I would like to know the price of the 1 inch sapphire substrate as I require it for the CVD growth of transition metal dichalcogenides. I would like to procure around 20 pieces. Hoping to hear from you soon.

Substrates for Metal Dichalcogenides

Sapphire Substrates CVD Growth

A postdoc researching control growth and synthesis of 2D transition metal dichalcogenides and their heterostructures for various optoelectronic applications requested a quote for the following.

Dia 25.4 x 1.0mm DSP C-plane round shape Sapphire wafers.

Reference #290010 for specs and pricing.

Get Your Quote FAST! Or, Buy Online and Start Researching Today!

van der Waals Heterostructures of Metal Dichalogenides Transition

A graduate student requested a quote for the following.

Recently, we got a 2-year grant for investigating the photovoltaic properties of van der Waals heterostructures of transition metal dichalcogenides, and we are in need for high-quality Si wafers. In particular, we need Si wafers with the following properties: -prime quality -orientation <100> -diameter of 4" -thickness of 525um -highly p-doped (Boron) Si with low resistivity and intrinsic Si -with 90nm and 285nm dry thermally grown SiO2 -single side polished -surface roughness RMS < 0.5nm If you have such wafers:

- What is the price for the available package sizes (containing for example 10-20 wafers)?

- 2. What would be the price if all the wafers within a package were diced to 1cm x 1cm pieces?

- 3. Is there a possibility for making a custom package containing, for example, 10 wafers with 90nm SiO2 and 10 wafers with 285nm SiO2?

The Si wafer surface roughness is guaranteed by repetition of the chemical-mechanical-planarization (CMP) polishing process, not by any measurement, which would be destructive. For the polished side of the wafers the normal roughness value is <0.5nm (<5Å). Any standard Quality Certificate doesn't mention any surface roughness measurements data as the roughness is guaranteed by the repetition of the chemical-mechanical-planarization (CMP) polishing process.

Reference #254198 for specs and pricing.

Metal Dichalcogenides (TMDs)

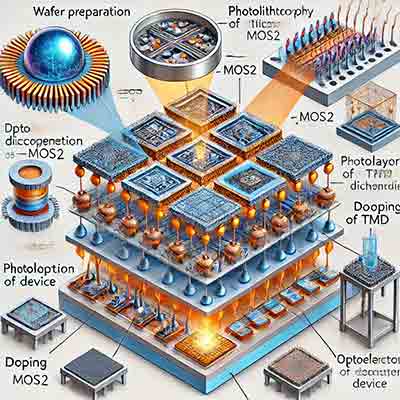

Transition metal dichalcogenides (TMDs) are a class of materials with the formula MX2, where M is a transition metal (such as molybdenum (Mo), tungsten (W), etc.) and X is a chalcogen (such as sulfur (S), selenium (Se), or tellurium (Te)). These materials have a layered structure, where a plane of metal atoms is sandwiched between two planes of chalcogen atoms. TMDs can exhibit various properties depending on their composition, including semiconducting, metallic, and even superconducting behaviors.

Key Characteristics of TMDs:

- Layered Structure: TMDs have a layered structure with weak van der Waals forces holding the

layers together. This allows them to be exfoliated into thin sheets, including monolayers, which have distinct electronic and optical properties compared to their bulk counterparts.

layers together. This allows them to be exfoliated into thin sheets, including monolayers, which have distinct electronic and optical properties compared to their bulk counterparts. - Semiconducting Properties: Many TMDs are semiconductors with a direct bandgap in the monolayer form, which makes them promising for applications in electronics and optoelectronics.

- Mechanical Flexibility: The thin, flexible nature of TMD layers makes them suitable for flexible electronics and other novel applications.

Relation to Substrates:

- Substrate Role: In the context of TMDs, substrates are surfaces or materials on which TMD layers are grown or transferred. The choice of substrate can significantly influence the properties and performance of TMD layers.

- Growth Methods: TMDs can be grown on substrates using methods like chemical vapor deposition (CVD). The substrate material, its surface properties, and lattice matching can affect the quality and uniformity of the TMD film.

- Strain Engineering: The interaction between the TMD layer and the substrate can introduce strain, which can be used to tune the electronic and optical properties of the TMD.

Relation to Semiconductors:

- Bandgap Engineering: TMDs offer the ability to engineer bandgaps by varying the number of layers, composition, and strain, making them versatile for semiconductor applications.

- Electronic Devices: TMDs are used in various semiconductor devices, such as transistors, photodetectors, and light-emitting diodes (LEDs), due to their excellent electronic and optical properties.

- Heterostructures: TMDs can be stacked with other 2D materials (like graphene and hexagonal boron nitride) to create heterostructures with unique properties, enabling the design of novel electronic and optoelectronic devices.

Applications:

- Transistors: TMDs, like MoS2, have been used to create field-effect transistors (FETs) with high on/off ratios, low power consumption, and excellent scalability.

- Photodetectors: The direct bandgap in monolayer TMDs enables efficient light absorption, making them suitable for photodetectors with high sensitivity and fast response times.

- Flexible Electronics: Due to their mechanical flexibility and stability, TMDs are promising for flexible and wearable electronic devices.

In summary, metal dichalcogenides are a fascinating class of materials with unique properties that make them highly relevant for substrates and semiconductor applications. Their ability to be exfoliated into thin layers and their versatile electronic properties open up a wide range of possibilities for advanced electronic, optoelectronic, and flexible devices.