We are currently working on the growing number of PIC related projects and I am looking for the SOI wafers which can be applied in integrated photonics circuits fabrication. The parameters: SOI: Si = 220 nm SiO2 = 2 - 3 microns Diameter: 4 inches, 6 inches. Upper Si layer thickness tolerance: several nm Si: monocrystal In case you can offer the suitable waffer, please tell the MOQ and provide the offer/datasheet.

Substrates Used in Integrated Photonic Devices

220nm Device Layer SOI Wafers for Integrated Photonics Circuits Fabrication

An application engineer requested a quote for the following.

Reference #252722 for specs and pricing.

We have The SOI Wafers You Need For Integrated Photonic Research.

Silicon Nitride Film for Integrated Photonics Devices

A postdoc requested a quote for the following.

I am inquiring whether your company still sells silicon nitride film products and whether it can be customized. We need silicon nitride film for our integrated photonics devices.The thin layer of silicon nitride we need is deposited on a silicon oxide layer, which grows on a silicon wafer.

Reference #258285 for specs and pricing.

Silicon Carbide Wafers for Integrated Photonic Device Fabrication

I'd like to request SiC on insulator wafer. Do you have it? Especially, 4H-SiC on insulator for integrated photonics. Additionally, is it possible to control the thickness about few hundreds nm?

I'd like to get 2 inch or 4 inch wafer, thickness is about 300-500nm and high purity semi insulating or n-type doped is also fine.

Pls seeing below for the offer on required SiCOI Wafer @ qty. 1

SiCOI Wafer -100 mm wafers consisting of a layer of Silicon Carbide of thickness 300~500 nm placed on top of a SiO2 layer of 2~3 um on top of a Si substrate. Single side polished

Reference #319496 for specs and pricing.

Integrated Photonics Chip

Gallium Nitride Used for Integrated Photonics Chip Applications

A Ph.D Candidate requested a quote for the following.

Question:

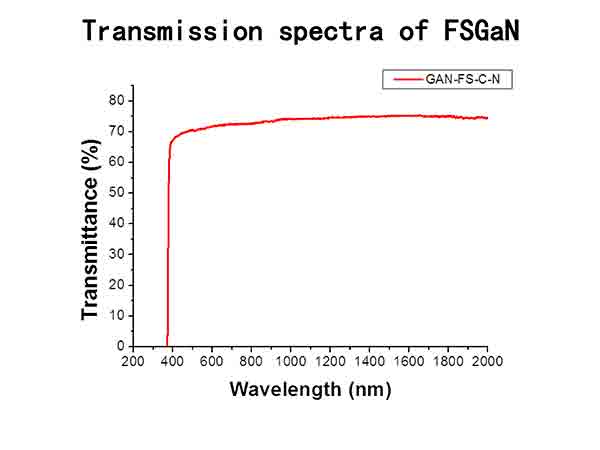

Our key interet is in integrated photonics chip. As for GaN, can it be used for photonics application? And what is the transmittance and absorption in the wavelength range from 300nm - 2000nm? Are there any customers who use your company's GaN materials to realize photonic structure? By the way, dose your company sell single crystalline BiTaO3 wafer?

Answer:

Many users using our GaN for photonics application, Pls see attached spectra for the transmittance in the wavelength range from 300nm - 2000nm,We can supply GaN from 2'' to 4'',Pls let us know your intentional spec.

Refererence #258382 for specs and pricing.

Integrated Photonics Chip With a Very Low Insertion Loss Silicon Nitride Waveguide

An assistant professor requested a quote for the following.

Would you share some information or papers about the optical properties of your nitride film. It would be great if you know anyone use your film making the low loss SiN waveguide.

Reference #266416 for specs and pricing.

Optical Quality Silicon-on-Insulator Wafers

A senior researcher requested a quote for the following.

We are trying to make integrated photonics circuits and are looking for optical quality SOI and Si3N4-SiO2-Si wafers. Si3N4 wafer requirements: - Silicon substrate, 001 orientation, 200-800 um, minimal conductivity without zone melting (“cheap” material) - SiO2 wafer, thermal oxide, >=2 um - Si3N4, ultralow stress, 200-1000 nm (preferably ~300 nm, to be confirmed by our simulation) - Size 3-4” - About 10-20 pcs SOI wafer requirements: - Substrate – same - SiO2 – same - Silicon - 200-1000 nm (preferably ~400 nm, to be confirmed by our simulation) - Size – same - Number – same 1). Has any research group made a working integrated photonics circuit on your material (paper with DOI)?

Reference #257784 for specs and pricing.

SOI Wafers for Integrated Photonic Applications

A nanophotonics lab technician requested a quote for the following.

We are looking for few SOI wafers for the applications in the integrated photonics. The diameter of wafers is not very important. It could be 200mm, 150mm or 100mm. The device layer should be 220nm.

Oxide layer - about 2-3 microns. Handle - about 675 microns.

It could be for example: 150mm SMB-6P675-3-0.22P-SIM-01.

Quantity is about 5-10 wafers. What have you in the stock and could you suggest for us?

Reference #164188 for specs and pricing.

Fabricating Integrated Photonic Chips Using Gallium Nitride Substrates

A Ph.D candidate from a functional materials lab requested a quote for the following.

Our key interet is in integrated photonics chip. As for GaN, can it be used for photonics application? And what is the transmittance and absorption in the wavelength range from 300nm - 2000nm? Are there any customers who use your company's GaN materials to realize photonic structure? By the way, dose your company sell single crystalline BiTaO3 wafer?

Reference #258382 for specs and pricing.

AlN Wafers For Our Integrated Photonics

An associate researcher requested a quote for the following.

My group is planing on implementing AlN wafers for our integrated photonics projects. Hence, I would like to ask you for a quotation to get an overview on the price. The quotation should inclide the listed items: - AlN wafers with 6inch in diameter, AlN width of 200nm.

UniversityWafer, Inc. Quoted:

- AlN wafers,200nm <001> AlN on <0001> Sapphire substrate wafer,Single side polished,thickness 1000+/-25um,AlN purity >/=5N

- AlN wafers,200nm <001> AlN on <111> Silicon substrate wafer,Single side polished,thickness 1000+/-25um,AlN purity >/=5N

Reference #258151 for specs and pricing.

Silicon Germanium (SiGe) Wafers for Integrated Photonic Applications

A postdoctoral scholar requested a quote for the following.

I would be interested in Ge on Si wafers with Ge thickness (SiGe) of 1 um and more for applications in integrated photonics. Both the Ge and Si should be of the undoped / intrinsic type. Wafersize 4" or any Resistivity > 10 kOhm Orientation (100) Polish One side Ge thickness > 1 um.

I need a quote for 20 wafers right now. No particular requirements but the ones stated below.

- Ge on Si wafers with Ge thickness of 1um and more for applications in integrated photonics. Both the Ge and Si should be of the undoped / intrinsic type. Wafer size 4" Resistivity > 10k Ohm Orientation (100) Polish One side Ge thickness 1um

- Ge on Si wafers with Ge thickness of 1um and more for applications in integrated photonics. the Ge undoped / intrinsic type. Wafer size 6" Resistivity 1-20 Ohm Orientation (100) Polish One side Ge thickness 1um

Reference #274228 for specs and pricing.

Why are silicon on insulator substrates with a 220 nanometer thick device layer often used for integrated photonic applications?

Silicon-on-insulator (SOI) substrates with a 220 nm thick device layer have become a standard choice for integrated photonics, particularly in silicon photonics, due to several key reasons:

1. Single-mode operation in the near-infrared (telecom  wavelength range)

wavelength range)

- The 220 nm thickness is carefully chosen to support single-mode light propagation in the near-infrared spectrum (~1550 nm), which is a critical range for telecommunications and data communications.

- A 220 nm thick silicon core waveguide, with a typical width of 400-500 nm, supports single transverse-electric (TE) and transverse-magnetic (TM) modes while minimizing higher-order modes.

- Single-mode operation is essential for low-loss, low-dispersion, and high-performance optical circuits.

2. High Refractive Index Contrast

- The SOI stack has high refractive index contrast between Si (n ≈ 3.48) and SiO₂ (n ≈ 1.44).

- This contrast allows for strong optical confinement in the silicon layer, enabling the design of compact waveguides and tight bends with low radiation loss, which is crucial for dense photonic integration.

3. Compatibility with CMOS fabrication processes

- The 220 nm device layer thickness aligns well with standard CMOS fabrication processes, as it originated from early work on leveraging existing semiconductor manufacturing infrastructure for photonics.

- This thickness is compatible with deep UV lithography, etching processes, and thin-film deposition techniques used in large-scale production.

4. Efficient coupling and manipulation of light

- A 220 nm silicon thickness supports the development of grating couplers, directional couplers, Mach-Zehnder interferometers (MZIs), and ring resonators that are widely used in photonic circuits.

- These components operate efficiently at 1550 nm with low insertion loss and high coupling efficiency when interfacing with optical fibers.

5. Established Ecosystem and Design Libraries

- Over time, 220 nm SOI platforms like those from IME, GlobalFoundries, and AIM Photonics have led to the development of mature photonic design kits (PDKs) and component libraries.

- This ecosystem accelerates development and reduces fabrication costs for photonic integrated circuits (PICs).

6. Low Propagation Loss

- A 220 nm silicon device layer exhibits low optical propagation loss (on the order of < 1 dB/cm) when fabricated with high-quality silicon and optimized processing.

- The buried oxide (BOX) layer acts as an optical insulator, reducing leakage into the substrate and minimizing substrate modes, further improving waveguide performance.

Summary of Benefits:

| Property | Impact on Photonic Applications |

|---|---|

| Single-mode operation | Low-loss, low-dispersion signal transmission |

| High refractive index contrast | Compact waveguides, tight bends |

| CMOS compatibility | Cost-effective, large-scale manufacturing |

| Efficient component performance | High-performance couplers, interferometers, resonators |

| Low propagation loss | Enhanced signal integrity over longer distances |

This combination of single-mode guidance, fabrication compatibility, high index contrast, and efficient component performance is why 220 nm SOI substrates have become the industry standard for integrated photonics.

What substrate and specs are used to fabricate photonic integrated circuit (PIC) with intricate waveguides, laser sources, and micro-ring resonators with glowing light propagation

Fabricating a photonic integrated circuit (PIC) with intricate waveguides, laser sources, and micro-ring resonators involves selecting the right substrate and specifications to ensure optimal light propagation, integration, and performance. Here are the key materials and parameters used:

1. Substrate Materials for PICs

The substrate is crucial in defining the optical and electrical properties of the PIC. The most commonly used substrates include:

a. Silicon-on-Insulator (SOI)

- Why SOI? SOI is the most widely used substrate for silicon photonics because of its excellent optical confinement.

- Typical Structure:

- Top Silicon Layer: 200-500 nm (for waveguides)

- Buried Oxide (BOX) Layer: 2-3 µm (for optical isolation)

- Handle Silicon: 500-750 µm

- Advantages:

- Strong light confinement in the high-index contrast Si waveguides.

- CMOS-compatible fabrication.

- Suitable for high-speed optical modulators and detectors.

b. Indium Phosphide (InP)

- Why InP? Used for active components like lasers, photodetectors, and amplifiers.

- Typical Structure:

- Multi-layer stack with InGaAsP/InP heterostructures for laser integration.

- Advantages:

- Direct-bandgap semiconductor (ideal for light emission).

- Used in telecom applications (1550 nm wavelength).

c. Silicon Nitride (SiN) on SiO₂

- Why SiN? Ideal for visible and near-infrared wavelengths.

- Typical Structure:

- SiN thickness: 100-400 nm.

- SiO₂ cladding: 2-5 µm.

- Advantages:

- Low propagation loss (< 0.1 dB/cm).

- High power-handling capability.

- Suitable for micro-ring resonators.

2. Key PIC Components and Their Specs

PICs typically consist of the following fabricated structures:

a. Optical Waveguides

- Material: Silicon (Si), SiN, or InP.

- Width: 400-500 nm (SOI for single-mode operation at 1550 nm).

- Height: 220 nm (SOI) or 100-400 nm (SiN).

- Propagation Loss:

- Silicon: ~1 dB/cm

- SiN: < 0.1 dB/cm

b. Micro-Ring Resonators

- Material: Si (on SOI) or SiN.

- Radius: 3-10 µm (for telecom applications at 1550 nm).

- Free Spectral Range (FSR): Typically 10-30 nm.

- Q-factor: ~10⁵ to 10⁶ for high selectivity.

c. On-Chip Lasers

- Material: III-V (InP, GaAs) bonded to SOI or native InP substrates.

- Wavelengths:

- 1310 nm (short-range optical links).

- 1550 nm (long-haul optical communication).

- Integration:

- Heterogeneous integration (III-V on Si).

- Hybrid integration using flip-chip bonding.

d. Photodetectors

- Material: Ge-on-Si or InP.

- Responsivity: 0.7-1.0 A/W at 1550 nm.

- Bandwidth: Up to 100 GHz for high-speed detection.

3. Fabrication Techniques

To realize such intricate PICs, several advanced fabrication techniques are used:

- Lithography:

- Electron Beam Lithography (EBL) for nanoscale precision.

- Deep UV (DUV) photolithography for mass production.

- Etching:

- Reactive Ion Etching (RIE) or Inductively Coupled Plasma (ICP) for precise etching.

- Deposition:

- Atomic Layer Deposition (ALD) or Plasma Enhanced Chemical Vapor Deposition (PECVD) for oxide/nitride layers.

- Bonding:

- Wafer bonding for III-V laser integration.

4. Optical Propagation and Performance

For glowing light propagation in the waveguides:

- The mode size and shape of the guided light must be optimized.

- Low-loss waveguide bends and tapers improve coupling efficiency.

- Passive SiN waveguides can guide light over several centimeters with minimal loss.

- Micro-ring resonators can filter and modulate light dynamically.

Conclusion

A PIC with intricate waveguides, laser sources, and micro-ring resonators is typically built on SOI (for passive Si photonics), InP (for active components), or SiN (for low-loss applications). The specifications of these components depend on the desired application, from optical communication to biophotonics. Would you like recommendations for specific fabrication vendors or design tools?