I would like to receive information on both Si and quartz double-side polished wafers.

Question:

Do you by chance know that would it effect the infrared absorption if the wafer is a prime or not?

A PhD candidate requested help with the following question.

I would like to receive information on both Si and quartz double-side polished wafers.

Question:

Do you by chance know that would it effect the infrared absorption if the wafer is a prime or not?

Answer:

he designation SEMI Prime and SEMI Test, refers only to the quality of the surface polish. For Infra-Red absorption surface defects in size less than half a wavelength of light (IR light), have no effect. So for the purposes of IR windows or lenses, SEMI Prime and Test are equally good. In fact, a common specifications for Optics surfaces is Scratch/Dig of 60/40 which is more lenient than even SEMI Test.

Reference #104318 for specs and pricing.

We have the following IR substrates in stock.

Get Your Quote FAST! Or, Buy Online and Start Researching Today!

Supply optical elements from small to medium quantity at 100-1000pcs per month.

optics: windows, spherical/doublet lenses, achromatic lenses,prism and mirror.

material: Si, GE, ZnSe, Bk7,UVFS,Stih53,SF,CaF2,

polishing: s/d: 40-20; fringes: 1/4 lambda; wedge: 1 arc min; coating: V-coating, VIS coating, BBAR/DLC coating.

testing: ZyGo and FuJi interferometers

We have a 6 persons team to do customized optical design, and the wavelength cover 0.2um to 16.0um.It used to UV camera lenses, NIR/SWIR lenses, Zoom Design, F-theta design, laser expander and collimators etc.

We have a new partner with; ISO9001, SGS RoHs, and D&B cetificates. We would like to introduce the following materials: crystal and optics for laser system, FTIR/NIR/UV analysis, F-theta, SWIR design, laser collimator, flameter detector, IR sensors, Customized cameras, Military, and R&D labs.

An accelerator physicist requested a quote for the following.

We are looking for Infra-Red transparent substrates. Including with thermal oxide deposited. It is important for our application to have flat surfaces. Can you provide polishing/smootheness after depositing SiO2 and/or other layers? I will call you in a minute as well.

UniversityWafer, Inc. Responded:

Essentially all electrically non-conductive substances are transpartent in the IR region of the spectrum.

More precisely, all electrically non-conductive substances have nil absorbtion in the IR region of the spectrum. Of course reflectance is a function of the refractive index of the substance and that of the surrounding medium (for example, air). Transparency depends on reflection as well as on absorbtion.

Commonly used for IR windows are Silicon (high resistivity), monocrystalline SiO2 (quartz), polycrystalline SiO2 (fused silica), Sapphire, Germanium, GaAs (Semi Insulating), InP (Semi Insulating or undoped), GaP (Semi Insulating or undoped), TiO2, CaF2, BaF2, MgF2 and many other salts.

For ultimate smoothness (low Surface Roughness), you want each of above substances in monocrystalline form. For monocrystalline wafers CMP polishing routinely achieves roughness <1nm.

If you deal with SiO2 films, then by far the most convenient material is monocrystalline Silicon. It has the advantage in that you can polish Silicon wafers to be very smooth, grow a Thermal Oxide (SiO2) layer on the polished face and the resultant SiO2 layer is just as smooth as the polished silicon {Ra<1nm).

For such IR optics there are two classes of Silicon monocrystals, crystals grown by the CZ process and crystals grown by the FZ process. The less expensive CZ silicon normally contains about 20ppma of Oxygen and as much as 0.4 to 4 ppma of Carbon. At these concentrations, Oxygen and Carbon have measureable absorption peaks in the IR spectrum. Other than that, provided its resistivity (p-type or n-type) is greater than about 10 Ohmcm (Ro>10 Ohmcm), CZ Silicon has very low absorbtion in the IR spectrum. The more expensive FZ silicon normally contains <0.2 ppma of Oxygen and < 0.2 ppma of Carbon. At these concentrations, Oxygen and Carbon have no measureable absorption peaks in the IR spectrum. FZ Silicon is commonly made with Resistivity > 100 Ohmcm and exhibits nil absorbtion in the IR spectrum.Thermal Oxide (SiO2) can be grown on both CZ and FZ silicon and forms a surface just as smooth as the polish of the underlying silicon wafer.

What wafer diameter do you require?

Reference #102504 for specs and pricing.

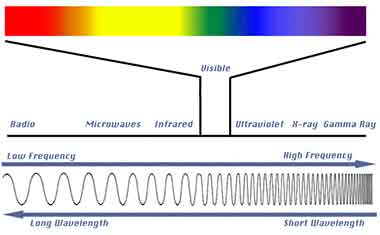

Infrared light, or infrared radiation, is a form of light with longer wavelengths than visible light. It is invisible to the human eye, and it encompasses wavelengths ranging from approximately one millimeter to 700 nanometers. For this reason, it is used in medical applications. Infrared is invisible to the human eye, but it can still penetrate the body. It has several benefits, as it is not only effective at detecting cancer but can also detect heat.

Infrared images of seawater are useful for mapping ocean currents and eddies. This data is of great value to the shipping industry. Moreover, infrared pictures can be useful for fishermen and farmers, as they can detect the onset of El Nino phenomena. Some weather satellites can also image the main water vapour channel, allowing researchers to determine how much moisture is present in the atmosphere. This information is helpful for meteorologists and scientists in forecasting weather conditions.

Some weather satellites can also image the main water vapour channel, allowing researchers to determine how much moisture is present in the atmosphere. This information is helpful for meteorologists and scientists in forecasting weather conditions.

Silicon: Silicon is a popular choice for IR measuring equipment because it is the least expensive of all IR materials. It is readily available, lightweight, and has excellent thermal and mechanical properties. However, it is prone to absorption in the 8-12 um range, which is beyond the wavelength range most useful for imaging applications. Although it is not suited for CO2 transmitting optics, silicon is widely used in mirror applications.

The longest wavelength of visible light makes IR more effective for observing objects. It is also less susceptible to scattering, which makes it useful for observing objects where the visible light cannot penetrate because of dust and gas. The light from newly-formed stars is also visible in IR, so it can be observed from space. The center of the Earth can also be viewed with infrared vision. If you're interested in astronomy, you'll want to learn more about infrared.

Another type of infrared-sensitive camera is the helium neon laser, which is ideal for IR applications. It is cheap, and has low absorption in the red end of the visible spectrum. It is also effective for measuring carbon black in ink. If you're interested in using an infrared-sensitive imaging system, you'll need to get a helium neon-neon-laser.

Infrared light is a wavelength that is longer than a human hair. This wavelength is the most common color of visible light. Despite its short wavelength, infrared light is also used to see ultraviolet light. This IR material has a high transmitting power. Its benefits are many. There are no limitations to the use of infrared, and it is possible to apply the technology for a variety of applications.

IR rays cause deep heating in the tissues of the body. This causes the heart to increase its volume, which in turn leads to vasodilation and increased circulation. Infrared helps increase blood flow to muscles, joints, and connective tissues, which can accelerate healing and reduce pain in many conditions. Infrared is a type of infrared light that can be used in a variety of applications.

IR is useful in astronomy to study the chemical makeup of dust particles in the interstellar medium. It is also used to study the chemical composition of cold gases, and it can also be used to determine the chemical composition of dust particles in the interstellar sphere. The IR emission from objects is also visible to humans, which means that infrared radiation is very beneficial to the human body. The energy of the sun is highly concentrated in the atmosphere, which causes the high sensitivity of our eyes.

Infrared light is produced by LEDs and lasers. Its wavelength ranges between eight and eighty nanometers. The majority of surfaces reflect light in a diffuse way. This means that infrared light will be reflected almost isotropically. During the day, the amount of infrared light that passes through the aperture of a sensor is a good indicator of the temperature of an object.

Infrared is the most effective wavelength of light. Its wavelengths are long enough to penetrate dense gas or dust. Infrared light can reveal objects that are invisible to optical telescopes. Infrared is also used for sensing. All objects on Earth emit IR radiation in the form of heat. Hence, infrared sensors can detect heat and identify the sources of heat. These are a few of the benefits of infrared.

A scientist asked us to quote the following:

"I want to buy some silicon wafers from your company, but I don't know which one I can choose since I can't see the characteristic details on the website, what I need is the Infrared transmission silicon wafer, I want the silicon wafer has high transmittance in the wavelength range of 5-14 microns, and it will be better if the shape can be square, the size I want is 100mm*100mm*0.5mm. Can you able to provide this kind of sample?"

UniversityWafer, Inc. Quoted

200mm x 200mm x 0.775mm thick. As well, silicon wafer has high IR transmittance in the wavelength range of 5-14 microns than "Silicon EPI/Silicon-on-insulator",Pls see below for the offer

Silicon wafer for the Infrared transmission,Resis. > 100 Ohm.cm,Square wafer, the size 200mm*200mm*0.775mm,double sides polished,qty. 10pcs $Reference #266522 for pricing.

IR thermometers use Infrared radiation to measure temperatures. Infrared radiation is reflected, absorbed and concentrated into a small spot. With a convex lens, infrared radiation is focused on a thermopile, which converts the thermal energy into electrical energy. The thermopile consists of one or more thermocouples stacked in series or in parallel.

a small spot. With a convex lens, infrared radiation is focused on a thermopile, which converts the thermal energy into electrical energy. The thermopile consists of one or more thermocouples stacked in series or in parallel.

Infrared temperature sensors use infrared radiation to detect heat. These thermometers work by taking advantage of all objects that emit heat above absolute zero. This is also known as black body radiation. Infrared radiation is very sensitive, and the temperature of a given object is directly proportional to how much of it the object emits. Infrared temperature sensors can be placed in a number of different applications, from home security to food preparation.

IR thermometers have a sensitivity range of -50 360 deg C, -30 380 deg C, and -18 280 deg C. They can also measure the temperature of an object up to eight inches in diameter. Their accuracy varies depending on their distance to the target. A high-end thermometer's D:S ratio will allow it to measure up to 60 degrees Fahrenheit (°C) in the same area.

The emissivity of different materials varies from 0 to 1. Infrared radiation that falls on a black body emits all energy. However, real-life objects have emissivity values between 0 and 1. Therefore, a sensor that measures infrared temperature should consider how much energy is reflected from an object or transmitted from a distant source. To ensure that you get accurate readings, you should first survey the surrounding area to determine if there are any extraneous sources of IR energy. Moreover, you should choose a position that minimizes any effects caused by extraneous IR radiation.

Infrared thermometers use a laser guide to measure surface temperatures. To make a proper calibration, you should place the thermometer in an area that has a consistent temperature. Infrared thermometers have the advantage of being sensitive to temperature variations. The distance to spot ratio is crucial when choosing a thermometer. It also helps in determining the emissivity of the surface.

When considering how IR-based thermometers work, it is important to understand the emissivity of materials. Emissivity is a measure of a surface's ability to reflect or absorb energy. It ranges from 0 to 1, with 0 being a perfect reflector and 1 being an object that absorbs all incoming radiation. Since most objects are not perfectly reflective, the energy they emit will differ depending on their emissivity. However, emissivity measurement requires a good calibration of materials before using a thermometer.

A common infrared thermometer uses a pair of thermocouples that are connected in parallel or series. Infrared energy strikes the thermopile and converts to heat. The voltage output is proportional to the incident energy. The detector then uses this voltage to determine the temperature. This entire process takes a few seconds. This allows for accurate temperature measurement. IR thermometers are a good choice for a wide variety of applications, including the measurement of heat.

Infrared thermometers use the same principle. The distance between the sensor and the object is adjusted for surface temperature measurements. The result is an IR thermometer with a higher accuracy than conventional thermometers. They can detect a very high or low temperature without touching the subject. However, there are some important factors to consider when purchasing an IR thermometer. This article will cover the basics of how IR thermometers work.

IR thermometers have the lowest error rate of any temperature sensor. These thermometers are great for measuring temperature changes in objects that are hot or moving. IR thermometers need to be rugged and durable, and many are equipped with a protective shell. A backlit screen is another great benefit for a device like this. Then again, it is easier to read in poor lighting conditions. When using an IR thermometer, be sure to read the label carefully.

A thermometer that measures the temperature of a target has a distance-to-spot ratio, which is the area the thermometer can accurately measure from a certain distance away. Infrared thermometers have a spot size that accounts for a small percentage of their field of view. The spot size may be adequate for practical field measurements, but not for accurate laboratory measurement. To overcome this problem, most IR thermometers must be calibrated using a large enough spot size.

To measure the temperature of a target, an IR thermometer must be able to accurately measure the temperature of all objects within a certain range. The distance-to-spot ratio, also known as the distance-to-target ratio, is an important consideration when purchasing a thermometer. The distance-to-spot ratio can vary dramatically depending on the complexity of the optical system, ranging from 1:1 on a cheap infrared thermometer to 60:1 on a high-end instrument. The chart below illustrates examples of the field-of-view diameters for different D:S ratios.

Using IR thermometers with a high D:S ratio allows you to accurately measure smaller areas at a greater distance. However, the manufacturer recommends that IR thermometers be used at close range. To select an IR thermometer with a high D:S ratio, consider the distance between the sensor and the target. A larger target requires a high D:S ratio, while a smaller one is too close for accurate measurement.

A typical IR sensor produces a signal in the microvolt range. Because the IR output is nonlinear, it requires a signal-conditioning circuit. These sensors have a built-in display, an analog-to-digital converter, and a voltage output for many applications. The curves are shown in a logarithmic scale for more detail at wide temperatures.

A curved substrate was created, resulting in a sensor that is much more resistant to deformation and damage than a conventional straight-edged sensor. In addition, a microscale wavy substrate improves the three-dimensional structure of the sensor. The resulting detector output vs temperature curves reveal the effect of the wavy substrate. The wavy substrate also allows for better measurement of temperature fluctuations.

The resolution of a Laser temperature sensor can be a crucial factor for measuring the temperature of a target. The resolution depends on the number of pixels in the sensor, and how high or low the object's temperature must be. Laser thermometers measure both the temperature of the target and its surrounding environment using a laser, and this allows for an accurate measurement. This method of temperature measurement is ideal for analyzing various objects and materials.

To understand how a laser thermometer's optical system works, it is important to understand how the measurement spot is formed. An infrared thermometer's optical system collects energy from the circular measurement spot and concentrates it on a detector. Optical resolution is defined as the ratio of the distance between the sensor and the target object, where a smaller distance will ensure higher resolution. This is especially important when measuring small targets, which require a sensor with high optical resolution.

Video: Temerature Sensors Explained

Detector Type |

Advantages |

Disadvantages |

Thermal |

Light, rugged, reliable, and low cost Room temperature operation |

Low detectivity at high frequency Slow response (ms order) |

Photon Intrinsic |

||

| IV-VI | Available low-gap materials Well studied |

Poor mechanical |

| II-VI | Easy band-gap tailoring Well-developed theory and exp. Multicolour detectors |

Non-uniformity over large area High cost in growth and processing |

| III-V | Good material and dopants Advanced technology Possible monolithic integration |

Heteroepitaxy with large lattice mismatch |

| Extrinsic | Very long wavelength operation Relatively simple technology |

Extremely low temperature operation |

Quantum well |

||

| Type I | Matured material growth Good uniformity over large area Multicolour detectors |

Low quantum efficiency Complicated design and growth |

| Type II | Low Auger recombination rate Easy wavelength control |

Complicated design and growth Sensitive to the interfaces |

Read the entire research report.