for the following:

Reference # 267661 for specs and pricing.

Get Your Quote FAST! Or, Buy Online and Start Your Research Today!

What is FET?

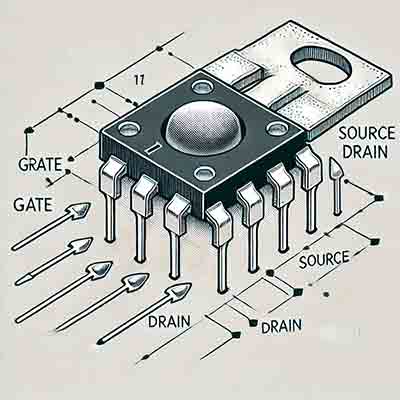

FET stands for Field-Effect Transistor. It is a type of transistor used in electronic circuits. FETs are three-terminal devices that control current flow through a semiconductor channel. FETs applications include amplifiers, switches, oscillators, and voltage regulators.

FETs operate based on the principle of the electric field effect, where an electric field controls the behavior of the semiconductor channel. The most common FET types are Metal-Oxide-Semiconductor Field-Effect Transistors (MOSFETs) and Junction Field-Effect Transistors (JFETs).

MOSFETs are the most widely used FETs and are commonly found in digital integrated circuits. They have high input impedance, low output impedance and can be used as voltage-controlled switches or amplifiers. On the other hand, JFETs have lower input impedance and are often used in applications requiring high input impedance and low noise.

FETs have played a crucial role in advancing electronic technology, enabling the development of smaller, faster, and more efficient electronic devices. They are integral components in modern electronics, including computers, smartphones, televisions, and many other electronic systems.

Graphene FET to Detect Electrical Charge

A doctoral student researcher requested the following quote:

We are working on dual biosensors for cancer cell detection; surface acoustic waves to detect mass and Graphene field effect transistor to detect electrical charge. For this research project we want to try quartz substrate. Kindly give a quotation for a following order: ST-cut 90˚, Y-axis (Guided Love Wave using Polymer on Quartz) 2 inches diameter and 500µm thick. 50 to 100 samples.

Reference #259037 for specs and pricing.

Video: Learn About Field Effect Transistors

Pin-Hole Free Silicon Dioxide to Fabricate FET

A physisist requested a quote for the following:

Question:

What we really need are doped silicone wafers with a really high quality pin-hole free SiO2 on top.

We need it for the field-effect transistor devices, where the highly doped Si bulk is used as a gate and SiO2 is used as an insulator.

We are having troubles with most of the Si/SiO2 wafers we found around here at Rutgers (borrowed from different groups).

Most of these wafers show huge leakage (practically, a direct short) when a metal contact is evaporated on top of the oxide.

Do you have doped-Si/SiO2 wafers that are really designed for transistor work?

The oxide thickness we need is in the range 200-500 nm.

Answer:

We would recommend a Dry Chlorinated Thermal Oxide with a Forming Gas Anneal.

Reference #125269 for specs and pricing.

3" Silicon Wafers for FET

A assistant professor requested a quote for the following.

The wafers will be used as substrates for organic field-effect transistors, therefore the quality (capacitance) of oxide dielectric is of importance. The heavily doped silicon (after applying bac kohmic contacts) serves as gate.

3" P/B (100) <0.01 Ohm-cm 380um SSP

We have 3" Silicon Substrates Item #1318 on sale here.

Reference #99296 for specs and pricing.

What is Meant by Field Effect?

A "field effect" generally refers to the influence of an electric or magnetic field on the behavior of charges in a material or system. The concept is widely used in physics and electronics, particularly in the context of semiconductors and field-effect transistors (FETs).

Here are two common contexts in which the term "field effect" is used:

-

Field Effect in Semiconductors:

- In semiconductors, the field effect refers to the control of the electrical

conductivity of a material by an external electric field. This is the principle behind field-effect transistors (FETs), where the voltage applied to a gate terminal can control the current flowing through a channel between source and drain terminals.

conductivity of a material by an external electric field. This is the principle behind field-effect transistors (FETs), where the voltage applied to a gate terminal can control the current flowing through a channel between source and drain terminals.

- In semiconductors, the field effect refers to the control of the electrical

-

Field Effect in Electrochemistry:

- In electrochemistry, the field effect might refer to the influence of an electric field on the distribution of ions near an electrode. This can affect the electrochemical reactions taking place at the electrode's surface.

Overall, the term "field effect" is a broad concept that can apply to various physical systems where an external field influences the behavior of particles, such as electrons or ions, within that system.

What is the Field Effect and Inductive Effect?

The field effect and inductive effect are two important concepts in chemistry, particularly in understanding the behavior of molecules and the distribution of electron density within them. Both effects are related to how atoms or groups within a molecule can influence the distribution of electron density, but they operate through different mechanisms.

1. Field Effect

- Definition: The field effect refers to the influence of an external electric field or the electric field created by charged or polarized groups within a molecule on the distribution of electron density in other parts of the molecule.

- Mechanism: Unlike the inductive effect, which operates through the chemical bonds, the field effect can act through space. It is often significant in cases where there are charged or strongly polarized groups in a molecule that can influence the electron density at a distance.

- Example: In a molecule where a positively charged group is located near a bond, the positive charge can attract electron density from the bond, affecting its properties even if the charged group is not directly bonded to the atoms in the bond.

2. Inductive Effect

- Definition: The inductive effect refers to the electron-withdrawing or electron-donating effects transmitted through sigma bonds in a molecule, due to the electronegativity of atoms or groups attached to the molecule.

- Mechanism: The inductive effect operates through the bonds of a molecule. Atoms or groups with higher electronegativity will pull electron density towards themselves, creating a partial positive charge on adjacent atoms, while atoms or groups with lower electronegativity will push electron density away.

- Types:

- Electron-Withdrawing Inductive Effect (-I Effect): Occurs when an electronegative atom or group pulls electron density towards itself, creating a dipole.

- Electron-Donating Inductive Effect (+I Effect): Occurs when a less electronegative atom or group pushes electron density away from itself, donating electron density to the rest of the molecule.

- Example: In a molecule like chloroethane (CH₃CH₂Cl), the chlorine atom (which is more electronegative) exerts an electron-withdrawing inductive effect on the carbon atoms, pulling electron density towards itself through the sigma bonds.

Comparison

- Range: The inductive effect typically decreases rapidly with distance from the electronegative atom or group, while the field effect can be more significant over longer distances since it acts through space.

- Cause: The inductive effect is caused by differences in electronegativity between atoms or groups connected by bonds, while the field effect is due to the influence of a charged or polarized group on other parts of the molecule, regardless of direct bonding.

Both effects are crucial in understanding the reactivity, stability, and properties of organic molecules.

What is the Field Effect Phenomenon?

The field effect phenomenon refers to the influence of an external electric field on the behavior of charges within a material, typically in semiconductors or other electronic systems. This phenomenon is fundamental in the operation of various electronic devices, particularly transistors, where an electric field is used to control the flow of current.

Key Aspects of the Field Effect Phenomenon:

-

Control of Charge Carriers:

- The field effect allows for the control of charge carriers (electrons or holes) in a semiconductor material by applying an external electric field. This is usually achieved by placing a voltage across a gate electrode that influences the charge distribution in the semiconductor.

- The field effect allows for the control of charge carriers (electrons or holes) in a semiconductor material by applying an external electric field. This is usually achieved by placing a voltage across a gate electrode that influences the charge distribution in the semiconductor.

- Field-Effect Transistors (FETs):

- The most common application of the field effect is in Field-Effect Transistors (FETs), such as Metal-Oxide-Semiconductor FETs (MOSFETs). In these devices, the gate voltage creates an electric field that modulates the conductivity of a channel between the source and drain terminals, effectively controlling the current flow.

- In a MOSFET, for instance, when a voltage is applied to the gate, it creates an electric field that either attracts or repels electrons (or holes) in the channel, turning the device on or off.

- Surface States and Capacitance:

- The field effect can also influence the distribution of charges at the surface of a semiconductor. This is important in the study of surface states, which are energy levels at the surface of a material that can trap charge carriers. The capacitance of the material (its ability to store charge) can also be affected by the field effect.

- The field effect can also influence the distribution of charges at the surface of a semiconductor. This is important in the study of surface states, which are energy levels at the surface of a material that can trap charge carriers. The capacitance of the material (its ability to store charge) can also be affected by the field effect.

- Applications Beyond Transistors:

- The field effect is not limited to transistors. It can also be observed in other electronic components and sensors where an external electric field influences the properties of the material. For example, in some chemical sensors, the field effect is used to detect the presence of specific molecules by observing changes in the electric field near a sensor surface.

Summary:

The field effect phenomenon is a crucial concept in electronics, where it is used to control the behavior of charge carriers in a material through the application of an external electric field. This principle underpins the operation of various electronic devices, most notably field-effect transistors, which are essential components in modern electronic circuits.

Ten Substrates Used to Fabricate Field Effect Transistors (FET)

Si (Silicon) and GaAs (Gallium Arsenide) are commonly used to fabricate Field Effect Transistors. These materials have the advantage of forming an oxide layer on their surface that can be used as the gate electrode. By applying a positive gate voltage  The oxide layer will attract charge-carrying holes and permit them to pass through. On the other hand, when a negative voltage is applied to the gate terminal, these holes will be repelled away from it, and current flow will decrease. A FET comprises two electrodes separated by a channel whose width determines how much current flows between them when a voltage is applied across it. As such, when voltage increases, so does the width of this channel, allowing for more current flow, which increases device performance. Conversely, if the positive charge is applied to the gate terminal, this will cause the narrowing of this channel, resulting in lower current flow and reduced device performance.

The oxide layer will attract charge-carrying holes and permit them to pass through. On the other hand, when a negative voltage is applied to the gate terminal, these holes will be repelled away from it, and current flow will decrease. A FET comprises two electrodes separated by a channel whose width determines how much current flows between them when a voltage is applied across it. As such, when voltage increases, so does the width of this channel, allowing for more current flow, which increases device performance. Conversely, if the positive charge is applied to the gate terminal, this will cause the narrowing of this channel, resulting in lower current flow and reduced device performance.

Below are the ten substrates most commonly used to fabricate Field Effect Transistors.

-

Silicon

-

Germanium

-

Gallium Arsenide

-

Indium Phosphide

-

Silicon Carbide

-

Diamond

-

Graphene

-

Carbon Nanotubes

-

Zinc Oxide

-

Organic Semiconductors

How are Substrates Used to Fabricate Field Effect Transistors?

Silicon Substrates:

are commonly used to fabricate field effect transistors (FETs) due to their excellent electrical properties and the availability of high-quality, large-area silicon wafers. Fabricating a FET on a silicon substrate typically involves depositing various layers of materials on top of the substrate, such as a gate dielectric layer and a conductive gate electrode.

Once the gate structure is in place, the source and drain regions are created by introducing dopant atoms into the silicon substrate using ion implantation or diffusion techniques. The resulting FET device consists of a channel region between the source and drain, which is electrically controlled by the voltage applied to the gate electrode through the gate dielectric layer. By varying the gate voltage, the conductivity of the channel can be modulated, allowing for the amplification and switching of electrical signals.

Germanium Substrates:

Germanium substrates can also be used to fabricate field effect transistors (FETs), although they are less commonly used than silicon due to their higher cost and more limited availability of high-quality germanium wafers.

The process of fabricating a FET on a germanium substrate is similar to that on a silicon substrate, but with some differences in the materials used and the doping process. Germanium has higher carrier mobility than silicon, which makes it attractive for high-speed electronics. However, it is also more challenging to control doping in germanium than in silicon, which can affect the performance of the resulting FET device.

While germanium substrates can offer some advantages in specific applications, silicon remains the dominant substrate material for FET fabrication due to its excellent electrical properties, availability of high-quality wafers, and lower cost.

Gallium Arsenide:

Gallium arsenide (GaAs) substrates are another material that can fabricate field-effect transistors (FETs). GaAs have higher electron mobility than silicon, making them attractive for high-speed and high-frequency applications.

Fabricating a FET on a GaAs substrate involves depositing various layers of materials on top of the substrate, including a gate dielectric layer and a conductive gate electrode. The source and drain regions are created by introducing dopant atoms into the GaAs substrate using ion implantation or diffusion techniques.

However, the fabrication process for GaAs FETs is more complex than for silicon-based FETs, and the cost of GaAs substrates is generally higher. In addition, GaAs substrates are more sensitive to defects and impurities, which can affect the performance of the resulting FET device. Despite these challenges, GaAs FETs have found applications in high-speed communication systems, microwave circuits, and other areas where high performance is critical.

Indium Phosphide

Indium phosphide (InP) is another substrate material that can be used to fabricate field-effect transistors (FETs). InP has a higher electron mobility than both silicon and GaAs, making it attractive for high-speed and high-frequency applications.

The process of fabricating a FET on an InP substrate is similar to that on a GaAs substrate, involving the deposition of various layers of materials on top of the substrate, including a gate dielectric layer and a conductive gate electrode. The source and drain regions are created by introducing dopant atoms into the InP substrate using techniques such as ion implantation or diffusion.

However, InP substrates can be even more challenging to work with than GaAs substrates, as they are more sensitive to defects and impurities. In addition, the cost of InP substrates is generally higher than that of GaAs substrates. Despite these challenges, InP FETs have found applications in high-speed optical communication systems, microwave circuits, and other areas where high performance is critical.

Silicon Carbide

Silicon carbide (SiC) is a substrate material that can fabricate field-effect transistors (FETs) for high-temperature and high-power applications. SiC has a wide bandgap, allowing high breakdown voltages and high-temperature operation.

Fabricating a FET on a SiC substrate involves depositing various layers of materials on top of the substrate, including a gate dielectric layer and a conductive gate electrode. The source and drain regions are created by introducing dopant atoms into the SiC substrate using ion implantation or diffusion techniques.

The high thermal conductivity of SiC also allows for efficient heat dissipation, making it suitable for high-power applications. However, the high cost and limited availability of high-quality SiC substrates can hinder its widespread use. Despite these challenges, SiC FETs have found applications in power electronics, high-temperature sensors, and other areas where high performance is critical.

Diamond

Diamond is a substrate material that can fabricate field-effect transistors (FETs) for high-power and high-frequency applications. Diamond has a wide bandgap, high thermal conductivity, and excellent electrical properties, which makes it attractive for high-performance electronics.

Fabricating a FET on a diamond substrate involves depositing various layers of materials on top of the substrate, including a gate dielectric layer and a conductive gate electrode. The source and drain regions are created by introducing dopant atoms into the diamond substrate using ion implantation or diffusion techniques.

However, the cost and availability of high-quality diamond substrates can hinder their widespread use. In addition, the doping process for a diamond can be challenging, which can affect the performance of the resulting FET device. Despite these challenges, diamond FETs have found applications in high-power and high-frequency electronics, as well as in sensing and other areas where high performance is critical.

Graphene

Graphene is a substrate material that can fabricate field-effect transistors (FETs) for high-speed and low-power applications. Graphene has excellent electrical properties, including high carrier mobility and low intrinsic resistance, making it attractive for high-performance electronics.

Fabricating a FET on a graphene substrate involves depositing various layers of materials on top of the substrate, including a gate dielectric layer and a conductive gate electrode. The source and drain regions are created by introducing dopant atoms into the graphene substrate using ion implantation or chemical doping techniques.

However, the fabrication process for graphene-based FETs can be challenging, as graphene's high surface sensitivity and low thickness require careful handling and processing. In addition, the lack of a bandgap in graphene can make it challenging to achieve high on/off ratios, limiting its use in specific applications.

Despite these challenges, graphene FETs have found applications in high-speed electronics, flexible electronics, and other areas where high performance is critical. Research on graphene-based FETs continues to explore ways to improve their performance and reliability.

Carbon Nanotubes

Carbon nanotubes (CNTs) are a substrate material that can be used to fabricate field-effect transistors (FETs) for high-speed and low-power applications. CNTs have excellent electrical properties, including high carrier mobility and low intrinsic resistance, making them attractive for high-performance electronics.

The process of fabricating a FET on a CNT substrate involves depositing various layers of materials on top of the substrate, including a gate dielectric layer and a conductive gate electrode. The source and drain regions are created by introducing dopant atoms into the CNT substrate using techniques such as ion implantation or chemical doping.

CNTs offer the advantage of having a quasi-one-dimensional structure, which can enhance their electrical properties and allow for better control of the channel length in the resulting FET device. However, the fabrication process for CNT-based FETs can be challenging, as the growth and alignment of CNTs require careful control and optimization.

Despite these challenges, CNT-based FETs have found applications in high-speed electronics, flexible electronics, and other areas where high performance is critical. Research on CNT-based FETs continues to explore ways to improve their performance and reliability.

Zinc Oxide

Zinc oxide (ZnO) is a substrate material that can fabricate field-effect transistors (FETs) for various applications, including sensing, energy harvesting, and transparent electronics. ZnO has excellent electrical and optical properties, making it attractive for these applications.

Fabricating a FET on a ZnO substrate involves depositing various layers of materials on top of the substrate, including a gate dielectric layer and a conductive gate electrode. The source and drain regions are created by introducing dopant atoms into the ZnO substrate using ion implantation or chemical doping techniques.

ZnO FETs offer several advantages, including their transparency and flexibility, which make them suitable for use in transparent and flexible electronics. In addition, ZnO is a relatively low-cost substrate material, which can make it attractive for specific applications.

However, the fabrication process for ZnO-based FETs can be challenging, as the growth and processing of ZnO require careful control and optimization. In addition, the stability and reliability of ZnO FETs can be affected by environmental factors such as humidity and temperature.

Despite these challenges, ZnO-based FETs have found applications in various fields, and research on their performance and reliability continues to advance the development of this technology.

Organic Semiconductors

Organic semiconductors are substrate materials that can fabricate field-effect transistors (FETs) for applications such as organic electronics, flexible electronics, and printed electronics. Organic semiconductors are carbon-based molecules, and their electrical properties can be tuned by controlling the molecular structure and doping.

Fabricating a FET on an organic semiconductor substrate involves depositing various layers of materials on top of the substrate, including a gate dielectric layer and a conductive gate electrode. The source and drain regions are created by introducing dopant molecules into the organic semiconductor substrate using techniques such as chemical doping.

Organic semiconductor FETs offer several advantages, including flexibility, low cost, and compatibility with solution-based processing techniques. However, the performance of organic semiconductor FETs can be limited by factors such as low carrier mobility, limited stability, and sensitivity to environmental factors such as temperature and humidity.

Despite these challenges, organic semiconductor FETs have found applications in areas such as displays, sensors, and energy harvesting, and research on their performance and reliability continues to advance the development of this technology.

What is Heterojunction Field Effect Transistors (FET)?

Heterojunction Field Effect Transistors (FETs) are able to achieve better performance than traditional FETs by taking advantage of the different electron and hole affinity of different materials. - A heterojunction FET is composed of two different semiconductor materials with different band gap energies, such as GaAs and Si. These materials are arranged in layers such that the electrons and holes can flow through channels in between them. The larger band gap material, typically GaAs, forms a wide band gap layer while the smaller band gap material, typically Si or AlGaAs, forms a narrow band gap layer. The two layers together form a heterojunction which is capable of introducing electrons from the wider band gap material into the narrow one. This is done by applying modulation doping which creates an electric field across the junction in order to attract electrons from one layer to another. The resulting electron-hole gas channels allow for larger electron and hole currents than traditional FETs due to its larger electron affinity and higher carrier supply layer.

What Is Heterojunction Field Effect Transistor?

FETs are able to achieve better performance than traditional FETs by taking advantage of the different electron and hole affinity of different materials. - A heterojunction FET is composed of two different semiconductor materials with different band gap energies, such as GaAs and Si. These materials are arranged in layers such that the electrons and holes can flow through channels in between them. The larger band gap material, typically GaAs, forms a wide band gap layer while the smaller band gap material, typically Si or AlGaAs, forms a narrow band gap layer. The two layers together form a heterojunction which is capable of introducing electrons from the wider band gap material into the narrow one. This is done by applying modulation doping which creates an electric field across the junction in order to attract electrons from one layer to another. The resulting electron-hole gas channels allow for larger electron and hole currents than traditional FETs due to its larger electron affinity and higher carrier supply layer.

Junction Field Effect Transistors (JFETs) are a type of FET that operate using a junction between two different materials, such as silicon and gallium arsenide. JFETs are used in logic circuits, as well as amplifiers and oscillators. The AlGaN/GaN Heterojunction Field Effect Transistor (HFET) is an advanced JFET device with a barrier layer made up of Aluminum Gallium Nitride (AlGaN) and Gallium Nitride (GaN). HFETs have demonstrated maximum oscillation frequency over 100 GHz, making them attractive for high-frequency applications. This is due to the establishment of lateral electric fields along the gate length that modulate the channel 2DEG at gate devices. This fringe electric field is created by the PN diode formed between the AlGaAs layer and the gate oxide. The gate length can also be reduced in HFET devices leading to higher power density than traditional Si FET devices. Over 100 devices from multiple vendors have been tested, demonstrating excellent performance characteristics.

What is the difference between field-effect transistors (FETs) and bipolar junction transistors (BJTs) in terms of input bias current?

Field-Effect Transistors (FETs) and Bipolar Junction Transistors (BJTs) are both crucial electronic components used for signal amplification and switching applications, among others. However, they have fundamental differences, one of which pertains to the input bias current.

-

Bipolar Junction Transistors (BJTs):

BJTs are current-controlled devices. The input current, referred to as the base current (I_B), is used to control the larger output current, which flows from the collector to the emitter (I_C). The output current is a multiple of the input current, and the multiplier is the transistor's current gain, usually denoted by 'β' or 'hfe'. Thus, BJTs require a significant input bias current for operation.

-

Field-Effect Transistors (FETs):

On the other hand, FETs are voltage-controlled devices. The input voltage, known as the gate voltage (V_G), controls the current flowing from the source to the drain (I_D). FETs, particularly those of the MOSFET type, have an insulating layer (usually silicon dioxide) between the gate and the body of the transistor. Because of this insulating layer, practically no current flows into the gate terminal. Therefore, the input bias current for a FET is virtually zero.

In conclusion, the input bias current is one of the fundamental differences between BJTs and FETs. BJTs require a certain amount of current to be fed into the base for them to work, while FETs, especially MOSFETs, do not require any gate current due to their voltage-controlled operation and the insulation between the gate and the body.