We are working on nanostructures made of silicon. Usually, the ![]() thickness of silicon film ranges from 300nm to 700nm in our research. The substrate can be SiO2 or other transparent insulators. Do you think it is possible to provide silicon film at this thickness range? If yes, may I know the parameters of your silicon, such as refractive index (n, k)? We will use SOI to fabricate nanostructures by electron beam lithography. The SOI should be transparent. The absorption of Si should be as small ad possible.

thickness of silicon film ranges from 300nm to 700nm in our research. The substrate can be SiO2 or other transparent insulators. Do you think it is possible to provide silicon film at this thickness range? If yes, may I know the parameters of your silicon, such as refractive index (n, k)? We will use SOI to fabricate nanostructures by electron beam lithography. The SOI should be transparent. The absorption of Si should be as small ad possible.

Substrates used to Fabricate Nanostructures

What Substrates do Researchers Use to Fabricate Nanostructures

University reseachers have used the following substrate to fabricate nanostructures:

Reference #205719 for specs and pricing.

I will used as p-GaN / n-ZnO (nanostructures) heterojunction based light emitting diode.I will let you know how it work.

Reference #38046 for specs/pricing

Get Your Quote FAST! Or, Buy Online and Start Researching Today!

3 Inch Silicon Wafer Used in Nanostructure Research

A postdoc client requested a quote for the following:

Our group previous postdoc used to order Si wafers from your company. Could you please give us a quotation for the silicon wafers with the following details. I'm using these wafers for nanostructure fabrication (magnetic nanowire, rings etc.) using E-beam lithography.

Wafer Details: Part Number (447)

Resistivity: 0 -100 Ohm-Cm

Surface: 1 side polished

Ori <100>

Thickness: 406-480 microns.

Reference #211263 for specs/pricing.

Nanostructures to Improve Solar Panel Solar Absorption

A university research group requested the following specs:

My research group is working on a project aimed at improving broadband absorption in thin film solar cells using aperiodic nanostructures deposited on their surface. In order to avoid actually fabricating solar cells ourselves, we have been wondering if it is possible to find solar cells without any electrodes or AR coating so we can build our nanostructures on top of them. Would you be able to supply us with such wafers? We would need wafers that are a 40-50mm in diameter. I'm not sure I'm the So we would get about a dozen to start with, and will get more as our research progresses. I'd appreciate it if you could provide me with quote to take to my advisor. We're hoping to move on this as quickly as possible. quantity at the moment but I can update you on that later today. I take it that you can indeed provide us with solar wafers with no electrodes or coating then?

UniversityWafer, Inc. Replied

We have: Solar cells are made in the following steps:

- One starts with an "As-sliced by wire-saw" silicon wafer Si:B[100] (0.5-5.0)Ohmcm. Typically such wafers are pseudo-square 156×156mm × 200µm.

- By Chemical Diffusion one creates an n-type layer, perhaps 10µm thick

- One deposits metal electrodes on the back and transparent electrodes on the front.

- 4. One passivates the front surface with an anti-reflection coating.

Reference #224157 for more specs and pricing.

UV Grade Fused Silica Wafers for Nanostructure Research

A Postdoctoral Appointee working in a Electronic and Nanostructured Materials department requested the following quote:

Two items (both fused Silica wafers).

Item 1: 25 wafers, 3” x 0.5mm wafers, Optical Grade “Wet” fused silica, 40/20 scratch dig, <2nm roughness), Double side polish, wafer flat, with Standard Clean and Package.

Item 2: 25 wafers, 3” x 0.5mm, UV grade (Corning 7980 HPFS KrF grade fused silica or equivalent UV transparency), 20/10 scratch/dig, <1nm roughness, Double side polish, 22mm flat, wafer flat, with Standard Clean and Package.

Does item 2 (the UV Grade fused silica) have a wafer flat as well?

Are these wafers the Corning 7980 HPFS KrF grade fused silica?

Reference #116470 for specs and pricing.

Spin-on-Glass for Embedding Si Nanostructures

A postdoc requested the following quote:

We are interested in buying Spin-on-Glass (SoG) product for embedding Silicon nanostructures. Can you send me a quote?

Reference #273362 for specs and pricing.

Ssilicon-on-Glass Wafers for an Optical Application

A nanotechnology researcher requested the following quote:

I would be interested to know if you can supply coated silicon-on-glass wafers? For an optical application in the 940nm wavelength range, we would like to fabricate silicon nanostructures (~600nm height) using e-beam on a transparent substrate. Are there material combinations of silicon coating (e.g., amorphous, crystalline, ...) and glass substrates for which you can supply a small quantity of wafers? Being a computer scientist, I would also love to hear your opinion on these material combinations (e.g., are there some that are easier to supply or some that have potential issues).

Reference #273694 for specs and pricing.

Thermal Oxide Coated Silicon to Fabricate Nanostructures

A PhD researcher requested help with the following:

I am looking for thermal oxide wafers (100 mm) with an oxide thickness in the range of 150 nm to 200 nm. I am going to make nanostructures using EBL (feature size is about 100 nm). I see you have item #2005 and #2006 that can have the desired thickness of the oxide layer. Not sure if they are the right one to go. If not, we would mind please let me know your suggestion and give a quote please.

Reference #277556 for specs and pricing.

What are Nanostructures?

Nanostructures are structures with dimensions in the nanometer scale, typically ranging from 1 to 100  nanometers. These structures have unique physical, chemical, and electronic properties that differ from those of bulk materials. Nanostructures can be made from a variety of materials, including metals, semiconductors, polymers, and biological materials. They are widely studied for their potential applications in fields such as electronics, energy, medicine, and materials science.

nanometers. These structures have unique physical, chemical, and electronic properties that differ from those of bulk materials. Nanostructures can be made from a variety of materials, including metals, semiconductors, polymers, and biological materials. They are widely studied for their potential applications in fields such as electronics, energy, medicine, and materials science.

Examples of nanostructures include:

- Nanoparticles: Nanoparticles are microscopic particles with at least one dimension measuring less than 100 nanometers. They have unique properties due to their small size, which result from the high surface-to-volume ratio and quantum confinement effects. Nanoparticles have a variety of applications in fields such as electronics, medicine, energy, and materials science.

- Nanotubes: Nanotubes are a type of nanostructure, having the shape of a tube with diameter on the nanometer scale (typically 1-100 nm). They can be single-walled (SWCNTs) or multi-walled (MWCNTs), and are typically made of carbon. Nanotubes have unique mechanical, electrical, and thermal properties due to their tubular structure and the arrangement of their atoms. They have potential applications in areas such as electronics, energy storage, and biomedical engineering.

- Nanowires: Nanowires are nanoscale cylindrical structures with a diameter on the order of a few nanometers to several hundred nanometers, and a length that can be several micrometers to millimeters. They can be made of various materials, such as metals, semiconductors, and insulators. Nanowires have unique properties due to their small size, such as high surface-to-volume ratio and quantum confinement effects, that make them useful for a range of applications in electronics, energy, and biomedicine. For example, nanowires can be used as electrical conductors, transistors, and battery electrodes.

- Nanoporous materials: Nanoporous materials are materials with pores or voids on the nanometer scale (typically 1-100 nm). These pores can be uniform in size or have a controlled distribution of pore sizes. Nanoporous materials have a high surface-to-volume ratio, which makes them useful for various applications such as catalysis, separations, energy storage, and drug delivery. Some examples of nanoporous materials include zeolites, metal-organic frameworks (MOFs), and silica aerogels. The pore structure and size can be tailored to meet specific requirements, making nanoporous materials versatile and useful in a wide range of applications.

- Nanocomposites: Nanocomposites are materials that consist of a matrix and nanoscale fillers (typically 1-100 nm) dispersed within it. The nanoscale fillers can be made of various materials, such as nanoparticles, nanotubes, and nanofibers, and can greatly enhance the properties of the matrix material. The small size of the fillers results in a large surface area, which can improve the mechanical, thermal, electrical, and optical properties of the nanocomposite. Nanocomposites have a wide range of applications, including in materials science, electronics, energy, and biomedicine. For example, they can be used as stronger and lighter materials, as catalysts, and as drug delivery systems.

- Nanolaminates: Nanolaminates are multi-layer materials that consist of alternating thin layers of different materials on the nanometer scale (typically 1-100 nm). The individual layers can be made of various materials, such as metals, ceramics, and polymers, and the combination of different materials results in new properties and functions. The properties of nanolaminates can be tailored by controlling the composition and thickness of each layer, making them useful for a wide range of applications. Nanolaminates are used in areas such as electronics, energy, and materials science, for example, as high-strength and high-temperature materials, as catalysts, and as protective coatings.

- Nanograins: Nanograins are small grains or particles on the nanometer scale (typically 1-100 nm) that can form in materials. They can occur naturally or be produced artificially through processes such as ball milling, electron beam irradiation, or laser ablation. Nanograins have unique properties compared to larger grains, such as improved mechanical, thermal, and electrical properties, due to their high surface-to-volume ratio and quantum confinement effects. Nanograins have a wide range of applications in fields such as materials science, electronics, and energy. For example, they can be used as high-strength materials, as catalysts, and as battery electrodes.

- Nanofibers: Nanofibers are ultra-thin fibers with a diameter on the nanometer scale (typically 1-100 nm). They can be made from various materials such as polymers, ceramics, and metals, and can be produced using techniques such as electrospinning, template-assisted synthesis, and self-assembling. Nanofibers have a high surface-to-volume ratio, which gives them unique properties, such as high mechanical strength, high thermal stability, and high porosity. They have a wide range of applications in fields such as materials science, electronics, energy, and biomedicine. For example, they can be used as high-strength and high-temperature materials, as filtration membranes, and as drug delivery systems.

The properties of nanostructures are highly dependent on their size, shape, and composition, and they are often synthesized using techniques such as chemical synthesis, physical vapor deposition, and self-assembly. Their unique properties make nanostructures an important area of research, with potential applications in areas such as catalysis, electronics, energy, and biomedicine.

What Substrates are often used to Fabricate Nanostructures?

The fabrication of nanostructures often involves the use of various substrates, which serve as the base material on which these structures are created. The choice of substrate depends on the intended application, the properties required, and the fabrication methods used. Some commonly used substrates include:

-

Silicon (Si): Silicon is the most widely used substrate in the semiconductor industry. It is particularly favored for electronic and photonic nanostructures due to its well-understood properties and the mature technology available for its processing.

-

Glass: Glass substrates are used for optical applications due to their transparency and smooth surface. They are often used in photonics, optoelectronics, and for biological applications.

-

Sapphire (Al2O3): Sapphire is used for its high thermal and chemical stability. It is particularly useful for high-temperature and harsh-environment applications. It's also used for the growth of some types of compound semiconductor nanostructures.

-

Silicon Carbide (SiC): SiC is known for its high thermal conductivity and electrical breakdown strength, making it suitable for high-power and high-frequency applications.

-

Gallium Arsenide (GaAs): GaAs is used for its direct bandgap and high electron mobility, making it ideal for high-speed electronics and optoelectronic devices.

-

Quartz: Quartz substrates are used for their low thermal expansion and good optical properties. They are often used in applications requiring high-precision and stability.

-

Metals: Metal substrates like gold, silver, and copper are used for plasmonic nanostructures, which are utilized in sensing, imaging, and photonic devices.

-

Flexible Substrates: Materials like polyimide and PET (Polyethylene Terephthalate) are used for flexible and wearable electronics.

-

Mica: Mica is used for its atomically smooth surface, making it ideal for the study of two-dimensional materials and molecular self-assembly.

-

Graphene and other 2D Materials: Graphene, MoS2, and other two-dimensional materials are increasingly used as substrates for the fabrication of novel nanostructures.

The choice of substrate significantly influences the properties of the nanostructures and can determine their compatibility with different applications and environments.

Single Crystal Quartz for Nanostructure Research

A PhD candidate researching Nanomaterials and Nanostructure Optics (NaNO) requested the following quote:

I need a quote for 10 3" double polished quartz wafers. I want 10 wafers of the following specification, Quartz Wafers 3", Z-Cut, 0.5mm thickness, Double side polished.

Reference #91181 for specs and quantity.

Silicon-on-Insulator Wafers for Fabricating Nanostructures

A PhD nanotechnology researcher requested the following:

Can you please send me your SOI listing? All your stock has device layers that are too thick: I need device layers between 300 nm to 1 um thick. Do you have any stock that has a 500nm thick device layer? The silicon is probably too thin, if you ever have 500 nm device layer SOI I would be immediately interested. Thank you for spending the time to provide the quote below; I currently have two wafers with the 500nm device layer and am hoping to use those until some more become available.v

UniversityWafer, Inc. Quoted

4" SOI P(100) 9-23 ohm-cm 500-550 microns polished one side Prime grade with 2800 A Silicon Layer and 3800 A Oxide Layer Thickness

Reference #90409 for specs and pricing.

Ultra-Thin Silicon Wafers for Nanotechnology Research

A director, Nanotechnology Development requested the following quote:

What are the thinnest (100) Si wafers you can get? Are the 25um Ultra-Thin 2" and 4" still available? We only need a> few (depending on the size). Just to be sure, please confirm the availability of the 25um Si(100)

wafers and send the updated quote. Thanks!

Reference #76930 for specs and pricing.

Nickle (Ni) Sputtered Film for Nanstructure Research

Anassistant professor (Ph.D.) of a Nanostructured Materials Research Lab requested the following quote:

Ni sputtered film with a thickness of 1um on the silicon wafer (4", highly doping, p-type, one-side polishing)

Quantity: # 5

Reference #102453 for specs and pricing.

Silicon Germanium (SiGe)

Scanning x-ray microscopy imaging of strain relaxation and fluctuations in thin patterned SiGe-on-insulator nanostructures

The latest developments have led to a high-performance 14 nm-technology using Fully Depleted Silicon On Insulator (FDSOI) transistors and the integration of a strained SiGe channel in p-type MOSFETs. The choice of strained SiGe as a channel was driven by two factors.

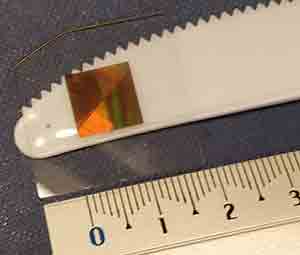

Silicon Nitride on fused silica for Metamaterials Applications

A Research Fellow, Faculty of Engineering requested the following quote:

Do you have “silicon nitride” (SiNx) deposited onto Silicon wafers? Wondering also what the silicon substrate information is too. I’m ideally looking for Silicon Nitride on fused silica for metamaterials applications, do you know if this is readily available or a bespoke process. it’s to produce metasurfaces/metamaterials on, with the fused silica wafers as the substrate material on which I will pattern the silicon nitride layer into nanostructures – see attached for previous versions I’ve made. This was for a metasurface lens working at 1064nm wavelength (using amorphous silicon layer on fused silica).

Do you have “silicon nitride” (SiNx) deposited onto Silicon wafers? Wondering also what the silicon substrate information is too. I’m ideally looking for Silicon Nitride on fused silica for metamaterials applications, do you know if this is readily available or a bespoke process. it’s to produce metasurfaces/metamaterials on, with the fused silica wafers as the substrate material on which I will pattern the silicon nitride layer into nanostructures – see attached for previous versions I’ve made. This was for a metasurface lens working at 1064nm wavelength (using amorphous silicon layer on fused silica).

Ideally I require as low roughness fused silica as possible for optical grade transmission experiments, but maybe the fabrication process causes some roughness anyway so “medium” quality may also work, I’ve never compared!

I’d like good quality fused silica wafers with SiN deposited ideally.

Reference #258731 for specs and pricing.

Test Grade Silicon for Fabricating Nanostructures

An Assistant Professor requested the following quote:

Could you help me select these items: Test grade Si 100 mm, <100>, 1-10 Ohm-cm, 500 um, Test Grade, 100 nm wet SiO2 on top, 25 count Prime grade Si 100 mm, <100>, 1-10 Ohm-cm, 500 um, Test Grade, 100 nm dry SiO2 on top, 10 count some like #1 but with no oxide? It will have a native SiO2 ~2 nm oxide.

Our application is to grow magnetic thin film stacks for spintronic nanostructures on top. That is why we are really just using the Si as a substrate, not trying to apply any voltage through it. We want somewhat thick SiO2 (at least 50 nm but can be 50-150 nm) on top so it is a smooth surface and well insulated from the Si. Those are all the requirements.

Given that, do you have some options that are in your standard line of products? In the past we bought some Test + 100 nm wet SiO2 and then some Prime + 100 nm dry SiO2, but I was surprised when it looked like the quote we got for Test was more expensive for Prime.

Reference #273859 for specs and pricing.

Silicon Wafers used to Support Plasmonic Nanostructures

A university principal investigator requested a quote for the following.

We used Si wafers purchased from your company (see attached order).

In our experiments we used these wafer as a support for plasmonic nanostructures. The obtained plasmonic spectra of this system is quite different than that we expected. One of the possible reasons might be the contribution from the substrate wafers. Now, we are going to calculate the refractive index of the substrate. For these calculation we need doping level (concentration of B) and crystal structure of the the thermal oxide layer. This is important in order to know which kind of Si wafers we need for our further research investigations.

There are two ways for our further research:

- If the calculated theoretical results are in agreement with the experimental ones, then we are going to investigate the synergy between plasmonic nanostructures and the substrate. In this case we will need various Si wafers with different doping level and different oxide layer thicknesses, in order to obtain substrate-induced tailoring of the plasmonic spectra.

- If the theoretical values are not in agreement with the experimental spectra then the problem might be with plasmonic structures (their chemical purity, structural imperfections and so on). In this case we will continue to work on plasmonic structures deposited on the same Si wafers that we purchased from your company. We tried several times with the same Si wafers, and our current conclusion is that there is contribution from Si wafers.

We have two questions:

- What is the approximate doping level (concentration of Boron) of the samples we purchased from your company (I sent the quote of that Si wafers in my previous e-mail); I think your technicians who dealing with preparation of the wafer can easily estimate the doping level.

- What is the crystalline structure of the 285 nm thick thermal oxide layer of the wafers: it is like fused silica or like alpha quartz? (or let us know the value of the optical refractive index of the thermal oxide layer, if it is known).

We need these two information. Depending on our theoretical calculations we will decide which kind of Si wafers we will purchase to continue our research.

Reference #134804 for specs and pricing.