Would you kindly provide us the quotation for 5 units of

4" Aluminium Gallium Nitride(AlGaN)/Gallium Nitride(GaN) High

Electron Mobility Transistor (HEMT) on SiC substrate?

Substrates Used for Measuring Electron Mobility

High Electron Mobility Transistor (HEMT)

A sales engineer requested the following quote:

Reference #201660 for specs and pricing.

Get Your Silicon Wafer Quote FAST! Or, Buy Online and Start Researching Today!

High Electron Mobility Substrates

A PhD candidate requested the following quote:

Are you capable of growing epitaxial layers over InP substrates?

We need high electron mobility substrates.

Previously, we were using AlGan/GaN/Sapphire substrates but the mobility is highly dependent on the temperature.

But, InAlAs/InGaAs/InP substrates has very high mobilities at room temperature.

You can find detailed information on the attached files.

We will need 3-4 pcs with 2" diameter wafers.

| Layer |

| 15 nm n++ In0.53GaAs |

| 15 nm n++ In0.52AlAs |

| 6 nm i-InP |

| 15 nm i-In0.50AlAs |

| 10 nm Si-δ-In0.50AlAs |

| 3 nm i-In0.50AlAs |

| 4 nm i-In0.53GaAs |

| 8 nm i-In0.71GaAs |

| 5 nm i-In0.53GaAs |

| 200 nm i-In0.50AlAs |

| InP substrate |

Reference #160191 for specs and pricing.

Graphene's Electron Mobility

A industrial engineer requested the following quote.

I'm graduating as an industrial engineer and I accidentally found your site, I find amazing what can be done with graphene. you can support that type of graphene is the optimal for a solar cell and how to make these. that is needed. I would need you to sell the right kind of graphene for solar panels and the theory behind graphene to make a technical and theoretical study. I have read oftener forms of graphene but not clear to me. I ask please if you can send as you get this, to try to make a practice in the laboratory.

Thank you. sorry for my English I need more practice.

UniversityWafer, Inc. replied:

Graphene Films: We have monolayer/bilayer/trilayer graphene films. The main properties are the high electron mobility and the excellent thermal conductivity. We have different substrates such as SiO2/Si, PET, QUARTZ, Cu

Reference #160526 for specs and pricing.

Electron Mobility of Monolayer Graphene

A bio-nanomaterials researcher requested help for the following.

Question:

Answer:

he mobility for the monolayer graphene is the following:

- FET Electron Mobility on Al2O3: 2000 cm2/Vs

- FET Electron Mobility on SiO2/Si: 4000 cm2/Vs

Reference #171450 for specs and pricing.

Silicon Wafers for Measuring Electron Mobility

A Ph.D. Materials Science requested help with the following.

I am conducting a research project that is about measuring the electron mobility of n-doped silicon as a function of concentration. As I was navigating through your site, I found that it was hard for me to be able to determine what would be appropriate for me to order. Time is a consideration.

What I want to do is have around six different samples with known conductivities and apply a voltage across the sample and measure its current density in order to find the electron mobility. I do not need large samples for this project, and the concentration is the most important factor in this project. Do you have any suggestions?

We can supply you a wide range of n-type silicon wafers, with resistivities from 0.001 to 20,000 Ohmcm, hence dopant concentrations from 8E19/cc (1,200ppma) to 5E11/cc (0.00001ppma). However, we have neither mobility nor dopant concentration measurements for individual wafers or even batches of wafers. We do have Resistivity measurements but even these are relatively broad ranges for groups of wafers.

To appreciate why this is so you have to understand how the silicon ingots and wafers are made. To grow a crystal, one charges a certain amount of dopant into a batch of very pure silicon which is then molten and from it a crystal is drawn. However, the dopant concentration in the crystal is not the amount of dopant charged divided by the amount of silicon in the charge. During crystallization, the dopant is preferentially excluded form the crystal (in some cases it is preferentially included in the crystal) so that during crystallization, dopant concentration in the melt rises and in the "pot scrub", in the bottom of the crucible, it can be very high indeed. In the monocrystalline part of the ingot, the resistivity changes from top to bottom, by a factor of 2 for p-type doped with Boron and by a factor of 3 for n-type doped with Phosphorus.

Thus to measure mobility, you have to measure, in the same place on the wafer, both Resistivity (Ro) and Dopant concentration (Nc). Dopant concentration has to be measured with a tool such SIMS (Secondary Ion Mass Spectroscopy). From Ro and Nc you calculate mobility.

We can supply you the sample wafers, but you have to do your own Resistivity measurements and SIMS analysis.

Another approach is to use Silicon wafers with Silicon Epitaxial layer. In growing the Epitaxial layer one can control the dopant concentration in the gas from which the Epi layer is deposited, hence know the dopant concentration in the Epi layer that is deposited to an accuracy of at least +/-10%. Of course in practice, one measures Resistivity (Ro) to verify the Dopant Concentration (Nc) under the assumption that mobility is constant, whereas you want to see the relatively small variations of dopant mobility dependant on dopant concentration. So, you are back to doing SIMS analysis. n-type Nc in Epi layers can be controlled from about 1E18/cc to 5E12/cc.

In summary, we can supply you Silicon wafers or Silicon Epi wafers, with wide range of n-type dopant concentrations, but you have to do Resistivity measurements and SIMS analysis, yourself.

Note: On polished wafers one has to measure Resistivity with a non-contact gauge (which measures the eddy currents induced within the silicon). One can use a 4 point probe Resistivity measurement only on "as-cut" and or ground or lapped wafer surfaces (not on alkaline etched silicon surfaces). You would have to grind or sand-paper the polished wafer surface for the 4-point probe to make good contact to give you a valid resistivity measurement.

Note: We do have some broken silicon wafers, with a wide range of dopant concentrations, which are available cheaply but which can be used for the measurements that you need to make.

There are very many n-type wafers that you can use for your purposes.

I have chosen a small sample for your review, concentrating on 2" wafers and [100] Oriented Wafers, and otherwise covering the resistivity range of 0.001 to 20,000 Ohmcm.

Reference #132111 for specs and pricing.

Gallium Arsenide Electron Mobility

I find myself in need of semi-insulating Gallium Arsenide wafers. A good format would be 2'' diameter (about 0.5 mm thick) with a resistivity of about 10^6 Ohm.cm. Do you have anything like that available, and if so what is the approximate cost per piece?

I would order 5 wafers initially. In terms of specs, nothing too special is required other than the resistivity. High quality crystalline material (high electron mobility) with a good one-sided optical polish is required. The application is photo-conductive semiconductor switches, whereby we will pattern the polished side of the wafer with Ni:AuGe:Au ohmic contacts. Can you send a quote?

Reference #226918 for specs and pricing.

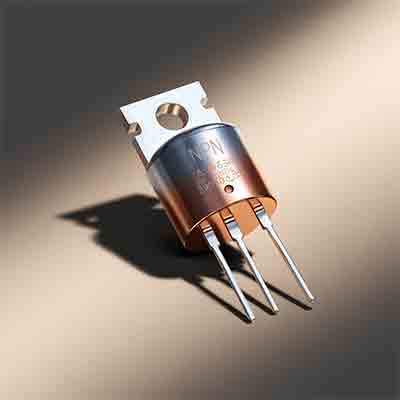

How To Achieve High Electron Mobility

A postdoc asked for help with the following question and quote.

Question:

We have been meaning to make an NPN Transistor which has electron mobility  upwards of 9000-1000 aiming for ballistic transport characteristics. May you assist me on suggesting different types of wafers that we may be using given these specifications, additionally the wafer should be less heat sensitive. Please let me know of some wafers that you would suggest as I am unable to set these parameters on the website. I look forward to hearing back from you.

upwards of 9000-1000 aiming for ballistic transport characteristics. May you assist me on suggesting different types of wafers that we may be using given these specifications, additionally the wafer should be less heat sensitive. Please let me know of some wafers that you would suggest as I am unable to set these parameters on the website. I look forward to hearing back from you.

Answer:

To achieve high electron mobility, the silicon has to be very pure and have perfect crystallinity. Purity means not just having high resistivity but rather one with few compensating dopants. This is best measured by Minority Charge Carrier Lifetime

Thus I suggest FZ crystallized Silicon (hence with minimum Carbon and Oxygen), Phosphorus doped (to a degree appropriate for the transistor base) and of the longest MCC Lifetime available.

We have the following hight MCC Lifetime wafers:

Reference #255850 for specs and pricing.